UL TEST REPORT AND PROCEDURE - ZIPPY

UL TEST REPORT AND PROCEDURE - ZIPPY

UL TEST REPORT AND PROCEDURE - ZIPPY

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

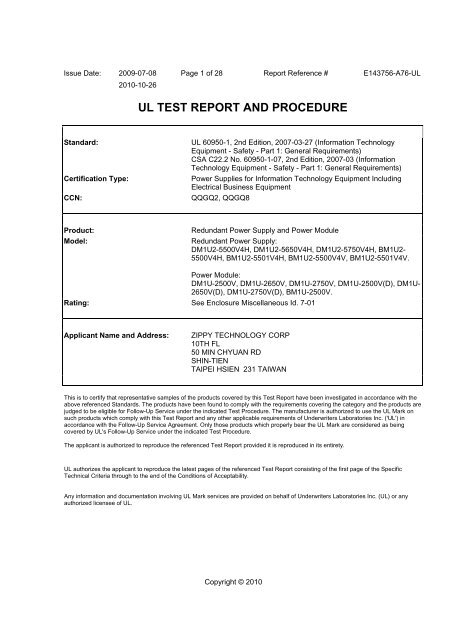

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 1 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

<strong>UL</strong> <strong>TEST</strong> <strong>REPORT</strong> <strong>AND</strong> <strong>PROCEDURE</strong><br />

Standard: <strong>UL</strong> 60950-1, 2nd Edition, 2007-03-27 (Information Technology<br />

Equipment - Safety - Part 1: General Requirements)<br />

CSA C22.2 No. 60950-1-07, 2nd Edition, 2007-03 (Information<br />

Technology Equipment - Safety - Part 1: General Requirements)<br />

Certification Type: Power Supplies for Information Technology Equipment Including<br />

Electrical Business Equipment<br />

CCN: QQGQ2, QQGQ8<br />

Product: Redundant Power Supply and Power Module<br />

Model: Redundant Power Supply:<br />

DM1U2-5500V4H, DM1U2-5650V4H, DM1U2-5750V4H, BM1U2-<br />

5500V4H, BM1U2-5501V4H, BM1U2-5500V4V, BM1U2-5501V4V.<br />

Power Module:<br />

DM1U-2500V, DM1U-2650V, DM1U-2750V, DM1U-2500V(D), DM1U-<br />

2650V(D), DM1U-2750V(D), BM1U-2500V.<br />

Rating: See Enclosure Miscellaneous Id. 7-01<br />

Applicant Name and Address: <strong>ZIPPY</strong> TECHNOLOGY CORP<br />

10TH FL<br />

50 MIN CHYUAN RD<br />

SHIN-TIEN<br />

TAIPEI HSIEN 231 TAIWAN<br />

This is to certify that representative samples of the products covered by this Test Report have been investigated in accordance with the<br />

above referenced Standards. The products have been found to comply with the requirements covering the category and the products are<br />

judged to be eligible for Follow-Up Service under the indicated Test Procedure. The manufacturer is authorized to use the <strong>UL</strong> Mark on<br />

such products which comply with this Test Report and any other applicable requirements of Underwriters Laboratories Inc. ('<strong>UL</strong>') in<br />

accordance with the Follow-Up Service Agreement. Only those products which properly bear the <strong>UL</strong> Mark are considered as being<br />

covered by <strong>UL</strong>'s Follow-Up Service under the indicated Test Procedure.<br />

The applicant is authorized to reproduce the referenced Test Report provided it is reproduced in its entirety.<br />

<strong>UL</strong> authorizes the applicant to reproduce the latest pages of the referenced Test Report consisting of the first page of the Specific<br />

Technical Criteria through to the end of the Conditions of Acceptability.<br />

Any information and documentation involving <strong>UL</strong> Mark services are provided on behalf of Underwriters Laboratories Inc. (<strong>UL</strong>) or any<br />

authorized licensee of <strong>UL</strong>.<br />

Copyright © 2010

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 2 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Terence She<br />

Prepared by: Underwriters Laboratories Inc.<br />

Rex Lin<br />

Reviewed by: Underwriters Laboratories Inc.<br />

Copyright © 2010

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 3 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Supporting Documentation<br />

The following documents located at the beginning of this Procedure supplement the requirements of this Test<br />

Report:<br />

A. Authorization - The Authorization page may include additional Factory Identification Code markings.<br />

B. Generic Inspection Instructions -<br />

i. Part AC details important information which may be applicable to products covered by this Procedure.<br />

Products described in this Test Report must comply with any applicable items listed unless otherwise<br />

stated in the body of this Test Report.<br />

ii. Part AE details any requirements which may be applicable to all products covered by this Procedure.<br />

Products described in this Test Report must comply with any applicable items listed unless otherwise<br />

stated in the body of each Test Report.<br />

iii. Part AF details the requirements for the <strong>UL</strong> Certification Mark which is not controlled by the technical<br />

standard used to investigate these products. Products are permitted to bear only the Certification<br />

Mark(s) corresponding to the countries for which it is certified, as indicated in each Test Report.<br />

Product Description<br />

Power Module: The product are composed of DC fan, power supply board and housed in metal chassis.<br />

Redundant Power Supply:<br />

The product is a 1+1 hot-swappable / hot-pluggable DC to DC Power Supply for using in Information<br />

Technology Equipment (ITE).<br />

Model Differences<br />

Models DM1U-2500V, DM1U-2650V, DM1U-2750V, DM1U-2500V(D), DM1U-2650V(D), DM1U-2750V(D),<br />

BM1U-2500V are Power Modules, which are similar mutually except for input/output ratings and model<br />

designation. See Enclosure Miscellaneous Id. 7-01 in detail.<br />

Models DM1U2-5500V4H, DM1U2-5650V4H, DM1U2-5750V4H, BM1U2-5500V4H, BM1U2-5501V4H,<br />

BM1U2-5500V4V, BM1U2-5501V4V are Redundant Power Supply, which are similar mutually except for<br />

input/output ratings and model designation. See Enclosure Miscellaneous Id. 7-01 in detail.<br />

Model BM1U-2500V is similar Model DM1U-2500V, except for input ratings, EMI board, L3, L4, T2, T4,<br />

schematic and PCB layout, front chassis and model designation.<br />

Model BM1U2-5501V4H is similar Model BM1U2-5500V4H, except for output ratings and model designation.<br />

Model BM1U2-5500V4H is similar Model DM1U2-5500V4H, except for input rating, backboard and model<br />

designation.<br />

Output Type of Power Module:<br />

(1) Connector for Models DM1U-2500V, DM1U-2650V, DM1U-2750V, BM1U-2500V. Refer to Enclosure Id<br />

3-03.<br />

(2) Wires with connectors for Models DM1U-2500V(D), DM1U-2650V(D), DM1U-2750V(D). Refer to<br />

Enclosure Id 3-06.<br />

Model nomenclature for Power Module:<br />

- The capital "D" and "B" of "DM1U-" and "BM1U-", which denotes DC input;<br />

- The numerical "2" of "DM1U-2500V" and "BM1U-2500V", which denotes 2 outputs;<br />

- The numerical "650" of "DM1U-2650V", which denotes total maximum output power consumption (ex. 650<br />

Watt);<br />

- The numerical "750" of "DM1U-2750V", which denotes total maximum output power consumption (ex. 750

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 4 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Watt).<br />

All Redundant Power Supply Models are composed of 2 Power Modules maximum, only Models DM1U-<br />

2500V, DM1U-2650V, DM1U-2750V, BM1U-2500V used.<br />

Model nomenclature for Redundant Power Supply:<br />

- The numerical "2" of "DM1U2-", which means 1+1 Redundant Power Supply.<br />

- The numerical "5" of "DM1U2-5", which denotes 5 outputs;<br />

- The numerical "500" of "DM1U2-5500", which denotes total maximum output power consumption (ex. 500<br />

Watt), and composed of 2 Power Modules Model DM1U-2500V maximum;<br />

- The numerical "650" of "DM1U2-5650", which denotes total maximum output power consumption (ex. 650<br />

Watt), and composed of 2 Power Modules Model DM1U-2650V maximum;<br />

- The numerical "750" of "DM1U2-5750", which denotes total maximum output power consumption (ex. 750<br />

Watt), and composed of 2 Power Modules Model DM1U-2750V maximum;<br />

- The last letter"H" denotes Power Module arrange horizontally;<br />

- The last letter"V" denotes Power Module arrange vertically.<br />

Technical Considerations<br />

Equipment mobility : for building-in<br />

Connection to the mains : To be evaluated in end product<br />

Operating condition : continuous<br />

Access location : N/A<br />

Over voltage category (OVC) : --<br />

Mains supply tolerance (%) or absolute mains supply values : no tolerance declared by manufacturer<br />

Tested for IT power systems : No<br />

IT testing, phase-phase voltage (V) : --<br />

Class of equipment : Class I (earthed)<br />

Considered current rating (A) : 20 A<br />

Pollution degree (PD) : PD 2<br />

IP protection class : IP X0<br />

Altitude of operation (m) : up to 3100 m

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 5 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Altitude of test laboratory (m) : up to 3100 m<br />

Mass of equipment (kg) : 1 kg (For Models DM1U-2500V, DM1U-2650V, DM1U-2750V, DM1U-<br />

2500V(D), DM1U-2650V(D), DM1U-2750V(D)); 3 kg (For Models DM1U2-5500V4H, DM1U2-<br />

5650V4H, DM1U2-5750V4H); 3.1 kg for Models BM1U2-5500V4H, BM1U2-5501V4H; 3.8 kg for<br />

Models BM1U2-5500V4V, BM1U2-5501V4V.<br />

The product was submitted and evaluated for use at the maximum ambient temperature (Tma)<br />

permitted by the manufacturer’s specification of: (1) 35 degree C for Models DM1U2-5750V4H,<br />

DM1U-2750V, DM1U-2750V(D); (2) 50 degree C for Models DM1U2-5650V4H, DM1U2-5500V4H,<br />

