ul test report and procedure - Zippy Switch Tech. Corp.

ul test report and procedure - Zippy Switch Tech. Corp.

ul test report and procedure - Zippy Switch Tech. Corp.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

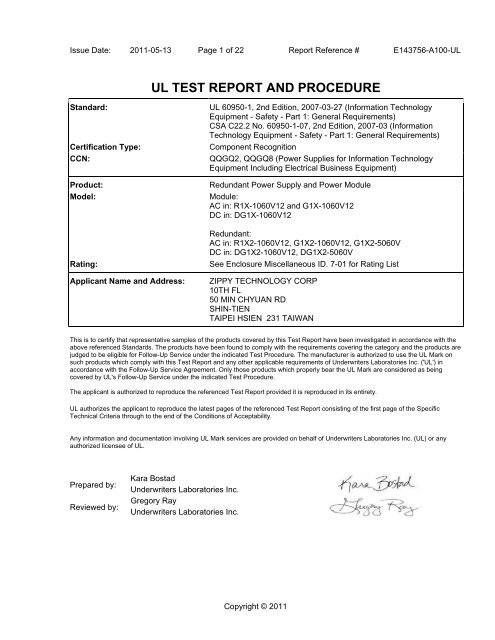

Issue Date: 2011-05-13 Page 1 of 22 Report Reference # E143756-A100-UL<br />

UL TEST REPORT AND PROCEDURE<br />

St<strong>and</strong>ard: UL 60950-1, 2nd Edition, 2007-03-27 (Information <strong>Tech</strong>nology<br />

Equipment - Safety - Part 1: General Requirements)<br />

CSA C22.2 No. 60950-1-07, 2nd Edition, 2007-03 (Information<br />

<strong>Tech</strong>nology Equipment - Safety - Part 1: General Requirements)<br />

Certification Type: Component Recognition<br />

CCN: QQGQ2, QQGQ8 (Power Supplies for Information <strong>Tech</strong>nology<br />

Equipment Including Electrical Business Equipment)<br />

Product: Redundant Power Supply <strong>and</strong> Power Mod<strong>ul</strong>e<br />

Model: Mod<strong>ul</strong>e:<br />

AC in: R1X-1060V12 <strong>and</strong> G1X-1060V12<br />

DC in: DG1X-1060V12<br />

Redundant:<br />

AC in: R1X2-1060V12, G1X2-1060V12, G1X2-5060V<br />

DC in: DG1X2-1060V12, DG1X2-5060V<br />

Rating: See Enclosure Miscellaneous ID. 7-01 for Rating List<br />

Applicant Name <strong>and</strong> Address: ZIPPY TECHNOLOGY CORP<br />

10TH FL<br />

50 MIN CHYUAN RD<br />

SHIN-TIEN<br />

TAIPEI HSIEN 231 TAIWAN<br />

This is to certify that representative samples of the products covered by this Test Report have been investigated in accordance with the<br />

above referenced St<strong>and</strong>ards. The products have been found to comply with the requirements covering the category <strong>and</strong> the products are<br />

judged to be eligible for Follow-Up Service under the indicated Test Procedure. The manufacturer is authorized to use the UL Mark on<br />

such products which comply with this Test Report <strong>and</strong> any other applicable requirements of Underwriters Laboratories Inc. ('UL') in<br />

accordance with the Follow-Up Service Agreement. Only those products which properly bear the UL Mark are considered as being<br />

covered by UL's Follow-Up Service under the indicated Test Procedure.<br />

The applicant is authorized to reproduce the referenced Test Report provided it is reproduced in its entirety.<br />

UL authorizes the applicant to reproduce the la<strong>test</strong> pages of the referenced Test Report consisting of the first page of the Specific<br />

<strong>Tech</strong>nical Criteria through to the end of the Conditions of Acceptability.<br />

Any information <strong>and</strong> documentation involving UL Mark services are provided on behalf of Underwriters Laboratories Inc. (UL) or any<br />

authorized licensee of UL.<br />

Prepared by:<br />

Reviewed by:<br />

Kara Bostad<br />

Underwriters Laboratories Inc.<br />

Gregory Ray<br />

Underwriters Laboratories Inc.<br />

Copyright © 2011

Issue Date: 2011-05-13 Page 2 of 22 Report Reference # E143756-A100-UL<br />

Supporting Documentation<br />

The following documents located at the beginning of this Procedure supplement the requirements of this Test<br />

Report:<br />

A. Authorization - The Authorization page may include additional Factory Identification Code markings.<br />

B. Generic Inspection Instructions -<br />

i. Part AC details important information which may be applicable to products covered by this Procedure.<br />

Products described in this Test Report must comply with any applicable items listed unless otherwise<br />

stated in the body of this Test Report.<br />

ii. Part AE details any requirements which may be applicable to all products covered by this Procedure.<br />

Products described in this Test Report must comply with any applicable items listed unless otherwise<br />

stated in the body of each Test Report.<br />

iii. Part AF details the requirements for the UL Certification Mark which is not controlled by the technical<br />

st<strong>and</strong>ard used to investigate these products. Products are permitted to bear only the Certification<br />

Mark(s) corresponding to the countries for which it is certified, as indicated in each Test Report.<br />

Product Description<br />

The Redundant Power Supply, Models R1X2-1060V12, G1X2-1060V12 <strong>and</strong> G1X2-5060V are a 1+1 hotswappable<br />

AC to DC Power Supply for use in Information <strong>Tech</strong>nology Equipment (ITE).<br />

The Redundant Power Supply, Models DG1X2-1060V12 <strong>and</strong> DG1X2-5060V are a 1+1 hot-swappable DC to<br />

DC Power Supply for use in Information <strong>Tech</strong>nology Equipment (ITE).<br />

The Power Supply Mod<strong>ul</strong>e is power supply board <strong>and</strong> housed in metal chassis.<br />

All Redundant Power Supply models are composed of 2 power mod<strong>ul</strong>es maximum.<br />

Model Differences<br />

Models R1X-1060V12, G1X-1060V12, DG1X-1060V12 are Power Mod<strong>ul</strong>es.<br />

Model R1X-1060V12, G1X-1060V12 is similar to Model DG1X-1060V12, except input voltage, primary<br />

circuit, <strong>and</strong> transformer.<br />

Models R1X2-1060V12, G1X2-1060V12, G1X2-5060V, DG1X2-1060V12, DG1X2-5060V are Redundant<br />

Power Supply.<br />

Model R1X2-1060V12, G1X2-1060V12 is similar to Model G1X2-5060V, except output rating.<br />

Model DG1X2-1060V12 is similar to Model DG1X2-5060V, except output rating.<br />

Model DG1X2-5060V is similar to Model G1X2-5060V, except input <strong>and</strong> output rating.<br />

Model nomenclature for Mod<strong>ul</strong>e:<br />

- R1X-"1" denotes 1 output;<br />

- R1X-1060V”12” denotes only 12V output;<br />

- DG1X-1060V12, "D" denotes DC main supply;<br />

Model nomenclature for Redundant Power Supply:<br />

- R1X"2" denotes 2 Mod<strong>ul</strong>es type chassis;<br />

- R1X2-"1" denotes 1 outputs;<br />

- R1X2-1060V”12” denotes only 12V output;<br />

- G1X2-“5” denotes 5 outputs;<br />

<strong>Tech</strong>nical Considerations<br />

Equipment mobility : for building-in<br />

Connection to the mains : pluggable A (For Models R1X <strong>and</strong> G1X series); permanent connection

Issue Date: 2011-05-13 Page 3 of 22 Report Reference # E143756-A100-UL<br />

(DC Mains) (For Models DG1X series)<br />

Operating condition : continuous<br />

Access location : operator accessible<br />

Over voltage category (OVC) : OVC II<br />

Mains supply tolerance (%) or absolute mains supply values : +10%, -10% ; DC Mains: no tolerance<br />

declared by manufacturer<br />

Tested for IT power systems : No<br />

IT <strong>test</strong>ing, phase-phase voltage (V) : --<br />

Class of equipment : Class I (earthed)<br />

Considered current rating (A) : 20A (For Models R1X <strong>and</strong> G1X series); 2A (For Models DG1X series)<br />

