Determination of Myo-Inositol - AOAC International

Determination of Myo-Inositol - AOAC International

Determination of Myo-Inositol - AOAC International

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

INFANT FORMULA AND ADULT NUTRITIONALS<br />

Schimpf et al.: Journal <strong>of</strong> aoac international Vol. 95, no. 4, 2012 1<br />

<strong>Determination</strong> <strong>of</strong> <strong>Myo</strong>-<strong>Inositol</strong> (Free and Bound as<br />

Phosphatidylinositol) in Infant Formula and Adult Nutritionals<br />

by Liquid Chromatography/Pulsed Amperometry with<br />

Column Switching: First Action 2011.18<br />

Karen Schimpf and Linda Thompson<br />

Abbott Laboratories, 3300 Stelzer Rd, Columbus, OH 43219<br />

steve Baugh<br />

<strong>AOAC</strong> INTERNATIONAL, 481 N. Frederick Ave, Suite 500, Gaithersburg, MD 20877<br />

<strong>Myo</strong>-inositol is a 6-carbon cyclic polyalcohol also<br />

known as meso-inositol, meat sugar, inosite,<br />

and i-inositol. It occurs in nature in both free<br />

(myo-inositol) and bound (inositol phosphates and<br />

phosphatidylinositol) forms. For the determination<br />

<strong>of</strong> free myo-inositol, samples are mixed with dilute<br />

hydrochloric acid to extract myo-inositol and<br />

precipitate proteins, diluted with water, and filtered.<br />

For the determination <strong>of</strong> myo-inositol bound as<br />

phosphatidylinositol, samples are extracted with<br />

chlor<strong>of</strong>orm, isolated from other fats with silica<br />

SPE cartridges, and hydrolyzed with concentrated<br />

acid to free myo-inositol. Prepared samples are<br />

first injected onto a Dionex CarboPac PA1 column,<br />

which separates myo-inositol from other late-eluting<br />

carbohydrates. After column switching, myo-inositol<br />

is further separated on a CarboPac MA1 column<br />

using a 0.12% sodium hydroxide mobile phase;<br />

strongly retained carbohydrates are eluted from the<br />

PA1 column with a 3% sodium hydroxide mobile<br />

phase. Eluant from the CarboPac MA1 analytical<br />

column passes through an electrochemical detector<br />

cell where myo-inositol is detected by pulsed<br />

amperometry using a gold electrode. The method<br />

showed appropriate performance characteristics<br />

versus selected established standard method<br />

performance requirement parameters for the<br />

determination <strong>of</strong> myo-inositol: linear response;<br />

repeatability (RSD r) <strong>of</strong> 2%; and intermediate<br />

precision (RSD ir) <strong>of</strong> 2.5%. Instrument LOD and LOQ<br />

Submitted for publication January 24, 2012.<br />

The method was approved by the Expert Review Panel on Infant<br />

Formula and Adult Nutritionals as First Action. See “Standards News,”<br />

(2011) Inside Laboratory Management, September/October issue.<br />

The <strong>AOAC</strong> Stakeholder Panel on Infant Formula and Adult<br />

Nutritionals (SPIFAN) invites method users to provide feedback<br />

on the First Action methods. Feedback from method users will<br />

help verify that the methods are fit for purpose and are critical<br />

to gaining global recognition and acceptance <strong>of</strong> the methods.<br />

Comments can be sent directly to the corresponding author.<br />

Corresponding author’s e-mail: karen.schimpf@abbott.com<br />

DOI: 10.5740/jaoacint.CS2011_18<br />

were 0.0004 and 0.0013 mg/100 mL, respectively,<br />

and correspond to a free myo-inositol quantitation<br />

limit <strong>of</strong> 0.026 mg/100 g and a phosphatidylinositol<br />

quantitation limit <strong>of</strong> 0.016 mg/100 g. Correlation with<br />

the reference microbiological assay was good. The<br />

proposed method has been accepted by the Expert<br />

Review Panel as an <strong>AOAC</strong> First Action Method,<br />

suitable for the routine determination <strong>of</strong> myo-inositol<br />

in infant formula and adult nutritionals.<br />

<strong>Myo</strong>-inositol is a 6-carbon cyclic polyalcohol<br />

(Figure 1) that occurs as anhydrous, hydroscopic<br />

crystals. <strong>Myo</strong>-inositol has a sweet taste, is soluble in<br />

water, and is slightly soluble in alcohol. It is insoluble in ether<br />

and other organic solvents. Aqueous solutions are neutral. It has<br />

a molecular weight <strong>of</strong> 180.16, a melting point <strong>of</strong> 225–227°C,<br />

