cover page for test report - Zippy

cover page for test report - Zippy

cover page for test report - Zippy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

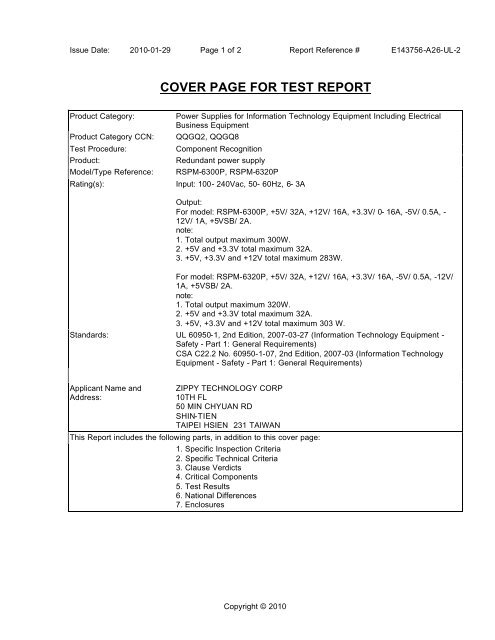

Issue Date: 2010-01-29 Page 1 of 2 Report Reference # E143756-A26-UL-2<br />

COVER PAGE FOR TEST REPORT<br />

Product Category: Power Supplies <strong>for</strong> In<strong>for</strong>mation Technology Equipment Including Electrical<br />

Business Equipment<br />

Product Category CCN: QQGQ2, QQGQ8<br />

Test Procedure: Component Recognition<br />

Product: Redundant power supply<br />

Model/Type Reference: RSPM-6300P, RSPM-6320P<br />

Rating(s): Input: 100- 240Vac, 50- 60Hz, 6- 3A<br />

Output:<br />

For model: RSPM-6300P, +5V/ 32A, +12V/ 16A, +3.3V/ 0- 16A, -5V/ 0.5A, -<br />

12V/ 1A, +5VSB/ 2A.<br />

note:<br />

1. Total output maximum 300W.<br />

2. +5V and +3.3V total maximum 32A.<br />

3. +5V, +3.3V and +12V total maximum 283W.<br />

For model: RSPM-6320P, +5V/ 32A, +12V/ 16A, +3.3V/ 16A, -5V/ 0.5A, -12V/<br />

1A, +5VSB/ 2A.<br />

note:<br />

1. Total output maximum 320W.<br />

2. +5V and +3.3V total maximum 32A.<br />

3. +5V, +3.3V and +12V total maximum 303 W.<br />

Standards: UL 60950-1, 2nd Edition, 2007-03-27 (In<strong>for</strong>mation Technology Equipment -<br />

Safety - Part 1: General Requirements)<br />

CSA C22.2 No. 60950-1-07, 2nd Edition, 2007-03 (In<strong>for</strong>mation Technology<br />

Equipment - Safety - Part 1: General Requirements)<br />

Applicant Name and<br />

Address:<br />

ZIPPY TECHNOLOGY CORP<br />

10TH FL<br />

50 MIN CHYUAN RD<br />

SHIN-TIEN<br />

TAIPEI HSIEN 231 TAIWAN<br />

This Report includes the following parts, in addition to this <strong>cover</strong> <strong>page</strong>:<br />

1. Specific Inspection Criteria<br />

2. Specific Technical Criteria<br />

3. Clause Verdicts<br />

4. Critical Components<br />

5. Test Results<br />

6. National Differences<br />

7. Enclosures<br />

Copyright © 2010

Issue Date: 2010-01-29 Page 2 of 2 Report Reference # E143756-A26-UL-2<br />

This is to certify that representative samples of the products <strong>cover</strong>ed by this Test Report have been investigated in accordance with the<br />

above referenced Standards. The products have been found to comply with the requirements <strong>cover</strong>ing the category and the products are<br />

judged to be eligible <strong>for</strong> Follow -Up Service under the indicated Test Procedure. The manufacturer is authorized to use the UL Mark on<br />

such products which comply with this Test Report and any other applicable requirements of Underwriters Laboratories Inc. ('UL') in<br />

accordance with the Follow -Up Service Agreement. Only those products which properly bear the UL Mark are considered as being<br />

<strong>cover</strong>ed by UL's Follow -Up Service under the indicated Test Procedure.<br />

The applicant is authorized to reproduce the referenced Test Report provided it is reproduced in its entirety.<br />

UL authorizes the applicant to reproduce the la<strong>test</strong> <strong>page</strong>s of the referenced Test Report consisting of the first <strong>page</strong> of the Specific<br />

Technical Criteria through to the end of the Conditions of Acceptability.<br />

Any in<strong>for</strong>mation and documentation provided to you involving UL Mark services are provided on behalf of Underwriters Laboratories<br />

Inc(ULI) or any authorized license of ULI.<br />

Test Report By: Reviewed By:<br />

Rex Lin Wim Liang<br />

Associate Project Engineer Project Engineer<br />

Underwriters Laboratories Taiwan Co., Ltd. UL-CCIC Company Limited<br />

Copyright © 2010

Issue Date: 2010-01-29 Page 1 of 69 Report Reference # E143756-A26-UL-2<br />

SPECIFIC INSPECTION CRITERIA<br />

BA1.0 Special Instructions to UL Representative<br />

BA1.1 Inspect the trans<strong>for</strong>mer(s) listed in BD1.1 per AA1.1-(C). When the <strong>test</strong>s are conducted at other<br />

location, inspect <strong>test</strong> record and specification sheet provided by the component manufacturer.<br />

Verify the specification sheet indicates 100% routine <strong>test</strong> specified in BD1.1 be conducted at the<br />

component manufacturer.<br />

BB1.0 Supporting Documentation<br />

BB1.1 The following documents located at the beginning of this Procedure supplement the requirements<br />

of this Test Report:<br />

A. Authorization - The Authorization <strong>page</strong> may include additional Factory Identification Code<br />

markings.<br />

B. Generic Inspection Instructions -<br />

i. Part AC details important in<strong>for</strong>mation which may be applicable to products <strong>cover</strong>ed by this<br />

Procedure. Products described in this Test Report must comply with any applicable items<br />

listed unless otherwise stated in the body of this Test Report.<br />

ii. Part AE details any requirements which may be applicable to all products <strong>cover</strong>ed by this<br />

Procedure. Products described in this Test Report must comply with any applicable items<br />

listed unless otherwise stated in the body of each Test Report.<br />

iii. Part AF details the requirements <strong>for</strong> the UL Certification Mark which is not controlled by the<br />

technical standard used to investigate these products. Products are permitted to bear only<br />

the Certification Mark(s) corresponding to the countries <strong>for</strong> which it is certified, as indicated<br />

in each Test Report.<br />

BC1.0 Markings and instructions<br />

BC1.1 The following markings and instructions are provided as indicated.<br />

BC1.2 All clause references are from UL 60950-1, 2nd Edition, 2007-03-27 (In<strong>for</strong>mation Technology<br />

Equipment - Safety - Part 1: General Requirements).<br />

Standard<br />

Clause<br />

Clause Title Marking or Instruction Details<br />

1.7.1 Power rating -<br />

Ratings<br />

Power rating -<br />

Company<br />

identification<br />

Power rating -<br />

Model<br />

Ratings (voltage, frequency/dc, current)<br />

Listee's or Recognized company's name, Trade Name, Trademark or File<br />

Number<br />

Model Number<br />

1.7.6 Fuses - Rating Rated current and voltage and type located on or adjacent to fuse or<br />

fuseholder.<br />

1.7.8.3 Symbols - On/Off All other controls to be marked with symbol <strong>for</strong> "ON" (60417-2-IEC-5007)<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.