Pollution degree (PD) : PD 2<br />

IP protection class : IP X0<br />

Altitude of operation (m) : up to 3100 m<br />

Altitude of <strong>test</strong> laboratory (m) : Less than 2000 m<br />

Mass of equipment (kg) : 0.33 kg for Mod<strong>ul</strong>e; 1.045 kg for Redundant<br />

The product was submitted <strong>and</strong> evaluated for use at the maximum ambient temperature (Tma)<br />

permitted by the manufacturer’s specification of: 40 °C<br />

The means of connection to the mains supply is: Detachable power cord, Pluggable A For Models<br />

R1X <strong>and</strong> G1X series , Permanently connected (field wired) For Models DG1X series,<br />

The product is intended for use on the following power systems: TN (For Models R1X <strong>and</strong> G1X<br />

series) , DC mains supply (For Models DG1X series)<br />

The equipment disconnect device is considered to be: Appliance inlet (For Models R1X <strong>and</strong> G1X<br />

series)<br />

The following were investigated as part of the protective earthing/bonding: Earth screw (For Models

Issue Date: 2011-05-13 Page 4 of 22 Report Reference # E143756-A100-UL<br />

DG1X series)<br />

The following are available from the Applicant upon request: Specific data sheets for LED indicators<br />

that are class I <strong>and</strong> operate at wavelength in the 400-710 nm range.,<br />

The manufacturer specified that the equipment co<strong>ul</strong>d be operated up to an altitude of 3100 m.<br />

Therefore the requirements of IEC 60664-1: 2007. for clearances were considered <strong>and</strong> the required<br />

clearance was m<strong>ul</strong>tiplied with an altitude correction factor of 1.155.<br />

Engineering Conditions of Acceptability<br />

For use only in or with complete equipment where the acceptability of the combination is determined by<br />

Underwriters Laboratories Inc. When installed in an end-product, consideration must be given to the<br />

following:<br />

The end-product Electric Strength Test is to be based upon a maximum working voltage of: For<br />

Models R1X <strong>and</strong> G1X series, Primary-SELV: 307 Vrms, 488 Vpk, Primary-Earthed Dead Metal: 283<br />

Vrms, 472 Vpk, , For Models DG1X series, DC Input-Earthed Dead Metal: 67 Vrms, 124 Vpk, DC<br />

Input-SELV: 76 Vrms, 144 Vpk<br />

The following secondary output circuits are SELV: All outputs.<br />

The following secondary output circuits are at non-hazardous energy levels: All outputs<br />

The following output terminals were referenced to earth during performance <strong>test</strong>ing: GND<br />

The power supply terminals <strong>and</strong>/or connectors are: Not investigated for field wiring for DC-DC units<br />

which employ Input terminal block by Howder Electric Co., Ltd.,Type HD-123. , Suitable for field<br />

wiring for DC-DC units which employ Input terminal block by Dinkle Enterprise Co Ltd, Type DT-4.<br />

The maximum investigated branch circuit rating is: 20A For Models R1X <strong>and</strong> G1X series; 2A For<br />

Models DG1X series<br />

The investigated Pollution Degree is: 2<br />

Proper bonding to the end-product main protective earthing termination is: Required<br />

An investigation of the protective bonding terminals has: Been conducted (all units)<br />

The following magnetic devices (e.g. transformers or inductor) are provided with an OBJY2 ins<strong>ul</strong>ation<br />

system with the indicated rating greater than Class A (105°C): T1 (Class B)<br />

The following end-product enclosures are required: Fire, Electrical<br />

The following input terminals were evaluated as suitable for direct connection to the DC Mains

Issue Date: 2011-05-13 Page 5 of 22 Report Reference # E143756-A100-UL<br />

Supply: Terminal block For Models DG1X series<br />

The equipment is suitable for direct connection to: AC mains supply For Models R1X <strong>and</strong> G1X<br />

series, DC mains supply For Models DG1X series<br />

The product was investigated to the following additional st<strong>and</strong>ards: IEC 60664-1: 2007 clearance<br />

requirements for 3100 m above sea level. The required clearance is m<strong>ul</strong>tiplied by the altitude<br />

correction factor (1.155), as specified in Table A.2.<br />

Additional Information<br />

N/A<br />

Additional St<strong>and</strong>ards<br />

The product f<strong>ul</strong>fills the requirements of: N/A<br />

Markings <strong>and</strong> instructions<br />

Clause Title Marking or Instruction Details<br />

Power rating - Ratings<br />

Power rating -<br />

Company identification<br />

Model<br />

Power rating -<br />

Fuses - Non-operator<br />

access/soldered-in<br />

fuses<br />

M<strong>ul</strong>tiple power sources<br />

Ratings (voltage, frequency/dc, current)<br />

Listee's or Recognized company's name, Trade Name, Trademark or File<br />

Number<br />

Model Number<br />

Special Instructions to UL Representative<br />

Unambiguous reference to service documentation for instructions for<br />

replacement of fuses replaceable only by service personnel<br />

Following statement indicated on redundant units.<br />

Warning: M<strong>ul</strong>tiple power sources. Refer to service manual before servicing.<br />

Following statement included in service manual.<br />

Redundant power supplies are provided with more than one power source.<br />

Disconnect one power supply cord <strong>and</strong> p<strong>ul</strong>l out this power mod<strong>ul</strong>e when just a<br />

single power mod<strong>ul</strong>e has failed <strong>and</strong> servicing <strong>and</strong> maintaining that mod<strong>ul</strong>e.<br />

Disconnect all power supply cords before servicing the complete unit if whole<br />

redundant unit servicing is necessary.<br />

Inspect the transformer(s) listed in BD1.1 per AA1.1- (C). When the <strong>test</strong>s are conducted at other<br />

location, inspect <strong>test</strong> record <strong>and</strong> specification sheet provided by the component manufacturer.

Issue Date: 2011-05-13 Page 6 of 22 Report Reference # E143756-A100-UL<br />

Verify the specification sheet indicates 100% routine <strong>test</strong> specified in BD1.1 is conducted at the<br />

component manufacturer. The <strong>test</strong> record noted above shall be submitted to the manufacturer<br />

from transformer manufacturer. The <strong>test</strong> record can be in the form of a actual <strong>test</strong> record. A<br />

stamp or sticker on the transformer or other method verifying the routine <strong>test</strong> is being completed<br />

on 100% production is also acceptable.<br />

Production-Line Testing Requirements<br />

Electric Strength Test Special Constructions - Refer to Generic Inspection Instructions, Part AC for<br />

further information.<br />

Model Component<br />

Removable<br />

Parts Test probe location<br />

All models Transformer T1 -- Input winding - Output<br />

winding<br />

V<br />

rms V dc<br />

Earthing Continuity Test Exemptions - This <strong>test</strong> is not required for the following models:<br />

All models.<br />

Electric Strength Test Exemptions - This <strong>test</strong> is not required for the following models:<br />

All models.<br />

200<br />

0<br />

Test Time,<br />

s<br />

-- 1<br />

Electric Strength Test Component Exemptions - The following solid-state components may be<br />

disconnected from the remainder of the circuitry during the performance of this <strong>test</strong>:<br />

--<br />

Sample <strong>and</strong> Test Specifics for Follow-Up Tests at UL<br />

Model Component Material Test Sample(s)<br />

-- -- -- -- -- --<br />

Test<br />

Specifics

Issue Date: 2011-05-13 Page 7 of 22 Report Reference # E143756-A100-UL<br />

TABLE: List of Critical Components<br />

Object/part or<br />

Description<br />

Manufacturer/<br />

trademark<br />

Power Mod<strong>ul</strong>e <strong>Zippy</strong> <strong>Tech</strong>nology<br />