and is optically inactive.<br />

There are nine possible stereoisomeric forms <strong>of</strong> inositol.<br />

Seven are optically inactive or “meso.” Two optically active<br />

forms, the racemic form, and several cis, trans-isomers occur<br />

naturally. <strong>Myo</strong>-inositol is the most widely distributed inositol<br />

isomer and is present in all living cells. It occurs in nature<br />

in both free (myo-inositol) and bound (inositol phosphates<br />

and phosphatidylinositol) forms. Fruits, beans, grains, and<br />

nuts are all good sources <strong>of</strong> myo-inositol. <strong>Myo</strong>-inositol is<br />

essential for the growth <strong>of</strong> many mammalian cells. Although<br />

free myo-inositol is not essential for humans, the abnormal<br />

metabolism <strong>of</strong> myo-inositol by the body has been associated<br />

with diabetes mellitus and chronic renal failure.<br />

<strong>AOAC</strong> Official Method 2011.18<br />

<strong>Myo</strong>-<strong>Inositol</strong> (Free and Bound as<br />

Phosphatidylinositol) in Infant Formula<br />

and Adult Nutritionals<br />

Liquid Chromatography/Pulsed Amperometry<br />

with Column Switching<br />

First Action 2011<br />

The liquid chromatography method with electrochemical<br />

(pulsed amperometry) detection (PAD) allows for the<br />

quantitation <strong>of</strong> myo-inositol in infant, pediatric, and adult<br />

nutritional formulas. The concentration <strong>of</strong> myo-inositol

2 Schimpf et al.: Journal <strong>of</strong> aoac international Vol. 95, no. 4, 2012<br />

OH<br />

OH<br />

HO<br />

OH<br />

OH<br />

Figure 1. <strong>Myo</strong>-inositol. Figure 1. <strong>Myo</strong>-inositol<br />

OH<br />

is calculated by comparison with standards <strong>of</strong> known<br />

concentration. Total myo-inositol, as defined by <strong>AOAC</strong> standard<br />

method performance requirement (SMPR) 2011.007 (1), can be<br />

calculated by adding the free myo-inositol and myo-inositol<br />

bound as phosphatidylinositol data.<br />

The method was validated for the quantitation <strong>of</strong> free<br />

myo-inositol only. Repeatability was determined from triplicate<br />

analyses performed on the same day. Intermediate precision<br />

was determined from replicate determinations performed over<br />

multiple days. Accuracy was determined by comparison to a<br />

reference microbiological assay and expressed as the percentage<br />

<strong>of</strong> HPLC results relative to microbiological results. Instrument<br />