DM1U-2650V, DM1U-2650V(D), DM1U-2500V, DM1U-2500V(D), BM1U-2500V, BM1U2-5500V4H,<br />

BM1U2-5501V4H, BM1U2-5500V4V, BM1U2-5501V4V.<br />

The product is intended for use on the following power systems: DC mains supply<br />

The following are available from the Applicant upon request: Installation (Safety) Instructions /<br />

Manual. , Specific data sheets for LED indicators that are class I and operate at wavelength in the<br />

400-710 nm range.<br />

An investigation of the protective bonding terminals has been conducted 40 A specified by the<br />

manufacturer.<br />

Engineering Conditions of Acceptability<br />

For use only in or with complete equipment where the acceptability of the combination is determined by<br />

Underwriters Laboratories Inc. When installed in an end-product, consideration must be given to the<br />

following:<br />

The end-product Electric Strength Test is to be based upon a maximum working voltage of: Input -<br />

Output: 99 Vrms, 176 Vpk<br />

The following secondary output circuits are SELV: All outputs.<br />

The following secondary output circuits are at hazardous energy levels: +12 Vdc output of all models<br />

The following secondary output circuits are at non-hazardous energy levels: All outputs except for<br />

+12 Vdc of all models<br />

The following output terminals were referenced to earth during performance testing: Input (0V) and<br />

Output common return<br />

The power supply terminals and/or connectors are: Suitable for factory wiring only<br />

The investigated Pollution Degree is: 2

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 6 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Proper bonding to the end-product main protective earthing termination is: Required<br />

An investigation of the protective bonding terminals has: Been conducted<br />

The following magnetic devices (e.g. transformers or inductor) are provided with an OBJY2 insulation<br />

system with the indicated rating greater than Class A (105°C): Transformer T4 and T2 (Class B)<br />

The following end-product enclosures are required: Mechanical, Fire, Electrical<br />

The following input terminals were evaluated as suitable for direct connection to the DC Mains<br />

Supply: Input connector or terminal block.<br />

The equipment is suitable for direct connection to: DC mains supply<br />

The product was investigated to the following additional standards: IEC 60664-1: 2007 clearance<br />

requirements for 3100 m above sea level. The required clearance is multiplied by the altitude<br />

correction factor (1.155), as specified in Table A.2.<br />

The power supply is expected to use in hot-swappable condition and clause 4.3.5 Connector Current<br />

Interruption Test has been conducted.<br />

The power supply with internal insulation serving as Reinforced/Double insulation between input and<br />

output cirucit.<br />

Protective Current Rating of the power supply was 16A/20A as specified by the manufacturer.<br />

An investigation of the protective bonding terminals has been conducted 40 A specified by the<br />

manufacturer.<br />

Additional Information<br />

Air flow of DC fan may be used inward or outward.<br />

Markings and instructions<br />

Clause Title Marking or Instruction Details<br />

Power rating - Ratings<br />

Power rating -<br />

Company identification<br />

Model<br />

Power rating -<br />

Ratings (voltage, frequency/dc, current)<br />

Listee's or Recognized company's name, Trade Name, Trademark or File<br />

Number<br />

Model Number

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 7 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Fuses - Rating<br />

1.7.9 Multiple power<br />

sources<br />

Special Instructions to <strong>UL</strong> Representative<br />

Rated current and voltage and type located on or adjacent to fuse or<br />

fuseholder.<br />

Following statement indicated on redundant units.<br />

Warning: Multiple power sources. Refer to service manual before servicing.<br />

Following statement included in service manual.<br />

Redundant power supplies are provided with more than one power source.<br />

Disconnect one power supply cord and pull out this power module when just a<br />

single power module has failed and servicing and maintaining that module.<br />

Disconnect all power supply cords before servicing the complete unit if whole<br />

redundant unit servicing is necessary.<br />

Inspect the transformer(s) listed in BD1.1 per AA1.1- (C). When the tests are conducted at other location,<br />

inspect test record and specification sheet provided by the component manufacturer. Verify the specification<br />

sheet indicates 100% routine test specified in BD1.1 be conducted at the component manufacturer.<br />

Production-Line Testing Requirements<br />

Electric Strength Test Special Constructions - Refer to Generic Inspection Instructions, Part AC for<br />

further information.<br />

Model Component<br />

All models Transformer T2,<br />

T4<br />

Removable<br />

Parts Test probe location<br />

-- Input winding - Output<br />

winding<br />

V<br />

rms V dc<br />

Earthing Continuity Test Exemptions - This test is not required for the following models:<br />

All models.<br />

Electric Strength Test Exemptions - This test is not required for the following models:<br />

All models.<br />

200<br />

0<br />

Test Time,<br />

s<br />

-- 1<br />

Electric Strength Test Component Exemptions - The following solid-state components may be<br />

disconnected from the remainder of the circuitry during the performance of this test:<br />

--<br />

Sample and Test Specifics for Follow-Up Tests at <strong>UL</strong><br />

Model Component Material Test Sample(s)<br />

-- -- -- -- -- --<br />

Test<br />

Specifics

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 8 of 28 Report Reference # E143756-A76-<strong>UL</strong>

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 9 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

TABLE: List of Critical Components<br />

Object/part No. Manufacturer/<br />

trademark<br />

Redundant Power<br />

Supply<br />

Zippy Technology<br />

Corp.<br />

type/model technical data CCN Marks of<br />

Conformity<br />

DM1U2-5500V4H,<br />

DM1U2-5650V4H,<br />

DM1U2-5750V4H,<br />

BM1U2-5500V4H,<br />

BM1U2-5501V4H,<br />

BM1U2-5500V4V,<br />

BM1U2-5501V4V<br />

Consist of the following critical parts. -- --<br />

01. Redundant Chassis -- -- Metal (Nickel Plated Iron), secured together by<br />

screws. Overall approximately 355 by 106 by 41<br />

mm, minimum 0.9 mm thick. Can be provided with<br />

maximum two Power Modules. Provide with<br />

several slot ventilation openings on both side, each<br />

approximately maximum 25 by 3 mm; provide with<br />

several slot ventilation openings on top, each<br />

approximately maximum 25 by 3 mm; and 12.3 by<br />

103 mm.<br />

02. Rating Marking - Various Various Rated minimum 65 degree C, suitable for surface<br />

Label<br />

applied to chassis.<br />

-- --<br />

PGDQ2 or PGJI2 <strong>UL</strong><br />

03. Output Wires Various Various Secondary Wiring, Low voltage secondary (SEC,<br />

ELV, SELV), rated minimum 80 degree C, minimum<br />

30 V, minimum 18 AWG, FEP, PTFE, PVC, TFE,<br />

neoprene, or surface marked VW-1.<br />

AVLV2 <strong>UL</strong><br />

04. Printed Wiring<br />

Boards (Secondary Back<br />

Board)<br />

Various Various Rated minimum V-1, minimum 105 degree C. ZPMV2 <strong>UL</strong><br />

05. Connectors (CN5, Positronic Industries GFSH89F4 Mounted on Back Board, mated with output ECBT2 <strong>UL</strong><br />

CN6)<br />

Inc<br />

connector of Power Module. Rated 250V, 16A.<br />

er Module Zippy Technology DM1U-2500V, Consist of the following critical parts. -- --<br />

Corp.<br />

DM1U-2650V,<br />

DM1U-2750V,<br />

DM1U-2500V(D),<br />

DM1U-2650V(D),

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 10 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Object/part No. Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

01. Chassis (For Input --<br />

DM1U-2750V(D),<br />

BM1U-2500V<br />

-- Metal (Nickel Plated Iron and Aluminum<br />

-- --<br />

Connector Type) (For<br />

Magnesium alloy). Three pieces construction and<br />

Models DM1U-2500V,<br />

secured together by screws. Overall approximately<br />

DM1U-2650V, DM1U-<br />

300 by 50.5 by 40 mm, minimum 0.9 mm thick.<br />

2750V, DM1U-<br />

Provide with 2 slot ventilation openings on top,<br />

2500V(D), DM1U-<br />

each approximately 15 by 3 mm; provide with 23<br />

2650V(D), DM1U-<br />

ventilation openings on front (input / fan side), each<br />

2750V(D))<br />

maximum 9 by 4.5 mm.<br />

01a. Chassis (For Input -- -- Metal (Nickel Plated Iron and Aluminum<br />

-- --<br />

Terminal Block Type)<br />

Magnesium alloy). Three pieces construction and<br />

(For Models DM1U-<br />

secured together by screws. Overall approximately<br />

2500V, DM1U-2650V,<br />

300 by 50.5 by 40 mm, minimum 0.9 mm thick.<br />

DM1U-2750V, DM1U-<br />

Provide with 2 slot ventilation openings on top,<br />

2500V(D), DM1U-<br />

each approximately 15 by 3 mm; provide with 23<br />

2650V(D), DM1U-<br />

ventilation openings on front (input / fan side), each<br />

2750V(D))<br />

maximum 6 by 4.0 mm.<br />

02. Rating Marking - Various Various Rated minimum 65 degree C, suitable for surface PGDQ2 or PGJI2 <strong>UL</strong><br />

Label<br />

applied to chassis.<br />

03. Handle -- -- Plastic, U-shaped. Rated minimum HB, minimum<br />

85 degree C. Overall approximate 37.5 by 25 mm,<br />

5.5 mm diameter. Secured to front chassis by<br />

screws.<br />

QMFZ2 <strong>UL</strong><br />

04. Earth Screw (For -- -- Metal. Minimum 4 mm diameter (M4 size). -- --<br />

Input Terminal Block<br />

Type)<br />

Secured to front chassis with washer.<br />

05. DC Fan (Airflow can Sanyo Denki Co Ltd 9GV0412P3Jxxy One provided. Rated 12 Vdc, 0.6 A, minimum GPWV2 <strong>UL</strong><br />

be inward or outward)<br />

(xx = 00 to 99) (y 20.84 CFM. Secured to front chassis by screw,<br />

(For Models DM1U-<br />

= blank or 1) fans leads provided with Insulating Tubing /<br />

2500V, DM1U-2650V,<br />

DM1U-2750V, DM1U-<br />

2500V(D), DM1U-<br />

Sleeving, minimum 0.4 mm thick.

