Bio-remed Oil spills - Indian Coast Guard

Bio-remed Oil spills - Indian Coast Guard

Bio-remed Oil spills - Indian Coast Guard

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Bio</strong>-<strong>remed</strong>iation <strong>Bio</strong> <strong>remed</strong>iation techniques for<br />

responding to <strong>Oil</strong> <strong>spills</strong> at Sea<br />

Dr Pradeep Kumar<br />

Naval Materials Research Laboratory (NMRL)<br />

DRDO, Min. of Defence, Defence,<br />

Ambernath 421506,<br />

Thane, Maharashtra

EFFECTS OF SPILLED OIL ON<br />

BIRDS<br />

ANIMALS<br />

TURTLES<br />

Short-term Short term effects<br />

Tarring of beaches,<br />

Damage to fisheries<br />

Water Contamination<br />

Long-term Long term effects<br />

Persistent toxic chemical in water & soil<br />

Permanent genetic mutation on entry through food<br />

chain<br />

<strong>Oil</strong> Pollution<br />

EELS

Methods<br />

a) Natural<br />

Evaporation, Dissolution<br />

Photo-oxidation<br />

Photo oxidation<br />

<strong>Bio</strong>degradation<br />

Sedimentation, Dispersion,<br />

Spreading and Drifting<br />

d) <strong>Bio</strong><strong>remed</strong>iation<br />

ODB, <strong>Bio</strong>emulsifier, <strong>Bio</strong>emulsifier,<br />

other<br />

mediators<br />

Possible methods of oil spill removal<br />

b) Physical<br />

Mechanical recovery (Skimmers,<br />

Booms, Suctions, Separation)<br />

c) Chemical<br />

Sorbents – inorganic/organic<br />

(Vermiculites,Glass wool,Carbon<br />

Wool, foam)<br />

Limitations<br />

Limited to low MW<br />

Fractions.<br />

Slow and controlled by<br />

environmental factors.<br />

Limited Efficiency.<br />

Environmentally controlled.<br />

Clumsy, time consuming<br />

and costly.<br />

Requires other physical<br />

methods<br />

Reuse of<br />

chemicals/sorbents<br />

chemicals/ sorbents<br />

impractical.<br />

Requires supply of<br />

nutrients<br />

Adaptability<br />

Restricted<br />

Restricted<br />

Restricted<br />

Restricted and<br />

Unacceptable.<br />

Restricted<br />

Not ecofriendly.<br />

ecofriendly<br />

Ecofriendly and<br />

easy application.

<strong>Bio</strong><strong>remed</strong>iation<br />

What is bio<strong>remed</strong>iation?<br />

Management of pollution through <strong>Bio</strong>logical means<br />

<strong>Bio</strong><strong>remed</strong>iation of pollutant oil<br />

– microorganisms (fungi or bacteria)<br />

– to decompose toxic pollutants<br />

– Enhanced biodegradation of petroleum hydrocarbons<br />

– <strong>Bio</strong>degradation<br />

a natural process by which microbes alter and break<br />

down petroleum hydrocarbons into other substances.<br />

– Resultant products: products:<br />

CO 2, , water, and partially oxidized biologically inert by-<br />

products (Bragg et al. 1992).

AD/ABSORPTION<br />

BIOREMEDIATION<br />

TECHNOLOGIES<br />

BIOREMEDIATION<br />

PLANT MATERIALS BIOSURFACTANTS BIOPOLYMERS<br />

STRAW, SAW DUST, WOODSHAVINGS<br />

LOW MW BIOCHEMICALS<br />

TO CLEAN OILED SURFACE<br />

BIOEMULSIFIERS & ENZYMES

<strong>Bio</strong><strong>remed</strong>iation: Advantages<br />

Minimal physical disruption of site.<br />

No adverse effect, when used correctly.<br />

Helpful in removing - toxic components<br />

of oil.<br />

Simple and more thorough approach<br />

than mechanical technologies.<br />

Relatively less costly.

<strong>Bio</strong><strong>remed</strong>iation: Limitations<br />

Effectiveness may vary for different<br />

types of <strong>Oil</strong> (<strong>Oil</strong> Crude, HSD, FFO)<br />

May not be convenient during heavy<br />

rains & low visibility.<br />

Quick & specifically tailored approach<br />

for each polluted site.<br />

May require 2-3 2 3 periodic spraying of<br />

Nutrient depending upon the density of<br />

spilled oil.

