(CDM-NMB) Version 02

(CDM-NMB) Version 02

(CDM-NMB) Version 02

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>) - <strong>Version</strong> <strong>02</strong><br />

<strong>CDM</strong> – Executive Board page 1<br />

CLEAN DEVELOPMENT MECHANISM<br />

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>)<br />

<strong>Version</strong> <strong>02</strong> - in effect as of: 15 July 2005<br />

CONTENTS<br />

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>)<br />

A. Methodology title and summary description<br />

B. Applicability/ project activity<br />

C. Project boundary<br />

D. Baseline scenario<br />

E. Additionality<br />

F. Baseline emissions<br />

G. Project activity emissions<br />

H. Leakage<br />

I. Emission reductions<br />

J. Changes required for methodology implementation in 2 nd and 3 rd crediting periods (if relevant)<br />

K. Selected baseline approach from paragraph 48 of the <strong>CDM</strong> modalities and procedures<br />

L. Other information

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>) - <strong>Version</strong> <strong>02</strong><br />

<strong>CDM</strong> – Executive Board page 2<br />

SECTION A. Methodology title and summary description<br />

Methodology title:<br />

>> Baseline Methodology for Carbon Dioxide Mitigation Projects at Dry Process Cement Plants<br />

Summary description:<br />

>> The new methodology bundles a number of CO2 emissions reduction mitigation options that<br />

can be undertaken at cement plants. The mitigation options include increased use of blended<br />

cement, substitution of fossil fuels with alternative fuels, waste heat recovery for power<br />

generation, and energy efficiency. Such bundled mitigation options are envisioned to be<br />

identified and implemented at cement plants in response to an emissions reduction program<br />

initiated by a company, industry association, government or other entity.<br />

The new methodology combines elements from four approved methodologies and adds a new<br />

component related to energy efficiency to create a new methodology that covers a group of<br />

mitigation options that can be taken in cement plants. The new methodology covers mitigation<br />

project activities that include one or more of these mitigation options bundled under a program of<br />

activities such as a voluntary agreement program, a greenhouse gas (GHG) mitigation program,<br />

or a target-setting program.<br />

If this methodology is a based on a previous submission, please state the previous reference<br />

number (NMXXXX/AMXXXX) here:<br />

>> This baseline methodology is based on elements from the following methodologies:<br />

o ACM0003 “Emissions reduction through partial substitution of fossil fuels with<br />

alternative fuels in cement production”<br />

o ACM0004 “Consolidated monitoring methodology for waste gas and/or heat for power<br />

generation”<br />

o ACM0005 “Monitoring Methodology for the Production of Blended Cement”<br />

o AM0<strong>02</strong>4 “Monitoring methodology for greenhouse gas reductions through waste heat<br />

recovery and utilization for power generation at cement plants”<br />

SECTION B. Applicability/ project activity<br />

Methodology procedure:<br />

>> Defined project activities can be undertaken in response to a program initiated by a third party<br />

(e.g. government, industry association). This methodology applies to defined project activities<br />

undertaken by a single dry process cement plant that involve one or more of the following<br />

categories of measures:<br />

1) Blended cement: Measures that increase the share of additives (i.e. reduce the share of<br />

clinker 1 ) in the production of cement types beyond current practices in the country.<br />

1 Clinker is produced through a controlled high-temperature burn in a kiln of a measured blend of calcareous rocks<br />

(usually limestone) and lesser quantities of siliceous, aluminous, and ferrous materials. Cement plants grind clinker<br />

and add a variety of additives to produce cement.