LODs and LOQs were determined statistically from injections<br />

<strong>of</strong> low-level standards.<br />

Caution: Refer to Material Safety Data Sheets (MSDS) <strong>of</strong><br />

chemicals prior to use and follow safe handling<br />

procedures and the suggested personal protective<br />

equipment.<br />

A. Apparatus<br />

(a) Analytical balance.—Minimum weighing capacity <strong>of</strong> at<br />

least 0.0001 g.<br />

(b) Centrifuge.<br />

(c) Desiccator.<br />

(d) N-evap.—With water bath or equivalent.<br />

(e) Oven.—Capable <strong>of</strong> maintaining 110°C.<br />

(f) pH meter.—With pH 4 and 7 buffers.<br />

(g) Stir plate.—Multiposition with stir bars.<br />

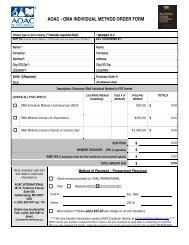

Table 2011.18A. Instrument operating conditions<br />

Pump 1 pressure limit 2000 psi<br />

Pump 1 mobile phase 0.12% (30 mM) NaOH<br />

Pump 1 flow rate 0.4 mL/min<br />

Pump 2 pressure limit 2000 psi<br />

Pump 2 mobile phase 3% (750 mM) NaOH<br />

Pump 2 flow rate 0.4 mL/min<br />

Injection volume 20 µL<br />

<strong>Myo</strong>-inositol retention time 11–13 min<br />

Run time 25 min<br />

t, min<br />

Switching valve configuration time table<br />

Configuration<br />

0.00 1 (see Figure 2011.18A)<br />

1.50 2 (see Figure 2011.18B)<br />

11.50 1 (see Figure 2011.18A)<br />

Electrochemical<br />

Detector<br />

MA1 Guard and<br />

Analytical Columns<br />

Pump 1<br />

PA1 Guard Column<br />

(h) Tubing.—PEEK or Teflon 0.007–.01 in. id.<br />

(i) Vacuum manifold.<br />

(j) Vortex mixer.<br />

(k) HPLC system.—Corrosion-resistant autosampler, isocratic<br />

pump (2), 6-port switching valve, and pulsed amperometry<br />

detector with a gold electrode. Autosampler capable <strong>of</strong> injecting<br />

20 µL.<br />

(l) Columns.—Dionex CarboPac MA1 (4 × 250 mm) P/N<br />

44066, MA1 (4 × 50 mm) P/N 44067, and PA1 (4 × 50 mm)<br />

P/N 43096, or equivalent (www.therm<strong>of</strong>isher.com/dionex/).<br />

B. Materials<br />

(a) Beakers.—Assorted sizes.<br />

(b) Centrifuge tubes.—50 mL with Teflon-coated caps.<br />

(c) Syringe filters.—Nylon, 0.45 and 0.2 µm.<br />

(d) Filter paper.—Whatman 2V or equivalent (www.<br />

whatman.com).<br />

(e) Erlenmeyer flasks.—50 or 125 mL or equivalent.<br />

(f) Volumetric flasks.—Assorted sizes.<br />

(g) Funnels.—Suitable for use with filter paper.<br />

(h) Pipets.—Volumetric (Class A); assorted sizes.<br />

(i) Solid-phase extraction (SPE) cartridges.—Silica, 1 g (J.T.<br />

Baker P/N 7086-07, www.avantormaterials.com) or equivalent.<br />

(j) Syringes.—1 mL disposable and 25 mL gas-tight glass<br />

with 4 in. stainless steel needles.<br />

C. Chemicals and Solvents<br />

(a) Acetic acid.—Glacial, ACS.<br />

(b) Chlor<strong>of</strong>orm.—High-purity, HPLC grade.<br />

(c) Diethyl ether.—Anhydrous, HPLC grade.<br />

(d) Drierite (desiccant).—Anhydrous calcium sulfate,<br />

8 mesh.<br />

(e) Helium.—Zero grade or equivalent.<br />

(f) Hexane.—HPLC grade.<br />

(g) Hydrochloric acid.—Concentrated (36–38%), ACS.<br />

(h) Distilled or deionized laboratory water.<br />

Waste<br />

Pump 2<br />

Figure 2011.18A. Switching valve configuration 1.<br />

Figure 2011.18B. Switching valve configuration 2.

Table 2011.18B. PAD settings with gold electrode<br />

Analog range 1 uC<br />

Detector program: Dionex PED t, s E, V<br />

0.0 0.00<br />

0.50 0.00<br />

0.51 +0.80<br />

0.59 +0.80<br />

0.60 –0.70<br />

0.80 –0.70<br />

Integration period<br />

Detector program: Dionex ED 50 with<br />

0.30–0.50 s<br />

special gold electrode cell SP4270 t, s E, V<br />

0.0 +0.05<br />

0.2 +0.05<br />

0.4 +0.05<br />

0.41 +0.75<br />

0.6 +0.75<br />

0.61 –0.15<br />

1.0 –0.15<br />

Integration period 0.20–0.40 s<br />

(i) Meta-phosphoric acid.—ACS.<br />

(j) Methanol.—HPLC grade.<br />

(k) <strong>Myo</strong>-inositol.—USP reference standard, <strong>of</strong>ficial lot; store<br />