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 11 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Object/part No. Manufacturer/<br />

trademark<br />

2650V(D), DM1U-<br />

2750V(D))<br />

05a. DC Fan (Airflow<br />

can be inward or<br />

outward) (Alternate)<br />

05b. DC Fan (Airflow<br />

can be inward or<br />

outward) (Alternate)<br />

05c. DC Fan (Airflow can<br />

be inward or outward)<br />

(Alternate)<br />

05d. DC Fan (Airflow<br />

can be inward or<br />

outward) (Alternate)<br />

05e. DC Fan (Airflow<br />

can be inward or<br />

outward) (Alternate)<br />

06. Input Terminal Block<br />

(For Models DM1U-<br />

2500V, DM1U-2650V,<br />

DM1U-2750V, DM1U-<br />

2500V(D), DM1U-<br />

2650V(D), DM1U-<br />

2750V(D))<br />

06a. Input Terminal<br />

Block (For Models<br />

DM1U-2500V, DM1U-<br />

2650V, DM1U-2750V,<br />

Sanyo Denki Co Ltd 9GV0412P3Kxxy<br />

(xx = 00 to 99) (y<br />

= blank or 1)<br />

Sanyo Denki Co Ltd 9GV0412K3DXXy<br />

*(xx = 00 to 99)*(y<br />

= blank or 1)<br />

ADDA Corp AD0412VB-<br />

B53DS<br />

Sunonwealth Electric<br />

Machine Industry Co<br />

Ltd<br />

Sanyo Denki Co Ltd 9GE0412P3Jxx<br />

(xx = 01 to 99)<br />

Dinkle Enterprise Co<br />

Ltd<br />

Howder Electric Co<br />

Ltd<br />

type/model technical data CCN Marks of<br />

Conformity<br />

One provided. Rated 12 Vdc, 0.84 A, minimum<br />

23.31 CFM. Secured to front chassis by screw,<br />

fans leads provided with Insulating Tubing /<br />

Sleeving, minimum 0.4 mm thick.<br />

One provided. Rated 12 Vdc, 0.84 A, minimum<br />

23.31 CFM. Secured to front chassis by screw,<br />

fans leads provided with Insulating Tubing /<br />

Sleeving, minimum 0.4 mm thick.<br />

One provided. Rated 12 Vdc, 0.8 A, 27 CFM.<br />

Secured to front chassis by screw, fans leads<br />

provided with Insulating Tubing / Sleeving,<br />

minimum 0.4 mm thick.<br />

PMD1204PQB1-A One provided. Rated 12 Vdc, 0.72 A, 24 CFM.<br />

Secured to front chassis by screw, fans leads<br />

provided with Insulating Tubing / Sleeving,<br />

minimum 0.4 mm thick.<br />

One provided. Rated 12 Vdc, 0.65 A, minimum<br />

21.19 CFM. Secured to front chassis by screw,<br />

fans leads provided with Insulating Tubing /<br />

Sleeving, minimum 0.4 mm thick.<br />

DT-45 Rated 300V, 25A. Secured to front chassis by<br />

screws.<br />

HD-122 Rated 300V, 25A. Secured to front chassis by<br />

screws.<br />

GPWV2 <strong>UL</strong><br />

GPWV2 <strong>UL</strong><br />

GPWV2 <strong>UL</strong><br />

GPWV2 <strong>UL</strong><br />

GPWV2 <strong>UL</strong><br />

XCFR2 <strong>UL</strong><br />

XCFR2 <strong>UL</strong>

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 12 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Object/part No. Manufacturer/<br />

trademark<br />

DM1U-2500V(D),<br />

DM1U-2650V(D),<br />

DM1U-2750V(D))<br />

(Alternate)<br />

06b. Input Connector<br />

(Substitute Input<br />

Terminal) (For Models<br />

DM1U-2500V, DM1U-<br />

2650V, DM1U-<br />

2500V(D), DM1U-<br />

2650V(D))<br />

07. Bonding wire (For<br />

Input Connector Type)<br />

(For Models DM1U-<br />

2500V, DM1U-2650V,<br />

DM1U-2750V, DM1U-<br />

2500V(D), DM1U-<br />

2650V(D), DM1U-<br />

2750V(D))<br />

08. Internal DC Input<br />

Wires (For Models<br />

DM1U-2500V, DM1U-<br />

2650V, DM1U-2750V,<br />

DM1U-2500V(D),<br />

DM1U-2650V(D),<br />

DM1U-2750V(D))<br />

Positronic Industries,<br />

Inc.<br />

type/model technical data CCN Marks of<br />

Conformity<br />

PLB06 Rated 600V maximum, 23A. Secured to front<br />

chassis by screws.<br />

Various Various Green/yellow lead. Rated VW-1, minimum 14<br />

AWG, minimum 105 degree C, minimum 300 Vac.<br />

One end secured then soldered to Input Connector;<br />

other end terminates in closed-loop, double crimptype<br />

connector, secured to chassis with dedicated<br />

threaded post, screw nut and lock-washer.<br />

Various Various FEP, PTEF, PVC, TFE, neoprene or surface<br />

marked rated VW-1, min. 12 AWG, minimum 105<br />

degree C, minimum 300 V. One end secured then<br />

soldered to Input Connector or Input Terminal<br />

Block; other end terminates secured then soldered<br />

to Main Board.<br />

09. LED Wires Various Various Secondary Wiring, Low voltage secondary (SEC,<br />

ELV, SELV), rated minimum 80 degree C, minimum<br />

30 V, FEP, PTFE, PVC, TFE, neoprene, or surface<br />

marked VW-1. Provided with Insulating Tubing /<br />

10. Position of Insulation<br />

Sheet<br />

Sleeving, minimum 0.4 mm thick.<br />

-- -- Two provided. One provided between Main Board<br />

and bottom chassis. See Enclosure ID 4-01 for<br />

dimension details; other one secured on top<br />

ECBT2 <strong>UL</strong><br />

AVLV2 <strong>UL</strong><br />

AVLV2 <strong>UL</strong><br />

AVLV2 <strong>UL</strong><br />

-- --

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 13 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Object/part No. Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

11. Materials of Sabic Innovative FR1<br />

chassis by adhesive-backed. See Enclosure ID 4-<br />

02 for dimension details<br />

Rated minimum V-2, minimum 0.25 mm thick. QMFZ2 <strong>UL</strong><br />

Insulation Sheet Plastics Us L L C<br />

11a. Materials of Formex,Div Of Il Tool FORMEX Rated minimum V-2, minimum 0.25 mm thick. QMFZ2 <strong>UL</strong><br />

Insulation Sheet Works Inc,Frmrly<br />

(Alternate)<br />

Fastex,Div Of Il Tool<br />

Works Inc<br />

12. Silicon Rubber Various Various Two provided, minimum V-2. Secured on bottom<br />

chassis.<br />

QMFZ2 <strong>UL</strong><br />

13. Insulation Tape 3M Company 1350-1, 1350F-1 Wrapped on top of capacitors (C4, C4A) OANZ2 <strong>UL</strong><br />

(Optional)<br />

Electrical Markets Div<br />

(EMD)<br />

14. Printed Wiring Various Various Rated minimum V-1, minimum 105 degree C. ZPMV2 <strong>UL</strong><br />

Boards<br />

Consists of Main Board, daughter card (CN1, CN3,<br />

CN2 and CN9) and several secondary daughter<br />

cards. The daughter cards secured and soldered<br />

to Main Board vertically; Main Board secured to<br />

bottom chassis by screws and kept minimum 3.5<br />

mm height to chassis.<br />

15. Y-Capacitors (CY1, Walsin Technology AC, AH Soldered on Main Board. Rated maximum 4700 FOWX2 <strong>UL</strong><br />

CY2, CY3 and CY4) Corp<br />

pF, minimum 250 V, minimum 125 degree C.<br />

(Optional)<br />

Marked with an Y1 or Y2 and Certified by VDE,<br />

DEMKO or SEV. (Meets IEC60384-14.)<br />

15a. Y-Capacitors (CY1,<br />

CY2, CY3 and CY4)<br />

(Optional) (Alternate)<br />

TDK Corp CD Same as above. FOWX2 <strong>UL</strong><br />

15b. Y-Capacitors (CY1, Welson Industrial Co WD Same as above. FOWX2 <strong>UL</strong><br />

CY2, CY3 and CY4)<br />

(Optional) (Alternate)<br />

Ltd<br />

15c. Y-Capacitors (CY1, Success Electronics SE Same as above. FOWX2 <strong>UL</strong><br />

CY2, CY3 and CY4)<br />

(Optional) (Alternate)<br />

Co Ltd

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 14 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Object/part No. Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

16. Capacitors (C17,<br />

C12, C24) (Optional)<br />

-- -- Rated minimum 100 V, maximum 2.2 uF. -- --<br />

17. Bleeder Resistors Various Various SMD Type. R1, R2 in series, each rated 56 k ohm, -- --<br />

(R1, R2)<br />

minimum 1/4 W.<br />

18. Fuse (F1) Cooper Bussmann ABC Rated 125 Vdc, F 30 A. Fuse provided with JDYX2 <strong>UL</strong><br />

Inc<br />

Insulating Tubing / Sleeving.<br />

19. Varistor<br />

Epcos (Zhuhai Ftz) S14K95 Rated 95Vac, 150Vdc. The body and lead VZCA2 <strong>UL</strong><br />

(VZ1)(Optional) Co Ltd<br />

provided with Insulation Tubing / Sleeving.<br />

19a. Varistor (VZ1) Nippon Chemi-con TND14V-151K Rated 95 Vac, 150 Vdc. The body provided with VZCA2 <strong>UL</strong><br />

(Optional) (Alternate) Corp<br />

Insulation Tubing / Sleeving.<br />

19b. Varistor (VZ1) Joyin Co., Ltd. 14N151k Rated 95 Vac, 125 Vdc. The body provided with VZCA2 <strong>UL</strong><br />