<strong>Corp</strong><br />

01. Chassis ( For R1X-<br />

1060V12 <strong>and</strong> G1X-<br />

1060V12)<br />

02. Chassis<br />

(DG1X-1060V12)<br />

type/model technical data CCN Marks of<br />

Conformity<br />

R1X-1060V12,<br />

G1X-1060V12,<br />

DG1X-1060V12<br />

Consist of the following critical parts. -- --<br />

-- -- Metal (Nickel plated steel). Two pieces construction<br />

secured together by screws. Overall measured<br />

approximately 135 by 50.5 by 38 mm, minimum 0.8<br />

mm thick. Provided with following ventilation<br />

openings: a. Front side - Provide with 1 slots<br />

ventilation openings each measured 7 by 4.5 mm.<br />

<strong>and</strong> Provided with 7 slots ventilation openings each<br />

measured 9 by 4.5 mm <strong>and</strong> Provided with 4 slots<br />

ventilation openings each measured 6 by 2 mm <strong>and</strong><br />

Provided with 2 slots ventilation openings each<br />

measured 5 by 4.5 mm; b. Top side - Provide with 8<br />

slots ventilation openings each measured 20 by 4<br />

mm <strong>and</strong> Provide with 2 slots ventilation openings<br />

each measured 15 by 4 mm; c. Right side - Provide<br />

with 9 slots ventilation openings each measured 20<br />

by 4 mm <strong>and</strong> Provide with 2 slots ventilation<br />

openings each measured 13 by 4 mm; d. Left side -<br />

Provide with 5 slots ventilation openings each<br />

measured 20 by 4 mm <strong>and</strong> Provide with 12 slots<br />

ventilation openings each measured 15 by 4 mm.<br />

-- -- Metal (Nickel plated steel). Two pieces construction<br />

secured together by screws. Overall measured<br />

approximately 135 by 50.5 by 38 mm, minimum 0.8<br />

mm thick. Provided with following ventilation<br />

openings: a. – Front side - Provide with 10 slots<br />

ventilation openings each measured 6 by 4 mm.<br />

<strong>and</strong> Provided with 5 slots ventilation openings each<br />

measured 4 by 4 mm <strong>and</strong> Provided with 5 slots<br />

ventilation openings each measured 6 by 2 mm <strong>and</strong><br />

-- --<br />

-- --

Issue Date: 2011-05-13 Page 8 of 22 Report Reference # E143756-A100-UL<br />

Object/part or<br />

Description<br />

Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

Provided with 5 slots ventilation openings each<br />

measured 4 by 2 mm; b. Top side - Provide with 8<br />

slots ventilation openings each measured 20 by 4<br />

mm <strong>and</strong> Provide with 2 slots ventilation openings<br />

each measured 15 by 4 mm; c. Right side - Provide<br />

with 9 slots ventilation openings each measured 20<br />

by 4 mm <strong>and</strong> Provide with 2 slots ventilation<br />

openings each measured 13 by 4 mm; d. Left side -<br />

Provide with 5 slots ventilation openings each<br />

measured 20 by 4 mm <strong>and</strong> Provide with 12 slots<br />

ventilation openings each measured 15 by 4 mm.<br />

03. Label Various Various Rated minimum 70 degree C, suitable for surface<br />

applied to top chassis.<br />

PGDQ2 or PGJI2 UL<br />

04. LED Indicator -- -- (SELV) Fit to front chassis. The wavelength range<br />

of 400 nm to 710 mm. Lead wires provided with<br />

Ins<strong>ul</strong>ation Tubing / Sleeving from end to end,<br />

minimum 0.4 mm thick.<br />

-- --<br />

05. Earth Screw (For -- -- Steel, Dimension minimum 3.5 mm diameter. -- --<br />

Model DG1X-1060V12)<br />

06. H<strong>and</strong>le Various Various Plastic, U-shaped, rated minimum HB. Overall<br />

measured approximate 35.4 by 25 mm, 5.5 mm<br />

07. Appliance Inlet (For<br />

Models R1X-1060V12<br />

<strong>and</strong> G1X-1060V12)<br />

07a. Appliance Inlet (For<br />

Models R1X-1060V12<br />

<strong>and</strong> G1X-1060V12<br />

(Alternate)<br />

07b. Appliance Inlet (For<br />

Models R1X-1060V12<br />

<strong>and</strong> G1X-1060V12<br />

(Alternate)<br />

Solteam Electronics<br />

Co Ltd<br />

Supercom Wire &<br />

Cable Co Ltd<br />

Rong Feng Industrial<br />

Co Ltd<br />

diameter. Secured to front chassis by screws.<br />

ST-01 Rated 10/15A, 125/250V. Secure to chassis by<br />

snap-fit.<br />

QMFZ2 UL<br />

AXUT2 UL<br />

(E200241)<br />

SC-8 Rated 15A, 250V. Secure to chassis by snap-fit. AXUT2 UL<br />

SS-7B Rated 15A, 250V. Secure to chassis by snap-fit. AXUT2 UL

Issue Date: 2011-05-13 Page 9 of 22 Report Reference # E143756-A100-UL<br />

Object/part or<br />

Description<br />

07c. Appliance Inlet (For<br />

Models R1X-1060V12<br />

<strong>and</strong> G1X-1060V12<br />

(Alternate)<br />

07d. Appliance Inlet (For<br />

Models R1X-1060V12<br />

<strong>and</strong> G1X-1060V12<br />

(Alternate)<br />

08. DC Input Terminal<br />

Block (For Model DG1X-<br />

1060V12)<br />

08a. DC Input Terminal<br />

Block (For Model DG1X-<br />

1060V12) (Alternate)<br />

09. Ins<strong>ul</strong>ation Sheet<br />

(Located between solder<br />

side <strong>and</strong> bottom chassis)<br />

Manufacturer/<br />

trademark<br />

Jackson Electronics<br />

Industrial <strong>Corp</strong><br />

Tecx-Unions<br />

<strong>Tech</strong>nology <strong>Corp</strong><br />

Howder Electric Co<br />

Ltd<br />

Dinkle Enterprise Co<br />

Ltd<br />

Sabic Innovative<br />

Plastics Us L L C<br />

type/model technical data CCN Marks of<br />

Conformity<br />

JR-101 Rated 10A, 250V. Secure to chassis by snap-fit. AXUT2 UL<br />

TU-301-S Rated 15A, 250V. Secure to chassis by snap-fit. AXUT2 UL<br />

HD-123 Rated 300 V, 25 A. Secure to chassis by screw. XCFR2 UL<br />

(E112196)<br />

DT-4 Rated 300 V, 20 A. Secure to chassis by screw. XCFR2 UL<br />

(E102914)<br />

FR1 Rated minimum VTM-2, minimum 0.2 mm thick.<br />

See Enclosure ID 4-01 for construction details.<br />

10. Internal L/N Wire Various Various Minimum 105 degree C, FEP, PTEF, PVC, TFE,<br />

neoprene or surface marked rated VW-1, minimum<br />

300 Vac, minimum 18 AWG. One end mechanical<br />

secured <strong>and</strong> soldered to Appliance Inlet, other end<br />

provided with connector connected to CN1 of<br />

11. Bonding Conductor<br />

(For Models R1X-<br />

1060V12 <strong>and</strong> G1X-<br />

1060V12)<br />

Printed Wiring Board.<br />

Various Various Green / yellow lead used. FEP, PTFE, PVC, TFE<br />

neoprene, polyimide or marked VW-1; minimum 18<br />

AWG, 105 degree C, minimum 300 V. One end<br />

mechanically secured <strong>and</strong> soldered to earth<br />

terminal of Appliance Inlet; other end terminates in<br />

closed-loop, double crimp-type connector secured<br />

to Chassis with dedicated threaded post or screw<br />

nut <strong>and</strong> lock-washer. Bonding ground symbol<br />

(IEC60417, No. 5019) provided near screw hole.<br />

QMFZ2 UL<br />

(E121562)<br />

AVLV2 UL<br />

AVLV2 UL<br />

12. Printed Wiring Board Various Various Rated minimum V-1, minimum 130 degree C. ZPMV2 --

Issue Date: 2011-05-13 Page 10 of 22 Report Reference # E143756-A100-UL<br />

Object/part or<br />

Description<br />

Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

13. Primary Connector Alex Connector Co 8673 250V, 7A. for each pin. (total 2 pins) ECBT2 UL<br />

(CN1)<br />

Ltd<br />

(E114003)<br />

13a. Primary Connector Taiwan King Pin PVHI series 10A, 250V ECBT2 UL<br />

(CN1)<br />

Terminal Co., Ltd.<br />

(E118260)<br />

13b. Primary Connector Long Chu Electronics Series P3060 Rated 250 V, 7A. for each pin. (total 2 pins) ECBT2 UL E94662<br />

