Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

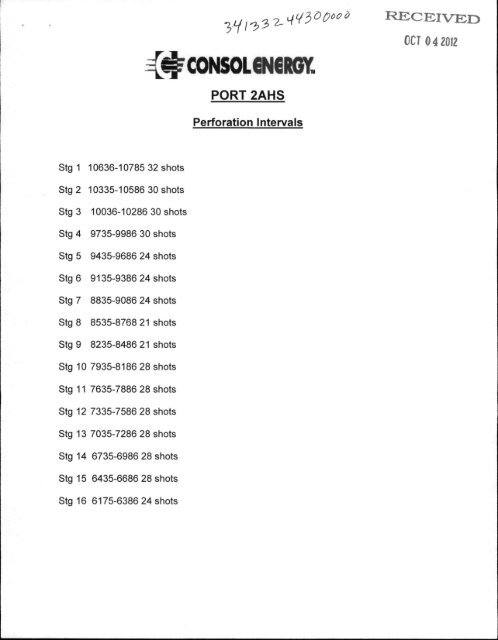

Stg 1 10636-10785 32 shots<br />

Stg 2 10335-10586 30 shots<br />

Stg 3 10036-10286 30 shots<br />

Stg 4 9735-9986 30 shots<br />

Stg 5 9435-9686 24 shots<br />

Stg 6 9135-938624 shots<br />

Stg 7 8835-9086 24 shots<br />

Stg 8 8535-8768 21 shots<br />

Stg 9 8235-8486 21 shots<br />

Stg 10 7935-8186 28 shots<br />

Stg 11 7635-7886 28 shots<br />

Stg 12 7335-758628 shots<br />

Stg 13 7035-7286 28 shots<br />

Stg 14 6735-6986 28 shots<br />

Stg 15 6435-6686 28 shots<br />

Stg 16 6175-638624 shots<br />

-=[ 4' CONSOL 1 ROY.<br />

PORT 2AHS<br />

Perforation Intervals<br />

RECEIVED<br />

OCT 04 ZOIZ

,---- - - ------ -<br />

[_CAL#:u'!BE!!!!<br />

717 -17th St, Suite 1445, Denver CO 80202<br />

Phone: (303) 293-2931 Fax: (303) 293-2939<br />

Contact: Steven Spitler<br />

Company: CNX Gas Company, LLC<br />

Address: 200 Evergreen Drive<br />

Waynesburg, PA, 15370<br />

Job Type: Hybrid DynAqua-l<br />

Phone:<br />

Fax:<br />

Area: Smithfield - OH<br />

County: Portage<br />

Quantity Units Equipment<br />

CNX Spreed<br />

12 2000 hhp Fluid Pumper(s)<br />

2 Blender Base charge<br />

1 Chemical Unit Base charge<br />

1 Acid Transport<br />

1 Hydration Unit charge<br />

1 Suction Discharge Trailer charge<br />

1 Suction Manifold Trailer<br />

1 Iron Truck charge<br />

4 Sandmaster(s)<br />

1 Proppant Conveyor System<br />

1 Computer Van wI Densitometer<br />

Equipment Subtotal One Frac per Day<br />

1 Satellite Treatment Monitoring (2 hours)<br />

Equipment Subtotal Discounted<br />

MATERIALS<br />

494 cwt Sand, 100 Mesh<br />

3665 cwt White Sand, 20/40<br />

Hybrid DynAqua-l Fracture Treatment Fluid<br />

400 gals DWP-603 , Friction Reducer<br />

140 gals DWP-1 11 , Gel Slurry<br />

334 gals DWP-913, Clay Control<br />

68 gals DWP-NE1 , Non-Emulsifier<br />

521bs DWP-901, Oxldlzer Breaker<br />

28 gals rlWP-690, PA Breaker<br />

66 gals DWP-944, Biocide<br />

41 gals DAP-903, Scale Inhibitor<br />

8600 gals 15% SpeartJead Acid<br />

52 gals DAP-l03, Iron Control<br />

Materials Subtotal<br />

Materials Subtotal Discounted<br />

CARTAGE<br />

25993.75 tonOmi Proppant Transport<br />

360 unltOmi Sandmaster Cartage<br />

2160 unitOmi Travel on Equipment (24 units @ 90 miles)<br />

Cartage Subtotal<br />

Cartage Subtotal Discounted<br />

ADDITIONAL CHARGES (no discount)<br />

1 job Continuous Operations Iron Charge<br />

Subtotal<br />

1 job Plug Pumping (on continuous operations)<br />

30 manoda) Subsistence (30 Guys, 1 Days)<br />

1449 cwt Slickwater Pumping Surcharge<br />

Additional Charges Subtotal<br />

GRAND TOTAL<br />

GRAND TOTAL -Discounted<br />

SERVICE ORDER<br />

Job Location: PORT2AHSU (Stage. I), 0<br />

Job Date: 09/14112<br />

Customer AFE #: 112403<br />

Customer PO #:<br />

Operator GIL Code #:<br />

User 10#:<br />

Sales Rep: Adam Winkler<br />

District: Smithfield<br />

Service Order #: 97985<br />

