Boltec s118-121.indd

Boltec s118-121.indd

Boltec s118-121.indd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

BOLTING RIG SPECIFICATION<br />

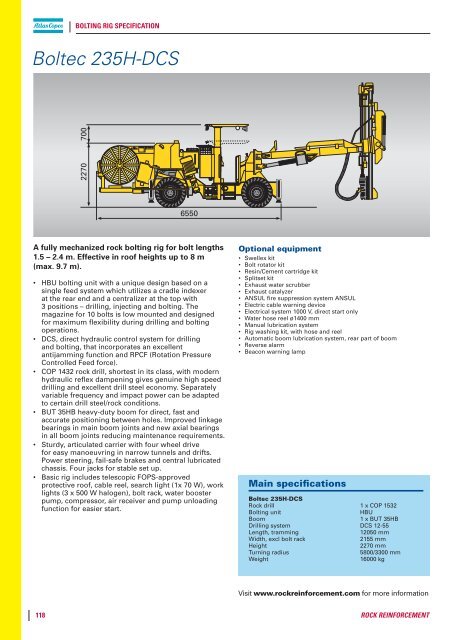

<strong>Boltec</strong> 235H-DCS<br />

2270 700<br />

6550<br />

A fully mechanized rock bolting rig for bolt lengths<br />

1.5 – 2.4 m. Effective in roof heights up to 8 m<br />

(max. 9.7 m).<br />

HBU bolting unit with a unique design based on a<br />

single feed system which utilizes a cradle indexer<br />

at the rear end and a centralizer at the top with<br />

3 positions – drilling, injecting and bolting. The<br />

magazine for 10 bolts is low mounted and designed<br />

for maximum fl exibility during drilling and bolting<br />

operations.<br />

DCS, direct hydraulic control system for drilling<br />

and bolting, that incorporates an excellent<br />

antijamming function and RPCF (Rotation Pressure<br />

Controlled Feed force).<br />

COP 1432 rock drill, shortest in its class, with modern<br />

hydraulic refl ex dampening gives genuine high speed<br />

drilling and excellent drill steel economy. Separately<br />

variable frequency and impact power can be adapted<br />

to certain drill steel/rock conditions.<br />

BUT 35HB heavy-duty boom for direct, fast and<br />

accurate positioning between holes. Improved linkage<br />

bearings in main boom joints and new axial bearings<br />

in all boom joints reducing maintenance requirements.<br />

Sturdy, articulated carrier with four wheel drive<br />

for easy manoeuvring in narrow tunnels and drifts.<br />

Power steering, fail-safe brakes and central lubricated<br />

chassis. Four jacks for stable set up.<br />

Basic rig includes telescopic FOPS-approved<br />

protective roof, cable reel, search light (1x 70 W), work<br />

lights (3 x 500 W halogen), bolt rack, water booster<br />

pump, compressor, air receiver and pump unloading<br />

function for easier start.<br />

118<br />

Optional equipment<br />

Swellex kit<br />

Bolt rotator kit<br />

Resin/Cement cartridge kit<br />

Splitset kit<br />

Exhaust water scrubber<br />

Exhaust catalyzer<br />

ANSUL fi re suppression system ANSUL<br />

Electric cable warning device<br />

Electrical system 1000 V, direct start only<br />

Water hose reel ø1400 mm<br />

Manual lubrication system<br />

Rig washing kit, with hose and reel<br />

Automatic boom lubrication system, rear part of boom<br />

Reverse alarm<br />

Beacon warning lamp<br />

Main specifi cations<br />

<strong>Boltec</strong> 235H-DCS<br />

Rock drill 1 x COP 1532<br />

Bolting unit HBU<br />

Boom 1 x BUT 35HB<br />

Drilling system DCS 12-55<br />

Length, tramming 12050 mm<br />

Width, excl bolt rack 2155 mm<br />

Height 2270 mm<br />

Turning radius 5800/3300 mm<br />

Weight 16000 kg<br />

Visit www.rockreinforcement.com for more information<br />

ROCK REINFORCEMENT

<strong>Boltec</strong> SL<br />

A seme-mechanized rock bolting rig with electrical<br />