Issue Date: 2010-01-29 Page 2 of 69 Report Reference # E143756-A26-UL-2<br />

switch<br />

BD1.0 Production-Line Testing Requirements<br />

and symbol <strong>for</strong> "OFF" (60417-2-IEC-5008)<br />

BD1.1 Electric Strength Test Special Constructions - Refer to Generic Inspection Instructions, Part AC <strong>for</strong><br />

further in<strong>for</strong>mation.<br />

Model Component Removable Parts Test probe location<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Test<br />

Potential<br />

V<br />

rms V dc<br />

All Models T3, T4 -- Pri - Sec 3000 424<br />

2<br />

BD1.2 Earthing Continuity Test Exemptions - This<br />

<strong>test</strong> is not required <strong>for</strong> the following models:<br />

BD1.3 Electric Strength Test Exemptions - This <strong>test</strong><br />

is not required <strong>for</strong> the following models:<br />

BD1.4 Electric Strength Test Component<br />

Exemptions - The following solid-state<br />

components may disconnected from the<br />

remainder of the circuitry during the<br />

per<strong>for</strong>mance of this <strong>test</strong>:<br />

All Models<br />

All Models<br />

N/A<br />

BE1.0 Sample and Test Specifics <strong>for</strong> Follow-Up Tests at UL<br />

BE1.1<br />

N/A<br />

Model Component Material Test Sample(s)<br />

Test<br />

Time, s<br />

1<br />

Test<br />

Specifics

Issue Date: 2010-01-29 Page 3 of 69 Report Reference # E143756-A26-UL-2<br />

SPECIFIC TECHNICAL CRITERIA<br />

UL 60950-1:2005 (2nd Edition)<br />

In<strong>for</strong>mation technology equipment - Safety -<br />

Part 1: General requirements<br />

Report Reference No ..................... : E143756-A26-UL-2<br />

Compiled by ................................. : Rex Lin<br />

Reviewed by ................................. : Wim Liang<br />

Date of issue ................................ : 2010-01-29<br />

Standards ..................................... : UL 60950-1, 2nd Edition, 2007-03-27 (In<strong>for</strong>mation Technology<br />

Equipment - Safety - Part 1: General Requirements)<br />

CSA C22.2 No. 60950-1-07, 2nd Edition, 2007-03 (In<strong>for</strong>mation<br />

Technology Equipment - Safety - Part 1: General Requirements)<br />

Test procedure .............................. : Component Recognition<br />

Non-standard <strong>test</strong> method ............. : N/A<br />

Test item description .................... : Redundant power supply<br />

Trademark .................................... : None<br />

Model and/or type reference .......... : RSPM-6300P, RSPM-6320P<br />

Rating(s) ...................................... : Input: 100- 240Vac, 50- 60Hz, 6- 3A<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Output:<br />

For model: RSPM-6300P, +5V/ 32A, +12V/ 16A, +3.3V/ 0- 16A, -5V/<br />

0.5A, -12V/ 1A, +5VSB/ 2A.<br />

note:<br />

1. Total output maximum 300W.<br />

2. +5V and +3.3V total maximum 32A.<br />

3. +5V, +3.3V and +12V total maximum 283W.<br />

For model: RSPM-6320P, +5V/ 32A, +12V/ 16A, +3.3V/ 16A, -5V/<br />

0.5A, -12V/ 1A, +5VSB/ 2A.<br />

note:<br />

1. Total output maximum 320W.<br />

2. +5V and +3.3V total maximum 32A.<br />

3. +5V, +3.3V and +12V total maximum 303 W.

Issue Date: 2010-01-29 Page 4 of 69 Report Reference # E143756-A26-UL-2<br />

Particulars: <strong>test</strong> item vs. <strong>test</strong> requirements<br />

Equipment mobility ................................................: <strong>for</strong> building-in<br />

Connection to the mains ........................................: pluggable A<br />

Operating condition ...............................................: continuous<br />

Over voltage category ...........................................: OVC II<br />

Mains supply tolerance (%) ....................................: +10%, -10%<br />

Tested <strong>for</strong> IT power systems ..................................: No<br />

IT <strong>test</strong>ing, phase-phase voltage (V) ........................: N/A<br />

Class of equipment ...............................................: Class I (earthed)<br />

Mass of equipment (kg) .........................................: 2.6Kg (Max)<br />

Pollution degree ....................................................: PD 2<br />

IP protection class .................................................: IP X0<br />

Possible <strong>test</strong> case verdicts:<br />

- <strong>test</strong> case does not apply to the <strong>test</strong> object .............: N / A<br />

- <strong>test</strong> object does meet the requirement ..................: Pass<br />

- <strong>test</strong> object does not meet the requirement ............: Fail (acceptable only if a corresponding, less stringent<br />

national requirement is "Pass")<br />

General remarks:<br />

- "(see Enclosure #)" refers to additional in<strong>for</strong>mation appended to the Test Report<br />

- "(see appended table)" refers to a table appended to the Test Report<br />

- Throughout the Test Report a point is used as the decimal separator<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.

Issue Date: 2010-01-29 Page 5 of 69 Report Reference # E143756-A26-UL-2<br />

GENERAL PRODUCT INFORMATION:<br />

CA1.0 Report Summary<br />

CA1.1 N/A<br />

CB1.0 Product Description<br />

CB1.1 The product is an enclosed switch mode power supply intended <strong>for</strong> factory installation as a<br />

component of end product In<strong>for</strong>mation Technology Equipment.<br />

CC1.0 Model Differences<br />

CC1.1 All models are identical except <strong>for</strong> output ratings, model designation and as described in the<br />

<strong>report</strong>.<br />

CD1.0 Additional In<strong>for</strong>mation<br />

CD1.1 Reissue 2:<br />

1. Upgrade Standard 69050-1 2nd Edition;<br />

2. Alternate Varistors source with CCN: VZCA2.<br />

CE1.0 Technical Considerations<br />

CE1.2 The product was submitted and evaluated <strong>for</strong> use at the maximum ambient temperature (Tma)<br />

permitted by the manufacturer’s specification of: 50°C<br />

CE1.3 The means of connection to the mains supply is: Detachable power cord or Pluggable A<br />

CE1.4 The product is intended <strong>for</strong> use on the following power systems: TN<br />

CE1.5 The equipment disconnect device is considered to be: Appliance inlet<br />

CE1.13 The following are available from the Applicant upon request: Specific data sheets <strong>for</strong> LED<br />

indicators that are class I and operate at wavelength in the 400-710 nm range.<br />

CF1.0 Engineering Conditions of Acceptability<br />

CF1.1 For use only in or with complete equipment where the acceptability of the combination is<br />

determined by Underwriters Laboratories Inc.<br />

When installed in an end-product, consideration must be given to the following:<br />

CF1.3 The end-product Electric Strength Test is to be based upon a maximum working voltage of:<br />

Primary-Earthed Dead Metal: 416 Vrms, 800 Vpk, Primary-SELV: 423Vrms, 820 Vpk<br />

CF1.5 The following secondary output circuits are SELV: All outputs<br />

CF1.6 The following secondary output circuits are at hazardous energy levels: Output +5V and +12V<br />

CF1.7 The following secondary output circuits are at non-hazardous energy levels: All outputs except<br />

+5V and +12V.<br />

CF1.10 The following output terminals were referenced to earth during per<strong>for</strong>mance <strong>test</strong>ing: Output (-)<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.

Issue Date: 2010-01-29 Page 6 of 69 Report Reference # E143756-A26-UL-2<br />

CF1.11 The power supply terminals and/or connectors are: Suitable <strong>for</strong> factory wiring only<br />

CF1.12 The maximum investigated branch circuit rating is: 20 A<br />

CF1.13 The investigated Pollution Degree is: 2<br />

CF1.15 Proper bonding to the end-product main protective earthing termination is: Required<br />

CF1.16 An investigation of the protective bonding terminals has: Been conducted<br />

CF1.18 The following magnetic devices (e.g. trans<strong>for</strong>mers or inductor) are provided with an OBJY2<br />

insulation system with the indicated rating greater than Class A (105°C): T3, T4(Class B)<br />

CF1.19 The following end-product enclosures are required: Electrical, Fire<br />

CF1.23 The equipment is suitable <strong>for</strong> direct connection to: AC mains supply<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.