(Optional) (Alternate)<br />

Insulation Tubing / Sleeving.<br />

19b. Varistor (VZ1) Nippon Chemi-con TNR15G151K Rated 95 Vac, 150 Vdc. The body provided with VZCA2 <strong>UL</strong><br />

(Optional) (Alternate) Corp<br />

Insulation Tubing / Sleeving.<br />

19c. Varistor (VZ1) Thinking Electronic TVR14151 Rated 95 Vac, 156 Vdc. The body provided with VZCA2 <strong>UL</strong><br />

(Optional) (Alternate) Industrial Co Ltd<br />

Insulation Tubing / Sleeving.<br />

20. Inductor (L2) -- -- Rated minimum 130 degree C. Core, Ferrite. Coil,<br />

copper magnet wire wound on core. See enclosure<br />

ID 4-03 for details.<br />

-- --<br />

21. Inductor (T3) -- -- Rated minimum 130 degree C. Core, Ferrite. Coil,<br />

copper magnet wire wound on core. See enclosure<br />

ID 4-04 for details.<br />

-- --<br />

22. Inductor (L3) (For -- -- Rated minimum 105 degree C. Core, Ferrite. Coil, -- --<br />

Models DM1U-2500V,<br />

copper magnet wire wound on core. See enclosure<br />

DM1U-2650V, DM1U-<br />

2750V, DM1U-<br />

2500V(D), DM1U-<br />

2650V(D), DM1U-<br />

2750V(D))<br />

ID 4-05 for details.<br />

23. Inductor (L4) (For -- -- Rated minimum 130 degree C. Core, Ferrite. Coil, -- --<br />

Models DM1U-2500V,<br />

copper magnet wire wound on core. See enclosure<br />

DM1U-2650V, DM1U-<br />

2750V, DM1U-<br />

ID 4-06 for details.

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 15 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Object/part No. Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

2500V(D), DM1U-<br />

2650V(D), DM1U-<br />

2750V(D))<br />

24. Transistors (Q1, Q2) -- -- Rated 180 to 96A, minimum 100 V. Secured to<br />

Heat sink (H1) by screw.<br />

-- --<br />

25. Heat Sink (H1) -- -- Tin Plated Brass and aluminum, secured to<br />

Transistors (Q1, Q2) by screw and soldered to<br />

PWB. Overall approximately 27.7 by 21 by 32 mm,<br />

2.0 mm thick. (H1 is input circuitry.)<br />

-- --<br />

26. Transistors (Q5, Q8, -- -- Rated 140 A, minimum 100 V. Secured to Heat -- --<br />

Q13, Q14, Q15, Q16)<br />

sink (H2) by screw.<br />

27. Heat Sink (H2) -- -- Tin Plated Brass and aluminum, secured to<br />

Transistors (Q5, Q8, Q13, Q14, Q15, Q16) by<br />

screw and soldered to PWB. Overall approximately<br />

70 by 18.7 by 32 mm, minimum 1.0 mm thick. (H2<br />

is input circuitry.)<br />

-- --<br />

28. Electrolytic<br />

-- -- Integral pressure relief. Rated 1200 uF, minimum -- --<br />

Capacitors (C4, C4A)<br />

100 V, minimum 105 degree C.<br />

29. Transistor (Q37) -- -- Rated 18 A, minimum 200V. -- --<br />

30. Drive Transformer<br />

(T1) (Secured on CN9<br />

Board)<br />

31. Bridge-Capacitor<br />

(CY5) (Optional)<br />

31a. Bridge-Capacitor<br />

(CY5) (Optional)<br />

(Alternate)<br />

31b. Bridge-Capacitor<br />

(CY5) (Optional)<br />

(Alternate)<br />

-- -- Rated minimum 105 degree C. See enclosure ID<br />

4-07 for details.<br />

Walsin Technology<br />

Corp<br />

AH Rated maximum 4700 pF, minimum 250 Vac<br />

minimum 125 degree C. Marked with an Y1 and<br />

Certified by VDE, DEMKO or SEV. (Meets<br />

IEC60384-14.)<br />

-- --<br />

FOWX2 <strong>UL</strong><br />

TDK Corp CD Same as above. FOWX2 <strong>UL</strong><br />

Welson Industrial Co<br />

Ltd<br />

WD Same as above. FOWX2 <strong>UL</strong><br />

31c. Bridge-Capacitor Success Electronics SE Same as above. FOWX2 <strong>UL</strong>

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 16 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Object/part No. Manufacturer/<br />

trademark<br />

(CY5) (Optional)<br />

(Alternate)<br />

32. Transformer (T2)<br />

(For Models DM1U-<br />

2500V, DM1U-2650V,<br />

DM1U-2750V, DM1U-<br />

2500V(D), DM1U-<br />

2650V(D), DM1U-<br />

2750V(D))<br />

32-1. Insulation system<br />

of Transformer (T2)<br />

32-2. Insulation Tape of<br />

Transformer (T2)<br />

32-3. Triple insulation<br />

wire of Transformer (T2)<br />

32-4. Tube of<br />

Transformer (T2)<br />

32a-1. Insulation system<br />

of Transformer (T2)<br />

(Alternate)<br />

32a-2. Insulation Tape of<br />

Transformer (T2)<br />

32a-3. Triple insulation<br />

wire of Transformer (T2)<br />

32a-4. Tube of<br />

Transformer (T2)<br />

33. Transformer (T4)<br />

(For Models DM1U-<br />

2500V, DM1U-2650V,<br />

DM1U-2750V, DM1U-<br />

Co Ltd<br />

type/model technical data CCN Marks of<br />

Conformity<br />

-- -- Open type construction. Core, Ferrite. Coil, copper<br />

magnet wire wound on core. See Enclosure ID 4-<br />

08 for construction details.<br />

-- --<br />

Li Chieh Electronic<br />

Industrial Co Ltd<br />

HIS-8A Class B. OBJY2 <strong>UL</strong><br />

3M Company<br />

Electrical Markets Div<br />

(EMD)<br />

1350F-1 Rated 130 degree C. OANZ2 <strong>UL</strong><br />

Furukawa Electric Co<br />

Ltd<br />

TEX-E Primary. Rated 130 degree C. OBJT2 <strong>UL</strong><br />

Zeus Industrial<br />

Products Inc<br />

TFE-TW-300 Rated 200 degree C. YDPU2 <strong>UL</strong><br />

Large Magnetic<br />

Electronic Co Ltd<br />

(Chief Superior<br />

Insustrial Co., Ltd.)<br />

SBI 4.2 Class B. OBJY2 <strong>UL</strong><br />

Jingjiang Yahua<br />

Pressure Sensitive<br />

Glue Co Ltd<br />

CT Rated 130 degree C. OANZ2 <strong>UL</strong><br />

Furukawa Electric Co<br />

Ltd<br />

TEX-E Primary. Rated 130 degree C. OBJT2 <strong>UL</strong><br />

Great Holding<br />

Industrial Co Ltd<br />

TFL Rated 200 degree C. YDPU2 <strong>UL</strong><br />

-- -- Open type construction. Core, Ferrite. Coil, copper --<br />

magnet wire wound on bobbin. See Enclosure ID<br />

4-09 for construction details.<br />

--

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 17 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Object/part No. Manufacturer/<br />

trademark<br />

2500V(D), DM1U-<br />

2650V(D), DM1U-<br />

2750V(D))<br />

33-1. Insulation system<br />

of Transformer (T4)<br />

33-2. Insulation Tape of<br />

Transformer (T4)<br />

33-3. Bobbin of<br />

Transformer (T4)<br />

33-4. Triple insulation<br />

wire of Transformer (T4)<br />

33-5. Varnish of<br />

Transformer (T4)<br />

33-6. Tube of<br />

Transformer (T4)<br />

33-7. Windings of<br />

Transformer (T4)<br />

33a-1. Insulation system<br />

of Transformer (T4)<br />

(Alternate)<br />

33a-2. Insulation Tape of<br />

Transformer (T4)<br />

33a-3. Bobbin of<br />

Transformer (T4)<br />

33a-4. Triple insulation<br />

wire of Transformer (T4)<br />

33a-5. Varnish of<br />

Transformer (T4)<br />

33a-6. Tube of<br />

Transformer (T4)<br />

type/model technical data CCN Marks of<br />

Conformity<br />

Li Chieh Electronic<br />

Industrial Co Ltd<br />

HIS-8A Class B. OBJY2 <strong>UL</strong><br />

3M Company<br />

Electrical Markets Div<br />

(EMD)<br />

1350F-1 Rated 130 degree C. OANZ2 <strong>UL</strong><br />

Hitachi Chemical Co CP-J-8800 Phenolic. Minimum V-2, minimum 0.71 mm thick, QFMZ2 <strong>UL</strong><br />

Ltd<br />

rated 150 degree C.<br />

Furukawa Electric Co<br />

Ltd<br />

TEX-E Secondary. Rated 130 degree C. OBJT2 <strong>UL</strong><br />

Hitachi Chemical Co<br />

Ltd<br />

WP-2952F-2G Rated 130 degree C. OBOR2 <strong>UL</strong><br />

Zeus Industrial<br />

Products Inc<br />

TFE-TW-300 Rated 200 degree C. YDPU2 <strong>UL</strong><br />

Various Various Rated 130 degree C. OBMW2 <strong>UL</strong><br />

Large Magnetic<br />

Electronic Co Ltd<br />

(Chief Superior<br />

Insustrial Co., Ltd.)<br />

SBI 4.2 Class B. OBJY2 <strong>UL</strong><br />

Jingjiang Yahua<br />

Pressure Sensitive<br />

Glue Co Ltd<br />

CT Rated 130 degree C. OANZ2 <strong>UL</strong><br />

Sumitomo Bakelite PM-9820 Phenolic. Minimum V-2, minimum 0.71 mm thick, QFMZ2 <strong>UL</strong><br />