desiccated. See standard label for purity.<br />

(l) Sodium acetate trihydrate or sodium acetate.—<br />

Anhydrous, ACS.<br />

(m) Sodium chloride.<br />

(n) Sodium hydroxide.—50% (w/w), low carbonate form.<br />

D. Preparation <strong>of</strong> Reagents and Standard Solutions<br />

All solutions can be scaled up or down for convenience<br />

provided good laboratory practices are observed. Solutions can<br />

be stored at 2–30°C in tight, inert containers otherwise noted.<br />

(a) <strong>Myo</strong>-inositol stock standard solution (approximately<br />

2000 mg/L).—Accurately weigh approximately 0.100 g<br />

myo-inositol and quantitatively transfer to a 50 mL volumetric<br />

flask. Dilute to volume with water. Mix well. Store refrigerated.<br />

Expiration: 3 months.<br />

(b) <strong>Myo</strong>-inositol intermediate standard solution<br />

(approximately 200 mg/L).—Dilute 10.0 mL stock standard to<br />

100 mL with laboratory water and mix well. Discard after use.<br />

(c) <strong>Myo</strong>-inositol working standard solutions (approximately<br />

4, 2, 1, 0.5, 0.2, and 0.05 mg/L).—Dilute 2.0, 1.0, and<br />

0.5 mL myo-inositol intermediate standard to 100 mL<br />

with laboratory water (4, 2, and 1 mg/L). Dilute 0.5 mL<br />

myo-inositol intermediate standard to 200 mL with laboratory<br />

water (0.5 mg/L). Dilute 4 and 1 mL <strong>of</strong> the 0.5 mg/L myoinositol<br />

working standard to 10 mL with laboratory water (0.2<br />

and 0.05 mg/L). Expiration: 2 weeks.<br />

(d) Hydrochloric acid, 0.5%.—Add 1.25 mL concentrated<br />

hydrochloric acid to approximately 200 mL water in a 250 mL<br />

volumetric flask. Dilute to volume with water and mix well.<br />

Expiration: 6 months.<br />

Schimpf et al.: Journal <strong>of</strong> aoac international Vol. 95, no. 4, 2012 3<br />

(e) Sodium chloride, 1 N.—Dissolve 5.8 g sodium chloride<br />

and dilute to 100 mL with water. Expiration: 1 month.<br />

(f) Sodium hydroxide, 0.12% or 30 mM (Pump 1).—Quickly<br />

weigh 4.8 (±0.1) g <strong>of</strong> 50% sodium hydroxide into a 2000 mL<br />

volumetric flask containing approximately 1900 mL water.<br />

(Note: It is important that the sodium hydroxide does not<br />

absorb carbon dioxide from the air.) Swirl to mix well. Dilute to<br />

volume with water and mix well. Expiration: 1 month.<br />

(g) Sodium hydroxide, 3.0% or 750 mM (Pump 2).—Quickly<br />

weigh 120 (±3) g <strong>of</strong> 50% sodium hydroxide into a 2000 mL<br />

volumetric flask containing approximately 1900 mL water.<br />

(Note: It is important that the sodium hydroxide does not<br />

absorb carbon dioxide from the air.) Swirl to mix well. Dilute to<br />

volume with water and mix well. Expiration: 1 month.<br />

(h) 6% Metaphosphoric acid.—Weigh 6.0 g metaphosphoric<br />

acid into a 100 mL volumetric flask. Dissolve and dilute to<br />

volume with laboratory water. Mix well. Store refrigerated.<br />

Expiration: 1 week.<br />

(i) Phosphatidylinositol extraction solutions.—<br />

(1) Chlor<strong>of</strong>orm:methanol (2:1).—Mix 60 mL chlor<strong>of</strong>orm and<br />