Issue Date: 2010-01-29 Page 7 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

1 GENERAL Pass<br />

1.5 Components Pass<br />

1.5.1 General Pass<br />

Comply with IEC 60950 or relevant component<br />

standard<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

See table 1.5.1 Pass<br />

1.5.2 Evaluation and <strong>test</strong>ing of components Components certified to IEC<br />

harmonized standard and<br />

checked <strong>for</strong> correct application<br />

1.5.3 Thermal controls N/A<br />

1.5.4 Trans<strong>for</strong>mers Trans<strong>for</strong>mer used is suitable<br />

<strong>for</strong> its intended application and<br />

complies with the relevant<br />

requirements of the standard<br />

and particularly Annex C.<br />

1.5.5 Interconnecting cables Interconnecting cables comply<br />

with the relevant requirements<br />

of this standard.<br />

1.5.6 Capacitors bridging insulation Line-to-Line capacitors are<br />

subclass X1 or X2. Primaryto-earth<br />

capacitors are<br />

subclass Y1 or Y2.<br />

1.5.7 Resistors bridging insulation Pass<br />

1.5.7.1 Resistors bridging functional, basic or<br />

supplementary insulation<br />

1.5.7.2 Resistors bridging double or rein<strong>for</strong>ced insulation<br />

between a.c. mains and other circuits<br />

1.5.7.3 Resistors bridging double or rein<strong>for</strong>ced insulation<br />

between a.c. mains and antenna or coaxial cable<br />

1.5.7.4 Accessible parts N/A<br />

1.5.8 Components in equipment <strong>for</strong> IT power systems N/A<br />

1.5.9 Surge suppressors Pass<br />

1.5.9.1 General Pass<br />

1.5.9.2 Protection of VDRs Pass<br />

1.5.9.3 Bridging of functional insulation by a VDR Pass<br />

1.5.9.4 Bridging of basic insulation by a VDR N/A<br />

1.5.9.5 Bridging of supplementary, double or rein<strong>for</strong>ced<br />

insulation by a VDR<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

N/A<br />

N/A

Issue Date: 2010-01-29 Page 8 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

1.6 Power interface Pass<br />

1.6.1 AC power distribution systems Pass<br />

1.6.2 Input current This equipment is the<br />

operation with the max.<br />

specified DC-load. Results see<br />

appended table.<br />

1.6.3 Voltage limit of hand-held equipment N/A<br />

1.6.4 Neutral conductor Neutral is insulated from earth<br />

with basic insulation.<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Pass<br />

Pass

Issue Date: 2010-01-29 Page 9 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

1.7 Marking and instructions Pass<br />

1.7.1 Power rating Pass<br />

Rated voltage(s) or voltage range(s) (V).............. : See "SPECIFIC TECHNICAL<br />

CRITERIA" <strong>for</strong> detail.<br />

Symbol <strong>for</strong> nature of supply, <strong>for</strong> d.c. only............. : N/A<br />

Rated frequency or rated frequency range (Hz)... : See "SPECIFIC TECHNICAL<br />

CRITERIA" <strong>for</strong> detail.<br />

Rated current (mA or A)..................................... : See "SPECIFIC TECHNICAL<br />

CRITERIA" <strong>for</strong> detail.<br />

Manufacturer's name or trademark or identification<br />

mark ................................................................. :<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

See "SPECIFIC TECHNICAL<br />

CRITERIA" <strong>for</strong> detail.<br />

Model identification or type reference.................. : See "SPECIFIC TECHNICAL<br />

CRITERIA" <strong>for</strong> detail.<br />

Symbol <strong>for</strong> Class II equipment only ..................... : N/A<br />

Other markings and symbols .............................. : The additional marking does<br />

not give rise to<br />

misunderstandings.<br />

1.7.2 Safety instructions and marking Installation instruction with<br />

directions to maintain the<br />

requirements of IEC 60950<br />

during the installation into the<br />

end system. Included are<br />

directions regarding the<br />

maximum ambient<br />

temperature and electrical<br />

rating of the equipment.<br />

1.7.2.1 General Pass<br />

1.7.2.2 Disconnect devices N/A<br />

1.7.2.3 Overcurrent protective device N/A<br />

1.7.2.4 IT Power distribution systems N/A<br />

1.7.2.5 Operator access with a tool N/A<br />

1.7.2.6 Ozone N/A<br />

1.7.3 Short duty cycles N/A<br />

1.7.4 Supply voltage adjustment ................................. : N/A<br />

Method and means of adjustment; reference to<br />

installation instructions ....................................... :<br />

1.7.5 Power outlets on the equipment ......................... : N/A<br />

1.7.6 Fuse identification (marking, special fusing<br />

characteristics, cross-reference)......................... :<br />

Fuse marking on PCB near<br />

fuse or provided in service<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

N/A<br />

Pass

Issue Date: 2010-01-29 Page 10 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

documentation.<br />

1.7.7 Wiring terminals Pass<br />

1.7.7.1 Protective earthing and bonding terminals........... : The earth terminal is marked<br />

with the standard earth symbol<br />

(60417-2-IEC-5017) near the<br />

terminal.<br />

1.7.7.2 Terminal <strong>for</strong> a.c. mains supply conductors Not permanently connected<br />

unit.<br />

1.7.7.3 Terminals <strong>for</strong> d.c. mains supply conductors N/A<br />

1.7.8 Controls and indicators See below. Pass<br />

1.7.8.1 Identification, location and marking ..................... : An LED provided <strong>for</strong> indicating<br />

power ON mode.<br />

1.7.8.2 Colours ............................................................. : A green LED is illuminated<br />

when the unit is operating.<br />

A red LED is illuminated when<br />

one board is not operating.<br />

1.7.8.3 Symbols according to IEC 60417 ........................ : The mains switch is marked<br />

with the symbols: "0" and "I"<br />

(60417-1-IEC-5007 and IEC-<br />

5008).<br />

1.7.8.4 Markings using figures ....................................... : N/A<br />

1.7.9 Isolation of multiple power sources ..................... : N/A<br />

1.7.10 Thermostats and other regulating devices ........... : N/A<br />

1.7.11 Durability All markings provided on UL<br />

Recognized Component labels<br />

suitable <strong>for</strong> surface they are<br />

applied upon and meet the<br />

durability <strong>test</strong>.<br />

1.7.12 Removable parts N/A<br />

1.7.13 Replaceable batteries ........................................ : N/A<br />

Language(s)...................................................... : -<br />

1.7.14 Equipment <strong>for</strong> restricted access locations............ : To be determined in the end<br />

product.<br />

Pass<br />

N/A<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

N/A

Issue Date: 2010-01-29 Page 11 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

2 PROTECTION FROM HAZARDS Pass<br />

2.1 Protection from electric shock and energy hazards Pass<br />

2.1.1 Protection in operator access areas Should be investigated in the<br />

final system assembly.<br />

2.1.1.1 Access to energized parts Equipment <strong>for</strong> building-in.<br />

Compliance with the<br />

requirements of this clause<br />

shall be evaluated during the<br />

approval of the final system.<br />

Test by inspection ............................................. : N/A<br />

Test with <strong>test</strong> finger (Figure 2A).......................... : N/A<br />

Test with <strong>test</strong> pin (Figure 2B).............................. : N/A<br />

Test with <strong>test</strong> probe (Figure 2C) ......................... : N/A<br />

2.1.1.2 Battery compartments N/A<br />

2.1.1.3 Access to ELV wiring N/A<br />

Working voltage (Vpeak or Vrms); minimum<br />

distance through insulation (mm)........................ :<br />

2.1.1.4 Access to hazardous voltage circuit wiring Should be investigated in the<br />

final system assembly.<br />

2.1.1.5 Energy hazards ................................................. : The output energy level<br />

exceeds 240VA. Compliance<br />

is to be evaluated <strong>for</strong> the final<br />

system.<br />

2.1.1.6 Manual controls N/A<br />

2.1.1.7 Discharge of capacitors in equipment No risk of electric shock. Pass<br />

Measured voltage (V); time-constant (s).............. : Fuse In, Switch both on:<br />

Maximum 376Vpk decay to<br />

139.12 Vpk (37% of its original<br />

value) at 0.318 sec within 1.0<br />

second.<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Fuse In, Switch one on, one<br />

off: Maximum 376Vpk decay to<br />

139.12Vpk (37% of its original<br />

value) at 0.524 sec within 1.0<br />

second.<br />

Fuse In, Switch both off:<br />

Maximum 368Vpk decay to<br />

136.16Vpk (37% of its original<br />

value) at 0.984 sec within 1.0<br />

second.<br />

Pass<br />

N/A<br />

-<br />

N/A<br />

N/A<br />

-

Issue Date: 2010-01-29 Page 12 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

