AXIAL-FLOW COMBINES - Service Motor Company

AXIAL-FLOW COMBINES - Service Motor Company

AXIAL-FLOW COMBINES - Service Motor Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

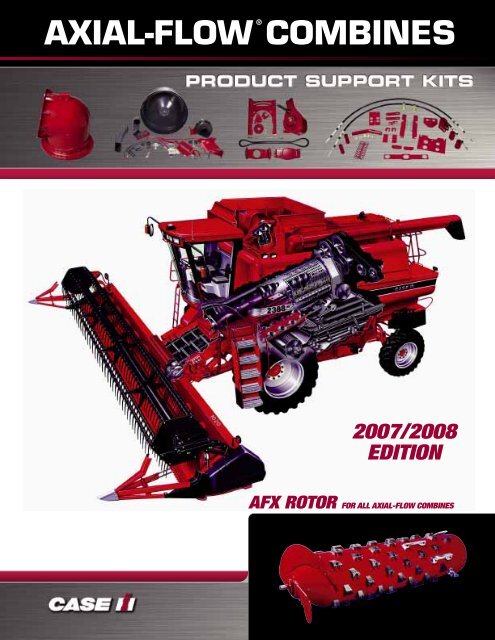

<strong>AXIAL</strong>-<strong>FLOW</strong><br />

®<br />

<strong>COMBINES</strong><br />

2007/2008<br />

EDITION<br />

AFX ROTOR FOR ALL <strong>AXIAL</strong>-<strong>FLOW</strong> <strong>COMBINES</strong>

2<br />

TABLE OF CONTENTS<br />

Description Page Description Page<br />

2200 Corn Head Completing Kits...............................................27<br />

2200 Series Corn Head Kits .......................................................24<br />

2200/2400 Series Corn Head Kits..............................................22<br />

3-Strand Chain Kits ....................................................................28<br />

52 Hole Configuration Cones......................................................32<br />

900 and 1000 Series Corn Head Accessories ............................26<br />

Advanced Farming System.........................................................79<br />

AFX Rotor.......................................................................34, 35, 36<br />

AFX Rotors with Chrome Alloy Rasp Bars ............................61, 66<br />

Alternator Externally Mounted Screen Kit....................................77<br />

Auger Bed Bearing/Flange Kit ....................................................50<br />

Auger Drive Kit ...........................................................................24<br />

Auger Bed Grain Spreader Kit ....................................................50<br />

Auger Stainless Steel Trough Wear Liner Kit ...............................42<br />

Automated Lubrication System...................................................84<br />

Automatic Header Height Control Linkage Kit.............................16<br />

Bat Kits ......................................................................................53<br />

Battery Relocation Kit .................................................................49<br />

Beacon Light Kit.........................................................................77<br />

Bearing Kit - Horizontal Unloading Auger....................................44<br />

Bearing Kit - Tailings Delivery Auger............................................50<br />

Bearing/Bushing Kit - Torque Sensor Kit.....................................39<br />

Bed Auger Mounting Block Kit ...................................................50<br />

Bolted Feeder Chains .................................................................30<br />

Bushing Kit - Sieve .....................................................................51<br />

Cab Recondition Kits..................................................................73<br />

Cab Halogen Working Light Kit...................................................77<br />

Case IH Light Kits for 1000 Series Grain Headers ......................17<br />

Case IH Light Kits for 1000 Series Corn Headers.......................19<br />

Case IH Rasp Bar Kits................................................................41<br />

Case IH Reman Combine Components Application Chart..........69<br />

Case IH Reman Combine Drive Train Components ....................68<br />

Case IH Reman Electrical .....................................................70, 71<br />

Chain Breaker.............................................................................74<br />

Chain Guide - Sprocket Kit.........................................................75<br />

Chain Guide Wood Blocks..........................................................77<br />

Chain Idler Sprocket Package ....................................................75<br />

Chain Roller Kits .........................................................................78<br />

Chain Tighteners ........................................................................75<br />

Channel/Grate Adjusting Kit........................................................40<br />

Chopper Knife Kits ...............................................................57, 58<br />

Clean Grain Elevator Wear Strip .................................................75<br />

Cleaning System Speed Reduction Kit .......................................50<br />

Combine Maintenance Overview ..................................................5<br />

Complete Rotor Hub Assembly ..................................................38<br />

Complete Spreader Assemblies (Straw or Chaff) ........................53<br />

Complete Spreader Repair Kit ....................................................55<br />

Complete Straw Chopper Kits for Axial-Flow Combines .............58<br />

Concave Adjuster Kit..................................................................39<br />

Concave Interrupter Bar Kit ........................................................40<br />

Concave Kits One Piece Concaves ............................................40<br />

Concave Round Bar Kit..............................................................40<br />

Concaves ...................................................................................39<br />

Concaves for 80 Size Machines .................................................67<br />

Concaves, One Piece Extenda-Wear..........................................63<br />

Cone/Cage Repair Kits, Stainless Steel ......................................65<br />

Corn Head Ear Saver Kit ......................................................21, 22<br />

Corn Head Handy Packs............................................................18<br />

Corn Head Knife for 2200/2400 Series Corn Heads...................22<br />

Corn Head Wear Plate Kit ..........................................................22<br />

Corn Head Weed Knife Kits........................................................21<br />

Coupler Kits................................................................................14<br />

Crop Deflector Kits .....................................................................17<br />

Crop Dividers and Accessories...............................................9, 10<br />

Crop Lifter Kit .............................................................................14<br />

Cross Flow Fan Kit..................................................................45

Description Page Description Page<br />

Cutter Bar Rebuild Kits...............................................................10<br />

Disrupter Bar Kit.........................................................................39<br />

Drum Stop Kit ............................................................................30<br />

Ear Saver Kit/Tall Corn................................................................24<br />

Elevator Chains/Sprockets..........................................................44<br />

Elevator Door Kits.......................................................................74<br />

Elevator Kit, Extenda-Wear Stainless Steel .................................64<br />

Engine Overhaul Kits ..................................................................81<br />

Extenda-Wear Auger Kits........................................................62<br />

Extenda-Wear Concaves ........................................................63<br />

Extenda-Wear Product Support Kits .......................................61<br />

Extenda-Wear Rasp Bar Kits (Cast Chrome Alloy).............42, 66<br />

Extenda-Wear AFX Rotors ......................................................66<br />

External Sieve Adjuster Kit..........................................................59<br />

External Sieve Adjustment Kit.....................................................52<br />

Feeder Drive Tension Kit .............................................................44<br />

Feeder Reverser Basic Kit and Completion Packages ................60<br />

Feeder Reverser Maintenance Performance Kit ..........................59<br />

Feeder Silencer Kit .....................................................................32<br />

Feeder Upgrade Kit ....................................................................23<br />

Field Tracker® Kits ...............................................................28, 29<br />

Fire Extinguisher Kit ....................................................................77<br />

Fold-Down Cab Rear Window....................................................73<br />

Full Width Retracting Finger Auger Kit ........................................15<br />

Gathering Chain..........................................................................19<br />

Grain Drain .................................................................................76<br />

Grain Header and Corn Head Completing Kits .............................8<br />

Grain Pan Auger Bearing Kit (Wood Block Repair Kit).................78<br />

Grain Seal Kit .............................................................................51<br />

Grain Tank Kits ...........................................................................42<br />

Grate Kit.....................................................................................40<br />

Guard Kits ..................................................................................10<br />

Header Auger Fingers.................................................................12<br />

Header Auger Fingers and Kits...................................................13<br />

Header Reel Kits.........................................................................15<br />

Header Latch Kits.......................................................................14<br />

Heavy-Duty Rotor Belt................................................................38<br />

Heavy-Duty Auger Bearing Kit ....................................................51<br />

Heavy-Duty Center Unloading Coupling......................................46<br />

Heavy-Duty Concave Support Kit ...............................................40<br />

Heavy-Duty Feeder Jackshaft.....................................................31<br />

Heavy-Duty Rotor Drive Gear Box Kit .........................................33<br />

Heavy-Duty Rotary Air Screen Shaft ...........................................49<br />

Heavy-Duty Rotor Drive Coupling ...............................................37<br />

HID Light Kit ...............................................................................77<br />

High Arch Hold-Down Clip <strong>Service</strong> Kits ......................................11<br />

Horizontal Unloading Auger Kits .................................................45<br />

Knife Reinforcing Kit ...................................................................10<br />

Ladder Extension Kit ..................................................................46<br />

Latch Kits ...................................................................................76<br />

Lightbar Guidance System ...................................................47, 48<br />

Long-Wear Feeder Feedplate .....................................................31<br />

Low Profile Divider Point Kits................................................22, 24<br />

Lube Minder® Automatic Chain Lubrication System ..................75<br />

Lubrication..................................................................................72<br />

Lubrication Equipment................................................................83<br />

Moisture Testers - Grain .............................................................82<br />

Pick-Up Belt with Teeth Installed.................................................15<br />

Power-Luber ® Cordless Grease Gun...........................................83<br />

One Piece Extenda-Wear Concaves...........................................63<br />

Poly Drum Guards ......................................................................30<br />

Poly Hoods Divider Kits and Completing Kit<br />

for 2200/2400 Series Corn Heads..............................................27<br />

Poly Skid Shoe Kits ....................................................................17<br />

Power-Clean Evacuation System ................................................57<br />

Quick Release Coupler ...............................................................55<br />