30 mL methanol.<br />

(2) Hexane:diethyl ether (80:20).—Mix 80 mL hexane and<br />

20 mL diethyl ether.<br />

(3) Hexane:diethyl ether (50:50).—Mix 50 mL hexane and<br />

50 mL diethyl ether.<br />

(4) Methanol:chlor<strong>of</strong>orm:water (75:15:10).—Mix 75 mL<br />

methanol, 15 mL chlor<strong>of</strong>orm, and 10 mL water.<br />

E. Sample Preparation and Extraction<br />

(a) Sample preparation for free myo-inositol<br />

determinations.—Prepared samples that are constantly stored<br />

at 1–8°C in closed containers are stable for up to 5 days. After<br />

5 days, samples must be prepared again.<br />

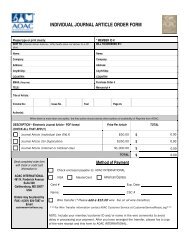

Figure 2011.18C. Examples <strong>of</strong> typical chromatograms<br />

<strong>of</strong> (a) myo-inositol standard, (b) free myo-inositol in<br />

SRM 1849, (c) myo-inositol from phosphatidylinositol in<br />

SRM 1849.<br />

(a)<br />

(b)<br />

(c)

4 Schimpf et al.: Journal <strong>of</strong> aoac international Vol. 95, no. 4, 2012<br />

Table 1. Free myo-inositol validation data—<br />

intermediate precision, mg/100 g<br />

HPLC method<br />

Day<br />

Product type 1 2 3<br />

Hypoallergenic infant formula RTF 8.11 8.06 8.17<br />

n 3 3 3<br />

RSD, % 3.64 5.01 3.40<br />

Soy-based infant formula powder 31.1 31.8 30.9<br />

n 3 3 3<br />

RSD, % 2.49 0.327 1.35<br />

Specialty infant formula RTF 19.7 18.9 19.0<br />

n 3 3 3<br />

RSD, % 1.60 0.976 1.73<br />

Milk-based infant formula RTF 4.36 4.43 4.38<br />

n 3 3 3<br />

RSD, % 1.91 4.26 0.784<br />

Very low-fat infant formula powder 125 126 122<br />

n 3 3 3<br />

RSD, % 1.46 3.37 1.19<br />

Free amino acid-based infant formula<br />

powder<br />

65.5 65.0 64.9<br />

n 3 3 3<br />

RSD, % 1.56 1.20 2.78<br />

Pediatric nutritional beverage 10.3 10.5 11.1<br />

n 3 3 3<br />

RSD, % 2.02 1.00 4.19<br />

Adult nutritional beverage 91.6 92.3 NA a<br />

n 4 4<br />

RSD, % 1.35 1.22<br />

a NA = No data generated.<br />

Table 3. Free myo-inositol validation data—accuracy data<br />

Product type<br />

HPLC method a ,<br />

mg/100 g<br />

Table 2. Free myo-inositol validation data—<br />

intermediate precision, mg/100 g<br />

Product type n Avg.<br />

Hypoallergenic infant formula RTF 9 a<br />

Soy-based infant formula powder 9 a<br />

Specialty infant formula RTF 9 a<br />

Milk-based infant formula RTF 20 b<br />

Very low-fat infant formula powder 9 a<br />

Free amino acid-based infant formula powder 9 a<br />

Pediatric nutritional beverage 9 a<br />

Adult nutritional beverage 8 c<br />

a Intralaboratory triplicate analyses on 3 days.<br />

HPLC method<br />

RSD,<br />

%<br />

8.13 3.58<br />

31.3 1.89<br />

19.2 2.22<br />

4.39 2.53<br />

125.0 2.72<br />

65.0 1.82<br />

10 4.25<br />

91.9 1.25<br />

b Intralaboratory single, duplicate, or triplicate analyses on 9 days.<br />

c Intralaboratory quadruplicate analyses on 2 days.<br />

Thoroughly mix or stir products prior to sampling. For<br />

liquid products, accurately weigh 0.5 to 5 g (±10%) <strong>of</strong> product<br />

into a 100 mL volumetric flask and record the weight to the<br />

nearest 0.0001 g. For powdered products that do not require<br />

reconstitution, accurately weigh 0.25 to 1.5 g powder into a<br />

100 mL volumetric flask and record the weight to the nearest<br />

0.0001 g. Add approximately 10 to 15 mL laboratory water<br />

to the volumetric and swirl or stir to completely dissolve the<br />

powder. For powdered products that are not homogeneous at<br />

the subgram level, reconstitute following the product label<br />

instructions and accurately weigh 0.5 to 5 g reconstituted product<br />

into a 100 mL volumetric flask. Record the weight to the nearest<br />

0.0001 g. Add enough 0.5% hydrochloric acid to each sample<br />

to adjust the sample pH to 4.5 ± 0.2 and swirl to mix. Allow the<br />

volumetric flasks to set a minimum <strong>of</strong> 2 min. Dilute to volume<br />