Co Ltd<br />

rated 150 degree C.<br />

Furukawa Electric Co<br />

Ltd<br />

TEX-E Secondary. Rated 130 degree C. OBJT2 <strong>UL</strong><br />

John C Dolph Co BC-346A Rated 200 degree C. OBOR2 <strong>UL</strong><br />

Great Holding<br />

Industrial Co Ltd<br />

TFL Rated 200 degree C. YDPU2 <strong>UL</strong>

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 18 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Object/part No. Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

33a-7. Windings of<br />

Transformer (T4)<br />

Various Various Rated 130 degree C. OBMW2 <strong>UL</strong><br />

33b-1. Insulation system Li Tai Electronic CIS.04 Class B. OBJY2 <strong>UL</strong><br />

of Transformer (T4)<br />

(Alternate)<br />

Enterprise Co, Ltd<br />

33b-2. Bobbin of Sumitomo Bakelite PM-9820 Phenolic. Minimum V-2, minimum 0.71 mm thick, QMFZ2 <strong>UL</strong><br />

Transformer (T4) Co Ltd<br />

rated 150 degree C.<br />

33b-3. Insulation Tape of Symbio Inc<br />

Transformer (T4)<br />

35660Y Rated 130 degree C. OANZ2 <strong>UL</strong><br />

33b-4. Insulation Tape of 3M Company 1350F-1 Rated 130 degree C. OANZ2 <strong>UL</strong><br />

Transformer (T4) Electrical Markets Div<br />

(Alternate)<br />

(EMD)<br />

33b-7. Varnish of<br />

Transformer (T4)<br />

John C Dolph Co BC-346A Rated 130 degree C. OBOR2 <strong>UL</strong><br />

33b-8. Tube of<br />

Great Holding TFL Rated 200 degree C. External side provided with YDPU2 <strong>UL</strong><br />

Transformer (T4) Industrial Co Ltd<br />

Insulation Tubing / Sleeving.<br />

33b-9. Windings of<br />

Transformer (T4)<br />

Various Various Rated 130 degree C. OBMW2 <strong>UL</strong><br />

33b-10. Triple insulation<br />

wire of Transformer (T4)<br />

Cosmolink Co Ltd TIW-M Rated 130 degree C. OBJT2 <strong>UL</strong><br />

34. Optical Isolator (U11) Sharp Corp<br />

Electronic<br />

Components Group<br />

PC817 Rated Isolation minimum 5000 V ac. FPQU2 <strong>UL</strong><br />

34a. Optical Isolator Everlight Electronics EL817 series Rated Isolation minimum 5000 V ac. FPQU2 <strong>UL</strong><br />

(U11) (Alternate) Co Ltd<br />

34b. Optical Isolator Fairchild<br />

H11A817 series Rated Isolation minimum 5000 V ac. FPQU2 <strong>UL</strong><br />

(U11) (Alternate) Semiconductor Corp.<br />

34c. Optical Isolator Lite-On Technology LTV 817 Rated Isolation minimum 5000 V ac. FPQU2 <strong>UL</strong><br />

(U11) (Alternate) Corp<br />

34d. Optical Isolator Cosmo Electronics K1010 Rated Isolation minimum 5000 V ac. FPQU2 <strong>UL</strong><br />

(U11) (Alternate) Corp<br />

35. Optical Isolators (U2, Vishay<br />

TCLT1000series, Rated Isolation minimum 5000 V ac. Double FPQU2 <strong>UL</strong><br />

U9 and U20)<br />

Semiconductor TCLT1001series, protection. U2, U9 and U20 mounted on daughter

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 19 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Object/part No. Manufacturer/<br />

trademark<br />

35a. Optical Isolators<br />

(U2, U9 and U20)<br />

(Alternate)<br />

36. Non-Optical Isolators<br />

(U19)<br />

37. Output Connector<br />

(CN11) (For Models<br />

DM1U-2500V, DM1U-<br />

2650V, DM1U-2750V)<br />

38. Insaulation Tubing /<br />

Sleeving<br />

39. Secondary Internal<br />

Wiring<br />

40. Connector and<br />

Receptacles (secondary<br />

ELV/SELV circuits) (For<br />

models DM1U-2750V(D)<br />

DM1U-2650V(D),<br />

DM1U-2500V(D))<br />

40a. Connector and<br />

Receptacles (secondary<br />

Gmbh TCLT1002series,<br />

TCLT1003series,<br />

TCLT1004series,<br />

TCLT1005series,<br />

TCLT1006series,<br />

TCLT1007series,<br />

TCLT1008series,<br />

TCLT1009series<br />

Fairchild<br />

Semiconductor Corp<br />

type/model technical data CCN Marks of<br />

Conformity<br />

card (CN2).<br />

H11A817 series Rated Isolation minimum 5000 V ac. U2, U9 and<br />

U20 mounted on daughter card (CN2).<br />

Analog Devices Inc ADuM240 series Rated Isolation minimum 5000 V ac. Double<br />

Protection type. The IC mounted on daughter card<br />

Positronic Industries<br />

Inc<br />

FPQU2 <strong>UL</strong><br />

FPPT2 <strong>UL</strong><br />

GFSH89M4<br />

CN2.<br />

250V, 16A. ECBT2 <strong>UL</strong><br />

Various Various FEP, PTFE, PVC, TFE, neoprene, polyimide or<br />

marked VW-1; minimum 105 degree C, minimum<br />

300 V.<br />

Various Various (Secondary) Low voltage secondary (SEC, ELV,<br />

SELV), rated minimum 85 degree C, minimum 60<br />

V, FEP, PTFE, PVC, TFE, neoprene, or surface<br />

marked VW-1.<br />

Various Various Copper alloy pins housed in bodies of plastic rated<br />

min. V-2.<br />

YDPU2 <strong>UL</strong><br />

AVLV2 <strong>UL</strong><br />

QMFZ2 <strong>UL</strong><br />

Various Various -- ECBT2, RTRT2,<br />

DUXR or DUXR2<br />

<strong>UL</strong>

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 20 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Object/part No. Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

ELV/SELV circuits) (For<br />

models DM1U-2750V(D)<br />

DM1U-2650V(D),<br />

DM1U-2500V(D))<br />

(Alternate)<br />

41. Thermal State (TS1) Seki Controls Co Ltd ST-22 Rated 250V, 1A, 150 degree C XAPX2 <strong>UL</strong><br />

42. Chassis (For Input<br />

Connector Type) (For<br />

Model BM1U-2500V)<br />

42a. Chassis (For Input<br />

Terminal Block Type)<br />

(For Model BM1U-<br />

2500V)<br />

44. Input Terminal Block<br />

(Alternate) (For Models<br />

BM1U-2500V<br />

44b. Input Connector<br />

(Substitute Input<br />

Terminal) (For Models<br />

DM1U-2750V, DM1U-<br />

2750V(D), BM1U-<br />

2500V)<br />

45. Internal DC Input<br />

Wires (For Model BM1U-<br />

2500V)<br />

-- -- Metal (Nickel Plated Iron and Aluminum<br />

Magnesium alloy). Three pieces construction and<br />

secured together by screws. Overall approximately<br />

300 by 50.5 by 40 mm, minimum 0.9 mm thick.<br />

Provide with 26 ventilation openings on front (input /<br />

fan side), each maximum 5 by 4 mm.<br />

-- -- Metal (Nickel Plated Iron and Aluminum<br />

Magnesium alloy). Three pieces construction and<br />

secured together by screws. Overall approximately<br />

300 by 50.5 by 40 mm, minimum 0.9 mm thick.<br />

Provide with 2 slot ventilation openings on top,<br />

each approximately 15 by 3 mm; provide with 22<br />

ventilation openings on front (input / fan side), each<br />

Dinkle Enterprise Co<br />

Ltd<br />

Positronic Industries,<br />

Inc.<br />

maximum5 by 4 mm.<br />

DT-66-C11W Rated 300V, 40A. Secured to EMI board and front<br />

chassis by soldering and physical fit<br />

PLBH06 Rated 600V maximum, 32A. Secured to front<br />

chassis by screws For Models DM1U-2750V,<br />

DM1U-2750V(D); Secured to EMI board and front<br />

chassis by soldering and physical fit for Model<br />

BM1U-2500V.<br />

Various Various FEP, PTEF, PVC, TFE, neoprene or surface<br />

marked rated VW-1, min. 12 AWG, minimum 105<br />

degree C, minimum 300 V. One end secured then<br />

soldered to EMI Board; other end terminates<br />

-- --<br />

-- --<br />

XCFR2 <strong>UL</strong><br />

ECBT2 <strong>UL</strong><br />

AVLV2 <strong>UL</strong>

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 21 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Object/part No. Manufacturer/<br />