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>) - <strong>Version</strong> <strong>02</strong><br />

<strong>CDM</strong> – Executive Board page 3<br />

Additives are defined as materials blended with clinker to produce blended cement types<br />

and include fly ash, gypsum, slag, etc.<br />

2) Use of alternative fuels: Measures that partially substitute fossil fuels with alternative<br />

fuels such as solvents, tires, renewable biomass, and other wastes in cement<br />

manufacture. 2<br />

3) Energy efficiency: Measures that increase the energy efficiency of a plant, such as energy<br />

efficiency in kilns, grinding, finish grinding, and motor and drive systems.<br />

4) Electricity production: Measures that use waste heat gas generated in the clinker making<br />

process to produce electricity.<br />

The methodology is applicable assuming certain conditions. Most essentially, adequate data must<br />

be available on cement types in the market. For the blended cement measures, the output of the<br />

project activity plant should be domestically sold and excludes export of blended cement. For the<br />

use of alternative fuels measures, renewable biomass 3 can be used provided renewable biomass<br />

residues are in surplus and leakages in other uses of the renewable biomass will not occur. For<br />

both the blended cement and use of alternative fuels measures the amount of additives/alternative<br />

fuels available for the project is at least 1.5 times the amount required to meet the consumption<br />

of all users consuming the same additives/alternative fuels, i.e. the project and other additives<br />

/alternative fuel users.<br />

In situations where both energy efficiency and electricity production measures are implemented<br />

within the <strong>CDM</strong> project and electricity production projects are used for captive power production,<br />

the baseline for electricity generation for the energy efficiency measures should be the emissions<br />

after the implementation of the electricity production project. The electricity produced must be<br />

used within the cement works where the proposed project activity is located and excess<br />

electricity is supplied to the grid; it is assumed that there is no electricity export to the grid in the<br />

baseline scenario (in case of existing captive power plant). For electricity production measures,<br />

the recycling of waste heat in the baseline scenario should be only within the boundary of the<br />

clinker making process.<br />

Explanation/justification:<br />

>> Previously accepted methodologies focused on a single aspect of the actions included in this<br />

methodology. This methodology allows for the simultaneous introduction of multiple measures<br />

or actions in a single project, while accounting for the interaction of the various measures on the<br />

total reduction of GHG emissions. This will avoid double counting of emission reductions. For<br />

this reason the system boundaries will encompass the total production facilities (see Section C)<br />

of a cement plant.<br />

2 CERs are calculated on the basis of the difference between the carbon emissions factor of the alternative fuels and<br />

the fossil fuel that is replaced, and the amount of fossil fuel replaced and alternative fuel used.<br />

3 Renewable biomass residues are such that they do not contribute to global warming. The Executive Board may<br />

further define renewable biomass based on recommendations from the Methodology Panel and the afforestation and<br />

reforestation working group (AR WG).

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>) - <strong>Version</strong> <strong>02</strong><br />

<strong>CDM</strong> – Executive Board page 4<br />

SECTION C. Project Boundary<br />

Methodology procedure:<br />

>> The project boundary includes the cement production facilities, on-site power generation<br />

facilities, and generation sources connected to the grid that serve the cement production facilities<br />

for the participating cement plant. GHG emission sources include direct emissions at the cement<br />

plant due to fuel combustion, direct emissions due to calcination of limestone, and indirect<br />

emissions from fossil fuel combustion in grid-connected power plants due to electricity use at the<br />

cement plant. The participating cement plant must use a dry process rotary kiln for clinker<br />

production and use suspension preheaters.<br />

Project participants shall account only the following emission sources for the project activity:<br />

• Direct emissions at the cement plant due to:<br />

o Fuel combustion for firing the kiln (including supplemental fuels used in the precalciner);<br />

o Fuel combustion for processing (including drying) of solid fuels, raw materials, and<br />

additives;<br />

o Fuel combustion for on-site generation of electricity (if applicable).<br />

o Direct emissions due to calcination of limestone (i.e. calcium carbonate and magnesium<br />

carbonate, if present in the raw meal).<br />

• Indirect emissions from fossil fuel combustion in power plants in the grid due to electricity<br />

use at the cement plant, including electricity consumption for:<br />

o Crushing and grinding the raw materials used for clinker production;<br />

o Driving the kiln and kiln fans;<br />

o Finish grinding of cement;<br />

o Processing of additives.<br />

The power grid or plant from which the cement plant purchases electricity and its losses will be<br />

considered in determining indirect emissions. Any transport related emissions for the delivery of<br />

additional additives and alternative fuels will be included in the emissions related to the project<br />