2.1.1.8 Energy hazards - d.c. mains supply N/A<br />

a) Capacitor connected to the d.c. mains supply .. : N/A<br />

b) Internal battery connected to the mains supply : N/A<br />

2.1.1.9 Audio amplifiers ................................................. : N/A<br />

2.1.2 Protection in service access areas Equipment <strong>for</strong> building-in.<br />

Compliance shall be<br />

investigated in the final system<br />

assembly.<br />

2.1.3 Protection in restricted access locations Equipment <strong>for</strong> building-in. N/A<br />

2.2 SELV circuits Pass<br />

2.2.1 General requirements SELV levels are maintained<br />

after single fault condition.<br />

2.2.2 Voltages under normal conditions (V).................. : All accessible voltages are<br />

less than 42.4 Vp or 60 V dc<br />

and are classified as SELV.<br />

2.2.3 Voltages under fault conditions (V) ..................... : Under fault conditions.<br />

voltages never exceed 71V<br />

peak and 120Vdc and do not<br />

exceed 42.2V peak or 60V dc<br />

<strong>for</strong> more than 0.2 sec.<br />

2.2.4 Connection of SELV circuits to other circuits ....... : SELV circuits are only<br />

connected to other secondary<br />

circuits. SELV circuit and all<br />

interconnected circuits<br />

separated from primary by<br />

Rein<strong>for</strong>ced insulation. The<br />

SELV circuit does not exceed<br />

the SELV limits under normal<br />

and fault conditions.<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

N/A<br />

Pass<br />

Pass<br />

Pass<br />

Pass

Issue Date: 2010-01-29 Page 13 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

2.3 TNV circuits N/A<br />

2.3.1 Limits No TNV circuit. N/A<br />

Type of TNV circuits .......................................... : -<br />

2.3.2 Separation from other circuits and from accessible<br />

parts<br />

2.3.2.1 General requirements N/A<br />

2.3.2.2 Protection by basic insulation N/A<br />

2.3.2.3 Protection by earthing N/A<br />

2.3.2.4 Protection by other constructions ........................ : N/A<br />

2.3.3 Separation from hazardous voltages N/A<br />

Insulation employed........................................... : -<br />

2.3.4 Connection of TNV circuits to other circuits N/A<br />

Insulation employed........................................... : -<br />

2.3.5 Test <strong>for</strong> operating voltages generated externally N/A<br />

2.4 Limited current circuits N/A<br />

2.4.1 General requirements N/A<br />

2.4.2 Limit values N/A<br />

Frequency (Hz) ................................................. : -<br />

Measured current (mA) ...................................... : -<br />

Measured voltage (V) ........................................ : -<br />

Measured circuit capacitance (nF or uF) ............. : -<br />

2.4.3 Connection of limited current circuits to other<br />

circuits<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

N/A<br />

N/A

Issue Date: 2010-01-29 Page 14 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

2.5 Limited power sources N/A<br />

a) Inherently limited output N/A<br />

b) Impedance limited output N/A<br />

c) Regulating network limited output under normal<br />

operating and single fault condition<br />

d) Overcurrent protective device limited output N/A<br />

Max. output voltage (V), max. output current (A),<br />

max. apparent power (VA) ................................. :<br />

Current rating of overcurrent protective device (A): -<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

N/A<br />

-

Issue Date: 2010-01-29 Page 15 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

2.6 Provisions <strong>for</strong> earthing and bonding Pass<br />

2.6.1 Protective earthing Accessible parts (chassis) are<br />

earthed.<br />

2.6.2 Functional earthing SELV circuits. Pass<br />

2.6.3 Protective earthing and protective bonding<br />

conductors<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Pass<br />

Appliance Inlet used. Pass<br />

2.6.3.1 General Pass<br />

2.6.3.2 Size of protective earthing conductors No power cord provided. N/A<br />

Rated current (A), cross-sectional area (mm²),<br />

AWG ................................................................ :<br />

2.6.3.3 Size of protective bonding conductors Protective bonding evaluated<br />

based on 2.6.3.4.<br />

Rated current (A), cross-sectional area mm²), AWG<br />

........................................................................ :<br />

2.6.3.4 Resistance of earthing conductors and their<br />

terminations; resistance (ohm), voltage drop (V),<br />

<strong>test</strong> current (A), duration (min)............................ :<br />

Earth Pin of terminal to<br />

Chassis<br />

1: Test Current=25A,<br />

resistance=16.2m ohm.<br />

2: Test Current=40A,<br />

resistance=14.4m ohm.<br />

2.6.3.5 Colour of insulation ............................................ : Green / Yellow wire from AC<br />

inlet to chassis. The wire is<br />

reliably fixed to the chassis<br />

with star washer and screw.<br />

2.6.4 Terminals Appliance inlet used. Pass<br />

2.6.4.1 General Pass<br />

2.6.4.2 Protective earthing and bonding terminals Pass<br />

Rated current (A), type, nominal thread diameter<br />

(mm)................................................................. :<br />

2.6.4.3 Separation of the protective earthing conductor<br />

from protective bonding conductors<br />

Complies with the <strong>test</strong> of<br />

2.6.3.4<br />

Detachable power cord.<br />

Power Cord not provided.<br />

Appliance inlet has earthing<br />

terminal.<br />

2.6.5 Integrity of protective earthing Pass<br />

2.6.5.1 Interconnection of equipment Equipment contains a<br />

protective bonding conductor<br />

to maintain continuity of<br />

protective earthing circuits to<br />

other equipment through a<br />

standard outlet that complies<br />

with IEC 60320.<br />

-<br />

N/A<br />

-<br />

Pass<br />

Pass<br />

-<br />

N/A<br />

Pass

Issue Date: 2010-01-29 Page 16 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

2.6.5.2 Components in protective earthing conductors and<br />

protective bonding conductors<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

No switch or overcurrent<br />

protective device in protective<br />

earthing or bonding conductor.<br />

2.6.5.3 Disconnection of protective earth Disconnection of the protective<br />

earth at one assembly<br />

removes connection of<br />

HAZARDOUS VOLTAGES<br />

from the other assemblies at<br />

the same time.<br />

2.6.5.4 Parts that can be removed by an operator Protective earth required<br />

makes earlier and breaks later<br />

than the supply connectors.<br />

2.6.5.5 Parts removed during servicing Connections to protective<br />

earthing can be removed<br />

unless hazardous voltage is<br />

removed from the part<br />

simultaneously.<br />

2.6.5.6 Corrosion resistance No risk of corrosion. Complies<br />

with Annex J.<br />

2.6.5.7 Screws <strong>for</strong> protective bonding Metal thickness at least twice<br />

the pitch of the screw.<br />

At least two screws used.<br />

2.6.5.8 Reliance on telecommunication network or cable<br />

distribution system<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

No TNV. N/A

Issue Date: 2010-01-29 Page 17 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

2.7 Overcurrent and earth fault protection in primary circuits Pass<br />

2.7.1 Basic requirements Protection provided as part of<br />

the building installation.<br />

Instructions when protection relies on building<br />

installation<br />

2.7.2 Faults not <strong>cover</strong>ed in 5.3.7 Protection from faults not<br />

<strong>cover</strong>ed in 5.3 are provided by<br />

installation.<br />

2.7.3 Short-circuit backup protection The equipment is pluggable<br />

Type A.<br />

Building installation is<br />

considered as providing shortcircuit<br />

backup protection.<br />

2.7.4 Number and location of protective devices .......... : One protective device in the<br />

"LIVE" phase.<br />

2.7.5 Protection by several devices Only one protective device is<br />

provided.<br />

2.7.6 Warning to service personnel ............................. : N/A<br />

2.8 Safety interlocks N/A<br />

2.8.1 General principles N/A<br />

2.8.2 Protection requirements N/A<br />

2.8.3 Inadvertent reactivation N/A<br />

2.8.4 Fail-safe operation N/A<br />

2.8.5 Moving parts N/A<br />

2.8.6 Overriding N/A<br />

2.8.7 Switches and relays N/A<br />

2.8.7.1 Contact gaps (mm) ............................................ : N/A<br />

2.8.7.2 Overload <strong>test</strong> N/A<br />

2.8.7.3 Endurance <strong>test</strong> N/A<br />

2.8.7.4 Electric strength <strong>test</strong> N/A<br />

2.8.8 Mechanical actuators N/A<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Pass<br />

N/A<br />

Pass<br />

N/A<br />

Pass<br />

N/A

Issue Date: 2010-01-29 Page 18 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

2.9 Electrical insulation Pass<br />

2.9.1 Properties of insulating materials Natural rubber, asbestos or<br />

hygroscopic materials are not<br />

used.<br />

2.9.2 Humidity conditioning 120 hours Pass<br />

Relative humidity (%), temperature (°C) .............. : 93% , 40°C -<br />

2.9.3 Grade of insulation The adequate levels of safety<br />

insulation are provided and<br />

maintained to comply with the<br />

requirements of this standard.<br />

2.9.4 Separation from hazardous voltages Pass<br />

Method(s) used ................................................. : Method 1 used -<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Pass<br />