(CN1)<br />

Co Ltd<br />

13c. Primary Connector Taiwan King Pin P8800I series 7A, 250V ECBT2 UL<br />

(CN1)<br />

Terminal Co Ltd<br />

(E118260)<br />

13d. Primary Connector Jowle <strong>Tech</strong>nology Co A3963WV2-3P-D 6A, 250V ECBT2 UL<br />

(CN1)<br />

Ltd<br />

(E144544)<br />

14. Fuse (F1) (For Cooper Bussmann SS-5 Can Type. Rated 250 Vac, T 3.15 A. JDYX2 UL (E19180)<br />

Models R1X-1060V12<br />

<strong>and</strong> G1X-1060V12)<br />

Inc<br />

14a. Fuse (F1) (For Conquer Electronics MST (MST-series) Can Type. Rated 250Vac, T 3.15 A. JDYX2 UL (E82636)<br />

Models R1X-1060V12<br />

<strong>and</strong> G1X-1060V12)<br />

Co Ltd<br />

14b. Fuse (F1) (For Hollyl<strong>and</strong> Co Ltd 5 ET (5ET-series) Can Type. Rated 250Vac, T 3.15 A. JDYX2 UL<br />

Models R1X-1060V12<br />

<strong>and</strong> G1X-1060V12)<br />

(E156471)<br />

15. Fuse (F1) (For Model Cooper Bussmann 6125FFxxx-R SMD Type. Rated 72 Vdc, F 5 A. JDYX2 UL (E19180)<br />

DG1X-1060V12)<br />

(Alternate)<br />

Inc<br />

15a. Fuse (F1) (For Conquer Electronics SEF SMD Type. Rated 125 Vdc, F 5 A. JDYX2 UL (E82636)<br />

Model DG1X-1060V12)<br />

(Alternate)<br />

Co., Ltd<br />

16. Thermistor (TH1)<br />

(For Models R1X-<br />

1060V12 <strong>and</strong> G1X-<br />

1060V12)<br />

-- -- Rated 5 ohm, 4A at 25 degree C. -- --<br />

17. X-Capacitors (XC1, Cheng Tung CTX Rated minimum 250 V, maximum 0.1 uF. Marked FOWX2 UL<br />

XC2) (For Models R1X- Industrial Co Ltd<br />

with a "X1" or "X2" <strong>and</strong> Certified by VDE, DEMKO<br />

(E193049)<br />

1060V12 <strong>and</strong> G1X-<br />

or SEV. (Meets IEC 60384-14)... The damp heat<br />

1060V12) (Optional)<br />

<strong>test</strong> duration in 21 days minimum.

Issue Date: 2011-05-13 Page 11 of 22 Report Reference # E143756-A100-UL<br />

Object/part or<br />

Description<br />

17a. X-Capacitors (XC1,<br />

XC2) (For Models R1X-<br />

1060V12 <strong>and</strong> G1X-<br />

1060V12) (Optional)<br />

(Alternate)<br />

17b. X-Capacitors (XC1,<br />

XC2) (For Models R1X-<br />

1060V12 <strong>and</strong> G1X-<br />

1060V12) (Optional)<br />

(Alternate)<br />

17c. X-Capacitors (XC1,<br />

XC2) (For Models R1X-<br />

1060V12 <strong>and</strong> G1X-<br />

1060V12) (Optional)<br />

(Alternate)<br />

17d. X-Capacitors (XC1,<br />

XC2) (For Models R1X-<br />

1060V12 <strong>and</strong> G1X-<br />

1060V12) (Optional)<br />

(Alternate)<br />

17e. X-Capacitors (XC1,<br />

XC2) (For Models R1X-<br />

1060V12 <strong>and</strong> G1X-<br />

1060V12) (Optional)<br />

(Alternate)<br />

17f. X-Capacitors (XC1,<br />

XC2) (For Models R1X-<br />

1060V12 <strong>and</strong> G1X-<br />

1060V12) (Optional)<br />

(Alternate)<br />

17g. X-Capacitors (XC1,<br />

XC2) (For Models R1X-<br />

1060V12 <strong>and</strong> G1X-<br />

Manufacturer/<br />

trademark<br />

Pilkor Electronics Co<br />

Ltd<br />

Pilkor Electronics Co<br />

Ltd<br />

Pilkor Electronics Co<br />

Ltd<br />

Kemet Electronics<br />

Italia Srl<br />

Panasonic<br />

<strong>Corp</strong>oration,<br />

Panasonic*<strong>Corp</strong>orati<br />

on Of North America<br />

type/model technical data CCN Marks of<br />

Conformity<br />

PCX2 335 Rated minimum 250 V, maximum 0.1 uF. Marked<br />

with a "X1" or "X2" <strong>and</strong> Certified by VDE, DEMKO<br />

or SEV. (Meets IEC 60384-14)... The damp heat<br />

<strong>test</strong> duration in 21 days minimum.<br />

PCX2 337 Rated minimum 250 V, maximum 0.1 uF. Marked<br />

with a "X1" or "X2" <strong>and</strong> Certified by VDE, DEMKO<br />

or SEV. (Meets IEC 60384-14)... The damp heat<br />

<strong>test</strong> duration in 21 days minimum.<br />

PCX2 339 Rated minimum 250 V, maximum 0.1 uF. Marked<br />

with a "X1" or "X2" <strong>and</strong> Certified by VDE, DEMKO<br />

or SEV. (Meets IEC 60384-14)... The damp heat<br />

<strong>test</strong> duration in 21 days minimum.<br />

R.46#, R.49# Rated minimum 250 V, maximum 0.1 uF. Marked<br />

with a "X1" or "X2" <strong>and</strong> Certified by VDE, DEMKO<br />

or SEV. (Meets IEC 60384-14)... The damp heat<br />

<strong>test</strong> duration in 21 days minimum.<br />

ECQ-UV Rated minimum 250 V, maximum 0.1 uF. Marked<br />

with a "X1" or "X2" <strong>and</strong> Certified by VDE, DEMKO<br />

or SEV. (Meets IEC 60384-14)... The damp heat<br />

<strong>test</strong> duration in 21 days minimum.<br />

ISKRA MIS D D KNB1530 Rated minimum 250 V, maximum 0.1 uF. Marked<br />

with a "X1" or "X2" <strong>and</strong> Certified by VDE, DEMKO<br />

or SEV. (Meets IEC 60384-14)... The damp heat<br />

<strong>test</strong> duration in 21 days minimum.<br />

Okaya Electric<br />

Industries Co Ltd<br />

RE-Series, PA Rated minimum 250 V, maximum 0.1 uF. Marked<br />

with a "X1" or "X2" <strong>and</strong> Certified by VDE, DEMKO<br />

or SEV. (Meets IEC 60384-14)... The damp heat<br />

FOWX2 UL<br />

(E165646)<br />

FOWX2 UL<br />

(E165646)<br />

FOWX2 UL<br />

(E165646)<br />

FOWX2 UL (E97797)<br />

FOWX2 UL (E62674)<br />

FOWX2 UL<br />

(E145156)<br />

FOWX2 UL (E47474)

Issue Date: 2011-05-13 Page 12 of 22 Report Reference # E143756-A100-UL<br />

Object/part or<br />

Description<br />

Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

1060V12) (Optional)<br />

(Alternate)<br />

<strong>test</strong> duration in 21 days minimum.<br />

17h. X-Capacitors (XC1, Ultra <strong>Tech</strong> Xiphi HQX Rated minimum 250 V, maximum 0.1 uF. Marked FOWX2 UL<br />