with laboratory water and mix well. Filter samples through<br />

Whatman 2V filter paper into 125 mL Erlenmeyer flasks. (Note:<br />

Although some samples will filter cloudy, the filtrates can still<br />

be used.) Filter an aliquot <strong>of</strong> sample filtrate through a 0.45 µm<br />

syringe filter into an autosampler vial.<br />

(b) Sample preparation for phosphatidylinositol<br />

determinations.—(1) Extraction.—Weigh 4 g (±10%) liquid<br />

Microbiological method b ,<br />

mg/100 g HPLC/micro, %<br />

Hypoallergenic infant formula RTF 8.13 7.4 110<br />

Soy-based infant formula powder 31.3 37.0 84.5<br />

Specialty infant formula RTF 19.2 19.0 101<br />

Milk-based infant formula RTF 4.39 3.7 119<br />

Very low-fat infant formula powder 125.0 140.0 89.2<br />

Free amino acid-based infant formula powder 65.0 62.0 105<br />

Pediatric nutritional beverage 10.6 11.0 96.6<br />

Adult nutritional beverage 91.9 83.0 111<br />

a Multiple intralaboratory analyses on multiple days.<br />

b Single analyses.

or reconstituted powder product or 1 g (±10%) homogeneous<br />

powder into a 50 mL centrifuge tube and record the weight to<br />

the nearest 0.0001 g. Add 10 mL methanol and stir for at least<br />

20 min. Add 20 mL chlor<strong>of</strong>orm and stir for at least 5 min. If<br />

large clumps form when chlor<strong>of</strong>orm is added, cap tube and<br />

shake well to mix sample. Add 5 mL 6% metaphosphoric acid<br />

and 1 mL 1 N NaCl and mix well. Centrifuge. Remove the<br />

bottom chlor<strong>of</strong>orm layer and evaporate with nitrogen in a 60°C<br />

water bath.<br />

(2) Sample cleanup.—Condition a 1 g silica SPE cartridge<br />

with 6 mL hexane. Dissolve residue in bottom <strong>of</strong> centrifuge<br />

tube in 1 mL chlor<strong>of</strong>orm:methanol (2:1). Quantitatively transfer<br />

dissolved residue to the conditioned silica SPE cartridge. Rinse<br />

SPE cartridge with 3 mL hexane:diethyl ether (80:20) and discard<br />

the eluant. Rinse SPE cartridge with 3 mL hexane:diethyl ether<br />

(50:50), 4 mL methanol, and 4 mL methanol:chlor<strong>of</strong>orm:water<br />

(75:15:10) and collect all eluants in a single 50 mL centrifuge<br />

tube. Evaporate eluants collected from SPE cartridge with<br />

nitrogen in a 60°C water bath.<br />

(3) Hydrolysis.—Add 40 µL concentrated acetic acid and<br />

2 mL concentrated hydrochloric acid to residue in centrifuge<br />

tube from the sample cleanup step. Tightly cap tube. Heat in a<br />

110°C oven for 2 h. Cool. Dilute mixture with approximately<br />

10 mL H 2O and then add 1.25 mL 50% (w/w) sodium hydroxide.<br />

Transfer sample to a 50 mL volumetric flask and dilute to<br />

volume with water. Filter an aliquot <strong>of</strong> sample filtrate through a<br />