3

4<br />

TABLE OF CONTENTS (CONTINUED)<br />

Description Page Description Page<br />

Radiator Access Step Kit, Heavy-Duty........................................46<br />

Rasp Bar Kits, Extenda-Wear (Cast Chrome Alloy)..................42<br />

Rasp Bar <strong>Service</strong> Pack...............................................................41<br />

Rasp Bar, Half Set ......................................................................42<br />

Reel Repair Kits..........................................................................16<br />

Reel Tine Flap Kit .......................................................................12<br />

Reman Combine Engines ...........................................................80<br />

Repair Kit - Lower Gear Box - Enclosed Gearbox ......................43<br />

Repair Kit - Lower Gear Box - Unloading Auger .........................43<br />

Repair Kit - Upper Gear Box - Unloading Auger .........................43<br />

Rock Trap Beater Blade Kit ........................................................31<br />

Rock Trap Replacement Assemblies...........................................31<br />

Rotary Air Screen Kits.................................................................74<br />

Rotor Cage Kit with Standard Steel Vanes..................................33<br />

Rotor Cage Kit, Extenda-Wear................................................65<br />

Rotor Cage Stainless Steel Transport Vane Kit, Extenda-Wear....65<br />

Rotor Drive Sensor with Hardened Pulley ...................................39<br />

Rotor Front Shaft Stabilizer Kit....................................................36<br />

Rotor Hub Spacer Kit .................................................................37<br />

Rotor Impeller Kits ......................................................................37<br />

Rotors - Specialty Rasp Bar Configurations................................37<br />

Rotors Front Cover Door Seal ....................................................38<br />

Row Unit Kits .............................................................................25<br />

Seats..........................................................................................73<br />

Shaker Arm Bushing Tool Kit ......................................................51<br />

Shaker Arm Cam Kit...................................................................51<br />

Shaker Drive Pivot Support Kit ...................................................55<br />

Shaker Hanger Arm Kit...............................................................51<br />

Sieve Kits ...................................................................................52<br />

Speed Reduction Kit/Grain Elevator............................................67<br />

Spreader Kits..............................................................................54<br />

Spreader Repair Kit ....................................................................55<br />

Spreader Shield Kit (Straw/Chaff)................................................54<br />

Stainless Steel Repair Kit............................................................27<br />

Stalk Roll Kits .............................................................................20<br />

Stalk Roll Repair Kits for 2200/2400 Series Corn Heads ............23<br />

Stalk Roll Repair Kits for Corn Heads .........................................21<br />

Stalk Roll Stripper Plate Kit.........................................................19<br />

Stalk Roll Support Kit .................................................................21<br />

Stalk Stomper Kits......................................................................19<br />

Sta-Sharp and Super Sta-Sharp Sections ..................................11<br />

Stone Retarder Drum <strong>Service</strong> Kit for Combine Feeder Drum ......30<br />

Straw Chopper Kits ..............................................................56, 57<br />

Straw Spreader Driven Pulley Kit, Two-Speed ............................55<br />

Tailing Delivery Auger Hub - Upgrade Kit ....................................50<br />

Tailings Volume Monitor Kit .........................................................49<br />

Tall Bat Assemblies.....................................................................54<br />

T-Bolt Kit.....................................................................................65<br />

Three Way Electrical Plugs..........................................................76<br />

Tighteners, Snugulator®.............................................................78<br />

Tines and Tine <strong>Service</strong> Kits ........................................................12<br />

Trailer Hitch Kits..........................................................................76<br />

Trailer Hitch Kit Weight................................................................76<br />

Transition Cone and Vane Kits ....................................................33<br />

Transition Cone Vane Kits, Extenda-Wear ...............................64<br />

Transition Cone, Extenda-Wear...............................................63<br />

Transition Cone, Heavy-Duty ......................................................63<br />

Unloader Spill Saver ...................................................................44<br />

Unloading Auger Assembly with Enclosed Gearbox ...................43<br />

Unloading Auger Tube Support Kit .............................................45<br />

Unloading Relay Kit (Dipping Relay) ............................................46<br />

Vertical Unloading Auger Kit .......................................................43<br />

Viewing Door and Light ..............................................................59<br />

Voyager Observation Systems ....................................................79<br />

Weed Knife Kits..........................................................................22<br />

Windshield Washer Kit................................................................77<br />

Wobble Boxes and Repair Kits ...................................................11

COMBINE MAINTENANCE<br />

Pre-harvest planning<br />

Case IH has developed combine product support kits designed to enhance the performance of<br />

your Axial-Flow combine. And now is the perfect time to get started on evaluating your<br />

maintenance needs before the busy harvest season. Several different viewpoints were factored<br />

into the development and design of these performance and maintenance kits including:<br />

• Input from customers like you who own and operate Case IH Axial-Flow combines.<br />

• Advice from Case IH dealers’ product support departments. These parts and service specialists<br />

have submitted numerous suggestions based on actual experiences in the dealership.<br />

• Data from Case IH combine engineers who work to make improvements on later models,<br />

through packaged kits that can be installed on a previous model<br />

combine, corn head or grain header.<br />

Performance kits: These kits, such as the Cross-<br />

Flow ® fan and new style corn head stalk roll, were<br />

developed to improve the performance of later model<br />

machines,<br />

but could also be installed on earlier models to improve<br />

their performance.<br />

Maintenance kits: Examples include corn<br />

head repair kits, cutter bar kits and rasp<br />

bar kits, designed to make a<br />

complete repair on a machine.<br />

They include key<br />

components and<br />

hardware, helping to<br />

reduce repeated trips to<br />

the dealership for<br />

additional pieces needed<br />

to complete the repair.<br />

<strong>Service</strong> Packs: These<br />

handy carded packs for<br />

your shop or toolbox are<br />

designed for smaller repairs. Examples include auger fingers and chopper knife kits.<br />

These smaller kits still include key parts and attached hardware.<br />

Complete assembly: Knife drive boxes or complete rotors have the latest components and are<br />

complete and ready to install. These kits can reduce downtime during the season while upgrading<br />

your combine with the latest improvements.<br />

While you can install these kits yourself, other kits are best installed by your Case IH dealer who<br />

has the training and special tools to install these kits in your Axial-Flow combine. Ask your<br />

Case IH dealer for an installed price on any of these kits.<br />

Your recommendations on new kits for your Axial-Flow combines and header are always welcome.<br />

Talk to us and we’ll submit your ideas to Case IH parts marketing.<br />

5

6<br />

CASE IH PRODUCT SUPPORT KITS<br />

FOR <strong>AXIAL</strong>-<strong>FLOW</strong> <strong>COMBINES</strong><br />

Spreader Kits<br />

Automated Lubrication Kit<br />

Straw Chopper Kits<br />

AFS and Yield Monitor Kits<br />

Automatic Header Height Control Kit<br />

Unloading Auger Kit<br />

Rotor Cage Kits<br />

Rasp Bar Kit<br />

Impeller Blade Kit<br />

Feeder Silencer Kit / Feeder Roller Kit<br />

3-Strand Feeder Chain Kits<br />

Skid Shoe Kit<br />

External Sieve Adjuster Kits<br />

Cutter Bar Kit<br />

Cone and Vane Kit<br />

Rotor Kit<br />

Concave Kits<br />

Cross Flow Fan Kit<br />

Wobble Box<br />

EXTENDA-WEAR Products<br />

Poly Corn Hoods and Dividers<br />

Stalk Roll Kit (Corn Head)<br />

Curved Bat Kit / Quick Release Coupler

Adjustable Design<br />

Description: 2010/2020 adjustable conversion kits for<br />

Axial-Flow 2100, 2300, and 2500 series combines.<br />

2010 Rigid Head Kits:<br />

87362990 - Adjustable header frame adapter and mounting<br />

hardware. (Adjustable to four positions for easier installation<br />

of different heads to combines).<br />

87447947 - Hydraulic, electrical (lighting only) and PTO<br />

adapter parts<br />

87455606 - AHHC adapter kit (without Field Tracker) -<br />

includes control module and harnesses. (2010 header<br />

sensors not included - order with header or sensor DIA kit).<br />

87455402 - AHHC with Field Tracker adapter kit - control<br />

module and harnesses. (2010 header sensors not included -<br />

order with header or sensor DIA kit)<br />

2020 Flex Head Kits:<br />

87362290 - Adjustable header frame adapter and mounting<br />

hardware. (Adjustable to four positions for easier installation<br />

of different heads to combine.<br />

87447947 - Hydraulic, electrical (lighting only) and PTO<br />

adapter parts<br />

87455403 - AHHC adapter kit (without Field Tracker) - includes<br />

control module and harnesses. (2010 header sensors not<br />

included - order with header or sensor DIA kit).<br />

87455332 - AHHC with Field Tracker adapter kit - control<br />

module and harnesses. (2010 header sensors not included -<br />

order with header or sensor DIA kit).<br />

8<br />

GRAIN PLATFORM KITS<br />

GRAIN HEADER AND CORN HEAD COMPLETING KITS<br />

GRAIN HEADER COMPLETING KITS<br />

Fixed Design<br />

Part Number: 87448290 (shown) - 2010 Rigid Header<br />

87448291 - 2010 or 2020 Flex Header<br />

Description: Header conversion kits to install a 2010 rigid header onto 21/2300<br />

series combines. Includes weldment and mounting hardware for header frame only.<br />

