PRODUCT INFORMATION ROSOMA Check Weigher

PRODUCT INFORMATION ROSOMA Check Weigher

PRODUCT INFORMATION ROSOMA Check Weigher

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>PRODUCT</strong> <strong>INFORMATION</strong><br />

<strong>ROSOMA</strong> <strong>Check</strong> <strong>Weigher</strong><br />

<strong>ROSOMA</strong> machines and systems represent the current and future state-of-the-art technology in fish processing.<br />

They comply with the rules and regulations in force and the high hygiene standards of the food<br />

industry.<br />

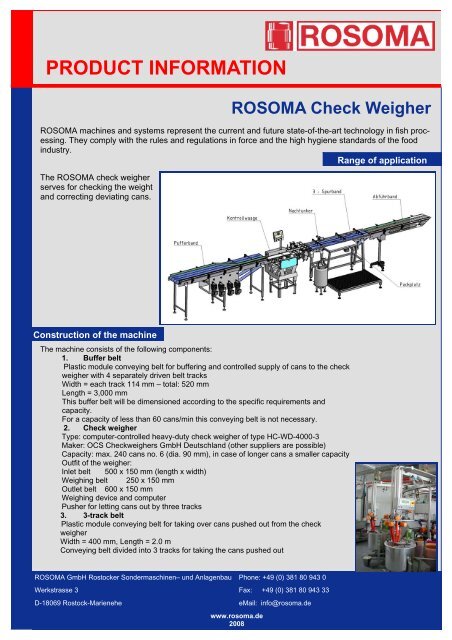

Range of application<br />

The <strong>ROSOMA</strong> check weigher<br />

serves for checking the weight<br />

and correcting deviating cans.<br />

Construction of the machine<br />

The machine consists of the following components:<br />

1. Buffer belt<br />

Plastic module conveying belt for buffering and controlled supply of cans to the check<br />

weigher with 4 separately driven belt tracks<br />

Width = each track 114 mm – total: 520 mm<br />

Length = 3,000 mm<br />

This buffer belt will be dimensioned according to the specific requirements and<br />

capacity.<br />

For a capacity of less than 60 cans/min this conveying belt is not necessary.<br />

2. <strong>Check</strong> weigher<br />

Type: computer-controlled heavy-duty check weigher of type HC-WD-4000-3<br />

Maker: OCS <strong>Check</strong>weighers GmbH Deutschland (other suppliers are possible)<br />

Capacity: max. 240 cans no. 6 (dia. 90 mm), in case of longer cans a smaller capacity<br />

Outfit of the weigher:<br />

Inlet belt 500 x 150 mm (length x width)<br />

Weighing belt 250 x 150 mm<br />

Outlet belt 600 x 150 mm<br />

Weighing device and computer<br />

Pusher for letting cans out by three tracks<br />

3. 3-track belt<br />

Plastic module conveying belt for taking over cans pushed out from the check<br />

weigher<br />

Width = 400 mm, Length = 2.0 m<br />

Conveying belt divided into 3 tracks for taking the cans pushed out<br />

<strong>ROSOMA</strong> GmbH Rostocker Sondermaschinen– und Anlagenbau Phone: +49 (0) 381 80 943 0<br />

Werkstrasse 3 Fax: +49 (0) 381 80 943 33<br />

D-18069 Rostock-Marienehe eMail: info@rosoma.de<br />

www.rosoma.de<br />

2008

4. Sauce refiller<br />

The sauce refiller is mounted at the left track of the three-track belt and consists of:<br />

Dosing head<br />

Pulse valve<br />

Pressure tank (0.5 - 0.9 bar)<br />

5. Working table<br />

Mounted on the right-hand side of the three-track belt, the table serves as a working<br />

place for 1-2 persons for manual re-packing of cans.<br />

6. Electrical switch cabinet<br />

A high-grade steel switch cabinet holds the program control and all electrical fittings<br />

for controlling of the overall system. The system is pre-installed with regard to cabling.<br />

Functional Description<br />

The cans are conveyed to the four-track belt and can here<br />

be buffered for a short time. The four-track belt has four individual<br />

drives which are controllable in each case.<br />

Thus it is avoided that a deformation of piled up cans happens.<br />

The check weigher ensures the following evaluation<br />

variants:<br />

�Can weight OK � Can passes through straight ahead.<br />

�Little deviation � Can is pushed out to the left-hand side and sauce is re-filled automatically.<br />

�Great deviation � Can is pushed out to the right-hand side, the weight is corrected manually.<br />

(Mirror-inverted design is possible.)<br />

The pushed out cans are subsequently lead to the center track again and carried on by the following conveying belt.<br />

All weight values and tolerances can be set. Furthermore, the weigher has a statistics version for evaluation of production<br />

and for statistical determination of weight deviations.<br />

Technical Parameters<br />

Dimensions<br />

Length: 6,500 mm<br />

Width: 1,700 mm<br />

Output max. 220 cans/minute<br />

Container for sauce re-filler Capacity of abt. 5 litres<br />

Pressure 0.5 – 0.9 bar<br />

Electric supply Totally abt. 3.5 kW, 400 V/50 Hz<br />

Degree of protection IP 56<br />

<strong>ROSOMA</strong> GmbH Rostocker Sondermaschinen– und Anlagenbau Phone: +49 (0) 381 80 943 0<br />

Werkstrasse 3 Fax: +49 (0) 381 80 943 33<br />

D-18069 Rostock-Marienehe eMail: info@rosoma.de<br />

www.rosoma.de