trademark<br />

46. Varistor (VZ1, VZ2)<br />

(VZ2 only for Model<br />

BM1U-2500V) (Optional)<br />

46a. Varistor (VZ1, VZ2)<br />

(VZ2 only for Model<br />

BM1U-2500V)<br />

(Optional) (Alternate)<br />

46b. Varistor (VZ1, VZ2)<br />

(VZ2 only for Model<br />

BM1U-2500V)<br />

(Optional) (Alternate)<br />

46b. Varistor (VZ1, VZ2)<br />

(VZ2 only for Model<br />

BM1U-2500V)<br />

(Optional) (Alternate)<br />

46c. Varistor (VZ1, VZ2)<br />

(VZ2 only for Model<br />

BM1U-2500V)<br />

(Optional) (Alternate)<br />

47. Inductor (L3) (For<br />

Model BM1U-2500V)<br />

48. Inductor (L4) (For<br />

Model BM1U-2500V)<br />

49. EMI Board (For<br />

Model BM1U-2500V)<br />

Epcos (Zhuhai Ftz)<br />

Co Ltd<br />

Nippon Chemi-con<br />

Corp<br />

type/model technical data CCN Marks of<br />

Conformity<br />

secured then soldered to Main Board.<br />

S14K95 Rated 95Vac, 150Vdc. The body and lead<br />

provided with Insulation Tubing / Sleeving.<br />

TND14V-151K Rated 95 Vac, 150 Vdc. The body provided with<br />

Insulation Tubing / Sleeving.<br />

Joyin Co., Ltd. 14N151k Rated 95 Vac, 125 Vdc. The body provided with<br />

Insulation Tubing / Sleeving.<br />

Nippon Chemi-con<br />

Corp<br />

Thinking Electronic<br />

Industrial Co Ltd<br />

TNR15G151K Rated 95 Vac, 150 Vdc. The body provided with<br />

Insulation Tubing / Sleeving.<br />

TVR14151 Rated 95 Vac, 156 Vdc. The body provided with<br />

Insulation Tubing / Sleeving.<br />

-- -- Rated minimum 105 degree C. Core, Ferrite. Coil,<br />

copper magnet wire wound on core. See enclosure<br />

ID 4-10 for details.<br />

-- -- Rated minimum 130 degree C. Core, Ferrite. Coil,<br />

copper magnet wire wound on core. See enclosure<br />

ID 4-11 for details.<br />

Various Various Rated minimum V-1, minimum 105 degree C.<br />

Secured to front chassis by two screws. Consist of<br />

the following critical parts.<br />

VZCA2 <strong>UL</strong><br />

VZCA2 <strong>UL</strong><br />

VZCA2 <strong>UL</strong><br />

VZCA2 <strong>UL</strong><br />

VZCA2 <strong>UL</strong><br />

-- --<br />

-- --<br />

ZPMV2 <strong>UL</strong><br />

49-1. Inductor (L1) -- -- Rated minimum 105 degree C. Core, Ferrite. Coil,<br />

copper magnet wire wound on core. See enclosure<br />

ID 4-12 for details.<br />

-- --<br />

49-2. Varistor (VZ1) Epcos (Zhuhai Ftz) S14K95 Rated 95Vac, 150Vdc. The body and lead VZCA2 <strong>UL</strong>

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 22 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Object/part No. Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

(Optional) Co Ltd provided with Insulation Tubing / Sleeving. (E321126)<br />

49-2a. Varistor (VZ1) Nippon Chemi-con TND14V-151K Rated 95 Vac, 150 Vdc. The body provided with VZCA2 <strong>UL</strong><br />

(Optional) (Alternate) Corp<br />

Insulation Tubing / Sleeving.<br />

(E323623)<br />

49-2b. Varistor (VZ1) Joyin Co., Ltd. 14N151k Rated 95 Vac, 125 Vdc. The body provided with VZCA2 <strong>UL</strong><br />

(Optional) (Alternate)<br />

Insulation Tubing / Sleeving.<br />

(E325508)<br />

49-2b. Varistor (VZ1) Nippon Chemi-con TNR15G151K Rated 95 Vac, 150 Vdc. The body provided with VZCA2 <strong>UL</strong><br />

(Optional) (Alternate) Corp<br />

Insulation Tubing / Sleeving.<br />

(E323623)<br />

49-2c. Varistor (VZ1) Thinking Electronic TVR14151 Rated 95 Vac, 156 Vdc. The body provided with VZCA2 <strong>UL</strong><br />

(Optional) (Alternate) Industrial Co Ltd<br />

Insulation Tubing / Sleeving.<br />

(E314979)<br />

49-3. Capacitors (C1,<br />

C2, C3) (Optional)<br />

-- -- Rated minimum 100 V, maximum 2.2 uF. -- --<br />

49-4. Bleeder Resistors -- -- SMD Type. R1, R2 in series, each rated 56 k ohm, -- --<br />

(R1, R2)<br />

minimum 1/4 W.<br />

50. Position of Insulation -- -- Provided between EMI Board and chassis. See -- --<br />

Sheet for Input<br />

Connector Type (For<br />

Model BM1U-2500V)<br />

Enclosure ID 4-13 for dimension details.<br />

50-1. Position of -- -- Provided between EMI Board and chassis. See -- --<br />

Insulation Sheet for Input<br />

Terminal Block Type<br />

(For Model BM1U-<br />

2500V)<br />

Enclosure ID 4-14 for dimension details.<br />

51. Materials of Sabic Innovative FR1 Rated minimum V-2, minimum 0.25 mm thick. QMFZ2 <strong>UL</strong><br />

Insulation Sheet Plastics Us L L C<br />

51a. Materials of Formex,Div Of Il Tool FORMEX Rated minimum V-2, minimum 0.25 mm thick. QMFZ2 <strong>UL</strong><br />

Insulation Sheet Works Inc,Frmrly<br />

(Alternate)<br />

Fastex,Div Of Il Tool<br />

Works Inc<br />

52. Transformer (T2) -- -- Open type construction. Core, Ferrite. Coil, copper -- --<br />

(For Model BM1U-<br />

magnet wire wound on core. See Enclosure ID 4-<br />

2500V)<br />

15 for construction details.<br />

52-1. Insulation system Li Chieh Electronic DASH 2 B-5 Class B. OBJY2 <strong>UL</strong><br />

of Transformer (T2) Industrial Co Ltd

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 23 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Object/part No. Manufacturer/<br />

trademark<br />

52-2. Insulation Tape of<br />

Transformer (T2)<br />

type/model technical data CCN Marks of<br />

Conformity<br />

3M Company<br />

Electrical Markets Div<br />

(EMD)<br />

1350F-1 Rated 130 degree C. OANZ2 <strong>UL</strong><br />

Various Various Primary. Rated 130 degree C. OBMW2 <strong>UL</strong><br />

52-3. Windings of<br />

Transformer (T2)<br />

52-4. Tube of<br />

Great Holding TFT Rated 200 degree C. Minimum 0.4 mm thick. YDPU2 <strong>UL</strong><br />

Transformer (T2) Industrial Co Ltd<br />

52-5. Tube of<br />

Great Holding TFS Rated 200 degree C. For external winding leads. YDPU2 <strong>UL</strong><br />

Transformer (T2) Industrial Co Ltd<br />

Min. 0.4 mm thick.<br />

52a-1. Insulation system Large Magnetic SBI 4.2 Class B. OBJY2 <strong>UL</strong><br />

of Transformer (T2) Electronic Co Ltd<br />

(Alternate)<br />

(Chief Superior<br />

Insustrial Co., Ltd.)<br />

52a-2. Insulation Tape of Jingjiang Yahua CT Rated 130 degree C. OANZ2 <strong>UL</strong><br />

Transformer (T2) Pressure Sensitive<br />

Glue Co Ltd<br />

52a-3. Windings of<br />

Transformer (T2)<br />

Various Various Primary. Rated 130 degree C. OBMW2 <strong>UL</strong><br />

52a-4. Tube of<br />

Great Holding TFL Rated 200 degree C. YDPU2 <strong>UL</strong><br />

Transformer (T2) Industrial Co Ltd<br />

52a-5. Tube of<br />

Great Holding TFS Rated 200 degree C. For external winding lead. YDPU2 <strong>UL</strong><br />

Transformer (T2) Industrial Co Ltd<br />

Min. 0.4 mm thick.<br />

53. Transformer (T4) -- -- Open type construction. Core, Ferrite. Coil, copper -- --<br />

(For Model BM1U-<br />

magnet wire wound on bobbin. See Enclosure ID<br />

2500V)<br />

4-16 for construction details.<br />

53-1. Insulation system Large Magnetic SBI 4.2 Class B. OBJY2 <strong>UL</strong><br />

of Transformer (T4) Electronic Co Ltd<br />

(Alternate)<br />

(Chief Superior<br />

Insustrial Co., Ltd.)<br />

53-2. Insulation Tape of Jingjiang Yahua CT Rated 130 degree C. OANZ2 <strong>UL</strong><br />

Transformer (T4) Pressure Sensitive<br />

Glue Co Ltd<br />

53-3. Bobbin of Sumitomo Bakelite PM-9820 Phenolic. Minimum V-2, minimum 0.71 mm thick, QFMZ2 <strong>UL</strong>

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 24 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Object/part No. Manufacturer/<br />

trademark<br />

type/model technical data CCN Marks of<br />

Conformity<br />

Transformer (T4) Co Ltd rated 150 degree C.<br />

53-4. Triple insulation Furukawa Electric Co TEX-E Secondary. Rated 130 degree C. OBJT2 <strong>UL</strong><br />

wire of Transformer (T4) Ltd<br />

53-5. Varnish of<br />

Transformer (T4)<br />

John C Dolph Co BC-346A Rated 200 degree C. OBOR2 <strong>UL</strong><br />

53-6. Tube of<br />

Great Holding TFL Rated 200 degree C. YDPU2 <strong>UL</strong><br />

Transformer (T4) Industrial Co Ltd<br />

53-7. Windings of<br />

Transformer (T4)<br />

Various Various Rated 130 degree C. OBMW2 <strong>UL</strong><br />

53a-1. Insulation system Dongguan<br />

SBI 4.2 Class B. OBJY2 <strong>UL</strong><br />

of Transformer (T4) Zhangmutou Hong<br />

(Alternate)<br />

Chan<br />

53a-2. Insulation Tape of Jingjiang Yahua CT Rated 130 degree C. OANZ2 <strong>UL</strong><br />

Transformer (T4) Pressure Sensitive<br />

Glue Co Ltd<br />

53a-2a. Insulation Tape 3M Company 1350F-1, 1350F-2 Rated 130 degree C. OANZ2 <strong>UL</strong><br />

of Transformer (T4) Electrical Markets Div<br />

(EMD)<br />

53a-3. Bobbin of Sumitomo Bakelite PM-9820 Phenolic. Minimum V-2, minimum 0.71 mm thick, QFMZ2 <strong>UL</strong><br />

Transformer (T4) Co Ltd<br />

rated 150 degree C.<br />

53a-4. Triple insulation Furukawa Electric Co TEX-E Secondary. Rated 130 degree C. OBJT2 <strong>UL</strong><br />

wire of Transformer (T4) Ltd<br />

53a-4a. Triple insulation Totoku Electric Co TIW-2 Secondary. Rated 130 degree C. OBJT2 <strong>UL</strong><br />

wire of Transformer (T4) Ltd<br />

53a-5. Varnish of Elantas Electrical V1380FC Rated minimum 130 degree C. OBOR2 <strong>UL</strong><br />