Remote control system for safety and productivity.<br />

For bolt lengths 1.6 – 1.8 m. Effective in roof<br />

heights up to 1.8 m<br />

Rock bolting with Swellex bolts, resin grouted rebar<br />

bolts or mechanical bolts. Hole size diameter 29 up to<br />

51 mm. In 1.8 m roof height max. bolt length is<br />

1.6 - 1.8 m depending on bolt type.<br />

Resin bolting quality is controlled by pre-setting the<br />

bolt rotator’s speed, torque and acting time for<br />

accurate mixing and curing of the resin.<br />

Swellex bolting quality is controlled by pre-setting<br />

the infl ation time.<br />

Extension drilling up to 51 mm enables installation of<br />

Connectable Swellex rockbolts up to any lengths in low<br />

roof heights.<br />

Electrical pilot system with controls for positioning,<br />

drilling and bolting in a portable operator’s control<br />

panel.<br />

MBU 16SL bolting unit with a unique design based on<br />

a single feed system utilizing a cradle indexer at the<br />

rear end and a robust drill steel support at the top end.<br />

Designed for maximum fl exibility during drilling and<br />

bolting. Bolting unit is connected to the boom via a<br />

fl exible positioning unit.<br />

Extendable protective roof at the bolting unit for<br />

improved operator’s safety. Hydraulic jacks to support<br />

the panel roof at the bolting unit with a force of 80 kN.<br />

COP 1028HB is a light rock drill with separate reversible<br />

rotation and stepless variable rotation speed, and high<br />

torque capacity that contribute to good drilling results.<br />

BUT 32SL heavy-duty boom for direct, fast and<br />

accurate positioning between holes. Improved linkage<br />

bearings in main boom joints and new axial bearings<br />

in all boom joints reduce maintenance.<br />

Sturdy, articulated carrier with four wheel drive<br />

for fast tramming and easy manoeuvring in narrow<br />

tunnels and drifts. Power steering, failsafe brakes and<br />

central lubricated chassis. Four jacks for stable set up.<br />

ROCK REINFORCEMENT<br />

BOLTING RIG SPECIFICATION<br />

Basic rig includes telescopic FOPS-approved protective<br />

roof, cable reel, work lights, water booster pump and<br />

pump unloading function for easier start with low<br />

voltage. Standardization with Rocket Boomer S1L on<br />

high capacity 55 kW electric motor and powerpack.<br />

Minimum tramming height 1.3 m.<br />

Optional equipment<br />

Automatic boom lubrication system, rear part<br />

Bolt rotator for max 240 Nm/ 810 rpm or<br />

max 480 Nm/450 rpm<br />

Rock drill lubrication warning kit<br />

Swellex installation equipment<br />

Alternative roof stops; min 1500 mm, max 1700 mm<br />

Exhaust catalyser<br />

Fire suppression system Ansul<br />

Guards to prevent start of tramming with jacks down,<br />

slide beam out or roof up<br />

Safety belt<br />

Rear view mirrors<br />

Beacon warning lamp<br />

Back-up alarm<br />

Electric outlet for accessories<br />