DRDO<br />

OIL SPILL CONTROL TECHNOLOGY

Schematic representation<br />

<strong>Bio</strong><strong>remed</strong>iation of oil in marine environments<br />

HSD+<br />

Bacteria+<br />

BE. HSD+<br />

Bacteria+<br />

BE+<br />

Nutrient<br />

HSD+<br />

Bacteria+<br />

BE+<br />

Nutrient+<br />

Oxygen

Infra-red Infra red<br />

signals<br />

(FTIR)<br />

Solubility<br />

Toxicity<br />

Characteristics : NMRL <strong>Bio</strong>emulsifier<br />

Thermal<br />

properties<br />

(TGA, under<br />

N2 ENV.)<br />

Molecular<br />

Weight (GPC)<br />

IDT 200°C. 200 C.<br />

STABLE UP<br />

199°C 199 C<br />

Peak Mw.5919;<br />

Polydispersity<br />

1.11.<br />

Alcohol, ester,<br />

carboxyl and<br />

proteins.<br />

Alcohol,<br />

Seawater and<br />

HSD<br />

Non toxic<br />

(Endotoxin Endotoxin free).<br />

80<br />

SURFACE TENSION<br />

(mN/m)<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

SURFACE TENSION REDUCTION BY BE<br />

Sea water<br />

Syn. Sea water<br />

Distilled Water<br />

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7<br />

BE CONC. (%)<br />

OIL Eating Bacteria<br />

Hallomonas cupida<br />

Pseudomonas stutzeri<br />

Bacillus pumilus<br />

Bacillus sphericus<br />

Micrococcus roseus<br />

Micrococcus varians. varians<br />

Characterized by Genetic<br />

engineering techniques and genes<br />

involved in biodegradation are<br />

sequenced.

Trials on <strong>Bio</strong><strong>remed</strong>iation of floating oil using<br />

<strong>Bio</strong>emulsifier<br />

• First <strong>Bio</strong><strong>remed</strong>iation Trial :<br />

• NMRL <strong>Bio</strong>emulsifier, <strong>Oil</strong> degrading bacteria and<br />

Nutrient compound as compared to control.<br />

• Naval harbour, Mumbai,(April 20th 2001),<br />

• Area of 25 m2 • Fast and effective dispersion (90 – 95% dispersion) and<br />

degradation of HSD (10 days) .<br />

• Extended Trials: 40 lit of weathered oil (Dec.21st to 31,<br />

2001): in an extended area of 100 m2 80-85% dispersion in 8-<br />

10days.<br />

• Conclusion: The results indicated effective dispersion of<br />

floating oil within 8-10 days.

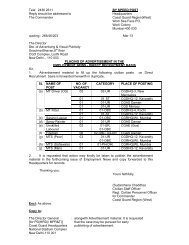

MATERIALS REQUIRED FOR BIOREMEDIATION OF<br />

FLOATING OIL (30 gallons) IN AN AREA OF 500 m 2<br />

BIOEMULSIFIER<br />

NUTRIENT MIXTURE<br />

OIL DEGRADING<br />

BACTERIA (ODB)<br />

50 grams<br />

10 litres.<br />

40 litres<br />

(10g powder)<br />

TOTAL RECURRING COAST<br />

(BE+NUTRIENT+ODB)<br />

Approximately Rs.50,000 / tonne of oil<br />

Rs2500/-<br />

Rs2000/-<br />

Rs500/-<br />

Rs5000/

<strong>Bio</strong><strong>remed</strong>iation process -Flow chart<br />

Spray all the ingredients evenly and sequentially as given below<br />

Day ‘0’ 3 rd Day 6th Day 9th Day<br />

Spray Nutrient<br />

Mixture uniformly<br />

over oil film on ‘0’ day<br />

Followed by<br />

<strong>Bio</strong>emulsifier<br />

(concentration 0.25% w/v)<br />

Followed by<br />

oil degrading<br />

bacteria<br />

Spray<br />

Nutrient<br />

Mixture<br />

alone<br />

Spray<br />

Nutrient<br />

Mixture<br />

alone<br />

Spray Nutrient<br />

Mixture alone

OIL BIODEGRADATION CYCLE<br />

FUEL OIL<br />

FATTY ACIDS + CO 2 + H 2 O<br />

ALDEHYDES<br />

BIOREMEDIATION<br />

OXIDATION BY<br />

MONOOXYGENASES<br />

PRIMARY ALCOHOLS

EFFECTS OF BIOREMEDIATION<br />

1. Initial oil film (HSD). 2. Complete emulsification.<br />

3. Fragmentation & precipitation.<br />

4. Dispersion of oil film.

BIOREMEDIATION AT VIZAG HARBOUR WATERS<br />

Spraying at N-10<br />

1100h<br />

<strong>Oil</strong> Slick N-9 N 9 OIL<br />

EMULSIFICATION,<br />

15-20 15 20 min after spraying 1115h<br />

Day “0”<br />

27 Apr 03

DO’S<br />

1. Boats and floating structures be preferably removed to facilitate facilitate<br />

easy accessibility and to ensure total coverage.<br />

2. BIOEMULSIFIER ALWAYS BE DISSOLVED IN SEAWATER as<br />

it contains required divalent metal cations, cations,<br />

necessary for<br />

solubilization.<br />

solubilization.<br />

3. Normal safety precautions must be observed during spraying of<br />

bioemulsifier ( such as use of face mask, gloves and apron etc ) .<br />

4. Movement of boats etc over the site be restricted.<br />

5. Spraying hardware should be washed immediately after use (with<br />

fresh water).<br />

6. <strong>Bio</strong><strong>remed</strong>iation exercise may be repeated in the areas where fresh<br />

oil is invading the treated site.<br />

7. In case of profuse skin contact wash immediately with excess of<br />

water.