XC2) (For Models R1X- Enterprise Co Ltd<br />

with a "X1" or "X2" <strong>and</strong> Certified by VDE, DEMKO<br />

(E183780)<br />

1060V12 <strong>and</strong> G1X-<br />

or SEV. (Meets IEC 60384-14)... The damp heat<br />

1060V12) (Optional)<br />

(Alternate)<br />

<strong>test</strong> duration in 21 days minimum.<br />

17i. X-Capacitors (XC1, Carli Electronics Co MPX Rated minimum 250 V, maximum 0.1 uF. Marked FOWX2 UL<br />

XC2) (For Models R1X- Ltd<br />

with a "X1" or "X2" <strong>and</strong> Certified by VDE, DEMKO<br />

(E120045)<br />

1060V12 <strong>and</strong> G1X-<br />

or SEV. (Meets IEC 60384-14)... The damp heat<br />

1060V12) (Optional)<br />

(Alternate)<br />

<strong>test</strong> duration in 21 days minimum.<br />

17j. X-Capacitors (XC1, Pilkor Electronics Co PCX2 335M Rated minimum 250 V, maximum 0.1 uF. Marked FOWX2 UL<br />

XC2) (For Models R1X- Ltd<br />

with a "X1" or "X2" <strong>and</strong> Certified by VDE, DEMKO<br />

(E165646)<br />

1060V12 <strong>and</strong> G1X-<br />

or SEV. (Meets IEC 60384-14)... The damp heat<br />

1060V12) (Optional)<br />

(Alternate)<br />

<strong>test</strong> duration in 21 days minimum.<br />

17k. X-Capacitors (XC1, Shiny Space SX1 Rated minimum 250 V, maximum 0.1 uF. Marked FOWX2 UL<br />

XC2) (For Models R1X- Enterprise Co Ltd<br />

with a "X1" or "X2" <strong>and</strong> Certified by VDE, DEMKO<br />

(E186561)<br />

1060V12 <strong>and</strong> G1X-<br />

or SEV. (Meets IEC 60384-14)... The damp heat<br />

1060V12) (Optional)<br />

(Alternate)<br />

<strong>test</strong> duration in 21 days minimum.<br />

17l. X-Capacitors (XC1, Epcos Electronic B81130 Rated minimum 250 V, maximum 0.1 uF. Marked FOWX2 UL (E97863)<br />

XC2) (For Models R1X- Components S A<br />

with a "X1" or "X2" <strong>and</strong> Certified by VDE, DEMKO<br />

1060V12 <strong>and</strong> G1X-<br />

or SEV. (Meets IEC 60384-14)... The damp heat<br />

1060V12) (Optional)<br />

(Alternate)<br />

<strong>test</strong> duration in 21 days minimum.<br />

18. Bleeder Resistor<br />

(R1, R2) (For Models<br />

R1X-1060V12 <strong>and</strong> G1X-<br />

1060V12)<br />

-- -- SMD Type. Rated 470 k ohm, minimum 1/4 W. -- --<br />

19. Capacitors (XC1,<br />

XC2) (For Model DG1X-<br />

-- -- Rated maximum 2.2 uF, minimum 100 V. -- --

Issue Date: 2011-05-13 Page 13 of 22 Report Reference # E143756-A100-UL<br />

Object/part or<br />

Description<br />

1060V12) (Optional)<br />

20. Bleeder Resistor<br />

(R1, R2) (For Model<br />

DG1X-1060V12)<br />

21. Capacitors (CY1,<br />

CY2, CY5, CY6)<br />

(Optional) (CY5, CY6<br />

only for Model DG1X-<br />

1060V12)<br />

21a. Capacitors (CY1,<br />

CY2, CY5, CY6)<br />

(Optional) (Alternate)<br />

(CY5, CY6 only for<br />

Model DG1X-1060V12)<br />

21b. Capacitors (CY1,<br />

CY2, CY5, CY6)<br />

(Optional) (Alternate)<br />

(CY5, CY6 only for<br />

Model DG1X-1060V12)<br />

21c. Capacitors (CY1,<br />

CY2, CY5, CY6)<br />

(Optional) (Alternate)<br />

(CY5, CY6 only for<br />

Model DG1X-1060V12)<br />

21d. Capacitors (CY1,<br />

CY2, CY5, CY6)<br />

(Optional) (Alternate)<br />

(CY5, CY6 only for<br />

Model DG1X-1060V12)<br />

22. Varistor (VZ1)<br />

(Optional)<br />

22a. Varistor (VZ1)<br />

(Optional) (Alternate)<br />

Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

-- -- SMD Type. Rated 10 k ohm, minimum 1/4 W. -- --<br />

Walsin <strong>Tech</strong>nology<br />

<strong>Corp</strong><br />

AC, AH Rated maximum 2200 pF, minimum 250 Vac.<br />

Marked with an Y1 or Y2 <strong>and</strong> Certified by VDE,<br />

DEMKO or SEV. (Meets IEC60384-14.)<br />

FOWX2 UL<br />

(E146544)<br />

TDK-Epc <strong>Corp</strong> CD, CS Same as above. FOWX2 UL (E37861)<br />

Welson Industrial Co<br />

Ltd<br />

Success Electronics<br />

Co Ltd<br />

WD Same as above. FOWX2 UL<br />

(E104572)<br />

SE Same as above. FOWX2 UL<br />

(E114280)<br />

Murata Mfg Co Ltd KH Same as above. FOWX2 UL (E37921)<br />

EPCOS (ZHUHAI<br />

FTZ) CO LTD<br />

CENTRA SCIENCE<br />

CORP<br />

S14K300 Rated 300 V VZCA2 UL<br />

(E321126)<br />

CNR-14D471K 300 Vac, 385 Vdc. VZCA2 UL

Issue Date: 2011-05-13 Page 14 of 22 Report Reference # E143756-A100-UL<br />

Object/part or<br />

Description<br />

22b. Varistor (VZ1)<br />

(Optional) (Alternate)<br />

22c. Varistor (VZ1)<br />

(Optional) (Alternate)<br />

22d. Varistor (VZ1)<br />

(Optional) (Alternate)<br />

Manufacturer/<br />

trademark<br />

THINKING<br />

ELECTRONIC<br />

INDUSTRIAL CO<br />

LTD<br />

NIPPON CHEMI-<br />

CON CORP<br />

DONGGUAN<br />

LITTELFUSE<br />

ELECTRONICS CO<br />

LTD<br />

EPCOS (ZHUHAI<br />

type/model technical data CCN Marks of<br />

Conformity<br />

TVR14471 300 Vac, 385 Vdc. VZCA2 UL<br />

TND14V471K 300 Vac, 385 Vdc. VZCA2 UL<br />

SAS-471KD14 300 Vac, 385 Vdc. VZCA2 UL<br />

22e. Varistor (VZ1)<br />

SIOV-S14K320 320 Vac, 420 Vdc. VZCA2 UL<br />

(Optional) (Alternate) FTZ) CO LTD<br />

23. Inductor (L1, L2) (L2 -- -- Rated minimum 105 degree C. See Enclosure ID -- --<br />

only for Model R1X-<br />

1060V12 <strong>and</strong> G1X-<br />

1060V12)<br />

4-02 for details.<br />

24. Thermal Cut-out Seki Controls Co Ltd ST-22 Rated 250 V, 1 A. Maximum Operating<br />

XAPX2 UL<br />

(TS1) (Secured on CN3<br />

board) (For Model<br />

DG1X-1060V12)<br />

Temperature 130 degree C.<br />

(E162183)<br />

25. Bridge Rectifier (D1)<br />

(For Model R1X-<br />

1060V12 <strong>and</strong> G1X-<br />

1060V12)<br />

-- -- Rated minimum 4 A, minimum 600 V. -- --<br />

26. B<strong>ul</strong>k Capacitors -- -- Integral pressure relief. Rated minimum 400 V, 68 -- --<br />

(C11, C11A) (For<br />

Models R1X-1060V12<br />

<strong>and</strong> G1X-1060V12)<br />

uF, minimum 105 degree C.<br />

26a. B<strong>ul</strong>k Capacitors -- -- Integral pressure relief. Rated minimum 100 V, 330 -- --<br />