-<br />

Price<br />

Units<br />

Receipt of Materials & Services on this Order Is Hereby Acknowledged<br />

CUSTOMER SIGNATURE<br />

THIS IS NOT AN INVOICE - DO NOT PAY!<br />

Code:<br />

Total<br />

v ,<br />

.-,<br />

REC ElVEI<br />

DC, 11 2012<br />

I<br />

I<br />

I<br />

I

!!!!SCA!!Lf.mlJeE.!!!! Water Analysis<br />

General Info 578<br />

Well Name, Loc'n: PORT2AHSU (Stages 1), 0 Calfrac Service Line: Frac<br />

Customer: Steven Spitler Job Date: 09/14/12<br />

CNX Gas Company, LLC Job Type: Hybrid DynAqua-1<br />

200 Evergreen Drive Program Number: FACI0008LC<br />

Waynesburg, PA 15370 Service Order #: 97985<br />

Pre-Job Fluid Test Results:<br />

QC Step: #1 #2 #3 #4 #5 #6 #7 #8 #9 #10 #11 #12 #13 #14 I<br />

I<br />

Initial Water Specific Iron Chloride Potassium Calcium Magnesium Total Sulfates Sodium TOS I<br />

Water Temp. Gravity (Fe) (CI) (K) (Ca) (Mg) Alkalinity (Su) (Na) calc.<br />

Tank #<br />

1<br />

pH<br />

7.30<br />

of<br />

68.4 1.0001<br />

mgll<br />

1.00<br />

mgll<br />

180.00<br />

mgll<br />

100.00,<br />

mgll<br />

32.10<br />

mgll<br />

9.70<br />

mgll<br />

96.10<br />

mgll<br />

24.00<br />

mgll<br />

40.10<br />

mgll<br />

I<br />

1 444.50 .1

!!!!SCA!!;Lf,:'!IJE.!!!! Water Analysis<br />

General Info 578<br />

Well Name, Loc'n: PORT2AHSU (Stage 2), 0 Calfrac Service Line: Frac<br />

Customer: Steven Spitler Job Date: 09/15/12<br />

CNX Gas Company, LLC Job Type: Hybrid DynAqua-1<br />

200 Evergreen Drive Program Number: FACI0008LC<br />

Waynesburg, PA 15370 Service Order #: 97986<br />

Pre-Job Fluid Test Results:<br />

QC Step: #1 #2 #3 #4 #5 #6 #7 #8 #9 #10 #11 #12 #13 #14<br />

Initial Water Specific Iron Chloride Potassium Calcium Magnesium Total Sulfates Sodium TDS<br />

Water Temp. Gravity (Fe) (CI) (K) (Ca) (Mg) Alkalinity (Su) (Na) calc.<br />

Tank # pH of mgll mgll mgll mgll mgll mgll mgll mgll mgll<br />

1 7.30 68.4 1.000 1.00 180.00 100.00 32.10 9.70 96.10 24.00 40.10 444.50

QUALITY CONTROL REPORT<br />

General Info 578<br />

Well Name, Loc'n: PORT2AHSU (Stage 2), 0 Calfrac Service Line: Frac<br />

Customer: Steven Spitler Job Date: 09/15/12<br />

CNX Gas Company, LLC Job Type: Hybrid DynAqua-1<br />

200 Evergreen Drive Program Number: FACI0008LC<br />

Waynesburg, PA 15370 Service Order #: 97986<br />

Pre-Job Fluid Test Results:<br />

QC Step: #1 #2 #3 #4 #5 #6 #7 #8 #9 #10 #11<br />

Tank #<br />

Water<br />

Temp<br />

of<br />

Initial<br />

Water<br />

pH -<br />

1-<br />

-<br />

Base Gel<br />

Viscosity<br />

cp<br />

Base Gel<br />

Sample<br />

pH -<br />

-<br />

-<br />

Crosslink<br />

Sample<br />

pH -<br />

Heated<br />

Lip<br />

Yes/No<br />

1 68.5 8.08 7.5 7.34 9.80 No<br />

Chemical Lot Numbers : -_.-f- .- r-- ...-- r---<br />

Job Fluid Test Results'<br />

Sand Stage Description Base X-Link Visco<br />

t-rac t-Iula<br />

Temp Comments:<br />

(Ib/Gal) pH pH cp of Gel viscosity was too low to allow for crosslink. Gel looked very th in. 3 min<br />