Pass

Issue Date: 2010-01-29 Page 19 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

2.10 Clearances, cree<strong>page</strong> distances and distances through insulation Pass<br />

2.10.1 General See 2.10.3, 2.10.4, 2.10.5 Pass<br />

2.10.1.1 Frequency......................................................... : Less than 30 KHz Pass<br />

2.10.1.2 Pollution degrees ............................................... : 2 Pass<br />

2.10.1.3 Reduced values <strong>for</strong> functional insulation N/A<br />

2.10.1.4 Intervening unconnected conductive parts N/A<br />

2.10.1.5 Insulation with varying dimensions N/A<br />

2.10.1.6 Special separation requirements N/A<br />

2.10.1.7 Insulation in circuits generating starting pulses N/A<br />

2.10.2 Determination of working voltage Unit was connected to a 240V<br />

TN power system.<br />

2.10.2.1 General Pass<br />

2.10.2.2 RMS working voltage (see appended table 2.10.3<br />

and 2.10.4).<br />

2.10.2.3 Peak working voltage (see appended table 2.10.3<br />

and 2.10.4).<br />

2.10.3 Clearances (see appended table 2.10.3<br />

and 2.10.4).<br />

2.10.3.1 General Pass<br />

2.10.3.2 Mains transient voltages Overvoltage Category II; Mains<br />

transient voltage is 2500<br />

Vpeak<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

a) AC mains supply ........................................... : Less than 300 Vrms. Pass<br />

b) Earthed d.c. mains supplies............................ : N/A<br />

c) Unearthed d.c.. mains supplies ....................... : N/A<br />

d) Battery operation ........................................... : N/A<br />

2.10.3.3 Clearances in primary circuits See appended table 2.10.3<br />

and 2.10.4.<br />

2.10.3.4 Clearances in secondary circuits See 5.3.4. Pass<br />

2.10.3.5 Clearances in circuits having starting pulses N/A<br />

2.10.3.6 Transients from a.c. mains supply....................... : See 2.10.3.2 Pass<br />

2.10.3.7 Transients from d.c. mains supply....................... : N/A<br />

2.10.3.8 Transients from telecommunication networks and<br />

cable distribution systems .................................. :<br />

2.10.3.9 Measurement of transient voltage levels N/A<br />

Pass<br />

a) Transients from a mains supply N/A<br />

N/A

Issue Date: 2010-01-29 Page 20 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

For an a.c. mains supply .................................... : N/A<br />

For a d.c. mains supply ...................................... : N/A<br />

b) Transients from a telecommunication network N/A<br />

2.10.4 Cree<strong>page</strong> distances See TABLE: 2.10.3 and 2.10.4 Pass<br />

2.10.4.1 General Pass<br />

2.10.4.2 Material group and comparative tracking index Pass<br />

CTI <strong>test</strong>s ........................................................... : Material group IIIb; 100

Issue Date: 2010-01-29 Page 21 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

Two wires in contact inside wound component;<br />

angle between 45° and 90° ................................ :<br />

2.10.5.13 Wire with solvent-based enamel in wound<br />

components<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Physical separation in the <strong>for</strong>m<br />

of insulating sleeving provided<br />

to relieve mechanical stress at<br />

the crossover point.<br />

Electric strength <strong>test</strong> .......................................... : -<br />

Routine <strong>test</strong> N/A<br />

2.10.5.14 Additional insulation in wound components Thin sheet insulation provided<br />

<strong>for</strong> rein<strong>for</strong>ced insulation. See<br />

Sub clause 2.10.5.6.<br />

Working voltage ................................................ : (see appended table 2.10.3<br />

and 2.10.4)<br />

- Basic insulation not under stress ...................... : N/A<br />

Pass<br />

N/A<br />

Pass<br />

Pass<br />

- Supplementary, rein<strong>for</strong>ced insulation ................ : See Sub clause 2.10.5.6. Pass<br />

2.10.6 Construction of printed boards Pass<br />

2.10.6.1 Uncoated printed boards Pass<br />

2.10.6.2 Coated printed boards N/A<br />

2.10.6.3 Insulation between conductors on the same inner<br />

surface of a printed board<br />

2.10.6.4 Insulation between conductors on different layers<br />

of a printed board<br />

Distance through insulation N/A<br />

Number of insulation layers (pcs)........................ : N/A<br />

2.10.7 Component external terminations The mechanical arrangement<br />

and rigidity of the termination<br />

with an insulating coating is<br />

adequate.<br />

2.10.8 Tests on coated printed boards and coated<br />

components<br />

2.10.8.1 Sample preparation and preliminary inspection N/A<br />

2.10.8.2 Thermal conditioning N/A<br />

2.10.8.3 Electric strength <strong>test</strong> N/A<br />

2.10.8.4 Abrasion resistance <strong>test</strong> N/A<br />

2.10.9 Thermal cycling N/A<br />

2.10.10 Test <strong>for</strong> Pollution Degree 1 environment and<br />

insulating compound<br />

N/A<br />

N/A<br />

Pass<br />

N/A<br />

N/A

Issue Date: 2010-01-29 Page 22 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

2.10.11 Tests <strong>for</strong> semiconductor devices and cemented<br />

joints<br />

2.10.12 Enclosed and sealed parts N/A<br />

3 WIRING, CONNECTIONS AND SUPPLY Pass<br />

3.1 General Pass<br />

3.1.1 Current rating and overcurrent protection Pass<br />

3.1.2 Protection against mechanical damage The wires are routed away<br />

from sharp edges and parts<br />

which could damage<br />

insulation.<br />

3.1.3 Securing of internal wiring Pass<br />

3.1.4 Insulation of conductors The insulation of the individual<br />

conductors is suitable <strong>for</strong> the<br />

application and the working<br />

voltage.<br />

3.1.5 Beads and ceramic insulators N/A<br />

3.1.6 Screws <strong>for</strong> electrical contact pressure All electrical screw<br />

connections are by metal<br />

screw with more than 2<br />

threads into a metal plate.<br />

3.1.7 Insulating materials in electrical connections The equipment does not have<br />

any electrical connections that<br />

rely on insulating material <strong>for</strong><br />

adequate contact pressure.<br />

3.1.8 Self-tapping and spaced thread screws Thread-cutting or space thread<br />

screws are not used <strong>for</strong><br />

electrical connections.<br />

Machine screws only.<br />

3.1.9 Termination of conductors All conductors are reliable<br />

secured.<br />

10 N pull <strong>test</strong> Break away or pivot on its<br />

terminal is unlikely.<br />

3.1.10 Sleeving on wiring The sleeving used as<br />

supplementary insulation on<br />

internal wiring is retained by<br />

positive means.<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

N/A<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

Pass

Issue Date: 2010-01-29 Page 23 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

3.2 Connection to mains supply Pass<br />

3.2.1 Means of connection Pass<br />

3.2.1.1 Connection to an a.c. mains supply The unit is provided with an<br />

appliance inlet.<br />

3.2.1.2 Connection to a d.c. mains supply N/A<br />

3.2.2 Multiple supply connections N/A<br />

3.2.3 Permanently connected equipment N/A<br />

Number of conductors, diameter of cable and<br />

conduits (mm) ................................................... :<br />

3.2.4 Appliance inlets The appliance inlet complies<br />

with IEC 60320.<br />

3.2.5 Power supply cords Cord not provided. N/A<br />

3.2.5.1 AC power supply cords N/A<br />

Type................................................................. : -<br />

Rated current (A), cross-sectional area (mm²),<br />

AWG ................................................................ :<br />

3.2.5.2 DC power supply cords N/A<br />

3.2.6 Cord anchorages and strain relief N/A<br />

Mass of equipment (kg), pull (N)......................... : -<br />

Longitudinal displacement (mm) ......................... : -<br />

3.2.7 Protection against mechanical damage N/A<br />

3.2.8 Cord guards N/A<br />

Diameter of minor dimension D (mm); <strong>test</strong> mass (g)<br />

........................................................................ :<br />

Radius of curvature of cord (mm)........................ : -<br />

3.2.9 Supply wiring space N/A<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Pass<br />

-<br />

Pass<br />

-<br />

-

Issue Date: 2010-01-29 Page 24 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

