Final Report - Ohio Department of Transportation

Final Report - Ohio Department of Transportation

Final Report - Ohio Department of Transportation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

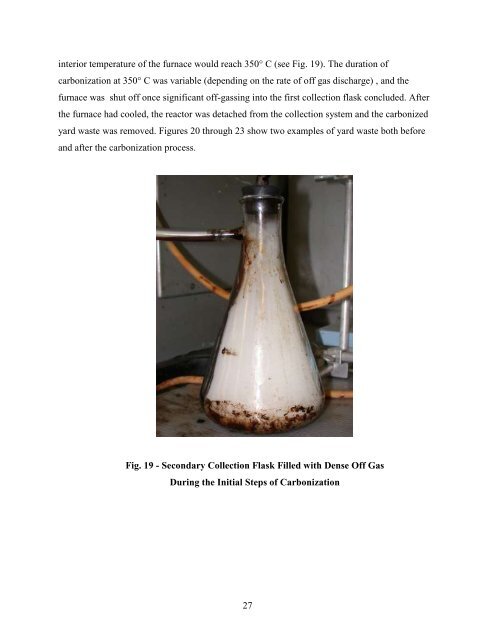

interior temperature <strong>of</strong> the furnace would reach 350° C (see Fig. 19). The duration <strong>of</strong><br />

carbonization at 350° C was variable (depending on the rate <strong>of</strong> <strong>of</strong>f gas discharge) , and the<br />

furnace was shut <strong>of</strong>f once significant <strong>of</strong>f-gassing into the first collection flask concluded. After<br />

the furnace had cooled, the reactor was detached from the collection system and the carbonized<br />

yard waste was removed. Figures 20 through 23 show two examples <strong>of</strong> yard waste both before<br />

and after the carbonization process.<br />

Fig. 19 - Secondary Collection Flask Filled with Dense Off Gas<br />

During the Initial Steps <strong>of</strong> Carbonization<br />

27