activity as leakage.<br />

Emissions reductions from transport of raw materials for clinker production are not taken into<br />

account as a conservative simplification.<br />

Emissions sources included in or excluded from the project boundary<br />

Baseline<br />

Source Gas Included? Justification / Explanation<br />

CO2 Yes<br />

Fuels CH4 No considered to be negligible<br />

N2O No considered to be negligible<br />

CO2 Yes<br />

Electricity CH4 No considered to be negligible<br />

N2O No considered to be negligible<br />

CO2 Yes<br />

CH4 No considered to be negligible<br />

N2O No considered to be negligible

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>) - <strong>Version</strong> <strong>02</strong><br />

<strong>CDM</strong> – Executive Board page 5<br />

Project Activity<br />

Fuels<br />

Electricity<br />

CO2 Yes<br />

CH4 No considered to be negligible<br />

N2O No considered to be negligible<br />

CO2 Yes<br />

CH4 No considered to be negligible<br />

N2O No considered to be negligible<br />

Explanation/justification:<br />

>> Only CO2 emissions are included. Changes in CH4 and N2O emissions from combustion<br />

processes are considered to be negligible and excluded because the differences in the baseline<br />

and project activity are not substantial. This assumption simplifies the methodology and is<br />

conservative.<br />

D. Baseline Scenario<br />

Methodology procedure:<br />

>> The baseline scenario and baseline emissions are developed using a Common Baseline<br />

Emissions Factor Approach that includes a projection of a historical weighted average emissions<br />

rate (emissions per ton of cement) of a representative sample of existing cement plants in the<br />

region.<br />

An initial estimation of baseline emissions is made by multiplying the historical weighted<br />

average emissions rate by the projected cement production output of the cement plant for the<br />

project validity period. Actual baseline emission will be based on monitored data.<br />

Baseline emissions involve all CO2 emissions within the project boundary. These include:<br />

• Emissions from combustion of fossil fuel for clinker production<br />

• Emission from electricity consumption for operating of ventilators and motors for clinker<br />

production, processing of raw material, additives preparation, and grinding of cement.<br />

• Emissions from calcination of limestone<br />

The determination of the emission factor for the grid is calculated as in ACM00<strong>02</strong>. If the amount<br />

of grid electricity consumption in the baseline and project situation are similar, the grid emission<br />

factor does not need to be taken into account.<br />

Explanation/justification:<br />

>> The baseline scenario needs to reflect business-as-usual adoption trends for all four measures<br />

included in this methodology (use of alternative fuels, energy efficiency, blended cement, use of<br />

waste heat for power generation).<br />

The region for the baseline calculation needs to be clearly determined and justified by project<br />

participants. The default is the national market, but project participants can define a geographic<br />

region as the area where each of the following conditions are met: at least 75% of project activity<br />

plant’s cement production is sold (percentage of domestic sales only); includes at least five other

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>) - <strong>Version</strong> <strong>02</strong><br />

<strong>CDM</strong> – Executive Board page 6<br />

plants with the required published data; and the production in the region is at least four times the<br />

project activity plant’s output. Only domestically sold output is considered and any export of<br />

cement produced by the project activity plant are excluded in the estimation of emission<br />

reductions (ACM0005).<br />

Also for the Common Baseline Emissions Factor Approach, the time period to be used for<br />

selecting input data for setting baselines must be justified based on historical trends. In cases<br />

where (1) the rate of change in common baseline emission rate is steady, any reasonable<br />

historical period would be appropriate, (2) the rate has been steadily increasing or declining, a<br />

recent time period is to be preferred, (3) the rate has been changing randomly, the historical<br />

period needs to be long enough to minimize the uncertainty range, and (4) for an inflexion point<br />

exists due to some historical event, the historical period should not include the period prior to the<br />

occurrence of such an event. 4<br />

SECTION E. Additionality<br />

Methodology procedure:<br />

>> The additionality of the project activity shall be demonstrated and assessed using the latest<br />

version of the “Tool for the demonstration and assessment of additionality” agreed by the <strong>CDM</strong><br />