-<br />

-<br />

3.0 ppg 20/40<br />

-<br />

8.11<br />

-<br />

9.6<br />

-<br />

6.4<br />

-<br />

68.7 hydration time seems insufficient for proper Gel hydration with water pH above<br />

6.<br />

- -<br />

-,----<br />

-- - - -<br />

Averages: 8.1 9.6 6.4 68.7

General Info<br />

Loc'n<br />

Customer:<br />

Detailed Stage Summary<br />

Remarks:<br />

Elapsed<br />

Time<br />

PORT2AHSU (Stage 13), 0<br />

Steven Spitler<br />

CNX Gas Company, LLC<br />

200 Evergreen Drive<br />

Waynesbul'll. PA 15370<br />

Treating<br />

Pressure (psi)<br />

Rate (bpm)<br />

Treatment Details<br />

Start<br />

Clean Fluid Pumped Cone.<br />

(bbl) (ppg)<br />

Calfrac Service Line:<br />

Job Date:<br />

Job Type:<br />

Program Number:<br />

Service Order #:<br />

End<br />

Cone.<br />

(ppg)<br />

Proppant (Ib)<br />

578<br />

09/20/12<br />

CWS-600<br />

FACI0008LC<br />

97997<br />

Pumped 8600 gal 15% Spearhead Acid and 52 gal DAP-1031ron Control. Spotted acid on perforations and then shut down for twenty minutes to allow acid to soak in<br />

formation. Pumping recommenced and rate was chased. 100 Mesh sand was started at a concentration of 0.25 ppg. A leak was noticed on the discharge manifold of the<br />

blender, so screws were cut and the well was flushed. Pumps shut down at 5:07 PM 9/20. The blender was rigged out and a new blender was rigged in. The well was<br />

reopened at 8:54 AM 9/21 with a pressure of 1583 pSi. A 10 Ib Linear Gel fluid system was pumped beginning in 3.0 ppg 20/40 sand. Recorded an ISIP of 2665 psi. Pumped as<br />

per customer request.<br />

CALFRAC Supervisor: Phillip Wireman 101012 Supervisor 3 SF Customer Representative: I Alex Worley<br />

Frac

General Info<br />

loc'n<br />

Customer:<br />

Detailed Stage Summary<br />

Elapsed<br />

Time<br />

PORT2AHSU (Stage 14), 0<br />

Steven Spitler<br />

CNX Gas Company, llC<br />

200 Evergreen Drive<br />

Wavnesbura, PA 15370<br />

Treating<br />

Pressure (psi)<br />

Rate (bpm)<br />

Treatment Details<br />

Start<br />

Clean Fluid Pumped Cone.<br />

(bbl) (ppg)<br />

Calfrac Service line:<br />

Job Date:<br />

Job Type:<br />

Program Number:<br />

Service Order #:<br />

End<br />

Cone.<br />

(ppg)<br />

Proppant (Ib)<br />

578<br />

09/21/12<br />

CWS-600<br />

FACI0008lC<br />

97998<br />

Remarks: Ran 8600 gal 15% Spearhead Acid and 52 gal DAP·1031ron Control. Pumped acid down to the perforations and shut down for twenty minutes to allow it to soak in the<br />

formation. Brought on a 10 Ib linear Gel fluid system in 3 ppg 20/40 sand. Recorded an ISIP of 2700 psi. Pumped as per customer request<br />

CAlFRAC Supervisor: Phillip Wireman 101012 Supervisor 3 SF Customer Representative: Alex Worley<br />

Frac

!!!SCAY;'-f.l!/JE.!!!! Water Analysis<br />

General Info 578<br />

Well Name, Loc'n: PORT2AHSU (Stage 14), 0 Calfrac Service Line:, Frac<br />

Customer: Steven Spitler Job Date: 09t21t12<br />

CNX Gas Company, LLC Job Type: CWS-600<br />

200 Evergreen Drive Program Number: FACI0008LC<br />

Waynesburg, PA 15370 Service Order #: 97998<br />

Pre-Job Fluid Test Results:<br />

QC Step: #1 #2 #3 #4 #5 #6 #7 #8 #9 #10 #11 #12 #13 #14<br />

Initial Water Specific Iron Chloride Potassium Calcium Magnesium Total Sulfates Sodium TDS<br />

Water Temp. Gravity (Fe) (CI) (K) (Ca) (Mg) Alkalinity (Su) (Na) calc.<br />

Tank # pH of mgtl mgtl mgtl mgtl mgtl mgtl mgtl mgtl mgtl<br />

1 7.30 68.4 1,000 1,00 180,00 100.00 32.10 9.70 96.10 24.00' 40 .10 444.50