Rig washing kit, with water hose and reel<br />

Manual lubrication system<br />

Main specifi cations<br />

<strong>Boltec</strong> SL<br />

Rock drill 1 x COP 1028<br />

Bolting unit MBU 16SL<br />

Boom 1 x BUT 32SL<br />

Drilling system EDS<br />

Length, tramming 10000 mm<br />

Width 2480 mm<br />

Height, carrier 1300 mm<br />

roof min/max 1300/1700 mm<br />

Turning radius 6180/3550 mm<br />

Weight 12800 kg<br />

Visit www.rockreinforcement.com for more information<br />

119

BOLTING RIG SPECIFICATION<br />

<strong>Boltec</strong> MC<br />

3010<br />

2265<br />

MC<br />

7385<br />

www.atlascopco.com<br />

A fully mechanized rock bolting rig with computerbased<br />

control system for high productivity and<br />

precision. For bolt lengths 1.5 – 3.5 m. Effective in<br />

roof heights up to 8 m.<br />

Rig Control System (RCS) with interactive operator<br />

control panel with full-colour display of the computer-<br />

based drilling system. Automatic functions in the<br />

drilling process such as auto-collaring and antijamming<br />

protection as well as improved regulation of<br />

the rock drill provide high performance and outstanding<br />

drill steel economy. Integrated diagnostic and<br />

fault location system. Distributed hydraulic system<br />

with fewer and shorter hoses for increased availability.<br />

PC-card for transfer of data and for service engineers<br />

to store optimal drill settings.<br />

MBU bolting unit with a unique design based on a<br />

single feed system utilizing a cradle indexer at the rear<br />

end and a robust drill steel support plus indexer for<br />

grouting at the top end. Low-mounted magazine for 10<br />

bolts, designed for maximum fl exibility during drilling<br />

and bolting.<br />

COP 1432 rock drill, shortest in its class, with modern<br />

hydraulic refl ex dampening gives genuine high speed<br />

drilling and excellent drill steel economy. Separately<br />

variable frequency and impact power can be adapted<br />

to certain drill steel/rock combinations.<br />

BUT 35HB heavy-duty boom for direct, fast and<br />

accurate positioning between holes. Improved linkage<br />

bearings in main boom joints and new axial bearings<br />

in all boom joints reduce maintenance.<br />

Sturdy, articulated carrier with turbocharged water-<br />

cooled, low emission diesel engine. High ground<br />

clearance, four-wheel traction and articulated steering<br />

for easy manoeuvring in narrow drifts and fast<br />

tramming in steep ramps.<br />

Optional ABC Basic, angle reading instrument.<br />

Smart oil leakage shut-down system minimises<br />

hydraulic oil pollution.<br />

Standard rig includes FOPS approved telescopic<br />

protective roof, fi xed seat, hydraulic driven compressor<br />

and water booster pump, cable reel, bolt<br />

rack, air receiver and working lights.<br />

120<br />

MC<br />

Other versions<br />

<strong>Boltec</strong> MD electric-hydraullic, direct controlled bolting rig.<br />