Completing Kits:<br />

• 87447947 – Coupler assembly (hydraulics, electrical) and PTO drive line<br />

• 87455402 – AHHC and/or Field Tracker sensor adapter packages (2010)<br />

• 87455332 – AHHC and/or Field Tracker sensor adapter packages (2020)<br />

Part Number: 87455402, 87455332<br />

Description: AHHC with Field Tracker adapter kit – control module and harnesses with<br />

mounting hardware and I-sheets (2010 header sensors not included; order with header<br />

or sensor DIA kit)<br />

87455332 – AHHC and Field Tracker sensor adapter package for 2020 headers on<br />

21/2300 series combines. Includes control module and adapter harnesses. Sensors<br />

are included on 2020 headers as standard equipment.<br />

87455402 – AHHC and Field Tracker sensor adapter package for 2010 headers on<br />

21/2300 series combines. Includes control module and adapter harnesses. Header<br />

must be equipped with AHHC and field tracker sensor package ordered with the header<br />

for production or service parts.<br />

Part Number: 87447947 (shown)<br />

Description: Coupler (hydraulics,<br />

electrical) and PTO drive line.<br />

Designed for us with header<br />

conversion kit (Part No.<br />

87448290 or Part No. 87448291)<br />

to install a 2010 or 2020 onto a<br />

21/2300 series combine.<br />

Kit includes: The couplers,<br />

hydraulic connectors, hose,<br />

bracket, mounting hardware,<br />

PTO drive shaft, and I-sheets.<br />

Does not include header height<br />

control harness or control module.<br />

CORN HEAD KITS<br />

Part Number: 87041928 (shown)<br />

Description: Kit to install a 2200 series corn head (for 2388)<br />

on a on a AFX 8010 combine<br />

Kit includes: Drive shafts, hydraulics and electrical -<br />

87041928 – 8 row kit, 87041425 – 12 row kit<br />

Part No. 87041928<br />

Part No. 87448290<br />

Part No. 87455332<br />

Part No. 87447947

GRAIN PLATFORM KITS<br />

CROP DIVIDERS AND ACCESSORIES<br />

Listed below are dividers options for 2010 and 2020 headers, kit includes components for a LH and RH divider.<br />