Executive Board, which is available on the UNFCCC <strong>CDM</strong> web site 5 .<br />

For bundled mitigation projects using the Common Baseline Emissions Factor Approach, project<br />

proponents must demonstrate that there exist real and demonstrable barriers to the<br />

implementation of each of the measures. Such barriers may include, among others, technological<br />

barriers (e.g. a substantial research effort is required to implement the measure; lack of<br />

infrastructure for implementation of the technology), institutional barriers to project activity<br />

implementation (e.g. lack of access to financing), investment barriers (e.g. the IRR or NPV of the<br />

cement plant is lower in the project situation than in the existing situation), or market<br />

acceptability barriers (e.g. perception that high additive blended cement is of inferior quality,<br />

lack of awareness of customers on the use high additive blended cement).<br />

Project participants shall demonstrate that the identified barriers prevent potential project<br />

proponents from carrying out the proposed project activity if it is not registered as a <strong>CDM</strong><br />

activity. The project participants shall provide transparent and documented evidence as<br />

illustrated in the “Tool for the demonstration and assessment of additionality”.<br />

In addition, project proponents shall use the common practice test to compare the results of the<br />

proposed bundled mitigation project to the trend among a representative sample of similar<br />

cement plants in the region chosen for the baseline. The level of penetration of the proposed<br />

mitigation options in similar applications can be used to determine the additionality of the<br />

proposed project. Those savings from the proposed project that are beyond common practice are<br />

4 Murtishaw S., Sathaye, J. and M. Lefranc (2005). “Spatial boundaries and temporal periods for setting greenhouse<br />

gas performance standards.” Energy Policy (In press) LBNL-54844.<br />

5 Please refer to http://cdm.unfccc.int/methodologies/PAmethodologies/approved.html

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>) - <strong>Version</strong> <strong>02</strong><br />

<strong>CDM</strong> – Executive Board page 7<br />

designated as additional. The common practice test provides a means for accounting for<br />

autonomous efficiency improvement, rebound effects, and planned replacements of equipment<br />

which would occur without the <strong>CDM</strong> project.<br />

Explanation/justification:<br />

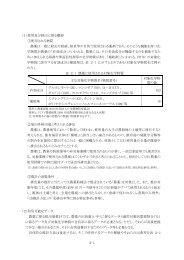

>> The figure below illustrates this concept. The solid line indicates that for the representative<br />

sample of similar cement plants in the chosen region, the 5-year historical average annual growth<br />

rate in the emissions per tonne of cement between 2000 and 2005 was -2%. Among these plants,<br />

this improvement encompasses the emissions reductions associated with “common practice”,<br />

which could include some combination of adoption of energy efficiency measures, increased use<br />

of blended cement, use of waste heat for electricity generation, and use of alternative fuels in the<br />

kiln. This common practice rate is then projected into the future to the end of the project validity<br />

period (2010 in this example). The dashed line in the figure indicates the expected improvement<br />

from the proposed project, showing an annual average growth rate of -5%. Since the -2% growth<br />

rate is determined to be “common practice”, the use of partial or scaled additionality 6 would<br />

require a reduction of the claimed CERs by this amount. Thus, the additional project emissions<br />

rate is projected to be -3% per year.<br />

Carbon Intensity (kgC/t cement)<br />

290<br />

270<br />

250<br />

230<br />

210<br />

190<br />

170<br />

Historical Improvement<br />

(AAGR -2.0% )<br />

Bundled Project Improvement<br />

(AAGR -5.0%)<br />

Baseline Improvement<br />

(AAGR -2.0% )<br />

2000 2005 2010<br />

Historical and Projected Baseline Emissions Rate and Projected Project Emissions Rate for the<br />

Common Baseline Emissions Factor Approach<br />

SECTION F. Baseline emissions<br />

6<br />

Kartha, S., Lazarus, M., and Lefranc, M. 2005. “Market penetration metrics: tools for additionality assessment?”<br />

Climate Policy. pp. 145-163.