Optional equipment<br />

Air-water mist fl ushing, external air<br />

Water mist fl ushing with external water and air supply<br />

Rock drill lubrication warning kit<br />

Automatic boom lubrication system, rear part of boom<br />

Swellex installation kit<br />

Automatic cartridge handler<br />

Manual cartridge shooting system<br />

Split Set installation kit<br />

Bulk cement with hose grouting system<br />

ABC Basic - with angle indication<br />

Cabin with fi xed seat, FOPS approved 80 dB(A)<br />

Additional operator’s control panel<br />

Exhaust water scrubber 150 l<br />

Fire suppression system Ansul/Forrex<br />

Automatic fi re suppression system, including suppression<br />

inside electric cabinet<br />

1000 V electric system, direct start only<br />

Extra transformer, 10 kVA<br />

Service platform<br />

Rig washing kit, with water hose and reel<br />

Manual lubrication system<br />

Main specifi cations<br />

<strong>Boltec</strong> MC<br />

Rock drill 1 x COP 1532<br />

Bolting unit MBU<br />

Boom 1 x BUT 35HB<br />

Drilling system RCS<br />

Length, tramming 12500 mm<br />

Width, excl bolt rack 2210 mm<br />

Height, standard 3050 mm<br />

Turning radius 6250/3800 mm<br />

Weight 22600 kg<br />

Visit www.rockreinforcement.com for more information<br />

ROCK REINFORCEMENT

<strong>Boltec</strong> LC<br />

3100<br />

2355<br />

LC<br />

ROCK REINFORCEMENT<br />

7845<br />

www.atlascopco.com<br />

A fully mechanized rock bolting rig with computerbased<br />

control system for high productivity and<br />

precision. For bolt lengths 1.5 – 6 m. Effective in<br />

roof heights up to 11 m.<br />

Rig Control System (RCS) with interactive operator<br />

control panel with full-colour display of the computerbased<br />

drilling system. Automatic functions in the<br />

drilling process such as auto-collaring and antijamming<br />

protection as well as improved regulation<br />

of the rock drill provide high performance and<br />

outstanding drill steel economy. Integrated diagnostic<br />

and fault location system. Distributed hydraulic system<br />

with fewer and shorter hoses for increased availability.<br />

PC-card for transfer of data and for service engineers to<br />

store optimal drill settings.<br />

MBU bolting unit with a unique design based on a<br />

single feed system utilizing a cradle indexer at the rear<br />

end and a robust drill steel support plus indexer for<br />

grouting at the top end. Low-mounted magazine for 10<br />

bolts, designed for maximum fl exibility during drilling<br />

and bolting.<br />

COP 1432 rock drill, shortest in its class, with modern<br />

hydraulic refl ex dampening gives genuine high speed<br />

drilling and excellent drill steel economy. Separately<br />

variable frequency and impact power can be<br />

adapted to certain drill steel/rock combinations.<br />

BUT 35HBE heavy-duty boom for direct, fast and<br />

accurate positioning between holes. Improved linkage<br />

bearings in main boom joints and new axial bearings in<br />

all boom joints reduce maintenance.<br />

Sturdy, articulated carrier with turbocharged watercooled,<br />

low emission diesel engine. High ground<br />

clearance, four-wheel traction and articulated steering<br />

for easy manoeuvring in narrow drifts and fast<br />

tramming in steep ramps.<br />

Optional ABC Basic, angle reading instrument.<br />

Smart oil leakage shut-down system minimises<br />

hydraulic oil pollution.<br />

Standard rig includes FOPS approved telescopic<br />

protective roof, fi xed seat, hydraulic driven compressor<br />

and water booster pump, cable reel, bolt rack, air<br />

receiver and working lights.<br />

LC<br />

BOLTING RIG SPECIFICATION<br />

Other versions<br />

<strong>Boltec</strong> LD electric-hydraullic, direct controlled bolting rig.<br />

Optional equipment<br />

Air-water mist fl ushing, external air<br />

Water mist fl ushing with external water and air supply<br />

Rock drill lubrication warning kit<br />

Automatic boom lubrication system, rear part of boom<br />

Swellex installation kit<br />

Automatic cartridge handler<br />

Manual cartridge shooting system<br />

Split Set installation kit<br />

Bulk cement with hose grouting system<br />

ABC Basic - with angle indication<br />

Cabin with fi xed seat, FOPS approved 80 dB(A)<br />

Additional operator’s control panel<br />

Exhaust water scrubber 150 l<br />

Fire suppression system Ansul/Forrex<br />

Automatic fi re suppression system, including suppression<br />

inside electric cabinet<br />

1000 V electric system, direct start only<br />

Extra transformer, 10 kVA<br />

Service platform<br />

Rig washing kit, with water hose and reel<br />

Manual lubrication system<br />

Main specifi cations<br />

<strong>Boltec</strong> LC<br />

Rock drill 1 x COP 1532<br />

Bolting unit MBU<br />

Boom 1 x BUT 35HBE<br />

Drilling system RCS<br />

Length, tramming 13200 mm<br />

Width, excl bolt rack 2500 mm<br />

Height, standard 3100 mm<br />

Turning radius 7200/4400 mm<br />

Weight 22600 kg<br />

Visit www.rockreinforcement.com for more information<br />

121