Transformer (T4) Insulation Elantas<br />

Pdg Inc<br />

53a-6. Tube of<br />

Great Holding TFL Rated 200 degree C. YDPU2 <strong>UL</strong><br />

Transformer (T4) Industrial Co Ltd<br />

53a-7. Windings of<br />

Transformer (T4)<br />

Various Various Rated 130 degree C. OBMW2 <strong>UL</strong><br />

53b-1. Insulation system Li Chieh Electronic HIA-8A Class B. OBJY2 <strong>UL</strong><br />

of Transformer (T4) Industrial Co Ltd

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 25 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Object/part No. Manufacturer/<br />

trademark<br />

53b-2. Insulation Tape of<br />

Transformer (T4)<br />

53b-3. Windings of<br />

Transformer (T4)<br />

53b-4. Tube of<br />

Transformer (T4)<br />

53b-5. Varnish of<br />

Transformer (T4)<br />

53b-6. Triple insulation<br />

wire of Transformer (T4)<br />

53a-7. Bobbin of<br />

Transformer (T4)<br />

54. Secondary Inductor<br />

(L1, L2) (For Models<br />

BM1U2-5501V4H and<br />

BM1U2-5501V4V)<br />

54a. Winding of<br />

Secondary Inductor (L1,<br />

L2) (For Models BM1U2-<br />

5501V4H and BM1U2-<br />

5501V4V)<br />

type/model technical data CCN Marks of<br />

Conformity<br />

3M Company<br />

Electrical Markets Div<br />

(EMD)<br />

1350F-1 Rated 130 degree C. OANZ2 <strong>UL</strong><br />

Various Various Rated 130 degree C. OBMW2 <strong>UL</strong><br />

Zeus Industrial<br />

Products Inc<br />

TFE-TW-300 Rated 200 degree C. YDPU2 <strong>UL</strong><br />

Hitachi Chemical Co., WP-2952F-2G<br />

Ltd<br />

Rated 130 degree C. OBJS2 <strong>UL</strong><br />

Furukawa Electric Co<br />

Ltd<br />

TEX-E Primary. Rated 130 degree C. OBJT2 <strong>UL</strong><br />

Hitachi Co.,Ltd CP-J-8800 Phenolic. Minimum V-2, minimum 0.71 mm thick,<br />

rated 150 degree C.<br />

QFMZ2 <strong>UL</strong><br />

-- -- 130 degree C -- --<br />

Various Various Rated 130 degree C. OBMW2 <strong>UL</strong>

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 26 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Enclosures<br />

Type Supplement Id Description<br />

Photographs 3-01 Overall Fornt view (used Input terminal block) of Power Module,<br />

Models DM1U-2500V, DM1U-2650V, DM1U-2750V<br />

Photographs 3-02 Alternate Overall Fornt view (used Input Connector) of Power<br />

Module, Models DM1U-2500V, DM1U-2650V, DM1U-2750V<br />

Photographs 3-03 Overall Rear view of Power Module, Models DM1U-2500V, DM1U-<br />

2650V, DM1U-2750V<br />

Photographs 3-04 Overall Front view (used Input terminal block) of Power Module,<br />

Models DM1U-2500V(D), DM1U-2650V(D), DM1U-2750V(D)<br />

Photographs 3-05 Alternate Overall Front view (used Input Connector) of Power<br />

Module, Models DM1U-2500V(D), DM1U-2650V(D), DM1U-<br />

2750V(D)<br />

Photographs 3-06 Overall Rear view of Power Module, Models DM1U-2500V(D),<br />

DM1U-2650V(D), DM1U-2750V(D)<br />

Photographs 3-07 Internal View of Power Module, Models DM1U-2500V, DM1U-<br />

2650V, DM1U-2750V<br />

Photographs 3-08 PWB component side of Power Module, Models DM1U-2500V,<br />

DM1U-2650V, DM1U-2750V<br />

Photographs 3-09 PWB solder side of Power Module, Models DM1U-2500V, DM1U-<br />

2650V, DM1U-2750V<br />

Photographs 3-10 Internal View of Power Module, Models DM1U-2500V(D), DM1U-<br />

2650V(D), DM1U-2750V(D)<br />

Photographs 3-11 PWB component side of Power Module, Models DM1U-2500V(D),<br />

DM1U-2650V(D), DM1U-2750V(D)<br />

Photographs 3-12 CN2 Control Board view 1 (across input and output circuit) of all<br />

Power Modules<br />

Photographs 3-13 CN2 Control Board view 2 (across input and output circuit) of all<br />

Power Modules<br />

Photographs 3-14 Overall Front view of Redundant Power Supply, Models DM1U2-<br />

5500V4H, DM1U2-5650V4H, DM1U2-5750V4H<br />

Photographs 3-15 Overall Rear view of Redundant Power Supply, Models DM1U2-<br />

5500V4H, DM1U2-5650V4H, DM1U2-5750V4H<br />

Photographs 3-16 Secondary Back board view 1 of Redundant Power Supply,<br />

Models DM1U2-5500V4H, DM1U2-5650V4H, DM1U2-5750V4H<br />

Photographs 3-17 Secondary Back board view 2 of Redundant Power Supply,<br />

Models DM1U2-5500V4H, DM1U2-5650V4H, DM1U2-5750V4H<br />

Photographs 3-18 Overall Fornt view (use Input terminal block) of Power Module,<br />

Model BM1U-2500V<br />

Photographs 3-19 Overall Fornt view (use Input connector) of Power Module, Model<br />

BM1U-2500V

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 27 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Photographs 3-20 Internal View of Power Module, Model BM1U-2500V<br />

Photographs 3-21 PWB component side of Power Module, Model BM1U-2500V<br />

Photographs 3-22 PWB solder side of Power Module, Model BM1U-2500V<br />

Photographs 3-23 PWB component side of EMI board (For Model BM1U-2500V with<br />

input connector)<br />

Photographs 3-24 PWB trace side of EMI board (For Model BM1U-2500V with input<br />

connector)<br />

Photographs 3-25 PWB component side of EMI board (For Model BM1U-2500V with<br />

input terminal block)<br />

Photographs 3-26 PWB trace side of EMI board (For Model BM1U-2500V with input<br />

terminal block)<br />

Photographs 3-27 Overall Front view of Redundant Power Supply, Models BM1U2-<br />

5500V4H, BM1U2-5501V4H<br />

Photographs 3-28 Overall Front view of Redundant Power Supply, Models BM1U2-<br />

5500V4V, BM1U2-5501V4V<br />

Photographs 3-29 Secondary Back board view 1 of Redundant Power Supply,<br />

Models BM1U2-5500V4H, BM1U2-5501V4H<br />

Photographs 3-30 Secondary Back board view 2 of Redundant Power Supply,<br />

Models BM1U2-5500V4H, BM1U2-5501V4H<br />

Photographs 3-31 Secondary Back board view 1 of Redundant Power Supply,<br />

Models BM1U2-5500V4V, BM1U2-5501V4V<br />

Photographs 3-32 Secondary Back board view 2 of Redundant Power Supply,<br />

Models BM1U2-5500V4V, BM1U2-5501V4V<br />

Diagrams 4-01 Insulation sheet between main board and internal bottom chassis<br />

of all Power Modules<br />

Diagrams 4-02 Insulation sheet located between main board amd internal top<br />

chassis of all Power Modules<br />

Diagrams 4-03 Inductor (L2) (provided 3 copies, they were all the same except for<br />

different manufacturer) of all Power Modules<br />

Diagrams 4-04 Inductor (T3) (provided 3 copies, they were all the same except for<br />

different manufacturer) of all Power Modules<br />

Diagrams 4-05 Inductor (L3) (For Models DM1U-2500V, DM1U-2650V, DM1U-<br />

2750V, DM1U-2500V(D), DM1U-2650V(D), DM1U-2750V(D))<br />

Diagrams 4-06 Inductor (L4)(For Models DM1U-2500V, DM1U-2650V, DM1U-<br />

2750V, DM1U-2500V(D), DM1U-2650V(D), DM1U-2750V(D))<br />

Diagrams 4-07 Drive Transformer (T1) (provided 2 copies, they were all the same<br />

except for different manufacturer) of all Power Modules<br />

Diagrams 4-08 Transformer (T2) (For Models DM1U-2500V, DM1U-2650V,<br />

DM1U-2750V, DM1U-2500V(D), DM1U-2650V(D), DM1U-<br />

2750V(D))<br />

Diagrams 4-09 Transformer (T4)(For Models DM1U-2500V, DM1U-2650V,<br />

DM1U-2750V, DM1U-2500V(D), DM1U-2650V(D), DM1U-<br />

2750V(D))<br />

Diagrams 4-10 Inductor (L3) (For Model BM1U-2500V)

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 28 of 28 Report Reference # E143756-A76-<strong>UL</strong><br />

Diagrams 4-11 Inductor (L4) (For Model BM1U-2500V)<br />

Diagrams 4-12 Inductor (L1) (For Model BM1U-2500V)<br />

Diagrams 4-13 Insulation Sheet for Input Connector Type provided between EMI<br />

Board and chassis (For Model BM1U-2500V)<br />

Diagrams 4-14 Insulation Sheet for Input Terminal Block Type provided between<br />

EMI Board and chassis (For Model BM1U-2500V)<br />

Diagrams 4-15 Transformer (T2) of Module (For Model BM1U-2500V)<br />

Diagrams 4-16 Transformer (T4) of Module (For Model BM1U-2500V)<br />

Schematics + PWB 5-01 Main Board of Power Modules (Models DM1U-2500V, DM1U-<br />

2650V, DM1U-2750V, DM1U-2500V(D), DM1U-2650V(D), DM1U-<br />

2750V(D))<br />

Schematics + PWB 5-02 CN2 Control Board (across input and output circuit) of all Power<br />