3.3 Wiring terminals <strong>for</strong> connection of external conductors N/A<br />

3.3.1 Wiring terminals N/A<br />

3.3.2 Connection of non-detachable power supply cords N/A<br />

3.3.3 Screw terminals N/A<br />

3.3.4 Conductor sizes to be connected N/A<br />

Rated current (A), cord/cable type, cross-sectional<br />

area (mm²) ........................................................ :<br />

3.3.5 Wiring terminal sizes N/A<br />

Rated current (A), type and nominal thread<br />

diameter (mm)................................................... :<br />

3.3.6 Wiring terminals design N/A<br />

3.3.7 Grouping of wiring terminals N/A<br />

3.3.8 Stranded wire N/A<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

-<br />

-

Issue Date: 2010-01-29 Page 25 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

3.4 Disconnection from the mains supply Pass<br />

3.4.1 General requirement A disconnect device is<br />

provided to disconnect the<br />

equipment from the AC mains<br />

supply <strong>for</strong> servicing.<br />

3.4.2 Disconnect devices The equipment is provided<br />

with an appliance coupler.<br />

3.4.3 Permanently connected equipment Not permanently connected<br />

equipment.<br />

3.4.4 Parts which remain energized No accessible parts on the<br />

supply side of the disconnect<br />

device.<br />

3.4.5 Switches in flexible cords N/A<br />

3.4.6 Number of poles - single-phase and d.c. equipment Disconnect device disconnects<br />

all poles simultaneously.<br />

3.4.7 Number of poles - three-phase equipment The unit is single-phase<br />

equipment.<br />

3.4.8 Switches as disconnect devices N/A<br />

3.4.9 Plugs as disconnect devices N/A<br />

3.4.10 Interconnected equipment Interconnection to other<br />

devices by secondary output<br />

cable only.<br />

3.4.11 Multiple power sources The equipment only receives<br />

power from one source, and<br />

there<strong>for</strong>e only employs one<br />

disconnect device.<br />

3.5 Interconnection of equipment Pass<br />

3.5.1 General requirements SELV output circuits of power<br />

supply to be connected to<br />

other SELV circuits only.<br />

3.5.2 Types of interconnection circuits......................... : Interconnection circuits are<br />

SELV circuits.<br />

3.5.3 ELV circuits as interconnection circuits N/A<br />

3.5.4 Data ports <strong>for</strong> additional equipment N/A<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Pass<br />

Pass<br />

N/A<br />

N/A<br />

Pass<br />

N/A<br />

N/A<br />

N/A<br />

Pass<br />

Pass

Issue Date: 2010-01-29 Page 26 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

4 PHYSICAL REQUIREMENTS Pass<br />

4.1 Stability N/A<br />

Angle of 10° N/A<br />

Test <strong>for</strong>ce (N).................................................... : N/A<br />

4.2 Mechanical strength Pass<br />

4.2.1 General Equipment is <strong>for</strong> building-in.<br />

Compliance has to be<br />

evaluated when installed into<br />

the final system.<br />

4.2.2 Steady <strong>for</strong>ce <strong>test</strong>, 10 N 10N applied to components. Pass<br />

4.2.3 Steady <strong>for</strong>ce <strong>test</strong>, 30 N Equipment is <strong>for</strong> building-in.<br />

Compliance has to be<br />

evaluated when installed into<br />

the final system.<br />

4.2.4 Steady <strong>for</strong>ce <strong>test</strong>, 250 N No hazards as a result of the<br />

250 N <strong>test</strong> (only evaluated <strong>for</strong><br />

inlet side of enclosure).<br />

4.2.5 Impact <strong>test</strong> Equipment is <strong>for</strong> building-in. Pass<br />

Fall <strong>test</strong> N/A<br />

Swing <strong>test</strong> N/A<br />

4.2.6 Drop <strong>test</strong>; height (mm) ....................................... : N/A<br />

4.2.7 Stress relief <strong>test</strong> N/A<br />

4.2.8 Cathode ray tubes N/A<br />

Picture tube separately certified.......................... : N/A<br />

4.2.9 High pressure lamps N/A<br />

4.2.10 Wall or ceiling mounted equipment; <strong>for</strong>ce (N) ...... : N/A<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Pass<br />

N/A<br />

Pass

Issue Date: 2010-01-29 Page 27 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

4.3 Design and construction Pass<br />

4.3.1 Edges and corners All edges and corners are<br />

judged to be sufficiently well<br />

rounded so as not to constitute<br />

a hazard.<br />

4.3.2 Handles and manual controls; <strong>for</strong>ce (N) .............. : N/A<br />

4.3.3 Adjustable controls N/A<br />

4.3.4 Securing of parts No loosening of parts impairing<br />

cree<strong>page</strong> distances or<br />

clearances over<br />

supplementary or rein<strong>for</strong>ced<br />

insulation is likely to occur.<br />

4.3.5 Connection by plugs and sockets IEC 60083 or IEC 60320 type<br />

connectors not used <strong>for</strong> SELV<br />

circuits.<br />

4.3.6 Direct plug-in equipment N/A<br />

Torque .............................................................. : N/A<br />

Compliance with the relevant mains plug standard: N/A<br />

4.3.7 Heating elements in earthed equipment N/A<br />

4.3.8 Batteries N/A<br />

- Overcharging of a rechargeable battery N/A<br />

- Unintentional charging of a non-rechargeable<br />

battery<br />

- Reverse charging of a rechargeable battery N/A<br />

- Excessive discharging of any battery N/A<br />

4.3.9 Oil and grease N/A<br />

4.3.10 Dust, powders, liquids and gases N/A<br />

4.3.11 Containers <strong>for</strong> liquids or gases N/A<br />

4.3.12 Flammable liquids ............................................. : N/A<br />

Quantity of liquid (l)............................................ : N/A<br />

Flash point (°C) ................................................. : N/A<br />

4.3.13 Radiation Pass<br />

4.3.13.1 General See below. Pass<br />

4.3.13.2 Ionizing radiation N/A<br />

Measured radiation (pA/kg) ................................ : -<br />

Measured high-voltage (kV) ............................... : -<br />

Measured focus voltage (kV).............................. : -<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Pass<br />

Pass<br />

Pass<br />

N/A

Issue Date: 2010-01-29 Page 28 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

CRT markings ................................................... : -<br />

4.3.13.3 Effect of ultraviolet (UV) radiation on materials N/A<br />

Part, property, retention after <strong>test</strong>, flammability<br />

classification ..................................................... :<br />

4.3.13.4 Human exposure to ultraviolet (UV) radiation....... : N/A<br />

4.3.13.5 Laser (including LEDs) Pass<br />

Laser class........................................................ : LEDs are used <strong>for</strong> indicating<br />

purposes and assumed to be<br />

inherently Class 1 and<br />

operating in the 400 - 700 nm<br />

wavelength range.<br />

4.3.13.6 Other types ....................................................... : N/A<br />

4.4 Protection against hazardous moving parts Pass<br />

4.4.1 General Certified Fan in SELV circuit.<br />

(See table1.5.1)<br />

4.4.2 Protection in operator access areas .................... : Hazardous moving parts of<br />

equipment are adequately<br />

enclosed and guarded.<br />

4.4.3 Protection in restricted access locations .............. : N/A<br />

4.4.4 Protection in service access areas Pass<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

N/A<br />

-<br />

Pass<br />

Pass

Issue Date: 2010-01-29 Page 29 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

4.5 Thermal requirements Pass<br />

4.5.1 General Pass<br />

4.5.2 Temperature <strong>test</strong>s See TABLE: 4.5 temperature<br />

rise measurements.<br />

Components working at high<br />

temperatures are shielded to<br />

prevent overheating of their<br />

surrounding materials.<br />

The equipment and its<br />

component parts did not attain<br />

excessive temperatures during<br />

normal operation.<br />

Normal load condition per Annex L ..................... : Operated in the most<br />

unfavorable way of operation<br />

given in the operating<br />

instructions until steady<br />

conditions established.<br />

4.5.3 Temperature limits <strong>for</strong> materials Pass<br />

4.5.4 Touch temperature limits Pass<br />

4.5.5 Resistance to abnormal heat .............................. : N/A<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Pass<br />

-

Issue Date: 2010-01-29 Page 30 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

4.6 Openings in enclosures N/A<br />

4.6.1 Top and side openings Mechanical enclosure<br />

evaluated.<br />

See critical component<br />

table/Power<br />

Module/Chassis construction.<br />

Unit intended <strong>for</strong> building-in.<br />

To be evaluated other<br />

enclosures in end product.<br />

Dimensions (mm) .............................................. : See table 1.5.1 -<br />

