OBEN GAS DEVELOPMENT PROJECT

OBEN GAS DEVELOPMENT PROJECT

OBEN GAS DEVELOPMENT PROJECT

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

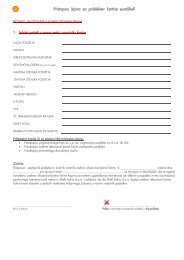

Chapter Two Project Justification<br />

liquids in a Free Liquid Knock-out Vessel (FLKO). Liquids from the FLKO vessels are separated in a<br />

three-phase classifier vessel into water, condensate and gas. Water is spiked into the oil saver pit.<br />

Condensate is sent to the condensate header, from where condensate can be routed to the condensate<br />

surge vessel or to existing Oben flowstation. Condensate routed to the surge vessel and flow station is<br />

pumped to the trunkline enroute to Forcados Terminal.<br />

Gas from the FLKO vessel passes through the inlet/sales gas heat exchanger, and is cooled to about<br />

9 o C, choked to 76-bar at the main choke valves. 75% by weight Diethylene Glycol (DEG) is injected<br />

upstream of the heat exchanger to inhibit hydrates downstream of the choke valves. Gas at 76-bar after<br />

choking enters the LTS separator via the hydrate Catcher. It is the low temperatures achieved in the<br />

LTS, below zero degree centigrade under normal operation, by the Joule Thompson effect that is the<br />

dew point control mechanism. Gas out of the LTS separator is sent into a 16-inch sales gas header,<br />

where it is metered via a senior Daniel orifice (DOF) meter connected to chart recorders. The gas from<br />

the sales gas header goes into the Escravos Lagos Pipeline System (ELPS) line.<br />

Feed Gas<br />

Figure. 2.2: Schematic of the Oben LTS Modules<br />

2.7 Project Scope<br />

FLKO<br />

Classifier<br />

Glycol<br />

Injection<br />

Gas/Gas<br />

Exchanger<br />

JT Valve<br />

Glycol/Cond.<br />

Glycol/Cond.<br />

Separator<br />

Separator<br />

Sales Gas<br />

2.7.1 Project Activity Overview<br />

The Workscope covered by this EIA for the WAGP Gas Supply is divided into two phases;<br />

Phase 1 works: This includes integrity related works covering upgrade of the process control system<br />

and modifications of Oben Gas Plant, necessary to deliver the contractual gas specification which is<br />

scheduled for completion in December 2006.<br />

Phase 2 works covers installation of smart-type metering/monitoring skids at custody transfer point at<br />

Oben Gas Plant with online flow computers, online gas chromatograph and V-SAT data transmission<br />

2-4<br />

LTS<br />

Glycol Regen<br />

To Flare<br />

Condensate<br />

Surge<br />

Vessel<br />

To Flow Station