(C11, C11A) (For Model<br />

DG1X-1060V12)<br />

(Alternate)<br />

uF, minimum 105 degree C.<br />

27. Transistors (Q1) (For -- -- Rated 8 A, minimum 600 V. Secured to heat sink -- --

Issue Date: 2011-05-13 Page 15 of 22 Report Reference # E143756-A100-UL<br />

Object/part or<br />

Description<br />

Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

Models R1X-1060V12<br />

<strong>and</strong> G1X-1060V12)<br />

(HS1) by screw.<br />

27a. Transistors (Q1) -- -- Rated 65 A, minimum 200 V. Secured to heat sink -- --<br />

(For Model DG1X-<br />

1060V12) (Alternate)<br />

(HS1) by screw.<br />

28. Heat sink (HS1) -- -- Copper. Secured <strong>and</strong> soldered to PCB. One<br />

overall measured approximately 42.7 by 0.8 by<br />

28.2 mm. (HS1 is primary)<br />

-- --<br />

29. Heat sink (HS2) -- -- Aluminum. Secured to PCB by screws. Overall<br />

measured approximately 37 by 29.3 by 27.9 mm.<br />

(HS2 is secondary)<br />

-- --<br />

30. Transformer (T1) -- -- Open type construction. Core, Ferrite, overall -- --<br />

(For Models R1X-<br />

approximately 29 by 11.3 by 28.7 mm. Coil wound<br />

1060V12 <strong>and</strong> G1X-<br />

on bobbin. See Enclosure ID 4-03 for construction<br />

1060V12)<br />

details.<br />

30a. Transformer (T1) -- -- Open type construction. Core, Ferrite, overall -- --<br />

(For Model DG1X-<br />

approximately 29 by 11.3 by 28.7 mm. Coil wound<br />

1060V12) (Alternate)<br />

on bobbin. See Enclosure ID 4-04 for construction<br />

details.<br />

30-1. Ins<strong>ul</strong>ation system ZHUHAI CHIEF SBI4.2 Class B OBJY2 UL<br />

of Transformer (T1) SUPERIOR<br />

ELECTRONIC CO<br />

LTD<br />

(E342591)<br />

30-2. Bobbin of Sumitomo Bakelite PM-9820 Phenolic. Minimum V-2, minimum 0.71 mm thick, QMFZ2 UL (E41429)<br />

Transformer (T1) Co Ltd<br />

rated 150 degree C.<br />

30-3. Ins<strong>ul</strong>ation Tape of JINGJIANG YAHUA CT Rated 130 degree C. OANZ2 UL<br />

Transformer (T1) PRESSURE<br />

SENSITIVE GLUE<br />

CO LTD<br />

(E165111)<br />

30-4. Tube of<br />

Great Holding TFL Rated 200 degree C. YDPU2 UL<br />

Transformer (T1) Industrial Co Ltd<br />

(E156256)<br />

30-5. Varnish of JOHN C DOLPH CO BC-346A Rated 200 degree C. OBOR2 UL<br />

Transformer (T1)<br />

(E317427)

Issue Date: 2011-05-13 Page 16 of 22 Report Reference # E143756-A100-UL<br />

Object/part or<br />

Description<br />

Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

30-6. Windings of<br />

Transformer (T1)<br />

Various Various Rated minimum 130 degree C. OBMW2 UL<br />

30-7. Triple ins<strong>ul</strong>ation FURUKAWAELECT TEX-E Rated 130 degree C. OBJT2 UL<br />

wire of Transformer (T1) RIC CO.,LTD<br />

(E206440)<br />

30-8. Margin tape of JINGJIANG YAHUA WF Rated 130 degree C. OANZ2 UL<br />

Transformer (T1) PRESSURE<br />

SENSITIVE GLUE<br />

CO LTD<br />

(E165111)<br />

30-1a. Ins<strong>ul</strong>ation system LI CHIEH<br />

HIS-8A Class B OBJY2 UL<br />

of Transformer (T1) ELECTRONIC<br />

INDUSTRIAL CO<br />

LTD<br />

(E183994)<br />

30-2a. Bobbin of Hitachi Chemical Co CP-J-8800 Phenolic. Minimum V-2, minimum 0.71 mm thick, QMFZ2 UL (E59481)<br />

Transformer (T1) Ltd<br />

rated 150 degree C.<br />

30-3a. Ins<strong>ul</strong>ation Tape of 3M Company 1350F-1 Rated 130 degree C. OANZ2 UL (E17385)<br />

Transformer (T1) Electrical Markets Div<br />

(EMD)<br />

30-4a. Tube of<br />

Zeus Industrial TFE-TW-300 Rated 200 degree C. YDPU2 UL<br />

Transformer (T1) Products Inc<br />

(E156256)<br />

30-5a. Varnish of Hitachi Chemical Co WA-238A, Rated minimum 130 degree C. OBOR2 UL (E75225)<br />

Transformer (T1) Ltd<br />

WF-285,<br />

WP-2952F-2G<br />

30-6a. Windings of<br />

Transformer (T1)<br />

Various Various Rated minimum 130 degree C. OBMW2 UL<br />

30-7a. Margin tape of 3M Company #44 Rated 130 degree C. OANZ2 UL (E17385)<br />

Transformer (T1) Electrical Markets Div<br />

(EMD)<br />

31. Bridging Capacitor Walsin <strong>Tech</strong>nology AH Rated maximum 3300 pF, minimum 250 Vac. FOWX2 UL<br />

(CY3) (Optional) (For <strong>Corp</strong><br />

Marked with an Y1 <strong>and</strong> Certified by VDE, DEMKO<br />

Models R1X-1060V12<br />

<strong>and</strong> G1X-1060V12)<br />

or SEV. (Meets IEC60384-14.)<br />

31a. Bridging Capacitor TDK-Epc <strong>Corp</strong> CD Rated maximum 3300 pF, minimum 250 Vac. FOWX2 UL<br />