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>) - <strong>Version</strong> <strong>02</strong><br />

<strong>CDM</strong> – Executive Board page 8<br />

Methodology procedure:<br />

>> An initial estimation of baseline emissions is made by multiplying the historical weighted<br />

average emissions rate by the projected cement production output of the cement plant for the<br />

project validity period. Actual baseline emission will be based on monitored data.<br />

Baseline emissions involve all CO2 emissions within the project boundary. These include:<br />

• Emissions from combustion of fossil fuel for clinker production<br />

• Emission from electricity consumption for operating of fans, pumps, ventilators and<br />

motors for clinker production, processing of raw material, additives preparation, and<br />

grinding of cement.<br />

• Emissions from calcination of limestone<br />

The determination of the emission factor for the grid is calculated as in ACM00<strong>02</strong>. If the amount<br />

of grid electricity consumption in the baseline and project situation are similar, the grid emission<br />

factor does not need to be taken into account.<br />

The “Region” for the benchmark calculation needs to be clearly determined and justified by<br />

project participants. The default is the national market but project proponents can define a<br />

geographic region as the area where each of the following conditions are met:<br />

(i) at least 75% of project activity plant’s cement production is sold (percentage of<br />

domestic sales only)<br />

(ii) includes at least 5 other plants with the required published data<br />

(iii) the production in the region is at least four times the project activity plant’s output.<br />

Only domestically sold output is considered and any export of cement produced by the project<br />

activity plant are excluded in the estimation of emission reductions.<br />

Consumption of fuel and electricity are monitored for at least one year prior to the start of the<br />

<strong>CDM</strong> project activity. If monitored data to determine specific energy consumption by type of<br />

fuels are available for two or three years prior to the start of the project activity, the average may<br />

be taken in determining baseline emissions.<br />

Baseline emissions per tonne cement are determined below. Consumption of fuel and electricity<br />

are monitored for at least one year prior to the start of the <strong>CDM</strong> project activity. If monitored<br />

data to determine specific energy consumption by type of fuels are available for two or three<br />

years prior to the start of the project activity, the average may be taken in determining baseline<br />

emissions.<br />

The values to be used in the formulae below relating to clinker production, fossil fuel<br />

consumption and electricity consumption shall be obtained by monitoring the operation of the<br />

plant before the project activity is implemented.<br />

Baseline emissions involve:<br />

• Emissions from combustion of fossil fuel for:<br />

o clinker production

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>) - <strong>Version</strong> <strong>02</strong><br />

<strong>CDM</strong> – Executive Board page 9<br />

• Emission from electricity generation for<br />

o operating of ventilators and motors for clinker production<br />

o processing of raw material<br />

o additives preparation<br />

o grinding of cement.<br />

• Emissions from calcinations of limestone;<br />

BEC,y = (BEfossilfuel,y + BEelectricity,y + BEprocess,y) /C,y<br />

where:<br />

BECy = CO2 emissions per tonne of cement in baseline situation in year y (t<br />

CO2 /tonne cement)<br />

BEfossil_fuel,y = CO2 emissions from fossil fuel combustion in the project activity<br />

plant in year y (t CO2)<br />

BEelectricity,y = Electricity emissions in year y (t CO2)<br />

BEprocess,y = Process emissions from the calcinations of limestone in year y (t<br />

CO2)<br />

Cy = Annual production of cement in year y (kilotonnes of cement)<br />

The CO2 emissions from combustion of fossil fuel in year y are calculated as follows:<br />

BEfossil_fuel, y = [ ΣFFi_,y * EFFi] * 1000<br />

where:<br />

BEfossil_fuel,y = CO2 emissions from fossil fuel combustion in the project activity<br />

plant in year y (t CO2/)<br />

FFi_,y = Fossil fuel of type i consumed in year y (tonnes of fuel i)<br />

EFFi = Emission factor for fossil fuel i (tCO2/tonne of fuel)<br />

The CO2 emissions from electricity consumption in year y are calculated as follows:<br />