Part Number: 801462 and 87058247<br />

Description:<br />

Crop divider - short<br />

Application:<br />

2010 and 2020 headers<br />

Recommended for short to medium standing crops<br />

Part Number: 87016131 and 87548554<br />

Description:<br />

Crop divider – medium<br />

Application:<br />

2010 and 2020 headers<br />

Recommended for medium to tall standing crops<br />

Part No. 87016131 - 2006 and earlier models<br />

Part No. 87548554 - 2007 models<br />

Part No. 87298163<br />

Part No. 801462 - Loop style shown - 2006 and earlier models<br />

Part No. 87058247 - 2007 models<br />

Part Number: 87053604 and 87544034<br />

Description:<br />

Crop divider – long<br />

Application:<br />

2010 and 2020 headers<br />

Recommended for medium to tall tangled crops<br />

Part No. 87053604 - 2006 and earlier models<br />

Part No. 87544034 - 2007 models<br />

Part Number: 87298163 (LH), 87298164 (RH)<br />

Description:<br />

Replacement crop divider end assembly for<br />

long dividers<br />

Application:<br />

For long divider<br />

Fully assembled, ready to install<br />

9

10<br />

GUARD KITS – 2 & 4 PACK<br />

• Kit includes guards, hold down clips, shims and hardware<br />

• Handy service 4-pack to repair two-foot sections or 2-pack to<br />

repair one-foot sections<br />

• Kits for 3" and 1-1/2" systems<br />

• Kits with double heat-treated guard for longer wear-life and<br />

improved toughness<br />

CUTTER BAR REBUILD KITS<br />

For 820/1010/1020 Headers<br />

Kits are available with or without the knife so you can<br />

select the knife of your choice; headed or headless<br />

for 1-1/2" or 3" systems, split knives for 3" and the<br />

section type best suited to your needs.<br />

Kits are complete and include: guards, hold-down<br />

clips, wear plates, and hardware. Kit may not include<br />

knife depending on ordering options.<br />

Cutterbar kits for 820 headers also available.<br />

CROP DIVIDERS AND<br />

ACCESSORIES<br />

• Complete<br />

• Assembled<br />

• Poly point<br />

Part No. B94154 (LH)<br />

Part No. B94155 (RH)<br />

Part No. B94154<br />

GUARD KITS – 2-PACK<br />

PART NO. DESCRIPTION<br />

B95478 3" SYSTEM DOUBLE HEAT-TREATED GUARD<br />

B95479 3" SYSTEM<br />

GUARD KITS – 4-PACK<br />

PART NO. DESCRIPTION<br />

B95278 3" SYSTEM<br />

B95407 3" SYSTEM DOUBLE HEAT-TREATED GUARD<br />

B95377 1-1/2" SYSTEM<br />

3 INCH CUTTER BAR KITS -1010 AND 1020 HEADERS<br />

HEADER SIZE ONE PIECE KNIFE SPLIT KNIFE SPLIT KNIFE SPLIT KNIFE W/O KNIFE W/O KNIFE<br />

SSS SECTIONS SSS SECTIONS SSS SECTIONS SS HIGH SHOULDER SECTIONS STD GUARDS DHT GUARDS<br />

STD GUARDS STD GUARDS DHT GUARDS STD GUARDS<br />

15' B92858E B95546 B95616 82797045 B92919E B95633<br />

16.5' B92859E N/A N/A N/A B92920E B95634<br />

17.5' B92860E B95548 B95617 82797046 B92921E B95635<br />

20' B92861E B95549 B95618 82797047 B92922E B95636<br />

22.5' B92862E B95550 B95619 82797048 B92923E B95637<br />

25' B92863E B95551 B95620 82797049 B92924E B95638<br />

30' B92864E B95552 B95621 82797050 B92925E B95639<br />

CUTTER BAR KITS -<br />

820 HEADERS<br />

ONE PIECE KNIFE WITH<br />

SUPER STA-SHARP SECTIONS<br />

HEADER SIZE KIT<br />

PART NO.<br />

15' B93985E<br />

16.5' B93986E<br />

17.5' B93987E<br />

20' B93988E<br />

22.5' B93989E<br />

TIME SAVER!<br />

GRAIN PLATFORM KITS<br />

1-1/2 INCH CUTTER BAR KITS<br />

HEADER SIZE WITH KNIFE<br />

SUPER STA-SHARP SECTIONS<br />

W/O KNIFE<br />

15' B94009E B92926E<br />

16.5' B94010E B92927E<br />

17.5' B94011E B92928E<br />

20' B94012E B92929E<br />

22.5' B94013E B92930E<br />

25' B94014E B92931E<br />

30' B94015E B92932E<br />

POLY POINT KIT<br />

Part No. B95408<br />

TUBE KIT<br />

Part No. B95409<br />

KNIFE REINFORCING KIT<br />

• 50 Straps/nuts/bolts<br />

• Reinforcing straps for<br />

improved strength and<br />

durability in high-load<br />

applications<br />

• Kit contains enough<br />

straps and hardware<br />

for a 30' knife<br />

Kit Part No. 321849A1<br />

3 inch System<br />

1-1/2 inch System

GRAIN PLATFORM KITS<br />

HIGH ARCH HOLD-DOWN CLIP SERVICE KITS<br />

For 1020 Headers with<br />

1-1/2" Knife System<br />

Case IH 1-1/2" Knife Systems currently<br />

have 100% hold-down clips down the<br />

length of the cutter bar. The High Arch<br />

Clip Kit now provides for a secure<br />

method of holding down the knife over<br />

the drive end. Longer service life and<br />

improved cutting are the benefits.<br />

Part No. B92983<br />

Case IH Sta-Sharp and Super Sta-<br />

Sharp sections have a special design<br />

root serration to prevent excessive wear<br />

across the top. Complete selection of<br />

Sta-Sharp and Super Sta-Sharp sections<br />

available.<br />

• High-carbon 1080 steel<br />

• Induction hardened for extra-long wear<br />

• Top-serrated sections have selfsharpening<br />

feature<br />

• Available for 3" and 1-1/2" knife<br />

systems<br />

COMBINE KNIFE SELECTION - STA-SHARP SECTIONS<br />

Header size 3" one piece* 3" split* 1-1/2" one piece<br />

15' 451824A2 451830A2 1970502C5<br />

16.5' N/A N/A 1970503C5<br />

17.5' 451825A2 451831A2 1970504C5<br />

20' 451826A2 451832A2 1970400C5<br />

22.5' 451827A2 451833A2 1970442C5<br />

25' 451828A3 451834A3 1970402C5<br />

30' 451829A3 451835A3 1970404C5<br />

*KNIFE WITH HIGH SHOULDER STA-SHARP SECTIONS<br />

COMBINE KNIFE SELECTION - SUPER STA-SHARP SECTIONS<br />

HEADER SIZE 3" ONE PIECE 3" SPLIT 1-1/2" ONE PIECE 1-1/2" ONE PIECE<br />

STD DUTY SECTION AUSTEMPERED SECTION<br />

15' 87439540E 371613A2 B93635E 398746A1<br />

16.5' 87439541E 371617A2 B93636E 398747A1<br />

17.5' 87439542E 371618A2 B93637E 398748A1<br />

20' 87439543E 371619A2 B93638E 398749A1<br />

22.5' 87439544E 371620A2 B93639E 398750A1<br />

25' 376534A3E 371621A3 B93640E 398751A1<br />

30' 376535A3E 371622A2 B93641E 398752A2<br />

WOBBLE BOX<br />

For 800 and 1000 Series<br />

For minimum downtime and new<br />

performance – choose the complete<br />

replacement.<br />

Part No. 1330048C91 for 810/820<br />

Headers<br />

(Does not include pulley)<br />

Kit includes:<br />

high arch knife clips (2)<br />

mounting hardware shims<br />

Part No. 1316987C91 for<br />

1010/1020 Headers<br />

(Includes pulley)<br />

(Prior to 1995 models)<br />

Split Knife Kit 371618A1 with<br />

Super Sta-Sharp Sections<br />

Part No. 398290A2E<br />

for 1010/1020 Headers<br />

(Oil bath) (1995 and<br />

After)<br />

For 1010 & 1020 Headers with<br />

3" Knife System<br />

The High Arch Clip Kit now provides a<br />

secure method of holding down the<br />

knife over the drive end. Longer service<br />

life and improved cutting are the<br />

benefits. Kit includes high arch clip (1),<br />

mounting hardware and shims.<br />

Part No. B95382 – 1010 Header<br />

Part No. B95383 – 1020 Header<br />

Competitor Section<br />

Excessive wear<br />

over top of section.<br />

Section does not<br />

have the required<br />

three-holes for<br />

proper mounting of<br />

the knife head.<br />

WOBBLE BOX<br />

REPAIR KIT<br />

• For boxes Part No.<br />

1330048C91 and<br />

Part No. 1316987C91<br />

• Includes bearings, shims,<br />

and hardware<br />

Part No. B95203<br />

CASE IH DIAMOND<br />

SUPER STA-SHARP SECTIONS<br />

11

HEADER AUGER FINGERS<br />

Now available as a service kit. Includes finger, guide, clip,<br />

and hardware. Part Numbers B96219 and B94602 also<br />

include finger hub.<br />

TINE SERVICE KITS<br />

• Handy service kit<br />

• Includes tine and mounting hardware<br />

12<br />

PART NO. BILL OF MATERIALS APPLICATION<br />

B94711 6 OF B93867<br />

(BULK PART NO.)<br />

1000 SERIES HEADERS<br />

B94712 6 OF B93866<br />

(BULK PART NO.)<br />

1000 SERIES HEADERS<br />

B94710 4 OF B93868<br />

(BULK PART NO.)<br />

1000 SERIES HIGH-VISIBILITY REEL<br />

B95856 2 OF B95872 1000 SERIES HEADER 2001 AND<br />

(BULK PART NO.) LATER, AND 2000 SERIES HEADERS<br />

Part No. 95856<br />

BULK TINES<br />

• Includes tines and hardware<br />

Part No. B93867 for 1000 series header.<br />

Part No. B93866 for 1000 series header.<br />

Part No. B93868 for 1000 series header with high-visibility reels.<br />

Part No. B95872 for 1000 series header 2001 and later, and also<br />

2000 series headers<br />

BULK TINES - 25 PACK<br />

Part No. B95857 for 1000 series header 2001 and later, and also<br />

2000 series headers<br />

GRAIN PLATFORM KITS<br />

Part No. B94710<br />

Part No. B94711<br />

810/820 SERIES HEADERS<br />

Part No.<br />

B94601<br />

Part No. B94712<br />

Part No.<br />

B94602<br />

REEL TINE FLAP KIT<br />

Twenty-five Pack<br />

1000 SERIES HEADERS<br />

Part No.<br />

B96216<br />

• Improves crop flow in light crops<br />

• Kit includes nine flaps and mounting hardware<br />

• For 1000 and 2000 series headers<br />

• Part No. 86705199<br />

Part No.<br />

B96219<br />

Part No. 86705199<br />

Large Bulk Pack

GRAIN PLATFORM KITS<br />

HEADER AUGER FINGERS AND KITS<br />

The new Auger Finger is tougher, stronger and more wear<br />

resistant and now has a roll-pin installed to capture the<br />

Auger Finger safely in the auger tube.<br />

• SURFACE HARDNESS - The surface<br />

hardness is increased to provide up to 60%<br />

more wear life than old style steel finger.<br />

• CORE HARDNESS - The core hardness<br />

increased by 40% for improved toughness to<br />

better resist breaking or bending.<br />

• ROLL-PIN RETAINER - A roll-pin is positioned<br />

between the finger guide and breakpoint to<br />

capture any broken finger inside the auger tube.<br />

Any broken finger can easily be removed at the<br />

operators convenience.<br />

STEEL VS. POLY/FIBERGLASS FINGER<br />

Steel is harder than Poly/Fiberglass and will provide substantially more wear life.<br />

Stronger - tougher - harder - longer lasting and with the retainer system the new<br />

Part No. B96216<br />

Auger Finger Kit<br />

Part No. B96219<br />

Deluxe Auger Finger Kit<br />

for 1000 series header<br />

NEW STYLE HEADER AUGER FINGER KITS<br />

Part No. B96220<br />

Auger Finger Conversion Kit<br />

KIT SELECTION<br />

PART NO. DESCRIPTION<br />

B96216 AUGER FINGER KIT - TWO FINGERS, GUIDES, AND HARDWARE<br />

B96217 AUGER FINGER KIT - SIX FINGERS<br />

B96218 AUGER FINGER KIT - EIGHTEEN FINGERS<br />

B96219 DELUXE AUGER FINGER KIT - ONE FINGER, HUB, GUIDE, AND HARDWARE<br />

B96220 *AUGER FINGER CONVERSION KIT - EIGHTEEN FINGERS, GUIDES, AND HARDWARE<br />

B96221 *DELUXE AUGER FINGER CONVERSION KIT - EIGHTEEN FINGERS, GUIDES, HUBS, AND HARDWARE<br />

87298139 AUGER FINGER KIT FOR 25’ FULL FINGER AUGER. INCLUDES 30 FINGERS, GUIDES, AND HARDWARE<br />

87298140 AUGER FINGER KIT FOR 30’ FULL FINGER AUGER. INCLUDES 32 FINGERS, GUIDES, AND HARDWARE<br />

*Header Conversion Kits - Parts convert all auger fingers on the header from older style<br />