4.6.2 Bottoms of fire enclosures This equipment is <strong>for</strong> buildingin.<br />

Compliance shall be<br />

evaluated <strong>for</strong> the final system.<br />

Construction of the bottom, dimensions (mm) ...... : No openings -<br />

4.6.3 Doors or <strong>cover</strong>s in fire enclosures N/A<br />

4.6.4 Openings in transportable equipment N/A<br />

4.6.4.1 Constructional design measures N/A<br />

Dimensions (mm) .............................................. : -<br />

4.6.4.2 Evaluation measures <strong>for</strong> larger openings N/A<br />

4.6.4.3 Use of metallized parts N/A<br />

4.6.5 Adhesives <strong>for</strong> constructional purposes N/A<br />

Conditioning temperature (°C), time (weeks) ....... : -<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

N/A<br />

N/A

Issue Date: 2010-01-29 Page 31 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

4.7 Resistance to fire Pass<br />

4.7.1 Reducing the risk of ignition and spread of flame Pass<br />

Method 1, selection and application of components<br />

wiring and materials<br />

Method 2, application of all of simulated fault<br />

condition <strong>test</strong>s<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Method 1: Selection and<br />

application of components and<br />

materials which minimize the<br />

possibility of ignition and<br />

spread of flame.<br />

4.7.2 Conditions <strong>for</strong> a fire enclosure For building-in, parts require a<br />

fire enclosure and shall be<br />

evaluated in final system.<br />

4.7.2.1 Parts requiring a fire enclosure N/A<br />

4.7.2.2 Parts not requiring a fire enclosure N/A<br />

4.7.3 Materials Pass<br />

4.7.3.1 General PCB rated V-1 or better. Pass<br />

4.7.3.2 Materials <strong>for</strong> fire enclosures This equipment is <strong>for</strong> buildingin.<br />

Compliance shall be<br />

evaluated <strong>for</strong> the final system.<br />

Product uses Metal.<br />

4.7.3.3 Materials <strong>for</strong> components and other parts outside<br />

fire enclosures<br />

4.7.3.4 Materials <strong>for</strong> components and other parts inside fire<br />

enclosures<br />

Internal components except<br />

small parts are V-2 or better.<br />

4.7.3.5 Materials <strong>for</strong> air filter assemblies N/A<br />

4.7.3.6 Materials used in high-voltage components N/A<br />

Pass<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

Pass

Issue Date: 2010-01-29 Page 32 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

5 ELECTRICAL REQUIREMENTS AND SIMULATED ABNORMAL CONDITIONS Pass<br />

5.1 Touch current and protective conductor current Pass<br />

5.1.1 General See sub-clauses 5.1.2 to 5.1.6. Pass<br />

5.1.2 Configuration of equipment under <strong>test</strong> (EUT) EUT has only one mains<br />

connection.<br />

5.1.2.1 Single connection to an a.c. mains supply Pass<br />

5.1.2.2 Redundant multiple connections to an a.c. mains<br />

supply<br />

5.1.2.3 Simultaneous multiple connections to an a.c. mains<br />

supply<br />

5.1.3 Test circuit Using <strong>test</strong> circuit as in figure<br />

5A.<br />

5.1.4 Application of measuring instrument Using measuring instrument in<br />

annex D1.<br />

5.1.5 Test procedure Pass<br />

5.1.6 Test measurements Pass<br />

Supply voltage (V) ............................................. : 264 -<br />

Measured touch current (mA) ............................. : Maximum 2.3mA -<br />

Max. allowed touch current (mA) ........................ : 3.5mA -<br />

Measured protective conductor current (mA) ....... : -<br />

Max. allowed protective conductor current (mA) .. : -<br />

5.1.7 Equipment with touch current exceeding 3,5 mA N/A<br />

5.1.7.1 General............................................................. : N/A<br />

5.1.7.2 Simultaneous multiple connections to the supply N/A<br />

5.1.8 Touch currents to telecommunication networks and<br />

cable distribution systems and from<br />

telecommunication networks<br />

5.1.8.1 Limitation of the touch current to a<br />

telecommunication network or to a cable<br />

distribution system<br />

Supply voltage (V) ............................................. : -<br />

Measured touch current (mA) ............................. : -<br />

Max. allowed touch current (mA) ........................ : -<br />

5.1.8.2 Summation of touch currents from<br />

telecommunication networks<br />

a) EUT with earthed telecommunication ports...... : N/A<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Pass<br />

N/A<br />

N/A<br />

Pass<br />

Pass<br />

b) EUT whose telecommunication ports have no N/A<br />

N/A<br />

N/A<br />

N/A

Issue Date: 2010-01-29 Page 33 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

reference to protective earth<br />

5.2 Electric strength Pass<br />

5.2.1 General Pass<br />

5.2.2 Test procedure See table 5.2 Pass<br />

5.3 Abnormal operating and fault conditions Pass<br />

5.3.1 Protection against overload and abnormal<br />

operation<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

See table 5.3 Pass<br />

5.3.2 Motors UL certified DC fan used. Pass<br />

5.3.3 Trans<strong>for</strong>mers Trans<strong>for</strong>mers are constructed<br />

in accordance with Annex C.<br />

5.3.4 Functional insulation.......................................... : Functional insulation complies<br />

with the requirements (c).<br />

5.3.5 Electromechanical components N/A<br />

5.3.6 Audio amplifiers in ITE ....................................... : N/A<br />

5.3.7 Simulation of faults See table 5.3. Pass<br />

5.3.8 Unattended equipment N/A<br />

5.3.9 Compliance criteria <strong>for</strong> abnormal operating and<br />

fault conditions<br />

During the <strong>test</strong>s: No fire<br />

occurred. No molten metal was<br />

emitted. After the <strong>test</strong>s:<br />

Electric strength <strong>test</strong> primary to<br />

secondary and primary to<br />

earth were passed.<br />

5.3.9.1 During the <strong>test</strong>s No fire, emission of molten<br />

metal or de<strong>for</strong>mation was<br />

noted during the <strong>test</strong>s.<br />

5.3.9.2 After the <strong>test</strong>s Electric Strength <strong>test</strong>s<br />

per<strong>for</strong>med after abnormal and<br />

fault <strong>test</strong>s.<br />

Pass<br />

Pass<br />

Pass<br />

Pass<br />

Pass

Issue Date: 2010-01-29 Page 34 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

6 CONNECTION TO TELECOMMUNICATION NETWORKS N/A<br />

6.1 Protection of telecommunication network service persons, and users of other<br />

equipment connected to the network, from hazards in the equipment<br />

6.1.1 Protection from hazardous voltages N/A<br />

6.1.2 Separation of the telecommunication network from earth N/A<br />

6.1.2.1 Requirements N/A<br />

Supply voltage (V) ............................................. : -<br />

Current in the <strong>test</strong> circuit (mA)............................ : -<br />

6.1.2.2 Exclusions ........................................................ : N/A<br />

6.2 Protection of equipment users from overvoltages on telecommunication<br />

networks<br />

6.2.1 Separation requirements N/A<br />

6.2.2 Electric strength <strong>test</strong> procedure N/A<br />

6.2.2.1 Impulse <strong>test</strong> N/A<br />

6.2.2.2 Steady-state <strong>test</strong> N/A<br />

6.2.2.3 Compliance criteria N/A<br />

6.3 Protection of the telecommunication wiring system from overheating N/A<br />

Max. output current (A) ...................................... : -<br />

Current limiting method...................................... : -<br />

7 CONNECTION TO CABLE DISTRIBUTION SYSTEMS N/A<br />

7.1 General N/A<br />

7.2 Protection of cable distribution system service persons, and users of other<br />

equipment connected to the system, from hazardous voltages in the equipment<br />

7.3 Protection of equipment users from overvoltages<br />

on the cable distribution system<br />

7.4 Insulation between primary circuits and cable<br />

distribution systems<br />

7.4.1 General N/A<br />

7.4.2 Voltage surge <strong>test</strong> N/A<br />

7.4.3 Impulse <strong>test</strong> N/A<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A

Issue Date: 2010-01-29 Page 35 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

A ANNEX A, TESTS FOR RESISTANCE TO HEAT AND FIRE N/A<br />

A.1 Flammability <strong>test</strong> <strong>for</strong> fire enclosures of movable equipment having a total mass<br />

exceeding 18 kg, and of stationary equipment (see 4.7.3.2)<br />

A.1.1 Samples ........................................................... : -<br />