DON’TS<br />

1. Do not undertake bio<strong>remed</strong>iation during dredging<br />

activity.<br />

2. Do not spray bioemulsifier on floating non oil dirt to<br />

avoid wastage and inconsistent results.<br />

3. Do not spray bioemulsifier during heavy rains to<br />

avoid wastage and inconsistent results.

<strong>Bio</strong><strong>remed</strong>iation<br />

of HSD, FFO & Crude <strong>Oil</strong><br />

BIOREMEDIATION<br />

DIESEL FFO CRUDE OIL<br />

TEST-1 HSD CONTROL-1 TEST-2 CONTROL-2 TEST-3 CONTROL-3<br />

HSD+NP+BE+ODB FFO+NP+BE+ODB CRUDE+NP+BE+ODB<br />

TEST-1 (HSD)<br />

SEAWATER : 5L<br />

HSD : 25g<br />

NP (0.05%) : 2.5g;<br />

BE (0.25%) : 2.5g<br />

ODB : 15X105 TEST-2 (FFO)<br />

SEAWATER : 5L<br />

FFO : 25g<br />

NP (0.05%) : 2.5g;<br />

BE (0.25%) : 2.5g<br />

ODB : 15X105<br />

TEST-3<br />

SEAWATER : 5L<br />

CRUDE : 25g<br />

NP (0.05%) : 2.5g;<br />

BE (0.25%) : 2.5g<br />

ODB : 15X105

<strong>Bio</strong><strong>remed</strong>iation - HSD<br />

TEST-1: Seawater + HSD + NUTRIENT + BE + ODB<br />

CONTROL-1:Seawater+HSD

<strong>Bio</strong><strong>remed</strong>iation – Crude <strong>Oil</strong>

<strong>Bio</strong><strong>remed</strong>iation – FFO

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0<br />

Optical Density and Bacterial Growth<br />

0 DAY 3 DAY 6 DAY<br />

HSD-T1<br />

FFO-T2<br />

CRU-OIL-T3<br />

DAY<br />

0<br />

3<br />

6<br />

HSD<br />

CFU / ml<br />

76 X 10 -5<br />

187 X 10 -5<br />

67 X 10 -5<br />

FFO<br />

CFU / ml<br />

67 X 10 -5<br />

133 X 10 -5<br />

43 X 10 -5<br />

CRUDE<br />

OIL<br />

CFU / ml<br />

71 X 10 -5<br />

155 X 10 -5<br />

51 X 10 -5

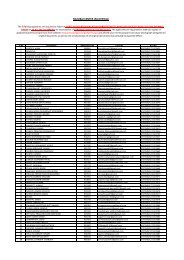

<strong>Oil</strong> <strong>Bio</strong><strong>remed</strong>iation technology :Market<br />

Probable users<br />

IOC,<br />

BPCL,HPCL,<br />

ONGC, OIL,<br />

IPCL, Reliance<br />

& ESSR<br />

Navy : 4<br />

Commands<br />

Annual requirements<br />

For 6 tonnes of spilled oil<br />

per annum each during<br />

drilling & refining<br />

(3x8 firms=24t)<br />

8 tonnes<br />

Cost/tonne Cost/ tonne<br />

of oil spilled<br />

@0.5 lacs/t lacs/t<br />

24 lacs<br />

4.0 lacs<br />

Initial Investment : 60 lacs on fermentor+separator+evaporator+overheads

ACKNOWLEDGEMENTS<br />

(A) WESTERN NAVAL COMMAND MUMBAI<br />

(B) COAST GUEST REGION WEST<br />

(C) CGPRT MAZGOAN DOCK<br />

(D) NMRL (DRDO)<br />

1. Dr Susan Titus, Sc. ‘E’<br />

2. Dr S.N. Gaonkar, Gaonkar<br />

Sc. ‘D’<br />

3. Mr B.S. Swami Sc. ‘D’<br />

4. Mrs Shobhana Chongdar Sc. ‘C’<br />

5. Mrs. Sapna Pavitran Sc. ‘C’<br />

6. Dr C.B. Jagtap Sc. ‘C’<br />

7. Mr. Udhay Kumar T.O. ‘C’<br />

8. Ku. Chitra Deshmukh T.A. ‘B’<br />

9. Shri R. Mohan Ram T.A. ‘A’