Modules<br />

Schematics + PWB 5-03 CN5, CN9 and CN1 Board (located on input circuit) of all Power<br />

Modules<br />

Schematics + PWB 5-04 Secondary Back board of Redundant Power Supplies (Models<br />

DM1U2-5500V4H, DM1U2-5650V4H, DM1U2-5750V4H)<br />

Schematics + PWB 5-05 Main Board of Power Modules (For Model BM1U-2500V)<br />

Schematics + PWB 5-06 Secondary Back board of Redundant Power Supplies (For Models<br />

BM1U2-5500V4H, BM1U2-5501V4H)<br />

Schematics + PWB 5-07 Secondary Back board of Redundant Power Supplies (For Models<br />

BM1U2-5500V4V, BM1U2-5501V4V)<br />

Schematics + PWB 5-08 EMI Board for Input Connector Type (For Model BM1U-2500V)<br />

Schematics + PWB<br />

Manuals<br />

5-09 EMI Board for Input Terminal Block Type (For Model BM1U-<br />

2500V)<br />

Miscellaneous 7-01 Models and rating list<br />

Miscellaneous 7-02 Test Result Tables (for reference only)<br />

Miscellaneous 7-03 Test Result Tables (for Models BM1U2-5500V4H, BM1U2-<br />

5501V4H, BM1U2-5500V4V, BM1U2-5501V4V, BM1U-2500V)

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 1 of 10 Report Reference # E143756-A76-<strong>UL</strong><br />

Enclosure<br />

National Differences<br />

USA / Canada

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 2 of 10 Report Reference # E143756-A76-<strong>UL</strong><br />

IEC 60950-1<br />

SubClause Difference + Test Result - Remark Verdict<br />

USA / Canada - Differences to IEC 60950-1:2005 (Second Edition)<br />

1.1 Equipment able to be installed in accordance with<br />

the National Electrical Code ANSI/NFPA 70 and the<br />

Canadian Electrical Code, Part1, and when<br />

applicable, the National Electrical Safety Code,<br />

IEEE C2.<br />

1.1.1 Equipment able to be installed in accordance with<br />

ANSI/NFPA 75 and NEC Art. 645 unless intended<br />

for use outside of computer room and provided with<br />

such instructions.<br />

1.1.2 Equipment in wire-line communication facilities<br />

serving high-voltage electric power stations<br />

operating at greater than 1kV are excluded.<br />

1.1.2 Special requirements apply to equipment intended<br />

for use outdoors.<br />

1.4.14 For Pluggable Equipment Type A, the protection in<br />

the installation is assumed to be 20 A.<br />

1.5.1 All IEC standards for components identified in<br />

Annex P.1 replaced by the relevant requirements of<br />

CSA and <strong>UL</strong> component standards in Annex P.1.<br />

1.5.1 All IEC standards for components identified in<br />

Annex P.2 alternatively satisfied by the relevant<br />

requirements of CSA and <strong>UL</strong> component standards<br />

in Annex P.2.<br />

1.5.5 Interconnecting cables acceptable for the<br />

application regarding voltage, current, temperature,<br />

flammability, mechanical serviceability and the like.<br />

1.5.5 For other than limited power and TNV circuits, the<br />

type of output circuit identified for output connector.<br />

1.5.5 External cable assemblies that exceed 3.05 m in<br />

length to be types specified in the NEC and CEC.<br />

1.5.5 Detachable external interconnecting cables 3.05 m<br />

or less in length and provided with equipment<br />

marked to identify the responsible organization and<br />

the designation for the cable.<br />

1.5.5 Building wiring and cable for use in ducts, plenums<br />

and other air handling space subject to special<br />

requirements and excluded from scope.<br />

1.5.5 Telephone line and extension cords and the like<br />

comply with <strong>UL</strong> 1863 and CSA C22.2 No. 233.<br />

1.6.1.2 Equipment intended for connection to a d.c. power<br />

(mains) distribution system is subject to special<br />

Pass<br />

Pass<br />

N/A<br />

N/A<br />

N/A<br />

Pass<br />

Pass<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

Pass

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 3 of 10 Report Reference # E143756-A76-<strong>UL</strong><br />

IEC 60950-1<br />

SubClause Difference + Test Result - Remark Verdict<br />

circuit classification requirements (e.g., TNV-2)<br />

1.6.1.2 Earthing of d.c. powered equipment provided. Pass<br />

1.7 Lamp replacement information indicated on<br />

lampholder in operator access area.<br />

1.7.1 Special marking format for equipment intended for<br />

use on a supply system with an earthed neutral and<br />

more than one phase conductor.<br />

1.7.1 Equipment voltage rating not higher than rating of<br />

the plug except under special conditions.<br />

1.7.6 Special fuse replacement marking for operator<br />

accessible fuses.<br />

1.7.7 Identification of terminal connection of the<br />

equipment earthing conductor.<br />

1.7.7 Connectors and field wiring terminals for external<br />

Class 2 or Class 3 circuits provided with marking<br />

indicating minimum Class of wiring to be used.<br />

1.7.7 Marking located adjacent to terminals and visible<br />

during wiring.<br />

2.1.1.1 Bare TNV conductive parts in the interior of<br />

equipment normally protected against contact by a<br />

cover intended for occasional removal are exempt<br />

provided instructions include directions for<br />

disconnection of TNV prior to removal of the cover.<br />

2.3.1.b Other telecommunication signaling systems (e.g.,<br />

message waiting) than described in 2.3.1(b) are<br />

subject to M.4.<br />

2.3.1.b For TNV-2 and TNV-3 circuits with other than<br />

ringing signals and with voltages exceeding 42.4 Vp<br />

or 60 V d.c., the maximum current limit through a<br />

2000 Ohm or greater resistor with loads<br />

disconnected is 7.1 mA peak or 30 mA d.c. under<br />

normal conditions.<br />

2.3.1.b Limits for measurements across 5000 ohm resistor<br />

in the event of a single fault are replaced after 200<br />

ms with the limits of M.3.1.4.<br />

2.3.2.1 In the event of a single fault, the limits of 2.2.3 apply<br />

to SELV circuits and accessible conductive parts.<br />

2.3.2.4 Enamel coating on signal transformer winding wire<br />

allowed as an alternative to Basic insulation in<br />

specific telecommunication applications when<br />

subjected to special construction requirements and<br />

routine testing.<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

Pass<br />

N/A<br />

Pass<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 4 of 10 Report Reference # E143756-A76-<strong>UL</strong><br />

IEC 60950-1<br />

SubClause Difference + Test Result - Remark Verdict<br />

2.5 Overcurrent protection device required for Class 2<br />

and Class 3 limiting in accordance with the NEC, or<br />

for a Limited Power Source, not interchangeable<br />

with devices of higher ratings if operator<br />

replaceable.<br />

2.6 Equipment having receptacles for output a.c. power<br />

connectors generated from an internal separately<br />

derived source have the earthed (grounded) circuit<br />

conductor suitably bonded to earth.<br />

2.6.3.3 For Pluggable Equipment Type A, if a) b) or c) are<br />

not applicable, the current rating of the circuit is<br />

taken as 20 A<br />

2.6.3.4 Capacity of connection between earthing terminal<br />

and parts required to be earthed subject to special<br />

conditions based on the current rating of the circuit.<br />

2.6.3.4 Protective bonding conductors and their terminals of<br />

non-standard constructions (e.g. PWB traces)<br />

evaluated to limited short-circuit test of CSA C22.2<br />

No.0.4.<br />

2.6.4.1 Field wiring terminals for earthing conductors<br />

suitable for wire sizes (gauge) used in US and<br />

Canada.<br />

2.7.1 Data for selection of special external branch circuit<br />

overcurrent devices marked on the equipment.<br />

2.7.1 Standard supply outlets protected by overcurrent<br />

device in accordance with the NEC, and CEC, Part<br />

1.<br />

2.7.1 Overcurrent protection for individual transformers<br />

that distribute power to other units over branch<br />

circuit wiring.<br />

2.7.1 Additional requirements for overcurrent protection<br />

apply to equipment provided with panelboards.<br />

2.7.1 Non-motor-operated equipment requiring special<br />

overcurrent protective device marked with device<br />

rating.<br />

2.10.5.12 Multi-layer winding wire subject to <strong>UL</strong> component<br />

wire requirements in addition to 2.10.5.12 and<br />

Annex U.<br />

3.1.1 Permissible combinations of internal wiring/external<br />

cable sizes for overcurrent and short circuit<br />

protection.<br />

Equipment is for building-in, An<br />

additional consideration has to<br />

be considered in the end<br />

product.<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

Pass<br />

Pass

Issue Date: 2009-07-08<br />

2010-10-26<br />

Page 5 of 10 Report Reference # E143756-A76-<strong>UL</strong><br />

IEC 60950-1<br />

SubClause Difference + Test Result - Remark Verdict<br />

3.1.1 All interconnecting cables protected against<br />

overcurrent and short circuit.<br />

3.2 Wiring methods permit connection of equipment to<br />

primary power supply in accordance with the NEC<br />

and CEC, Part 1.<br />

3.2.1 Permitted use for flexible cords and plugs. N/A<br />

3.2.1 Flexible cords provided with attachment plug rated<br />

125% of equipment current rating.<br />

3.2.1 Any Class II equipment provided with 15 or 20 A<br />

standard supply outlets, Edison-base lampholders<br />

or single pole disconnect device provided with a<br />

polarized type attachment plug.<br />

3.2.1.2 Equipment intended for connection to DC mains<br />

supply power systems complies with special wiring<br />

requirements (e.g., no permanent connection to<br />

supply by flexible cord).<br />

3.2.1.2 Equipment with one pole of the DC mains supply<br />

connected to both the equipment mains input<br />

terminal and the main protective earthing terminal<br />

provided with special instructions and construction<br />

provisions for earthing<br />

3.2.1.2 Equipment with means for connecting supply to<br />

earthing electrode conductor has no switches or<br />