Condor VC - Weiler Werkzeugmaschinen GmbH

Condor VC - Weiler Werkzeugmaschinen GmbH

Condor VC - Weiler Werkzeugmaschinen GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

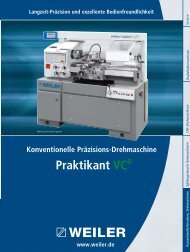

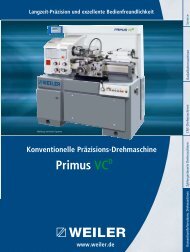

Long-term precision and operating convenience<br />

The New WEILER: The Next Step Forward<br />

Conventional Precision Lathe<br />

<strong>Condor</strong> <strong>VC</strong><br />

www.weiler.de<br />

Service<br />

Manual/Semi-CNC Lathes Cycle-Controlled Lathes CNC Lathes<br />

Radial Drilling Machines

<strong>Condor</strong> <strong>VC</strong><br />

Bed, subbase and sliding cover<br />

The bed is manufactured from highquality<br />

grey cast iron. Strong transverse<br />

ribbing and continuous guides ensure<br />

resistance to bending and torsional<br />

forces. The separate vee and flat guides<br />

for the carriage and tailstock are flamehardened<br />

and ground.<br />

The bed is bonded to the generously<br />

dimensioned sheet steel base to further<br />

enhance the absorption properties of<br />

the complete construction. Located in<br />

the base are the drives, electrics, the<br />

optionally available coolant system as<br />

well as a large lockable cabinet for the<br />

secure storage of collets and other accessories.<br />

The sliding cover can be moved<br />

over the enire bed length.<br />

Headstock<br />

The casing is thick-walled and manufacured from high-quality<br />

grey cast iron. This provides the basis for low-vibration running<br />

and exceptional dynamic rigidity. The main spindle of the<br />

<strong>Condor</strong> <strong>VC</strong> is directly driven. The high accuracy, precision and<br />

constant speed capability is ensured through precision angular<br />

contact ball bearings.<br />

Optional Equipment<br />

such as<br />

Angular tailstock turret head<br />

Wedge bar chucks<br />

Coolant attachment<br />

and further accessories out of our vast product range

The advantages of the conventional range are ultimate precision<br />

and operating convenience as well as refined technology.<br />

Standard Design<br />

Sliding cover over the entire machine length<br />

Central arrangement of all operating elements except<br />

for activation of spindle speed and feed<br />

Easy, quick and well arranged operation<br />

Entry of feed, thread, spindle speed and constant<br />

surfaces speed data via the operating panel<br />

of the DRO<br />

User defined data values within the<br />

indicated ranges<br />

Resolution 0.001 mm<br />

Without change gears<br />

Extremely smooth running<br />

Low noise level<br />

Tailstock<br />

To enable fine tapers to be turned, the top of<br />

the tailstock can be moved on a guideway in<br />

front or behind the centre line. The hardened<br />

and ground tailstock quill is provided with a<br />

depth scale which enables exact infeed using<br />

a graduated collar.<br />

Angular tailstock turret head<br />

for centering, drilling, countersinking and<br />

tapping<br />

Additional software functions<br />

for <strong>VC</strong>-machines<br />

Fading out of the axes values via key switch<br />

99 tool offsets<br />

Speed limitation via key switch<br />

Decoupling of Z and Zo axis<br />

Apron<br />

The apron is fully enclosed and also serves as the central<br />

lubrication system reservoir for the carriage, cross slide and<br />

half nuts. A central selection lever activates longitudinal and<br />

transverse movements as well as closing the half nuts. A trip<br />

worm interrupts feed movement when turning against the<br />

stop. The trip force is adjustable in 3 stages.<br />

4/4<br />

Drive<br />

The machine is equipped with a a maintenance-free threephase<br />

asynchronuous motor and a current and speed regulated<br />

frequency converter (<strong>VC</strong>) with actual value feedback. The<br />

advantages of this new drive concept are:<br />

Short start-up and braking times up to the max. speed<br />

Load independent constant speed<br />

Short speed regulating times and reversing times,<br />

e.g. for thread cutting<br />

A safety potentiometer allows the speed to be finely and<br />

infinitely optimized during the processing cycle.<br />

Mounting of the digital readout<br />

The scales and feed lines for the digital readout are optimally<br />

protected against damage in the working area of the machine<br />

through covers and a cable chain.

Service<br />

Manual/Semi-CNC Lathes Cycle-Controlled Lathes CNC Lathes<br />

Radial Drilling Machines<br />

Technical Data<br />

Working Range<br />

Distance between centres mm 800<br />

Centre height mm 180<br />

Swing over bed mm 360<br />

Swing over cross slide mm 190<br />

Travel of cross slide mm 205<br />

Bed width mm 260<br />

Tool shank cross section mm 25 x 25<br />

Main Spindle<br />

Spindle nose according to DIN 55027 size 6<br />

Spindle diameter in front bearing mm 90<br />

Spindle bore mm 56<br />

Taper bore similar to DIN 228 MT 6<br />

Main Drive<br />

Drive power kW 13<br />

Speed range rpm 30 – 3500<br />

Number of gear steps 1<br />

Number of spindle speeds<br />

Feed and thread cutting range taking<br />

the max. path speed into account – resolution 0.001 mm<br />

Any user-defined<br />

feed value between<br />

inf. variable<br />

Longitudinal mm/rev. 0.01 – 20<br />

Transverse<br />

Any user-defined thread<br />

pitch value between<br />

mm/rev. 0.003 – 6.5<br />

Metric threads mm 0.1 – 20<br />

Inch threads<br />

Tailstock<br />

TPI 112 – 3/4<br />

Quill travel mm 110<br />

Quill diameter mm 50<br />

Taper bore according to DIN 228 MT 3<br />

Weight kg 1400<br />

Dimensions incl. sliding cover<br />

L x W x H<br />

mm 2000 x 1175 x 1750<br />

www.weiler.de<br />

WEILER <strong>Werkzeugmaschinen</strong> <strong>GmbH</strong><br />

Mausdorf 46 • D-91448 Emskirchen<br />

Telephone +49 (0)9101-705-0<br />

Fax +49 (0)9101-705-122<br />

info@weiler.de • service@weiler.de<br />

Technical variations reserved · 06/10 · 5.0915.01.11.01.02