fingers to new improved style fingers<br />

• For 2006-2007, Model 2010, and 2020 Grain Headers<br />

• Long wearing heat treated auger finger and hardware<br />

Part No. 87298864 - complete set - 30' Header (shown)<br />

Part No. 87298865 - complete set - 25' Header<br />

Part No. 87298860 - complete set - 20' Header<br />

Part No. 87298867C - two pack kit<br />

Part No. 87298954C - deluxe finger kit Part No. 87298864<br />

13

14<br />

GRAIN PLATFORM KITS<br />

CROP LIFTER KIT/HEADER LATCH KITS / COUPLE KITS<br />

• Designed to lift down crop for maximum cutting efficiency<br />

• Manufactured from 5 mm thick spring steel for toughness<br />

and longer service life<br />

• The locking clip can secure the lifter at 3 different heights for<br />

flexibility in a variety of crop conditions<br />

• Attaches to foraged guards on the following headers with<br />

the spacer spool and hardware included in the kit<br />

APPLICATION LIFTER KIT W/ SPOOL AND HARDWARE REPLACEMENT LIFTER MODEL<br />

CASE IH HEADERS 87298403 87298400 ASX-120<br />

MACDON HEADERS 87298404 87298401 ASX-127<br />

HONEYBEE HEADERS 87298405 87298402 ASX-100<br />

ALL 87298406 (8 SPOOLS AND HARDWARE) – –<br />

CENTRALIZED HEADER<br />

LATCH KIT<br />

• This kit mounts to the left side of the feeder<br />

and has cables that connect to a pair of<br />

engagement pins that latch the header to the<br />

combine<br />

• Combine kit includes cables, handle guards,<br />

springs, hardware, and I-sheet<br />

• Header kits include engagement pins and<br />

mounting hardware<br />

• These kits are designed to make it easier to<br />

attach various Case IH headers to Case IH<br />

Combines<br />

EZ LATCH SINGLE LEVEL HYDRAULIC<br />

COUPLER KIT<br />

• Kit includes coupler assembly, hydraulic lines, and hardware<br />

• Kit is designed to make it easier to connect the hydraulics<br />

on the combine to the header<br />

• Coupler for 1010/1020 headers, 2200 Corn Heads, and mid-range<br />

Axial Flow Combines<br />

• Combine these kits with the centralized header latch kit for even<br />

greater convenience<br />

Part No. 87539791 -<br />

Combines with field tracker (shown)<br />

Part No. 87539793 -<br />

Combines without field tracker<br />

Crop lifter kit<br />

Part No. 87336803 - 1010/1020 Header<br />

(shown)<br />

Part No. 87337673 - 2200/2400 Corn Head<br />

Part No. 87352570 - 1015 Pick-up Header<br />

Part No. 87352569 - 1000 Corn Heads<br />

Part No. 87368703 - 2015 Pick-up Header<br />

Part No. 87552504 - coupler half for 1000 Series Headers<br />

Part No. 87301386E - coupler half for 1644, 1666, 1688,<br />

and later combines<br />

Part No. 87662931E - coupler half for 2200 Corn Head

GRAIN PLATFORM KITS<br />

FULL WIDTH RETRACTING FINGER AUGER KIT<br />

FEATURES –<br />

PERFORMANCE<br />

• Ten (10) additional tines positioned between<br />

the auger flight, evenly spaced the full width of<br />

the 25´ auger.<br />

• Twelve (12) additional tines positioned<br />

between the auger flight, evenly spaced the<br />

full width of the 30´ auger.<br />

• Crop missed by the flight is gathered by<br />

the extra fingers, providing an even,<br />

continuous feed.<br />

• Improves crop flow in high yield crops.<br />

• The fingers reduce the tendency for crop to<br />

bunch and feed in slugs, making the auger<br />

more efficient and feeding into the feeder<br />

more uniform.<br />

• Improves header and feeding<br />

performance.<br />

• Improves crop flow in damp crops to keep<br />

material moving off the cutter bar and along<br />

the header floor.<br />

• Improves feeding in new varieties of green<br />

stem soybeans. Allows the operator to start<br />

earlier in the morning and work later after dark<br />

when the beans are less apt to slide. Two<br />

extra hours of harvesting can produce<br />

15-20% more acres per day.<br />

PICK-UP BELT WITH<br />

TEETH INSTALLED<br />

• Genuine Case IH pick-up belt with teeth installed<br />

• Convenient – Save valuable time on belt installation<br />

• Part No. 1977190C1E – 1015 Headers<br />

• Part No. 185527C93E – 810 Headers<br />

25 foot full width retracting finger auger kit<br />

FEATURES – DESIGN<br />

AND CONSTRUCTION<br />

• Heavier center section than on all current production 25´ augers and 30´ augers<br />

produced prior to model year 2001<br />

• Bulk head locations designed to provide maximum bearing and auger support<br />

• Shorter drive and driven shafts to get auger finger closer to auger ends<br />

• New auger shell and new components – all designed by Case IH and manufactured by<br />

approved suppliers<br />

• New auger – no prior wear, cutting or rewelding on auger shell<br />

• Fully assembled by Case IH auger supplier<br />

• Ready to be installed<br />

• Twelve (12) month warranty<br />

PART NUMBERS / APPLICATIONS<br />

1010 AND 1020 GRAIN HEADERS (25' AND 30') 1995 AND LATER PRODUCTION<br />

PART NO. 87541527 25' AUGER KIT, INCLUDES 30 ASSEMBLED FINGERS, GUIDES, AND HARDWARE<br />

PART NO. 87541528 30' AUGER KIT, INCLUDES 32 ASSEMBLED FINGERS, GUIDES, AND HARDWARE<br />

HEADER REEL KITS<br />

PART NUMBER SIZE DESCRIPTION APPLICATION<br />

87298133 30' FIVE (5) BAT REEL KIT 1000 SERIES HEADER<br />

87298328 17.5' P.U. PLASTIC TINE REEL KIT 1000 SERIES HEADER<br />

87298134 20' P.U. PLASTIC TINE REEL KIT 1000 SERIES HEADER<br />

87298956 22.5' P.U. STEEL TINE REEL KIT 1000 SERIES HEADER<br />

87298135 25' P.U. PLASTIC TINE REEL KIT 1000 SERIES HEADER<br />

87298136 30' P.U. PLASTIC TINE REEL KIT 1000 SERIES HEADER<br />

87298338 25' P.U. STEEL TINE REEL KIT 1000 SERIES HEADER<br />

87298137 30' P.U. STEEL TINE REEL KIT 1000 SERIES HEADER<br />

Complete reel kit. Designed to replace a damaged reel or for harvesting<br />

different crops.<br />

15

REEL REPAIR KIT<br />

Gather more grain when your 1000 series pick-up reel is in top shape and ready for tough harvest<br />

conditions. New reel repair kits offer:<br />

• Convenience – key components and hardware in one kit<br />

• Save time and cost effectiveness – save time and money<br />

• Confidence – your reel will feed your valuable crop to your combine.<br />

KITS FOR OLDER STYLE 1000 SERIES HEADER REELS<br />

Reel Arm Bushing Kit -<br />

Deluxe<br />

B95648 - One Side (shown)<br />

B95649 - Two Sides<br />

Reel Arm Bushing Kit<br />

B95646 - One Side<br />

B95647 - Two Sides<br />

(shown)<br />

Reel Arm Bushing Kit<br />

B95642<br />

KITS FOR NEWER STYLE 1000 SERIES HEADER REELS<br />

Reel Arm Bushing Kit<br />

B95644 - One Side<br />

B95645 - Two Sides<br />

Reel Arm Bearing Kit<br />

B95623 - Kit for one<br />

spider<br />

AUTOMATIC HEADER HEIGHT CONTROL<br />

(AHHC) LINKAGE KIT<br />

• Kit includes parts to convert from a cable to a mechanical linkage to<br />

actuate the potentiometer on all 1020 headers<br />

• The mechanical linkage design has proven to be more<br />

reliable and durable<br />

• Standard on all 2002 model 1020 headers<br />

• Part Number 434092A4E - For 1400*, 1600*, 2100, and 2300 combines<br />

* 1400 and 1600 series combines require harness kit Part No. 87412210E<br />

16<br />

GRAIN PLATFORM KITS<br />

Part No. 434092A4E<br />

Reel Arm Bushing Kit<br />

B95643 - Uptime Pak<br />

Reel Arm Bearing Kit<br />

B95624 - Uptime Pak

GRAIN PLATFORM KITS<br />

POLY SKID SHOE KIT<br />

For Combine Headers<br />

Poly-Skid Shoes improve header<br />

performance in wet, sticky soils and extend<br />

metal shoe life in sandy, abrasive soils.<br />

The design of the new black poly-skid<br />

shoe material is changed to permit the<br />

shoe to nest into the ribs of the 1020<br />

steel skid shoe. This will allow the<br />

operator to cut grain at a lower height<br />

compared to the height of cut allowed<br />

by the previous design. This new polyskid<br />

shoe is standard equipment on all<br />

2001 model 1020 headers.<br />

Poly-Skid Shoe Kits<br />

Kit includes two black poly center skid<br />

Part No. B95902<br />

Part No. B95903 - <strong>Service</strong> Pack of 20 each 5/8"<br />

pound hammer rivets<br />

Part No. B95904 - <strong>Service</strong> Pack of 20 each 3/4"<br />

hammer rivets<br />

Part No. B95905 - Hammer rivet bulk pack - 5/8"<br />

Part No. 82797058 - Hammer rivet <strong>Service</strong> Pack - 1/2"<br />

Part No. B96608 - Hammer rivet bulk - 1/2"<br />

Part No. B95651<br />

CROP DEFLECTOR KIT<br />

• Add to inside of divider to improve crop feeding<br />

away from knife<br />

• Kit includes fingers and hardware<br />

Part Number 394417A1 - Individual<br />

replacement finger<br />

Kit shown for 2001 headers Kit shown for 2000 and prior headers<br />

Poly-Skid Shoe Kit<br />

Listing for Case IH 1020 headers with<br />

new black poly.<br />

2001 2000 AND PRIOR*<br />

LENGTH PART NO. PART NO.<br />

15' B95873 B95880<br />

16.5' B95874 B95881<br />

17.5' B95875 B95882<br />

20' B95876 B95883<br />

22.5' B95877 B95884<br />

25' B95878 B95885<br />

30' B95879 B95886<br />

Poly Steel Combination Kit<br />

Listing for Case IH 1020 headers with<br />

new black poly.<br />

2001 2000 AND PRIOR*<br />

LENGTH PART NO. PART NO.<br />

15' B95887 B95894<br />

16.5' B95888 B95895<br />

17.5' B95889 B95896<br />

20' B95890 B95897<br />

22.5' B95891 B95898<br />

25' B95892 B95899<br />

30' B95893 B95900<br />

*Headers prior to 1995 model year also require Part Number B95901.<br />

CASE IH LIGHT KITS<br />

For 1000 Series Grain Headers<br />

Now you can add flashing warning lights to 1000 series headers built<br />

prior to 1995!<br />

Install a Case IH Light Kit and get all items needed including hardware<br />

for easy installation!<br />

Header Light Kit<br />

No. B93448 –<br />

1010 and 1020 Lights<br />

Part No. B95903<br />

Part No. B95901<br />

17

CORN HEAD HANDY PACKS<br />

• Handy service packs • For steel and poly dividers • Includes hardware<br />

POINT KIT STEEL/POLY – DIVIDER<br />

PART NO. DESCRIPTION<br />

B94737 INNER – ALL ROW WIDTHS<br />

B94738 OUTER – ALL ROW WIDTHS<br />

• Handy service packs<br />

• Includes sprockets and<br />

hardware<br />

• For 800, 900, and 1000<br />

series corn heads<br />

18<br />

CORN HEAD KITS<br />

IDLER SPROCKET KIT<br />

PART NO. DESCRIPTION<br />

B94739 800–1000 SERIES<br />

SKID PAD KIT<br />

PART NO. DESCRIPTION<br />

B94736 INNER - 30" ROWS<br />

B94845 OUTER - ALL ROW WIDTHS<br />

B96355 INNER - 36" ROWS<br />

DRIVE SPROCKET KIT<br />

PART NO. DESCRIPTION<br />

B94733 800 SERIES<br />

B94734 900–1000 SERIES

CORN HEAD KITS<br />

LEVEL CORN STALKS AHEAD OF COMBINE<br />

DRIVE WHEELS<br />

CASE IH LIGHT KITS<br />

You benefit from extended tire life and savings in downtime from less frequent<br />

tire changes.<br />

Kit includes a pair of stalk stompers and attaching hardware.<br />

STALK STOMPER KITS<br />

PART NO. DESCRIPTION<br />

B92896 800 SERIES CORN HEAD<br />

B92897 800 SERIES (8 ROW) CORN HEAD<br />

B92898 900–1000 SERIES CORN HEAD<br />

B92899 900–1000 SERIES (8 ROW) CORN HEAD<br />

B94461 SPRING FOR STALK STOMPER<br />

For 1000 Series Corn Headers<br />

Now you can add flashing warning lights to 1000 series headers built prior to<br />