(CY3) (Optional)<br />

Marked with an Y1 <strong>and</strong> Certified by VDE, DEMKO

Issue Date: 2011-05-13 Page 17 of 22 Report Reference # E143756-A100-UL<br />

Object/part or<br />

Description<br />

Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

(Alternate) or SEV. (Meets IEC60384-14.)<br />

31b. Bridging Capacitor<br />

(CY3) (Optional)<br />

(Alternate)<br />

31c. Bridging Capacitor<br />

(CY3) (Optional)<br />

(Alternate)<br />

31d. Bridging Capacitor<br />

(CY3) (Optional) (For<br />

Model DG1X-1060V12)<br />

31e. Bridging Capacitor<br />

(CY3) (Optional)<br />

(Alternate)<br />

31f. Bridging Capacitor<br />

(CY3) (Optional)<br />

(Alternate)<br />

Welson Industrial Co<br />

Ltd<br />

Success Electronics<br />

Co Ltd<br />

Walsin <strong>Tech</strong>nology<br />

<strong>Corp</strong><br />

WD Rated maximum 3300 pF, minimum 250 Vac.<br />

Marked with an Y1 <strong>and</strong> Certified by VDE, DEMKO<br />

or SEV. (Meets IEC60384-14.)<br />

SE Rated maximum 3300 pF, minimum 250 Vac.<br />

Marked with an Y1 <strong>and</strong> Certified by VDE, DEMKO<br />

or SEV. (Meets IEC60384-14.)<br />

AH Rated maximum 3300 pF, minimum 250 Vac.<br />

Marked with an Y1 <strong>and</strong> Certified by VDE, DEMKO<br />

or SEV. (Meets IEC60384-14.)<br />

TDK-Epc <strong>Corp</strong> CD Rated maximum 3300 pF, minimum 250 Vac.<br />

Marked with an Y1 <strong>and</strong> Certified by VDE, DEMKO<br />

Welson Industrial Co<br />

Ltd<br />

32. Optical Isolators (U1) Vishay Infrared<br />

Components Inc<br />

32a. Optical Isolators<br />

(U1)<br />

32b. Optical Isolators<br />

(U1) (Alternate)<br />

32c. Optical Isolators<br />

(U1) (Alternate)<br />

32d. Optical Isolators<br />

(U1) (Alternate)<br />

Sharp <strong>Corp</strong><br />

Electronic<br />

Components And<br />

Devices Group<br />

Lite-On <strong>Tech</strong>nology<br />

<strong>Corp</strong><br />

Cosmo Electronics<br />

<strong>Corp</strong><br />

Fairchild<br />

Semiconductor <strong>Corp</strong><br />

or SEV. (Meets IEC60384-14.)<br />

WD Rated maximum 3300 pF, minimum 250 Vac.<br />

Marked with an Y1 <strong>and</strong> Certified by VDE, DEMKO<br />

SFH61, may be<br />

followed by<br />

additional letters<br />

<strong>and</strong> numbers.<br />

or SEV. (Meets IEC60384-14.)<br />

Double protection optical isolator, providing 4420<br />

Vac isolation.<br />

PC123 Double protection optical isolated switches,<br />

providing 3750 Vac<br />

FOWX2 UL<br />

FOWX2 UL<br />

FOWX2 UL<br />

(E146544)<br />

FOWX2 UL<br />

FOWX2 UL<br />

(E104572)<br />

FPQU2 UL<br />

FPQU2 UL<br />

LTV-357 series Double protection optical isolators having an<br />

isolation voltage of 3750 Vrms.<br />

FPQU2 UL<br />

KPC452,<br />

KPC357NT,<br />

KPC355NT,<br />

KPC354NT.<br />

Optical isolator providing 3750 V ac isolation. FPQU2 UL<br />

CNY17-1,<br />

CNY17-2,<br />

CNY17-3,<br />

Optical isolators, providing 5000 V ac isolation. FPQU2 UL (E90700)

Issue Date: 2011-05-13 Page 18 of 22 Report Reference # E143756-A100-UL<br />

Object/part or<br />

Description<br />

32e. Optical Isolators<br />

(U1) (Alternate)<br />

32f. Optical Isolators<br />

(U1) (Alternate)<br />

32g. Optical Isolators<br />

(U1) (Alternate)<br />

32h. Optical Isolators<br />

(U1) (Alternate)<br />

32i. Optical Isolators<br />

(U1) (Alternate)<br />

33. Ins<strong>ul</strong>ation Tubing /<br />

Sleeving<br />

Manufacturer/<br />

trademark<br />

Vishay<br />

Semiconductor<br />

Gmbh<br />

Cosmo Electronics<br />

<strong>Corp</strong><br />

NEC Electronics<br />

<strong>Corp</strong> Compound<br />

Semiconductor<br />

Device Div<br />

Lite-On <strong>Tech</strong>nology<br />

<strong>Corp</strong><br />

NEC Electronics<br />

<strong>Corp</strong> Compound<br />

Semiconductor<br />

Device Div<br />

type/model technical data CCN Marks of<br />

Conformity<br />

CNY17-4<br />

TCLT1008,<br />

TCLT1006<br />

Double Protection, provides 5000 Vac isolation. FPQU2 UL (E76222)<br />

K1010 Rated Isolation minimum 5000 V ac. FPQU2 UL<br />

PS 2561 series Rated Isolation minimum 5000 V ac. FPQU2 UL<br />

LTV-817 Rated Isolation minimum 5000 V ac. FPQU2 UL<br />

PS 2501 series Rated Isolation minimum 5000 V ac. FPQU2 UL<br />

Various Various FEP, PTFE, PVC, TFE, neoprene, polyimide or<br />

marked VW-1; minimum 105 degree C, minimum<br />

300 V. Provided on LED wire, minimum 0.4 mm<br />

thick.<br />

UZFT2, YDPU2,<br />

YDRY2, YDTU2<br />

34. Thermal Pad Various Various Minimum V-2. QMFZ2 UL<br />

Redundant Power <strong>Zippy</strong> <strong>Tech</strong>nology R1X2-1060V12, Consist of the following critical parts. -- --<br />

Supply<br />

<strong>Corp</strong><br />

G1X2-1060V12,<br />

G1X2-5060V,<br />

DG1X2-1060V12,<br />

DG1X2-5060V<br />

01. Chassis Various Various Metal (Nickel plated steel). Overall measured<br />

approximately 190 by 106 by 39.5 mm, minimum<br />

1.0 mm thick. Consists of the following ventilation<br />

openings: a. Right side - Provided with numerous<br />

openings,<br />

Provide with 18 slots ventilation openings each<br />

measured 15 by 3 mm. <strong>and</strong> Provided with 2 slots<br />

-- --<br />

UL

Issue Date: 2011-05-13 Page 19 of 22 Report Reference # E143756-A100-UL<br />

Object/part or<br />

Description<br />

Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

ventilation openings each measured 10 by 3 mm<br />

<strong>and</strong> Provided with 1 slots ventilation openings each<br />

measured 20 by 11 mm <strong>and</strong> Provided with 1 slots<br />

ventilation openings each measured 20 by 25 mm<br />

<strong>and</strong> Provided with 1 slots ventilation openings each<br />

measured 32 by 20 mm;<br />

b. Left side - Provided with numerous openings,<br />

Provide with 18 slots ventilation openings each<br />

measured 15 by 3 mm. <strong>and</strong> Provided with 2 slots<br />

ventilation openings each measured 10 by 3 mm<br />

<strong>and</strong> Provided with 2 slots ventilation openings each<br />

measured 20 by 25 mm <strong>and</strong> Provided with 1 slots<br />

ventilation openings each measured 25 by 15 mm<br />

<strong>and</strong> Provided with 1 slots ventilation openings each<br />

measured 32 by 15 mm; c. Top side - Provided with<br />

numerous openings, Provide with 4 slots ventilation<br />

openings each measured 42.5 by 25 mm. <strong>and</strong><br />

Provided with 2 slots ventilation openings each<br />

measured 31 by 25 mm <strong>and</strong> Provided with 1 slots<br />

ventilation openings each measured 91 by 12 mm<br />

d. Rear side - Provided with numerous openings,<br />

Provide with 8 slots ventilation openings each<br />

measured 10 by 3 mm.<br />

02. Label Various Various Rated minimum 70 degree C, suitable for surface<br />

03. Printed Wiring<br />

Boards<br />

04. Connectors (CN1,<br />

CN2) (For power mod<strong>ul</strong>e<br />

connection.)<br />

05. Secondary output<br />

Wiring<br />

applied to top chassis.<br />

Various Various Rated minimum V-1, minimum 130 degree C.<br />

Secured to Redundant Chassis by screws <strong>and</strong><br />

contain with daughter boards.<br />

Various Various Copper alloy pins housed in bodies of plastic min.<br />

rated V-2.<br />

Various Various (Secondary) Low voltage secondary (SEC, ELV,<br />

SELV), rated minimum 80 degree C, minimum 30<br />

V, FEP, PTFE, PVC, TFE, neoprene, or surface<br />

PGDQ2 or PGJI2 UL<br />

ZPMV2 UL<br />

QMFZ2 UL<br />

AVLV2 UL

Issue Date: 2011-05-13 Page 20 of 22 Report Reference # E143756-A100-UL<br />

Object/part or<br />

Description<br />

06. Connectors <strong>and</strong><br />

Receptacles (secondary<br />

ELV/SELV circuits)<br />

06a. Connectors <strong>and</strong><br />

Receptacles (secondary<br />

ELV/SELV circuits)<br />

(Alternate)<br />

Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

Various Various<br />

marked VW-1.<br />

Copper alloy pins housed in bodies of plastic rated<br />

V-2 minimum.<br />

QMFZ2 UL<br />

-- -- -- ECBT2, RTRT2 UL

Issue Date: 2011-05-13 Page 21 of 22 Report Reference # E143756-A100-UL<br />

Type Supplement Id Description<br />

Enclosures<br />

Photographs 3-01 External view_1 for Models R1X-1060V12, G1X-1060V12<br />

Photographs 3-02 External view_2 for Models R1X-1060V12, G1X-1060V12<br />

Photographs 3-03 Component side-with case for Models R1X-1060V12, G1X-<br />

1060V12<br />

Photographs 3-04 Component side for Models R1X-1060V12, G1X-1060V12<br />

Photographs 3-05 Solder side for Models R1X-1060V12, G1X-1060V12<br />

Photographs 3-06 External view for model G1X2-5060V_1<br />

Photographs 3-07 External view for model G1X2-5060V_2<br />

Photographs 3-08 External view_R1X2-1060V12 <strong>and</strong> G1X2-1060V12_1<br />

