JAEA-Review-2010-065.pdf:15.99MB - 日本原子力研究開発機構

JAEA-Review-2010-065.pdf:15.99MB - 日本原子力研究開発機構

JAEA-Review-2010-065.pdf:15.99MB - 日本原子力研究開発機構

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1-33<br />

Radiation-Induced Graft Polymerization of Styrene into<br />

a Poly(ether ether ketone) Film for Polymer Electrolyte<br />

Membranes<br />

S. Hasegawa a) , K. Sato b) , T. Narita b) , Y. Suzuki a) , S. Takahashi a) ,<br />

N. Morishita a) and Y. Maekawa a)<br />

a) Environment and Industrial Materials Research Division, QuBS, <strong>JAEA</strong>,<br />

b) Graduate School of Engineering, Saitama Institute of Technology<br />

Radiation-induced graft polymerization is a unique<br />

technique for direct grafting of a new functional polymer<br />

phase (grafts) into polymer films (substrate), in which<br />

functional polymers keep their characteristics such as<br />

thermal stability, mechanical strength, electronic properties,<br />

and crystallinity 1) . There have been many attempts for<br />

basic researches to reveal graft polymerization mechanisms<br />

and for making new grafts into various polymer substrates<br />

including chemical transformation of grafts 2) to be applied<br />

for battery separators, absorber resins, and polymer<br />

3)<br />

electrolyte membranes (PEMs) . Recently, we reported<br />

that the grafting of styrene into PEEK film pre-irradiated<br />

with 30 kGy was accelerated by using 1-propanol as a<br />

grafting solvent at 80 °C to obtain styrene-grafted PEEK<br />

4)<br />

with a grafting degree of more than 60% . Thus, we<br />

investigated the changes in morphology of PEEK films such<br />

as crystallinity and phase separation caused by grafting of<br />

styrene and subsequent sulfonation using differential<br />

scanning calorimetry (DSC), thermogravimetry (TGA),<br />

X-rays diffraction analysis (XRD), and electron spin<br />

resonance spectroscopy (ESR).<br />

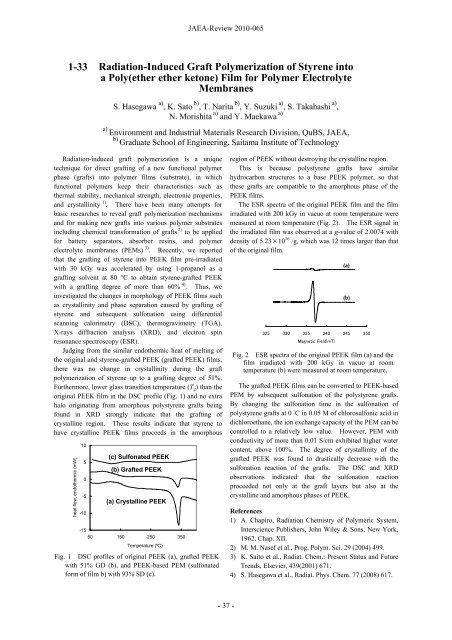

Judging from the similar endothermic heat of melting of<br />

the original and styrene-grafted PEEK (grafted PEEK) films,<br />

there was no change in crystallinity during the graft<br />

polymerization of styrene up to a grafting degree of 51%.<br />

Furthermore, lower glass transition temperature (Tg) than the<br />

original PEEK film in the DSC profile (Fig. 1) and no extra<br />

halo originating from amorphous polystyrene grafts being<br />

found in XRD strongly indicate that the grafting of<br />

crystalline region. These results indicate that styrene to<br />

have crystalline PEEK films proceeds in the amorphous<br />

heat flow, endothermic (mW)<br />

10<br />

5<br />

0<br />

-5<br />

-10<br />

(c) Sulfonated PEEK<br />

(b) Grafted PEEK<br />

(a) Crystalline PEEK<br />

-15<br />

50 150 250 350<br />

Temperature (ºC)<br />

Fig. 1 DSC profiles of original PEEK (a), grafted PEEK<br />

with 51% GD (b), and PEEK-based PEM (sulfonated<br />

form of film b) with 93% SD (c).<br />

<strong>JAEA</strong>-<strong>Review</strong> <strong>2010</strong>-065<br />

- 37 -<br />

region of PEEK without destroying the crystalline region.<br />

This is because polystyrene grafts have similar<br />

hydrocarbon structures to a base PEEK polymer, so that<br />

these grafts are compatible to the amorphous phase of the<br />

PEEK films.<br />

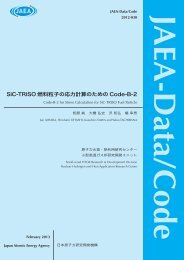

The ESR spectra of the original PEEK film and the film<br />

irradiated with 200 kGy in vacuo at room temperature were<br />

measured at room temperature (Fig. 2). The ESR signal in<br />

the irradiated film was observed at a g-value of 2.0074 with<br />

density of 5.23 × 10 16 /g, which was 12 times larger than that<br />

of the original film.<br />

325 330 335 340 345 350<br />

Magnetic Field(mT)<br />

Fig. 2 ESR spectra of the original PEEK film (a) and the<br />

film irradiated with 200 kGy in vacuo at room<br />

temperature (b) were measured at room temperature.<br />

The grafted PEEK films can be converted to PEEK-based<br />

PEM by subsequent sulfonation of the polystyrene grafts.<br />

By changing the sulfonation time in the sulfonation of<br />

polystyrene grafts at 0 ◦ C in 0.05 M of chlorosulfonic acid in<br />

dichloroethane, the ion exchange capacity of the PEM can be<br />

controlled to a relatively low value. However, PEM with<br />

conductivity of more than 0.01 S/cm exhibited higher water<br />

content, above 100%. The degree of crystallinity of the<br />

grafted PEEK was found to drastically decrease with the<br />

sulfonation reaction of the grafts. The DSC and XRD<br />

observations indicated that the sulfonation reaction<br />

proceeded not only at the graft layers but also at the<br />

crystalline and amorphous phases of PEEK.<br />

References<br />

1) A. Chapiro, Radiation Chemistry of Polymeric System,<br />

Interscience Publishers, John Wiley & Sons, New York,<br />

1962, Chap. XII.<br />

2) M. M. Nasef et al., Prog. Polym. Sci. 29 (2004) 499.<br />

3) K. Saito et al., Radiat. Chem.: Present Status and Future<br />

Trends, Elsevier, 439(2001) 671.<br />

4) S. Hasegawa et al., Radiat. Phys. Chem. 77 (2008) 617.<br />

(a)<br />

(b)