0.45 µm syringe filter into an autosampler vial.<br />

(c) HPLC analysis.—(1) See Tables 2011.18A and B for<br />

instrument operating conditions and PAD settings, respectively.<br />

(2) Instrument startup.—The HPLC system should be<br />

located in an area where temperature fluctuations will be<br />

minimal throughout the run.<br />

Prepare mobile phases. Helium sparge mobile phases<br />

Schimpf et al.: Journal <strong>of</strong> aoac international Vol. 95, no. 4, 2012 5<br />

and/or pressurize mobile phase reservoirs. If necessary, clean<br />

and polish the gold working electrode. Turn on the detector<br />

and pump mobile phase over the columns at a flow rate <strong>of</strong><br />

0.40 mL/min for at least ½ h to equilibrate the system. Verify<br />

that the detector is stable before beginning an analysis. Inject<br />

20 μL <strong>of</strong> the most concentrated standard at least 5 times and<br />

note the peak areas or heights. If the system is equilibrated,<br />

the RSD <strong>of</strong> the peak areas or heights <strong>of</strong> the last three standard<br />

injections should be ≤2.0%.<br />

(3) Standard and sample analysis.—Once the system has<br />

equilibrated, inject one standard at each concentration. After<br />

a set <strong>of</strong> standards has been injected, a control sample and up<br />

to 14 samples can be injected before another set <strong>of</strong> standards<br />

should be injected.<br />

(4) System shutdown.—After all samples and standards<br />

have been analyzed, inject one vial <strong>of</strong> water to clean out the<br />

autosampler needle and tubing. Store the analytical columns<br />

in mobile phase [0.12% (30 mM) sodium hydroxide]. Turn <strong>of</strong>f<br />

the electrochemical cell. Flush the pump heads with water to<br />

remove sodium hydroxide.<br />

F. Calculations<br />

Before calculating myo-inositol concentrations in samples,<br />

compare the myo-inositol standard peaks with the myo-inositol<br />

sample peaks and confirm that there are not any interfering<br />

compounds and that the myo-inositol sample peak areas or<br />

heights are within the range <strong>of</strong> the myo-inositol standard peak<br />

areas or heights. See Figure 2011.18C for examples <strong>of</strong> typical<br />

chromatograms. The concentration <strong>of</strong> myo-inositol cannot<br />

be calculated if there are interferences or if the separation is<br />

poor. The myo-inositol retention time should be 11 to 13 min<br />

(depending on the individual analytical column).<br />

(a) Concentration <strong>of</strong> working standards.<br />

Table 4. Free myo-inositol and myo-inositol from phosphatidylinositol data, mg/100 g<br />

Product type n<br />

SRM 1849 9 a<br />

<strong>Myo</strong>-inositol from<br />

phosphatidylinositol<br />

Free<br />

myo-inositol<br />

Total (free + phosphatidyl<br />

bound) myo-inositol<br />

<strong>Myo</strong>-inositol from<br />

phosphatidylinositol, % RSD, %<br />

0.909 41.3 42.2 2.15 5.62<br />

Hypoallergenic infant formula RTF Not detected 8.87 8.87 0<br />

Hypoallergenic infant formula powder Not detected 69.1 69.1 0<br />

Milk-based infant formula RTF 3 b<br />

0.428 3.83 4.26 10.1 1.91<br />

Milk-based infant formula powder 3 b<br />

2.81 31.4 34.2 8.21 1.09<br />

Soy-based infant formula RTF 3 b<br />

0.995 4.05 5.05 19.7 1.46<br />

Soy-based infant formula powder 3 b<br />

11.3 31.9 43.2 26.1 2.05<br />

Specialty infant formula RTF 3 b<br />

0.416 27.5 27.9 1.49 0.60<br />

Specialty infant formula powder 3 b<br />

1.67 mg/100 g 208.0 209.7 0.80 2.69<br />

Lactose-free infant formula RTF 3 b<br />

0.333 3.90 4.23 7.86 0.76<br />

Lactose-free infant formula powder 3 b<br />

0.258 31.7 32.0 0.81 8.12<br />

Specialty infant formula powder 3 b<br />

1.51 mg/100 g 132.0 133.5 1.13 2.13<br />

Rice starch infant formula RTF 3 b<br />

0.318 4.13 4.45 7.15 5.97<br />

Rice starch infant formula powder 3 b<br />

0.233 33.1 33.3 0.70 4.72<br />

Milk-based infant formula RTF 3 b<br />

0.672 4.60 5.27 12.7 8.92<br />

Milk-based infant formula powder 3 b<br />

1.75 37.2 39.0 4.50 4.20<br />

Pediatric nutritional beverage 3 b<br />

0.751 12.4 13.2 5.71 2.08<br />

a Intralaboratory triplicate analyses on 3 days.<br />

b Intralaboratory triplicate analyses on 1 day.