Photographs 3-09 External view_R1X2-1060V12 <strong>and</strong> G1X2-1060V12_2<br />

Photographs 3-10 External view_1 for Model DG1X-1060V12<br />

Photographs 3-11 External view_2 for Model DG1X-1060V12<br />

Photographs 3-12 Component side-with case for Model DG1X-1060V12<br />

Photographs 3-13 Component side for Model DG1X-1060V12<br />

Photographs 3-14 Solder side for Model DG1X-1060V12<br />

Photographs 3-15 External for model DG1X2-5060V_1<br />

Photographs 3-16 External for model DG1X2-5060V_2<br />

Photographs 3-17 Redundant backboard - component side for Models R1X2-<br />

1060V12, G1X2-1060V12, DG1X2-1060V12<br />

Photographs 3-18 Redundant backboard - solder side for Models R1X2-1060V12,<br />

G1X2-1060V12, DG1X2-1060V12<br />

Photographs 3-19 Redundant backboard - component side for Models R1X2-<br />

1060V12, G1X2-1060V12, DG1X2-1060V12<br />

Photographs 3-20 Redundant backboard - solder side for Models R1X2-1060V12,<br />

G1X2-1060V12, DG1X2-1060V12<br />

Diagrams 4-01 Ins<strong>ul</strong>ation sheet<br />

Diagrams 4-02 L2 SPEC<br />

Diagrams 4-03 T1 for Models R1X-1060V12, G1X-1060V12<br />

Diagrams 4-04 T1 for Model DG1X-1060V12<br />

Schematics + PWB 5-01 Layout for models DG1X series<br />

Schematics + PWB 5-02 Layout for models R1X <strong>and</strong> G1X series<br />

Manuals<br />

Miscellaneous 7-01 Input <strong>and</strong> output rating<br />

Miscellaneous 7-02 Additional <strong>test</strong> tables

File E143756 Vol. X1 Sec. A100 PHO-01 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-02 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-03 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-04 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-05 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-06 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-07 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-08 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-09 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-10 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-11 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-12 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-13 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-14 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-15 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-16 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-17 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-18 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-19 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 PHO-20 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 DIA-01 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 DIA-02(Page 1)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 DIA-02(Page 2)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 DIA-03(Page 1)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 DIA-03(Page 2)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 DIA-04(Page 1)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 DIA-04(Page 2)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 SCH-01(Page 1)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 SCH-01(Page 2)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 SCH-01(Page 3)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 SCH-01(Page 4)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 SCH-02(Page 1)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 SCH-02(Page 2)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 SCH-02(Page 3)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 SCH-02(Page 4)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 MIS-01 Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 MIS-02(Page 1)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 MIS-02(Page 2)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 MIS-02(Page 3)Issued: 2011-05-13

File E143756 Vol. X1 Sec. A100 MIS-02(Page 4)Issued: 2011-05-13

Issue Date: 2011-05-13 Page 1 of 3 Report Reference # E143756-A100-UL<br />

Test Record No. 1<br />

Test Record<br />

The manufacturer submitted representative production samples of Redundant Power Supply <strong>and</strong> Power<br />

Mod<strong>ul</strong>es, Models R1X-1060V12, G1X-1060V12, DG1X-1060V12, R1X2-1060V12, G1X2-1060V12,<br />

G1X2-5060V, DG1X2-1060V12 <strong>and</strong> DG1X2-5060V for <strong>test</strong>ing under Project 11CA18715. The noted <strong>test</strong>s<br />

were conducted in accordance with the St<strong>and</strong>ard for Safety of Information <strong>Tech</strong>nology Equipment, UL<br />

60950-1, Second Edition / CAN/CSA C22.2 No. 60950-1-07, Second Edition by Superior Product Cons<strong>ul</strong>ting<br />

(SPC), Taipei, Taiwan under TPTDP.<br />

The <strong>test</strong> methods <strong>and</strong> res<strong>ul</strong>ts of the noted <strong>test</strong>s have been reviewed <strong>and</strong> found to be in accordance with the<br />

requirements in the St<strong>and</strong>ards noted above. Test res<strong>ul</strong>ts are valid only for the <strong>test</strong>ed equipment.<br />

Unless otherwise indicated, all <strong>test</strong>s were conducted on Models R1X-1060V12, DG1X-1060V12,<br />

R1X2-1060V12, G1X2-5060V, DG1X2-1060V12, DG1X2-5060V <strong>and</strong> are considered to be representative of<br />

Models G1X-1060V12 <strong>and</strong> G1X2-1060V12.

Issue Date: 2011-05-13 Page 2 of 3 Report Reference # E143756-A100-UL<br />

The following <strong>test</strong>s were conducted:<br />

Test Record<br />

Test Testing Location/Comments<br />

End Product Reference Page<br />

General Guidelines<br />

Power Supply Reference Page<br />

Maximum Output Voltage, Current, <strong>and</strong> Volt-Ampere Measurement<br />

(1.2.2.1)<br />

Input: Single-Phase (1.6.2)<br />

Energy Hazard Measurements (2.1.1.5, 2.1.2, 1.2.8.10)<br />

Capacitance Discharge (2.1.1.7)<br />

Energy Hazard Measurements - DC Mains Supplies (2.1.1.8)<br />

SELV Reliability (2.2.2, 2.2.3, 2.2.4, Part 22 6.1)<br />

Limited Current Circuit Measurement (2.4.1, 2.4.2)<br />

Protective Bonding II (2.6.3.4, 2.6.1)<br />

Humidity (2.9.1, 2.9.2, 5.2.2)<br />

Determination of Working Voltage; Working Voltage Measurement<br />

(2.10.2)<br />

Determination of Working Voltage; Hazardous Voltage (Circuit)<br />

Measurement (2.10.2, Part 22 6.1)<br />

Thin Sheet Material (2.10.5.9, 2.10.5.10, 2.10.5.6)<br />

Transformer <strong>and</strong> Wire /Ins<strong>ul</strong>ation Electric Strength (2.10.5.13)<br />

Steady Force (4.2.1 - 4.2.4)<br />

Impact (4.2.5, 4.2.1, Part 22 10.2)<br />

Connector Current Interruption (4.3.5)<br />

Heating (4.5.1, 1.4.12, 1.4.13)<br />

Ball Pressure (4.5.5, 4.5)<br />

Touch Current (Single-Phase; TN/TT System) (5.1, Annex D)<br />

Electric Strength (5.2.2)<br />

Component Failure (5.3.1, 5.3.4, 5.3.7)<br />

Abnormal Operation (5.3.1 - 5.3.9)<br />

Transformer Abnormal Operation (5.3.3, 5.3.7b, Annex C.1)<br />

Power Supply Output Short-Circuit/Overload (5.3.7)<br />

Test res<strong>ul</strong>ts are valid only for the <strong>test</strong>ed equipment. These <strong>test</strong>s are considered representative of the products<br />

covered by this Test Report. The <strong>test</strong> methods <strong>and</strong> res<strong>ul</strong>ts of the above <strong>test</strong>s have been reviewed <strong>and</strong> found to<br />

be in accordance with the requirements in the St<strong>and</strong>ard(s) referenced at the beginning of this Test Report.

Issue Date: 2011-05-13 Page 3 of 3 Report Reference # E143756-A100-UL<br />

Test Record<br />

The following supplements are provided as a part of this Test Record. NOTE: These supplements are only<br />

available to the Applicant via the CDA system.<br />

Type Supplement Id Description<br />

Datasheet 2-01 Datasheets - 11CA18715