BEelectricity,y = PEelec_grid,y*EFgrid,y +PEelec_sg,y*EFsg_y<br />

Where:<br />

BEelectricity,y = Electricity emissions in year y (t CO2)<br />

BEelec_grid,y = Grid electricity in year y (MWh)<br />

EFgrid_y = Grid emission factor in year y(t CO2 /MWh)<br />

BEelec_sg_,y = Self generation of electricity in year y (MWh)<br />

EFsg_y = Emission factor for self generated electricity in year y (t CO2<br />

/MWh)

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>) - <strong>Version</strong> <strong>02</strong><br />

<strong>CDM</strong> – Executive Board page 10<br />

The determination of the emission factor for the grid is calculated as in ACM00<strong>02</strong>. In case the<br />

amount of grid electricity consumption in the baseline and project situation are similar, the grid<br />

emission factor does not need to be taken into account.<br />

The process emissions from clinker production in year y are calculated as follows:<br />

BEprocess,y = 0.785*(OutCaOy - InCaOy) + 1.092*(OutMgOy - InMgOy) / 1000<br />

where:<br />

BEcalcin,y = Emissions from the calcinations of limestone (t CO2)<br />

0.785 = Stoichiometric emission factor for CaO (t CO2 /t CaO)<br />

1.092 = Stoichiometric emission factor for MgO (t CO2 /t MgO)<br />

InCaO,y = CaO content (%) of the raw material * raw material quantity<br />

(tonnes)<br />

OutCaO,y = CaO content (%) of the clinker * clinker produced (tonnes)<br />

InMgO,y = MgO content (%) of the raw material * raw material quantity<br />

(tonnes)<br />

OutMgO,y = MgO content (%) of the clinker * clinker produced (tonnes)<br />

Explanation/justification:<br />

>><br />

SETION G. Project activity emissions<br />

Methodology procedure:<br />

>> Project emissions include emissions from combustion of fossil fuel for clinker production and<br />

auxiliary fuels for the waste heat recovery boiler, if any; emissions from electricity consumption<br />

for operating of ventilators and motors for clinker production, processing of raw material,<br />

additives preparation, and grinding of cement; and emissions from calcination of limestone. An<br />

initial estimation of project emissions is made by multiplying the projected emissions rate by the<br />

projected cement production output of the cement plant for the project validity period. Actual<br />

project emission will be based on monitored data.<br />

Project emissions involve:<br />

• Emissions from combustion of fossil fuel for:<br />

o clinker production<br />

o auxiliary fuels for the waste heat recovery boiler, if any.<br />

• Emission from electricity generation for<br />

o operating of ventilators and motors for clinker production<br />

o processing of raw material<br />

o additives preparation<br />

o grinding of cement.<br />

• Emissions from calcinations of limestone;

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>) - <strong>Version</strong> <strong>02</strong><br />

<strong>CDM</strong> – Executive Board page 11<br />

PEC,y = (PEfossilfuel,y + PEelectricity,y + PEprocess,y) /C,y<br />

where:<br />

PECy = CO2 emissions per tonne of cement in the project activity plant in<br />

year y (t CO2 /tonne cement)<br />

PEfossil_fuel,y = CO2 emissions from fossil fuel combustion in the project activity<br />

plant in year y (t CO2)<br />

PEelectricity,y = Electricity emissions in year y (t CO2)<br />

PEprocess = Process emissions from the calcinations of limestone (t CO2)<br />

Cy = Annual production of cement in year y (kilotonnes of cement)<br />

The CO2 emissions from combustion of fossil fuel in year y are calculated as follows:<br />

PEfossil_fuel, y = [ ΣFFi_,y * EFFi] * 1000<br />

where:<br />

PEfossil_fuel,y = CO2 emissions from fossil fuel combustion in the project activity<br />

plant in year y (t CO2)<br />

FFi_,y = Fossil fuel of type i consumed in year y (tonnes of fuel i)<br />

EFFi = Emission factor for fossil fuel i (t CO2/tonne of fuel)<br />

The CO2 emissions from electricity consumption in year y are calculated as follows:<br />