1995!<br />

Install a Case IH Light Kit and get all items needed including hardware for easy<br />

installation!<br />

Header Light Kit B93713 – 1000 Series Corn Heads<br />

Header Light Kit B93476 (8 Row Wide) – 1000 Series Corn Heads<br />

STALK ROLL STRIPPER PLATE KIT<br />

GATHERING CHAIN<br />

Far greater wear life than imported<br />

“look-a-likes”.<br />

Regular-duty chain Part No. B176279C91<br />

for 800, 900, and 1000 series.<br />

Extended life chain Part No. 86523386<br />

(with chrome pins) for 800, 900, and 1000<br />

series.<br />

Note: Wears 2.5 times longer than<br />

regular-duty chain.<br />

Both chains fit John Deere<br />

corn heads<br />

• Stripper plates made from high-strength material for superior performance<br />

• Kit includes stripper plates (LH & RH) and attaching hardware<br />

• 900-1000 series corn heads<br />

Part No. B95449<br />

19

20<br />

STALK ROLL KITS<br />

LOWER STALK ROW BEARING<br />

SHIELD<br />

Part No. B94982 - 2 row kit<br />

Part No. B94983 - 4 row kit<br />

Part No. B94984 - 6 row kit<br />

Part No. B94985 - 8 row kit<br />

CORN HEAD KITS<br />

For Case IH 800*/900/1000 Series Corn Heads<br />

*Requires row unit re-work.<br />

Aggressive new life for your 800/900/1000 series corn heads.<br />

Stalk Roll Assembly<br />

Kit includes:<br />

• LH and RH Roll Assembly<br />

• Spiral augers<br />

• Lower support shims<br />

• Lower support and hardware<br />

Part No. B92764A – 1 Row<br />

Stalk Roll Assembly with knives<br />

Kit includes:<br />

• LH and RH Roll Assembly with knives<br />

• Spiral augers<br />

• Lower support shims<br />

• Lower support and hardware<br />

Part No. 82797036 – 1 Row<br />

Complete Roll and Chain Assembly<br />

Kit includes:<br />

• LH and RH Roll Assembly • 2-Gatherer chain idler<br />

• Spiral augers<br />

sprockets<br />

• Lower support shims<br />

• Drive sprocket attaching<br />

• 2-Gatherer chain drive sprockets<br />

hardware<br />

• 2-Gatherer chains<br />

Part No. B92766A – 1 Row with regular duty chains<br />

Part No. B96434 – 1 Row Extenda-Wear chains<br />

Bearing and Shield Kit<br />

• Includes 2 bearings and two shields<br />

• Lower stalk row<br />

Part No. B95612<br />

Longer service life is now<br />

yours because of an<br />

improved lower bearing.<br />

A single, sealed,<br />

heavy-duty water pump<br />

type bearing now<br />

replaces the two needle<br />

bearings and seal.<br />

Greasing is no longer<br />

required!

CORN HEAD KITS<br />

STALK ROLL REPAIR KITS FOR CORN HEADS<br />

• KITS INCLUDE<br />

COMPONENTS TO<br />

REBUILD ONE ROW<br />

• ALL COMPONENTS ARE<br />

ORIGINAL EQUIPMENT<br />

QUALITY<br />

• CORN HEAD KNIVES<br />

HAVE SUPERIOR<br />

TUNGSTEN CARBIDE<br />

COATING FOR LONGER<br />

WEAR<br />

• CORN HEAD KNIFE<br />

HARDWARE IS GRADE 8<br />

• ALL HARDWARE IS<br />

INCLUDED<br />

Standard Kit - 1 Row<br />

Kit includes:<br />

• Corn head knives (8)<br />

• Hardware<br />

Part No. B94532 for 900 and 1000<br />

series corn heads.<br />

Part No. B94594 for 800 series<br />

corn heads.<br />

Chain/Sprocket Kit – 1 Row<br />

Kit includes:<br />

• Gatherer chain drive sprocket (2)<br />

• Gatherer chain idler sprocket (2)<br />

• Gatherer chains (2)<br />

• Hardware<br />

Part No. B95214 for 900 and 1000<br />

series corn heads.<br />

Part No. B95215 for 800 series<br />

corn heads.<br />

Deluxe Kit – 1 Row<br />

Weed Knife Kit (Rear)<br />

Kit includes:<br />

• Corn head knives (8)<br />

• Hardware<br />

• Gatherer chain drive sprockets (2)<br />

• Gatherer chain idler sprockets (2)<br />

• Gatherer chains (2)<br />

Part No. B94533 for 900 and 1000 series corn heads and Part No. B94541 for 800<br />