Wall thickness (mm) .......................................... : -<br />

A.1.2 Conditioning of samples; temperature (°C) .......... : N/A<br />

A.1.3 Mounting of samples .......................................... : N/A<br />

A.1.4 Test flame (see IEC 60695-11-3) N/A<br />

Flame A, B, C or D ............................................ : N/A<br />

A.1.5 Test procedure N/A<br />

A.1.6 Compliance criteria N/A<br />

Sample 1 burning time (s) .................................. : -<br />

Sample 2 burning time (s) .................................. : -<br />

Sample 3 burning time (s) .................................. : -<br />

A.2 Flammability <strong>test</strong> <strong>for</strong> fire enclosures of movable equipment having a total mass not<br />

exceeding 18 kg, and <strong>for</strong> material and components located inside fire enclosures<br />

(see 4.7.3.2 and 4.7.3.4)<br />

A.2.1 Samples, material.............................................. : -<br />

Wall thickness (mm) .......................................... : -<br />

A.2.2 Conditioning of samples; temperature (°C) .......... : N/A<br />

A.2.3 Mounting of samples .......................................... : N/A<br />

A.2.4 Test flame (see IEC 60695-11-4) N/A<br />

Flame A, B or C................................................. : -<br />

A.2.5 Test procedure N/A<br />

A.2.6 Compliance criteria N/A<br />

Sample 1 burning time (s) .................................. : -<br />

Sample 2 burning time (s) .................................. : -<br />

Sample 3 burning time (s) .................................. : -<br />

A.2.7 Alternative <strong>test</strong> acc. to IEC 60695-11-5, cl. 5 and 9 N/A<br />

Sample 1 burning time (s) .................................. : -<br />

Sample 2 burning time (s) .................................. : -<br />

Sample 3 burning time (s) .................................. : -<br />

A.3 Hot flaming oil <strong>test</strong> (see 4.6.2) N/A<br />

A.3.1 Mounting of samples N/A<br />

A.3.2 Test procedure N/A<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

N/A<br />

N/A

Issue Date: 2010-01-29 Page 36 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

A.3.3 Compliance criterion N/A<br />

B ANNEX B, MOTOR TESTS UNDER ABNORMAL CONDITIONS(see 4.7.2.2 and<br />

5.3.2)<br />

B.1 General requirements UL certified DC fan used, see<br />

table 1.5.1<br />

Position............................................................. : UL certified DC fan used, see<br />

table 1.5.1<br />

Manufacturer..................................................... : UL certified DC fan used, see<br />

table 1.5.1<br />

Type................................................................. : UL certified DC fan used, see<br />

table 1.5.1<br />

Rated values ..................................................... : UL certified DC fan used, see<br />

table 1.5.1<br />

B.2 Test conditions N/A<br />

B.3 Maximum temperatures N/A<br />

B.4 Running overload <strong>test</strong> N/A<br />

B.5 Locked-rotor overload <strong>test</strong> N/A<br />

Test duration (days)........................................... : -<br />

Electric strength <strong>test</strong>: <strong>test</strong> voltage (V).................. : -<br />

B.6 Running overload <strong>test</strong> <strong>for</strong> d.c. motors in secondary<br />

circuits<br />

B.6.1 General N/A<br />

B.6.2 Test procedure N/A<br />

B.6.3 Alternative <strong>test</strong> procedure N/A<br />

B.6.4 Electric strength <strong>test</strong>; <strong>test</strong> voltage (V).................. : N/A<br />

B.7 Locked-rotor overload <strong>test</strong> <strong>for</strong> d.c. motors in secondary circuits N/A<br />

B.7.1 General N/A<br />

B.7.2 Test procedure N/A<br />

B.7.3 Alternative <strong>test</strong> procedure N/A<br />

B.7.4 Electric strength <strong>test</strong>; <strong>test</strong> voltage (V).................. : N/A<br />

B.8 Test <strong>for</strong> motors with capacitors N/A<br />

B.9 Test <strong>for</strong> three-phase motors N/A<br />

B.10 Test <strong>for</strong> series motors N/A<br />

Operating voltage (V)......................................... : -<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Pass<br />

Pass<br />

-<br />

-<br />

-<br />

-<br />

N/A

Issue Date: 2010-01-29 Page 37 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

C ANNEX C, TRANSFORMERS (see 1.5.4 and 5.3.3) Pass<br />

Position............................................................. : See table 1.5.1 -<br />

Manufacturer..................................................... : See table 1.5.1 -<br />

Type................................................................. : See table 1.5.1 -<br />

Rated values ..................................................... : See table 1.5.1 -<br />

Method of protection.......................................... : See table 1.5.1 -<br />

C.1 Overload <strong>test</strong> See table 5.3 Pass<br />

C.2 Insulation See table 1.5.1 Pass<br />

Protection from displacement of windings............ : See table 1.5.1 Pass<br />

D ANNEX D, MEASURING INSTRUMENTS FOR TOUCH-CURRENT TESTS (see<br />

5.1.4)<br />

D.1 Measuring instrument Pass<br />

D.2 Alternative measuring instrument N/A<br />

E ANNEX E, TEMPERATURE RISE OF A WINDING (see 1.4.13) N/A<br />

F ANNEX F, MEASUREMENT OF CLEARANCES AND CREEPAGE DISTANCES<br />

(see 2.10 and Annex G)<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

Pass<br />

Pass

Issue Date: 2010-01-29 Page 38 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

G ANNEX G, ALTERNATIVE METHOD FOR DETERMINING MINIMUM<br />

CLEARANCES<br />

G.1 Clearances N/A<br />

G.1.1 General N/A<br />

G.1.2 Summary of the procedure <strong>for</strong> determining<br />

minimum clearances<br />

G.2 Determination of mains transient voltage (V) N/A<br />

G.2.1 AC mains supply ............................................... : N/A<br />

G.2.2 Earthed d.c. mains supply .................................. : N/A<br />

G.2.3 Unearthed d.c. mains supply .............................. : N/A<br />

G.2.4 Battery operation............................................... : N/A<br />

G.3 Determination of telecommunication network<br />

transient voltage (V) :......................................... :<br />

G.4 Determination of required withstand voltage (V) N/A<br />

G.4.1 Mains transients and internal repetitive peaks ..... : N/A<br />

G.4.2 Transients from telecommunication networks ...... : N/A<br />

G.4.3 Combination of transients N/A<br />

G.4.4 Transients from cable distribution systems N/A<br />

G.5 Measurement of transient voltages (V) N/A<br />

G.6 Determination of minimum clearances ................ : N/A<br />

H ANNEX H, IONIZING RADIATION (see 4.3.13) N/A<br />

J ANNEX J, TABLE OF ELECTROCHEMICAL POTENTIALS (see 2.6.5.6) Pass<br />

Metal(s) used .................................................... : Copper or copper alloy. -<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

N/A<br />

N/A<br />

N/A

Issue Date: 2010-01-29 Page 39 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

K ANNEX K, THERMAL CONTROLS (see 1.5.3 and 5.3.8) N/A<br />

K.1 Making and breaking capacity N/A<br />

K.2 Thermostat reliability; operating voltage (V)......... : N/A<br />

K.3 Thermostat endurance <strong>test</strong>; operating voltage (V) : N/A<br />

K.4 Temperature limiter endurance; operating voltage<br />

(V).................................................................... :<br />

K.5 Thermal cut-out reliability N/A<br />

K.6 Stability of operation N/A<br />

L ANNEX L, NORMAL LOAD CONDITIONS FOR SOME TYPES OF ELECTRICAL<br />

BUSINESS EQUIPMENT (see 1.2.2.1 and 4.5.2)<br />

L.1 Typewriters N/A<br />

L.2 Adding machines and cash registers N/A<br />

L.3 Erasers N/A<br />

L.4 Pencil sharpeners N/A<br />

L.5 Duplicators and copy machines N/A<br />

L.6 Motor-operated files N/A<br />

L.7 Other business equipment Pass<br />

TRF No. IECEN60950_1C Underwriters Laboratories Inc.<br />

N/A<br />

Pass

Issue Date: 2010-01-29 Page 40 of 69 Report Reference # E143756-A26-UL-2<br />

IEC 60950-1:2005<br />

Clause Requirement + Test Result - Remark Verdict<br />

M ANNEX M, CRITERIA FOR TELEPHONE RINGING SIGNALS (see 2.3.1) N/A<br />

M.1 Introduction N/A<br />

M.2 Method A N/A<br />

M.3 Method B N/A<br />

M.3.1 Ringing signal N/A<br />

M.3.1.1 Frequency (Hz) ................................................. : -<br />