PEelectricity,y = PEelec_grid,y*EFgrid,y +PEelec_sg,y*EFsg_y<br />

Where:<br />

PEelectricity,y = Electricity emissions in year y (t CO2)<br />

PEelec_grid,y = Grid electricity in year y (MWh)<br />

EFgrid_y = Grid emission factor in year y(t CO2 /MWh)<br />

PEelec_sg_,y = Self generation of electricity in year y (MWh)<br />

EFsg_y = Emission factor for self generated electricity in year y (t CO2<br />

/MWh)<br />

The determination of the emission factor for the grid is calculated as in ACM00<strong>02</strong>. In case the<br />

amount of grid electricity consumption in the baseline and project situation are similar, the grid<br />

emission factor does not need to be taken into account.<br />

The process emissions from clinker production in year y are calculated as follows:<br />

PEprocess,y = 0.785*(OutCaOy - InCaOy) + 1.092*(OutMgOy - InMgOy) / 1000<br />

where:<br />

PEcalcin,y = Emissions from the calcinations of limestone (t CO2 /tonne clinker)

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>) - <strong>Version</strong> <strong>02</strong><br />

<strong>CDM</strong> – Executive Board page 12<br />

0.785 = Stoichiometric emission factor for CaO (t CO2 /t CaO)<br />

1.092 = Stoichiometric emission factor for MgO (t CO2 /t MgO)<br />

InCaO,y = CaO content (%) of the raw material * raw material quantity<br />

(tonnes)<br />

OutCaO,y = CaO content (%) of the clinker * clinker produced (tonnes)<br />

InMgO,y = MgO content (%) of the raw material * raw material quantity<br />

(tonnes)<br />

OutMgO,y = MgO content (%) of the clinker * clinker produced (tonnes)<br />

Explanation/justification:<br />

>><br />

SECTION H. Leakage<br />

Methodology procedure:<br />

>> Leakage involves emissions associated transport of raw materials, fuels, fuel substitutes, and<br />

blending materials. Emissions due to fuel use for the transport of raw materials (e.g. limestone,<br />

gypsum), coal (or other fuels) and additives (blending materials) from offsite locations to the<br />

project plant will change due to the implementation of the project. The transport related<br />

emissions for raw materials and fuels are likely to decrease. To keep the methodology<br />

conservative this change shall not be included. In the project activity, emissions due to<br />

transportation of additives and alternative fuels will increase. These emissions will be accounted<br />

as leakage.<br />

Transport-related emissions for additives and alternative fuels are calculated as below.<br />

Ladd/alt fuel_trans = [(TFcons * Dadd/alt fuel_source * TEF)* 1/Qadd/alt fuel*1/1000 +<br />

(ELEconveyor_add/alt fuel * EFgrid)*1/add/alt fuel,y] (2)<br />

where:<br />

Ladd/alt fuels_trans = Transport-related emissions per tonne of additives and/or<br />

alternative fuels (t CO2 /tonne of additive/alternative fuel)<br />

TFcons = Fuel consumption for the vehicle per kilometre (kg of<br />

fuel/kilometre)<br />

Dadd/alt fuel_source = Distance between the source of additive and/or alternative fuel and<br />

the project activity plant (km)<br />

TEF = Emission factor for transport fuel (kg CO2 /kg of fuel)<br />

ELEconveyor_add/alt fuel<br />

= Annual electricity consumption for conveyor system for additives<br />

(MWh)<br />

EFgrid = Grid electricity emission factor (tonnes of CO2/MWh)<br />

Qadd/alt fuel = Quantity of additive and/or alternative fuel carried in one trip per<br />

vehicle (tonnes of additive/alternative fuel)

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>) - <strong>Version</strong> <strong>02</strong><br />

<strong>CDM</strong> – Executive Board page 13<br />

Add/altfuel,y = Annual consumption of additives and/or alternative fuels in year y.<br />

(t of additives/alternative fuels)<br />

And leakage emissions per tonne of cement due to additional additives are determined by:<br />

Ly = Ladd_trans * [Ablend,y – Pblend,y] * cement,y (2.1)<br />

where:<br />

Ly = Leakage emissions for transport of additives (kilotonnes of CO2)<br />

Cement,y = Production of cement in year y (kilotonnes of cement)<br />

Ablend,y = Baseline share of additives per tonne of cement updated for year y<br />