series corn heads.<br />

CORN HEAD WEED KNIFE KITS<br />

Weed Knife Kit (Front)<br />

KIT COMPONENTS<br />

PART NO. DESCRIPTION QTY.<br />

1306823C1 BLADE (LH) 1<br />

1306824C1 BLADE (RH) 1<br />

231-5146 NUT 4<br />

434-616 BOLT 4<br />

Part No. B94549<br />

Part No. B94548<br />

KIT COMPONENTS<br />

PART NO. DESCRIPTION QTY.<br />

1306079C1 KNIFE 2<br />

231-5146 NUT 4<br />

434-616 BOLT 4<br />

495-81135 WASHER 4<br />

CORN HEAD EAR<br />

SAVER KIT<br />

• Reduce ear loss<br />

• High-strength rubber<br />

• Hardware included<br />

Part No. B94550A Steel Hoods<br />

Part No. B94838A Poly Hoods<br />

STALK ROLL SUPPORT KIT<br />

• Kits include stalk roll supports and mounting hardware<br />

Part No. 87298082 - LH<br />

Part No. 87298083 - RH<br />

Part No. 87298084 - Both sides (shown)<br />

21

2200/2400 SERIES CORN HEADS<br />

UPTIME PACKS<br />

• Handy <strong>Service</strong> Packs<br />

• Includes hardware<br />

Idler Sprocket Kit<br />

Part No. B95573<br />

Weed Knife Kit - Front<br />

Part No. B95580<br />

• Genuine Case<br />

Drive<br />

Sprocket Kit<br />

Part No. B95574A<br />

Individual Knife Blades<br />

• Each stalk roll contains two bolt-on knives with two cutting edges.<br />

• The blades can be replaced individually without removing the stalk roll<br />

from the frame... reducing replacement time.<br />

• The cutting edge of the knives are coated with a long wearing tungsten<br />

carbide and heat treated making them extremely sharp and durable.<br />

• The coating on one side of the knife produces a self-sharpening design<br />

that ensures consistent performance throughout the life of the knife.<br />

22<br />

CORN HEAD KITS<br />

Low Profile Point Kits<br />

Part No. 87017985 - 30"<br />

Rows<br />

Part No. 87017986 - 36",<br />

38" Rows<br />

Part No. 87017987 - 20",<br />

22" Outer Points<br />

Weed Knife - Two piece design<br />

• Front weed knife is made of ductile cast iron for<br />

improved strength and wear life.<br />

• Rear weed knife is made of heat treated formed steel.<br />

• Both the front and rear knife kits include knives and<br />

hardware to repair one row.<br />

Ear Saver Kit<br />

Part No. B95582<br />

CORN HEAD KNIFE 2200/2400 SERIES CORN HEADS<br />

Wear Plate Kit<br />

• Replaceable wear plate<br />

• Kit includes plate and hardware<br />

• For 2200/2400 corn heads<br />

• Part No. 87297604<br />

Weed Knife Kit - Rear<br />

Part No. B95581<br />

Self-sharpening design<br />

Tungsten carbide coating

CORN HEAD KITS<br />

STALK ROLL REPAIR KITS FOR 2200/2400 SERIES CORN HEADS<br />

• KITS INCLUDE<br />

COMPONENTS TO<br />

REBUILD ONE ROW<br />

• ALL COMPONENTS ARE<br />

ORIGINAL EQUIPMENT<br />

QUALITY<br />

• CORN HEAD KNIVES HAVE<br />

SUPERIOR TUNGSTEN<br />

CARBIDE COATING FOR<br />

LONGER WEAR<br />

• CORN HEAD KNIFE<br />

HARDWARE IS GRADE 8<br />

• ALL HARDWARE IS<br />

INCLUDED<br />

Part No. B95584A<br />

Part No. 86978515<br />

FEEDER UPGRADE KIT<br />

• Improves feeding<br />

• Reduces congestion at the<br />

feeder opening<br />

• For 2200 corn heads prior to model<br />

year 2003<br />

• Part Number 87281396<br />

Standard Kit - 1 row<br />

Kit includes:<br />

• Corn head knives (4)<br />

• Special hardware<br />

• Part No. B95583A<br />

Deluxe Kit - 1 Row<br />

Kit includes:<br />

• Gatherer Chains (2)<br />

• Idler Sprocket (2)<br />

• Drive Sprocket (2)<br />

• Knife (4)<br />

• Special Hardware<br />

• Part No. B95585A - Kit with chrome<br />

pins in chains<br />

• Part No. B96153A - Kit with STD<br />

pins in chains<br />

Stalk Roll Assembly - 1 Row<br />

• Stalk Roll tube, knife style (2)<br />

• Knife (4)<br />

• Point RH (1)<br />

• Point LH (1)<br />

• Gatherer Chain (2) with chrome pins<br />

• Idler Sprocket (2)<br />

• Drive Sprocket (2)<br />

• Special Hardware<br />

Extenda-Wear chains<br />

• Chrome pins for longer service life<br />

• Wears up to 2.5 times longer than<br />

regular-duty chains<br />

• Factory equipment on all 2200/2400<br />

corn heads<br />

• Part No. 86978515<br />

Standard Duty Chains<br />

• Available for 2200/2400 Corn Heads<br />

• Part Number 86979313<br />

Part No. B95583A<br />

Part No. B95585A<br />

Corn Head Repair Kit<br />

• Gatherer chains<br />

• Sprockets and hardware<br />

• Packaged<br />

• Part number B96154A - Kit has chain<br />

with standard pins<br />

• Part number B96155A - Kit has chain<br />

23

EAR SAVER KIT / TALL CORN<br />

LOW PROFILE DIVIDER<br />

POINT KITS<br />

PART NO.<br />

PRODUCT SELECTION<br />

DESCRIPTION<br />

87017978 KIT, 6R30", 70CM CAST POINT<br />

87017979 KIT, 6R36", 38" CAST POINT<br />

87017980 KIT, 8R22", CAST POINT<br />

87017981 KIT, 8R30", 70CM CAST POINT<br />

87017982 KIT, 8R36", 38" CAST POINT<br />

87017983 KIT, 12R20", 22" CAST POINT<br />

87017984 KIT, 12R30", CAST POINT<br />

87017985 KIT, 30", 70CM CAST POINT<br />

87017986 KIT, 36", 38" CAST POINT<br />

87017987 KIT, 20", 22" END CAST POINT<br />

Part Numbers 87017985, 87017986, 87017987 include one point and<br />

unique mounting hardware. The other kits listed would include points and<br />

hardware to complete the corn head listed in the description.<br />

24<br />

CORN HEAD KITS<br />

KITS FOR 2200 SERIES CORN HEADS<br />

Corn Head Row Unit<br />

Part No. B96673A<br />

• Includes slip clutch<br />

• Painted<br />

• Less stalk roll assembly. Order either the fluted roll style kit or<br />

knife roll style kit to complete the corn head unit.<br />

• Use existing shields and dividers or poly kits for 2200 corn<br />

heads. Refer to page 27 for part number selection.<br />

• Includes only right hand stripper plate. Order components to<br />

equip with manual or hydraulic stripper plates.<br />

Part No. 87298886<br />

• Has the components<br />

included on Part No.<br />

B96673A plus stalk<br />

roll assemblies,<br />

gatherer chains,<br />

sprockets, weed knives, steel wear<br />

point, and hydraulic stripper plate (LH)<br />

Part No. B96673A<br />

• Kit includes components to extend the height of the outer heads/dividers to<br />

minimize ear loss in tall corn.<br />

• Can be raised to harvest standing corn or lowered to harvest down corn.<br />

• Design permits fold-ability of end dividers.<br />

• Design minimizes hair pinning.<br />

• Heavy-duty components for durability and longer service life.<br />

• Smooth front to rear transition.<br />

• Simple installation complete instruction manual included with each kit.<br />

For 2200/2400 Series Corn Heads<br />

AUGER DRIVE KIT –<br />

REDUCED SPEED<br />

• Application 2200, 2400 corn heads<br />

• Part No. 87501635 – single auger, 8 row<br />

• Part No. 87501785 – double auger drive, 12 row<br />

• Auger speed has been reduced 25 – 30% to reduce the<br />

amount of energy being applied to ear conveying. This<br />

results in fewer ears being tossed forward over the auger<br />

thus reducing ear loss, shatter loss, and reprocessing loss.<br />

The slower auger speed also gives the feeder a better<br />

chance of taking the ears away from the auger.<br />

• The auger speed idler support spindle is easily adjusted to<br />

obtain the desired amount of chain tension. The tension of<br />

both chains is adjusted at the same time to reduce<br />

adjustment effort.<br />

• The auger speed reduction drive increases the amount of<br />

torque that can be delivered to the auger before the clutch<br />

slips. This increases the auger capacity to convey tough<br />

heavy bunches of material.<br />

COMPLETING PACKAGES FOR UNIQUE SIZE HEADS<br />

PART NO. DESCRIPTION<br />

86615096 ADJUSTABLE STRIPPER PLATE<br />

ROW KIT - ONE PER ROW<br />

86615095 ADJUSTABLE STRIPPER PLATE<br />

CORN HEAD KIT, 30" SPACING - ONE PER CORN HEAD<br />

86615101 ADJUSTABLE STRIPPER PLATE<br />

CORN HEAD KIT, 20"-22" SPACING - ONE PER HEAD<br />

86620267 ADJUSTABLE STRIPPER PLATE<br />

CORN HEAD KIT, 36"-38" SPACING - ONE PER HEAD

POLY HOODS & DIVIDER KITS<br />

ROW UNIT KITS AND COMPLETE 4, 6, AND 8 ROW KITS<br />

for 900 and 1000 Series Corn Heads<br />

Complete Corn Head Kits<br />

(Shown with Optional Ear Saver Kit)<br />

4 Row – Part No. 337451A1<br />

6 Row – Part No. 337455A1<br />

8 Row – Part No. 337457A1<br />

Front View<br />

Complete Kit – Outer (RH)<br />

Hood and Divider with<br />

Hardware<br />

Part No. 337473A1 (Shown with<br />

Optional Ear Saver Kit)<br />

Complete Kit – Outer (LH) Hood<br />

and Divider with Hardware<br />

Part No. 337470A1 (Shown with<br />

Optional Ear Saver Kit)<br />

Complete Kit – Inner Hood and Divider with Hardware (Shown with Optional Ear Saver Kit) Part No. 337463A1<br />

Rear View<br />

25

26<br />

ACCESSORIES for 900 and 1000 Series Corn Heads<br />

EAR SAVER KIT<br />

• Reduces ear loss<br />

• High-strength rubber<br />

• Hardware included<br />

Part No. B94838A<br />

HEAVY-DUTY STEEL<br />

FRAME<br />

• Provides strength and durability<br />

• Replaceable components<br />

Inner Hood<br />

(Shown with Optional Ear Saver Kit)<br />

Part No. 318231A1E<br />

• New color-matched high-strength<br />

polyethylene shell over steel frame<br />

• High-strength polyethylene shell resistant<br />

to cracks, dents, and rust (reduced<br />

maintenance and painting requirements)<br />

• No spot welds to fail<br />

• Smoother surface than steel for<br />

improved crop flow<br />

• Steel frame for strength and durability<br />

POLY HOODS & DIVIDER KITS<br />

Stainless Steel Wear Strip Kit<br />

• For center hood<br />

• Reduces wear from back-flow from<br />

delivery auger<br />

• EXTENDS LIFE OF THE<br />

CENTER HOOD<br />

Part No. 346349A1<br />

Outer Hood<br />

(Shown with Optional Ear Saver Kit)<br />

Part No. 318229A1E (LH)<br />

Part No. 318230A1E (RH)<br />

• Each hood and divider is totally<br />

interchangeable with the current<br />

steel assemblies<br />

• Replaceable heavy-duty cast wear point<br />

• Crowned hood to reduce crop bunching<br />

• Hoods and dividers are identical to 1000<br />

series production assemblies<br />

• Field tested<br />

• Kit complete with mounting hardware<br />

Heavy-Duty Wear Point<br />

• Protects divider<br />

• High-strength cast steel<br />

• Hardware included<br />

Part No. B94737 (Inner)<br />

Part No. B94738 (Outer)<br />

Divider<br />

Part No. 320083A1E (Inner)<br />

Part No. 320084A1E (Outer LH)<br />

Part No. 320085A1E (Outer RH)<br />

• For both 900 and 1000 series corn<br />

heads<br />

• Complete kits available for 30" rows<br />

and outer kits both LH and RH for all<br />

row widths<br />

• Replaceable heavy-duty cast wear point<br />

• Durable ear saver kits available<br />

• Kits available to update and improve the<br />

appearance and value of your older<br />

model 900 & 1000 series corn heads

POLY HOODS, DIVIDER KITS<br />

AND COMPLETING KITS<br />

for 2200/2400 Series Corn Heads<br />

• Color-matched high-strength polyethylene shell over heavy-duty steel frame<br />

• High-strength polyethylene shell is resistant to cracks, dents, and rust for reduced maintenance<br />