6 Schimpf et al.: Journal <strong>of</strong> aoac international Vol. 95, no. 4, 2012<br />

C W = W × 1/0.05 × 1/10 × A 1/V 1 × A 2/V 2<br />

= W × 2 × A 1/V 1 × A 2/V 2<br />

where C W is the concentration <strong>of</strong> the working standard solution<br />

in milligrams per liter; W is the weight, in milligrams, <strong>of</strong><br />

myo-inositol standard weighed; 0.05 is the dilution volume <strong>of</strong><br />

the stock standard in liters; 1/10 is the intermediate standard<br />

dilution (10 to 100 mL); A 1 is the aliquot <strong>of</strong> intermediate<br />

standard used, in milliliters; V 1 is the dilution volume <strong>of</strong> the<br />

working standard in milliliters; A 2 is the aliquot <strong>of</strong> working<br />

standard used, in milliliters, if applicable; and V 2 is the dilution<br />

volume <strong>of</strong> the working standard in milliliters, if applicable.<br />

(b) Preparation <strong>of</strong> standard curve.—For each working<br />

standard concentration, average the peak areas or heights from<br />

each two consecutive sets <strong>of</strong> standards. Prepare a standard<br />

curve by performing linear least squares (regression) on the<br />

concentrations versus the averaged peak areas or heights. A<br />

standard curve must have a correlation <strong>of</strong> at least 0.999 to be<br />

considered acceptable for sample calculations.<br />

At each working standard level, the peak areas or heights <strong>of</strong><br />

standards injected before and after a set <strong>of</strong> samples must not<br />

increase or decrease by more than 7%.<br />

(c) Calculation <strong>of</strong> myo-inositol in samples and controls.—<br />

The concentration <strong>of</strong> myo-inositol in a prepared sample or<br />

control is extrapolated from the standard curve prepared above.<br />

From the diluted, prepared sample concentration, the product<br />

concentration can be calculated:<br />

C p = (C d × D 1)/S<br />

where C p is the concentration <strong>of</strong> myo-inositol in the product<br />

sample or control in milligrams per kilogram; C d is the<br />

concentration <strong>of</strong> myo-inositol in the prepared sample or control<br />

in milligrams per liter; D 1 is the dilution volume in milliliters;<br />

and S is the sample weight in grams.<br />

Total myo-inositol, as defined by <strong>AOAC</strong> SMPR 2011.007 (1),<br />

can be calculated by adding the free myo-inositol and myoinositol<br />

bound as phosphatidylinositol data.<br />

Note: For each set <strong>of</strong> samples, the control result must be<br />

within three standard deviations <strong>of</strong> the control mean.<br />

Reference: J. <strong>AOAC</strong> Int. 95, (future issue)<br />

Results and Discussion<br />

During validation, the average repeatability was 2.0% RSD<br />

and the intermediate precision was 2.5% RSD, as summarized<br />

in Tables 1 and 2. Accuracy was determined by comparison to a<br />

reference microbiological assay as detailed in Table 3 (2). The<br />

instrument LOD and LOQ <strong>of</strong> the method were estimated to be<br />

0.0004 and 0.0013 mg/100 mL, respectively, and correspond to<br />

a free myo-inositol quantitation limit <strong>of</strong> 0.026 mg/100 g.<br />

Although this method has not been fully validated for the<br />

quantitation <strong>of</strong> myo-inositol bound as phosphatidylinositol,<br />

some data have been generated and are summarized in Table 4.<br />

The phosphatidylinositol quantitation limit has been estimated<br />

to be 0.016 mg/100 g.<br />

References<br />

(1) <strong>AOAC</strong> SMPR 2011.007 (2012) J. <strong>AOAC</strong> Int. 95, 295. http://<br />

dx.doi.org/10.5740/jaoac.int.11-0443<br />

(2) Atkin, L., Schultz, A., Williams, W., & Frey, C. (1943) Ind.<br />

Eng. Chem. Anal. Ed., 15, 141–144. http://dx.doi.org/10.1021/<br />

i560114a022