(tonne of additives/tonne of cement)<br />

Pblend,y = Share of additives per tonne of cement in year y (tonne of<br />

additives/tonne of cement)<br />

Another possible leakage is due to the diversion of additives from existing uses. The project<br />

proponents shall demonstrate that additional amounts of additives used are surplus. If the project<br />

proponents do not substantiate x tonnes of additives used in the project activity are surplus, the<br />

project emissions reductions are reduced by the factor α, which is defined as:<br />

αy = x tonnes of additives in year y / total additional additives used in year y<br />

Explanation/justification:<br />

>><br />

SECTION I. Emission reductions<br />

Methodology procedure:<br />

>> Project emissions reductions are the difference between the baseline weighted average<br />

projected CO2 emissions and the project activity emissions, accounting for leakage if necessary.<br />

For the project cement plant, both project and baseline emissions per tonne of cement will be<br />

defined. Total emission reduction are then calculated by multiplying the emission reduction per<br />

tonne of cement by the production of cement.<br />

Emissions reductions in year y are the difference in the CO2 emissions per tonne of cement in the<br />

baseline and in the project activity multiplied by the production of cement in year y. The<br />

emissions reductions are discounted for the percentage of additives for which surplus availability<br />

is not substantiated.<br />

ERy = { [BEC,y – PEC,y] * Cy + Ly } * (1 – αy)<br />

where:<br />

ERy = Emissions reductions in year y due to project activity (thousand<br />

tonnes of CO2)<br />

BEC,y = Baseline emissions per tonne of cement (t CO2 /tonnes of cement)

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>) - <strong>Version</strong> <strong>02</strong><br />

<strong>CDM</strong> – Executive Board page 14<br />

PEC,y = Project emissions per tonne of cement in year y (t CO2 /tonnes of<br />

cement)<br />

Cy = Cement production in year y (thousand tonnes)<br />

Explanation/justification:<br />

>><br />

SECTION J. Changes required for methodology implementation in 2 nd and 3 rd crediting periods<br />

(if relevant / optional)<br />

Methodology procedure:<br />

>>The proposed methodology uses the additionality tool in order to determine an appropriate<br />

baseline scenario (based on the common production characteristics in the country or selected<br />

region). This determination is based on common practices, investment or barrier analysis. Given<br />

that the circumstances pertaining to the analysis of the baseline may change over time, all<br />

analyses of the baseline and additionality criteria should be conducted at the end of each<br />

crediting period to verify if the assumptions on the original baseline determination remains valid<br />

and whether the project activity remains additional. This may lead to a change in the baseline for<br />

following crediting periods, if such crediting were sought. If this analysis would demonstrate that<br />

part of the project activity are no long additional the baseline will be adapted, and no crediting<br />

would occur.<br />

Explanation/justification:<br />

>>The approach for estimating the credits for a 2 nd or 3 rd crediting period is conservative, as the<br />

method would not allow for automatic crediting of the CERs for a longer period than the<br />

commitment period. A revised baseline would allow for to only receive credits for those<br />

activities that are still considered additional when compared to the common production practices<br />

at the time of renewal (i.e. end of the previous crediting period) for the selected country or region.<br />

SECTION K. Selected baseline approach from paragraph 48 of the <strong>CDM</strong> modalities and<br />

procedures<br />

Choose One (delete others):<br />

XX Existing actual or historical emissions, as applicable;<br />

Emissions from a technology that represents an economically attractive course of action, taking<br />

into account barriers to investment;<br />

The average emissions of similar project activities undertaken in the previous five years, in<br />

similar social, economic, environmental and technological circumstances, and whose performance<br />

is among the top 20 per cent of their category.<br />

Explanation/justification of choice:<br />

>><br />

SECTION I. Other Information<br />

Explanation/justification:

PROPOSED NEW METHODOLOGY: BASELINE (<strong>CDM</strong>-<strong>NMB</strong>) - <strong>Version</strong> <strong>02</strong><br />

<strong>CDM</strong> – Executive Board page 15<br />

>><br />

-.-.-.-