• Completely assembled and ready to install<br />

• Includes ear saver<br />

• Replaceable heavy-duty cast point to reduce damage to dividers<br />

PART NUMBERS<br />

DIVIDER ASSEMBLIES<br />

• 86620219 - Inner 20" - 22"<br />

• 86620220 - Inner 30"<br />

• 86620221 - Inner 36" - 38"<br />

• 86620222 - Inner 70 cm<br />

• 86620218 - Outer - All row spacings<br />

2200 CORN HEAD<br />

COMPLETING KITS<br />

For Standard Row Configurations<br />

PART NO. DESCRIPTION<br />

86616314 Feeder Step Bracket Package<br />

86622117 Automatic Header Height Control - 2300<br />

86622118 Fielder Tracker Sensor - 2300<br />

86622122 Automatic Header Height Control - 1600<br />

86622123 Fielder Tracker Sensor - 1600<br />

86624040 Adjustable Stripper Plate 6R30<br />

86624041 Adjustable Stripper Plate 6R36-38<br />

86624042 Adjustable Stripper Plate 6R70<br />

86624043 Adjustable Stripper Plate 8R22<br />

86624044 Adjustable Stripper Plate 8R30<br />

86624045 Adjustable Stripper Plate 8R36-38<br />

86624046 Adjustable Stripper Plate 8R70<br />

86624047 Adjustable Stripper Plate 12R20<br />

86624048 Adjustable Stripper Plate 12R22<br />

86624049 Adjustable Stripper Plate 12R30<br />

HOOD ASSEMBLIES<br />

• 86620223 - Inner 20" - 22"<br />

• 86620224 - Inner 30"<br />

• 86620225 - Inner 36" - 38"<br />

• 86620226 - Inner 70 cm<br />

• 86620217 - Outer LH -<br />

All row spacings, 2200 Series<br />

• 86620216 - Outer RH -<br />

All row spacings, 2200 Series<br />

• 86978714 - Outer LH -<br />

All row spacings, 2400 series<br />

• 86978715 - Outer RH -<br />

All row spacings, 2400 series<br />

Part No. 87528035E<br />

Ear Saver Kit<br />

Part No. B95582<br />

Inner Divider<br />

Outer Hood<br />

Inner Hood<br />

STAINLESS STEEL REPAIR KIT<br />

• Kit includes stainless steel repair patches, hardware, and I-sheets<br />

• Kit is designed to extend the service life of corn head poly hoods<br />

Application: 2200/2400 Series Corn Heads<br />

Part No. 87528030E - Outer Row Kit<br />

Part No. 87528033E - Inner Row Kit - requires two per inner hood<br />

Part No. 87528034E - 6-Row Kit<br />

Part No. 87528035E - 8-Row Kit (shown)<br />

Part No. 87528036E - 12-Row Kit<br />

27

28<br />

FIELD TRACKER ® KITS<br />

AUTO CENTER KIT<br />

COMBINE KITS<br />

• Provides operator convenience<br />

• Permits automatic leveling of the header as it is raised in the<br />

“manual mode”<br />

• Allows the operator using<br />

headers not equipped with field<br />

tracker (corn heads, rigid<br />

headers) to level the header<br />

automatically when the header<br />

is raised<br />

Part No. 435906A1<br />

FIELD TRACKER ®<br />

PLASTIC SLIDE KIT<br />

• Kit contains plastic slides and<br />

mounting hardware<br />

• New slide material has greater wear<br />

resistance and is retained by larger rivets<br />

(3/16" old vs. 1/4" new style.)<br />

• Kit offers improved durability<br />

Part No. 416757A1<br />

SLIDE SUPPORT ANGLE KIT<br />

• Kit contains (4) support angles and instructions<br />

• Use to repair Field Trackers frame in instances where the slide<br />

support have failed and damaged the angle<br />

• Kit offers improved durability<br />

Part No. 416756A1<br />

THIRD CYLINDER LIFT KIT<br />

• Increased lift capacity<br />

Part No. 137856A2 - 60" Feeder<br />

Part No. 137857A2 - Feeder with Rock Trap<br />

Field Tracker ® is a registered trademark of HCC<br />

DIVIDER HILLSIDE<br />

GRAIN PAN KIT<br />

• Distribute grain evenly<br />

• Reduces grain loss in hillside applications<br />

Part No. 313399A1<br />

3-STRAND CHAIN KITS<br />

3-Strand Chain Kit<br />

BOLTED FEEDER CHAIN<br />

For 1680, 1682, 1688, and 2188 Series<br />

APPLICATION PART NO.<br />

54" SMOOTH WITH STONE RETARDER DRUM B93528<br />

54" SMOOTH WITHOUT DRUM B93532<br />

54" SERRATED WITH STONE RETARDER DRUM B93529<br />

54" SERRATED WITHOUT DRUM B93533<br />

60" SMOOTH WITH STONE RETARDER DRUM B93530<br />

60" SMOOTH WITHOUT DRUM B93534<br />

60" SERRATED WITH STONE RETARDER DRUM B93531<br />

60" SERRATED WITHOUT DRUM B93535<br />

If the drum is worn, replacement drum available as a<br />

regular parts item.

COMBINE KITS<br />

FIELD TRACKER KITS<br />

282718A3 – FIELD TRACKER BASE KIT<br />

(COMBINE PARTS ONLY)<br />

When used on 2100 Series combines Completing Kit 282727A1<br />

is required.<br />

Application: 2144, 2166, 2344, 2366<br />

282723A2 – FIELD TRACKER BASE KIT<br />

(COMBINE PARTS ONLY) (SHOWN)<br />

Application: 2188, 2388<br />

1994874C3 – FIELD TRACKER BASE KIT<br />

Requires certain completing packages (1640, 1644, 1660, 1666<br />

combines require one of P/N 1994875C1 Feeder Completing Kit.<br />

106256A1 – FIELD TRACKER<br />

COMPLETING KIT<br />

Hydraulic Completing Package required for: 1640 S/N<br />

JJC0097190 and above, all 1644 combines, 1660 S/N<br />

JJC013800 and above, all 1666 combines, 1680 combines S/N<br />

JJC0117060 and above, and all 1688.<br />

1994875C1 – FIELD TRACKER<br />

COMPLETING KIT<br />

Feeder Kit required for 1640, 1644, 1660, 1666.<br />

282727A1– FIELD TRACKER<br />

COMPLETING KIT<br />

Required for 2100 Series combines<br />

Application: 2100 Series<br />

Part No. 282727A1<br />

Part No. 282723A2<br />

Part No. 106256A1<br />

Part No. 1994875C1<br />

29

30<br />

BOLTED FEEDER CHAINS<br />

Serrated Slat Feeder Chain<br />

Smooth Slat Feeder Chain<br />

Part No. B96023 Part No. B96022<br />

Stone Retarder Drum <strong>Service</strong><br />

Kit For Combine Feeder Drums<br />

Case IH offers two types of<br />

Stone Retarder Drum <strong>Service</strong><br />

Kits for <strong>AXIAL</strong>-<strong>FLOW</strong><br />

combines.<br />

Steel <strong>Service</strong> Strip<br />

<strong>Service</strong> package consists of 1/8"<br />

steel weld-in inserts (2 strands).<br />

Part No. 112047A2<br />

<strong>Service</strong> package consists of 1/8"<br />

steel weld-in inserts (3 strands).<br />

Part No. B94584<br />

Poly Drum Guards<br />

2-Strand (Part No. B92774) and 3-Strand (Part No. B93634)<br />

Poly Drum Guards consist of 1/4" thick poly-rubber strips that<br />

are attached to the drum with steel pop rivets. Kit comes<br />

complete with rivets and drill bit.<br />

Drum Stop Kit<br />

• Part No. B95679 (shown) - combines<br />

with Stone Retarder Drum<br />

• Part No. B95680 - combines with<br />

Standard Drum<br />

• Includes hardware and stops<br />

COMBINE KITS<br />

Heavy-duty #557 chain with chrome pins, now available<br />

with heavy-duty bolt-on slats. This long lasting feeder<br />

chain comes with slats that are replaceable.<br />

Case IH serrated slats are the same heavy-duty material as<br />

smooth slats.<br />

2-STRAND BOLTED FEEDER CHAIN<br />

NUMBER BOLTED<br />

APPLICATION OF SLATS PART NO.<br />

47" SERRATED – 1420, 1620 8 117868A1<br />

47" SMOOTH – 1620, 1640, 1644, 1660, 1666, 10 117869A1<br />

2144, 2166, 2344, 2366<br />

47" SERRATED – 1640, 1644, 1660, 1666, 10 117864A1<br />

2144, 2166, 2344, 2366<br />

54" SERRATED – 1640, 1644, 1660, 1666, 9 117865A1<br />

2144, 2166, 2344, 2366<br />

54" SMOOTH – 1640, 1644, 1660, 1666, 2166, 2366 12 117871A1<br />

54" SERRATED – 1480, 1680, 1688 9 117866A1<br />

54" SMOOTH – 1480 1680, 1688 12 117872A1<br />

60" SERRATED – 1480, 1680, 1688 10 117867A1<br />

60" SERRATED – 2144, 2166, 2344, 2366 10 136438A1<br />

60" SMOOTH – 2144, 2166, 2344, 2366 12 136439A1<br />

60" SMOOTH – 2188 12 136440A1<br />

3-STRAND BOLTED FEEDER CHAIN<br />

NUMBER BOLTED<br />

APPLICATION OF SLATS PART NO.<br />

54" SMOOTH – 1680, 1682, 1688, 2188, 2388 11 LH, 195664A1<br />

11 RH<br />

54" SERRATED – 1680, 1682, 1688, 2188, 2388 11 LH, 195666A2<br />

11 RH<br />