- Page 2: Clean-In-Place for Biopharmaceutica

- Page 13 and 14: Informa Healthcare USA, Inc. 52 Van

- Page 15 and 16: iv Preface period, the industry rec

- Page 18 and 19: Preface iii Contents Acknowledgment

- Page 20: Contributors Barry J. Andersen Seib

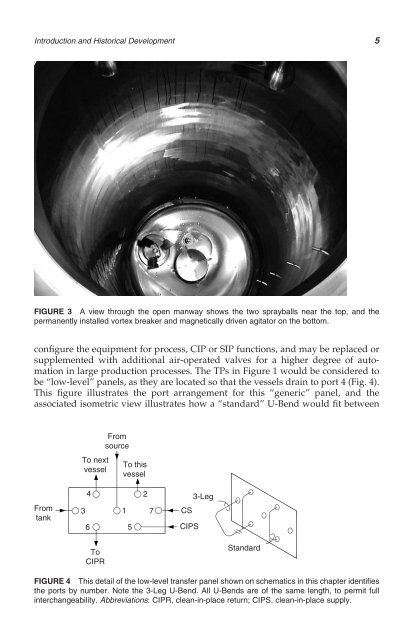

- Page 23 and 24: 2 the last step of abatch manufactu

- Page 25: 4 Seiberling The vessel capacity ma

- Page 29 and 30: 8 AWFI (or Any Water) Supply If the

- Page 31 and 32: 10 Seiberling program, and through

- Page 33 and 34: 12 Seiberling (380 L) for the solut

- Page 35 and 36: 14 AWFI CIP skid Drain When steam a

- Page 37 and 38: 16 Seiberling products in asingle f

- Page 39 and 40: 18 Seiberling The literature began

- Page 42 and 43: 2 Project Planning for the CIPable

- Page 44 and 45: Project Planning for CIPable Facili

- Page 46 and 47: Project Planning for CIPable Facili

- Page 48 and 49: Project Planning for CIPable Facili

- Page 50 and 51: Project Planning for CIPable Facili

- Page 52 and 53: Project Planning for CIPable Facili

- Page 54 and 55: Project Planning for CIPable Facili

- Page 56 and 57: Project Planning for CIPable Facili

- Page 58 and 59: Project Planning for CIPable Facili

- Page 60 and 61: Project Planning for CIPable Facili

- Page 62 and 63: 3 Water for the CIP System Jay C. A

- Page 64 and 65: Water for the CIP System 43 FIGURE

- Page 66 and 67: Water for the CIP System 45 of clea

- Page 68 and 69: Water for the CIP System 47 FIGURE

- Page 70 and 71: Water for the CIP System 49 FIGURE

- Page 72: Water for the CIP System 51 WATER U

- Page 75 and 76: 54 Time Temperature FIGURE 2 The cl

- Page 77 and 78:

56 Classification of Cleaners by pH

- Page 79 and 80:

58 [mg/sec] Cleaning velocity C v ,

- Page 81 and 82:

60 + - Na O O C CH 2 CH 2 (CH 2 ) n

- Page 83 and 84:

62 CH3 -(CH2 ) n -CH2 -O -CH2 -CH2

- Page 85 and 86:

64 B C D E FIGURE 17 Capability of

- Page 87 and 88:

66 pH 13 pH 7 pH, %, Excess water h

- Page 89 and 90:

68 dramatically increased rinsing t

- Page 91 and 92:

70 desorption. If the affinity is v

- Page 93 and 94:

72 & Cleaning procedure inthe case

- Page 95 and 96:

74 effort being performed relativel

- Page 97 and 98:

76 Rush & A1000 Lmixing vessel, hav

- Page 99 and 100:

78 TABLE 2 Typical Single-Pass Chem

- Page 101 and 102:

80 Rush Rinse Volume (Duration) The

- Page 103 and 104:

82 Rush Intermediate Drain Objectiv

- Page 105 and 106:

84 Rush Final Drain Phase (Gravity)

- Page 107 and 108:

86 TABLE 4 Recirculated Chemical Wa

- Page 109 and 110:

88 Rush type of soil include fermen

- Page 111 and 112:

90 The pre-cleaning process flush w

- Page 113 and 114:

92 REFERENCES Rush 1. Howard T, Wie

- Page 115 and 116:

94 CIP return (CIPR)-piping to conv

- Page 117 and 118:

96 Seiberling provided, generally o

- Page 119 and 120:

98 Single-Tank CIP Skid Operational

- Page 121 and 122:

100 Single-Tank Bypass or Recycle O

- Page 123 and 124:

102 Seiberling Single-Tank Single P

- Page 125 and 126:

104 Seiberling installation of an e

- Page 127 and 128:

106 Chemical loop AB FE Chemical bl

- Page 129 and 130:

108 Chemical loop AB FCV FE Steam C

- Page 131 and 132:

CIP supply Transfer line (typical)

- Page 133 and 134:

112 Seiberling FIGURE 14 This singl

- Page 135 and 136:

114 Seiberling FIGURE 15 This large

- Page 137 and 138:

116 Seiberling FIGURE 17 This mini-

- Page 140 and 141:

7 CIP System Instrumentation and Co

- Page 142 and 143:

CIP System Instrumentation and Cont

- Page 144 and 145:

CIP System Instrumentation and Cont

- Page 146 and 147:

CIP System Instrumentation and Cont

- Page 148 and 149:

CIP System Instrumentation and Cont

- Page 150 and 151:

CIP System Instrumentation and Cont

- Page 152 and 153:

CIP System Instrumentation and Cont

- Page 154 and 155:

CIP System Instrumentation and Cont

- Page 156 and 157:

CIP System Instrumentation and Cont

- Page 158 and 159:

CIP System Instrumentation and Cont

- Page 160 and 161:

CIP System Instrumentation and Cont

- Page 162 and 163:

CIP System Instrumentation and Cont

- Page 164:

CIP System Instrumentation and Cont

- Page 167 and 168:

146 Lebowitz should be considered f

- Page 169 and 170:

148 Lebowitz barrels and the chemic

- Page 171 and 172:

150 Lebowitz Electromagnetic-Operat

- Page 173 and 174:

152 Lebowitz FIGURE 5 The venturi o

- Page 175 and 176:

154 Chemical pump enclosure Acid AL

- Page 177 and 178:

156 Steam Facility acid header Faci

- Page 179 and 180:

158 Lebowitz That is to say aweak a

- Page 181 and 182:

160 CIP Philosophy The production p

- Page 183 and 184:

162 Franks and Seiberling the numbe

- Page 185 and 186:

164 Franks and Seiberling Similar s

- Page 187 and 188:

166 Franks and Seiberling FIGURE 3

- Page 189 and 190:

168 Franks and Seiberling FIGURE 5

- Page 191 and 192:

170 (A) (B) Franks and Seiberling F

- Page 193 and 194:

172 Franks and Seiberling FIGURE 9

- Page 195 and 196:

174 The variables that impact the r

- Page 197 and 198:

176 There are two guiding concepts

- Page 199 and 200:

178 Mezz. Floor(ref.) V-5 1000L CIP

- Page 201 and 202:

180 return line piping, substantial

- Page 203 and 204:

182 Lebowitz U-bend transfer panels

- Page 205 and 206:

184 Lebowitz oriented vertically. T

- Page 207 and 208:

186 Lebowitz suction-side port on T

- Page 209 and 210:

CIPS loop Primary CIPS CIPSPS CIPS

- Page 211 and 212:

190 Lebowitz FIGURE 10 Photo of sma

- Page 213 and 214:

192 Drain CIP return Drain Recycle

- Page 216 and 217:

11 Materials of Construction and Su

- Page 218 and 219:

Materials of Construction and Surfa

- Page 220 and 221:

Materials of Construction and Surfa

- Page 222 and 223:

Materials of Construction and Surfa

- Page 224 and 225:

Materials of Construction and Surfa

- Page 226 and 227:

Materials of Construction and Surfa

- Page 228 and 229:

Materials of Construction and Surfa

- Page 230 and 231:

Materials of Construction and Surfa

- Page 232 and 233:

12 Cleanable In-Line Components INT

- Page 234 and 235:

Cleanable In-Line Components 213 &

- Page 236 and 237:

Cleanable In-Line Components 215 Al

- Page 238 and 239:

Cleanable In-Line Components 217 Ex

- Page 240 and 241:

Cleanable In-Line Components 219 FI

- Page 242 and 243:

Cleanable In-Line Components 221 Tr

- Page 244 and 245:

Cleanable In-Line Components 223 it

- Page 246 and 247:

Cleanable In-Line Components 225 FI

- Page 248 and 249:

Cleanable In-Line Components 227 FI

- Page 250 and 251:

Cleanable In-Line Components 229 eq

- Page 252 and 253:

Cleanable In-Line Components 231 Th

- Page 254 and 255:

Cleanable In-Line Components 233 co

- Page 256 and 257:

13 Cleanable Liquids Processing Equ

- Page 258 and 259:

Cleanable Liquids Processing Equipm

- Page 260 and 261:

Cleanable Liquids Processing Equipm

- Page 262 and 263:

Cleanable Liquids Processing Equipm

- Page 264 and 265:

Cleanable Liquids Processing Equipm

- Page 266 and 267:

Cleanable Liquids Processing Equipm

- Page 268 and 269:

1-9 CIPS 2 Plant steam CIPS valves

- Page 270 and 271:

Cleanable Liquids Processing Equipm

- Page 272 and 273:

Cleanable Liquids Processing Equipm

- Page 274 and 275:

Cleanable Liquids Processing Equipm

- Page 276:

Cleanable Liquids Processing Equipm

- Page 279 and 280:

258 8. Projectile-type thermometer

- Page 281 and 282:

260 Forder control of the drying pr

- Page 283 and 284:

262 Forder FIGURE 5 Pharmaceutical

- Page 285 and 286:

264 Forder FIGURE 7 Pharmaceutical

- Page 287 and 288:

266 FIGURE 9 Pleated filter cartrid

- Page 289 and 290:

268 FIGURE 12 Disassembledstainless

- Page 291 and 292:

270 The acid wash of 85% phosphoric

- Page 293 and 294:

272 FIGURE 17 Sanitary Vbenders. So

- Page 295 and 296:

274 one each for the upper, central

- Page 297 and 298:

276 CIP VS. TRADITIONAL BOIL-UP MET

- Page 299 and 300:

278 Cerulli were not designed to be

- Page 301 and 302:

280 by large flanged connections fo

- Page 303 and 304:

282 CIP header Once thru CIP soluti

- Page 305 and 306:

284 Nozzle Use A Manway B Agitator

- Page 307 and 308:

286 3" Stub end w/150# flange 2A 1

- Page 309 and 310:

288 In most cases, the pressure dro

- Page 311 and 312:

290 CIP fluids Process fluids 1 2 3

- Page 313 and 314:

292 A Vent to atm. B M Conical drye

- Page 315 and 316:

294 One of the designer’s first t

- Page 318 and 319:

16 CIP System Troubleshooting Guide

- Page 320 and 321:

CIP System Troubleshooting Guide 29

- Page 322 and 323:

CIP System Troubleshooting Guide 30

- Page 324 and 325:

CIP System Troubleshooting Guide 30

- Page 326 and 327:

CIP System Troubleshooting Guide 30

- Page 328 and 329:

CIP System Troubleshooting Guide 30

- Page 330 and 331:

CIP System Troubleshooting Guide 30

- Page 332 and 333:

CIP System Troubleshooting Guide 31

- Page 334 and 335:

CIP System Troubleshooting Guide 31

- Page 336 and 337:

17 Waste Treatment for the CIP Syst

- Page 338 and 339:

Waste Treatment for the CIP System

- Page 340 and 341:

Waste Treatment for the CIP System

- Page 342 and 343:

Waste Treatment for the CIP System

- Page 344 and 345:

Waste Treatment for the CIP System

- Page 346 and 347:

Waste Treatment for the CIP System

- Page 348 and 349:

18 Commissioning and Qualification

- Page 350 and 351:

Commissioning and Qualification 329

- Page 352 and 353:

Commissioning and Qualification 331

- Page 354 and 355:

Commissioning and Qualification 333

- Page 356 and 357:

Commissioning and Qualification 335

- Page 358 and 359:

Commissioning and Qualification 337

- Page 360 and 361:

Commissioning and Qualification 339

- Page 362 and 363:

Commissioning and Qualification 341

- Page 364 and 365:

Commissioning and Qualification 343

- Page 366:

Commissioning and Qualification 345

- Page 369 and 370:

348 & Sterilization refers to the r

- Page 371 and 372:

350 Lankford All analytical methods

- Page 373 and 374:

352 should be based upon scientific

- Page 375 and 376:

354 Lankford acleaning validation p

- Page 377 and 378:

356 In summary, TOC analysis is are

- Page 379 and 380:

358 In-Situ In-situ measurement tec

- Page 381 and 382:

360 15. Karen A. Clark, Product Man

- Page 383 and 384:

362 Actually, most countries revise

- Page 385 and 386:

364 §211.100 Written procedures; d

- Page 387 and 388:

366 §211.186 Master production and

- Page 389 and 390:

368 Equipment Regulation C.02.005 T

- Page 391 and 392:

370 … C.02.004 … 4. Pipework sy

- Page 393 and 394:

372 5.20 Schedules and procedures (

- Page 395 and 396:

374 TABLE 1 Directives of the Europ

- Page 397 and 398:

376 TABLE 5 Cleanability Performanc

- Page 400 and 401:

Index Accessibility, 28 Acid cleane

- Page 402 and 403:

Index 381 CIP supply flow troublesh

- Page 404 and 405:

Index 383 [Cleaning cycle sequences

- Page 406 and 407:

Index 385 Flow alarm, no-return, 30

- Page 408 and 409:

Index 387 Off skid instrumentation,

- Page 410 and 411:

Index 389 Rising stem valves, 223-2

- Page 412:

Index 391 [Troubleshooting] spray c