Analysis and modelling of the seismic behaviour of high ... - Ingegneria

Analysis and modelling of the seismic behaviour of high ... - Ingegneria

Analysis and modelling of the seismic behaviour of high ... - Ingegneria

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

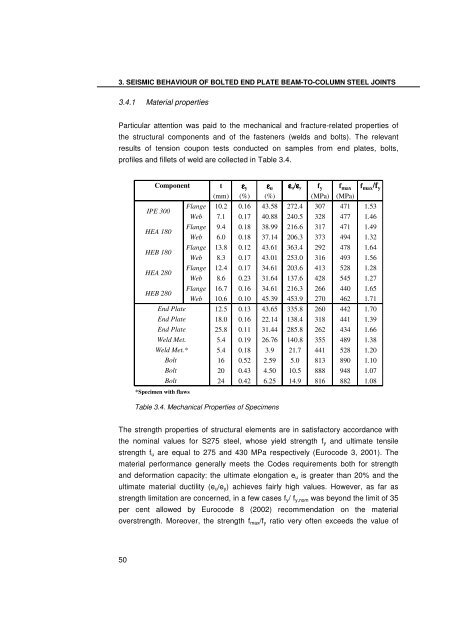

3. SEISMIC BEHAVIOUR OF BOLTED END PLATE BEAM-TO-COLUMN STEEL JOINTS<br />

3.4.1 Material properties<br />

Particular attention was paid to <strong>the</strong> mechanical <strong>and</strong> fracture-related properties <strong>of</strong><br />

<strong>the</strong> structural components <strong>and</strong> <strong>of</strong> <strong>the</strong> fasteners (welds <strong>and</strong> bolts). The relevant<br />

results <strong>of</strong> tension coupon tests conducted on samples from end plates, bolts,<br />

pr<strong>of</strong>iles <strong>and</strong> fillets <strong>of</strong> weld are collected in Table 3.4.<br />

50<br />

Component t εy εu εu/εy fy fmax fmax/fy (mm) (%) (%) (MPa) (MPa)<br />

IPE 300<br />

Flange<br />

Web<br />

10.2<br />

7.1<br />

0.16<br />

0.17<br />

43.58<br />

40.88<br />

272.4<br />

240.5<br />

307<br />

328<br />

471<br />

477<br />

1.53<br />

1.46<br />

HEA 180<br />

HEB 180<br />

HEA 280<br />

HEB 280<br />

End Plate<br />

End Plate<br />

End Plate<br />

Weld Met.<br />

Weld Met.*<br />

Bolt<br />

Bolt<br />

Bolt<br />

*Specimen with flaws<br />

Flange 9.4 0.18 38.99 216.6 317 471 1.49<br />

Web 6.0 0.18 37.14 206.3 373 494 1.32<br />

Flange 13.8 0.12 43.61 363.4 292 478 1.64<br />

Web 8.3 0.17 43.01 253.0 316 493 1.56<br />

Flange 12.4 0.17 34.61 203.6 413 528 1.28<br />

Web 8.6 0.23 31.64 137.6 428 545 1.27<br />

Flange 16.7 0.16 34.61 216.3 266 440 1.65<br />

Web 10.6 0.10 45.39 453.9 270 462 1.71<br />

Table 3.4. Mechanical Properties <strong>of</strong> Specimens<br />

12.5 0.13 43.65 335.8 260 442 1.70<br />

18.0 0.16 22.14 138.4 318 441 1.39<br />

25.8 0.11 31.44 285.8 262 434 1.66<br />

5.4 0.19 26.76 140.8 355 489 1.38<br />

5.4 0.18 3.9 21.7 441 528 1.20<br />

16 0.52 2.59 5.0 813 890 1.10<br />

20 0.43 4.50 10.5 888 948 1.07<br />

24 0.42 6.25 14.9 816 882 1.08<br />

The strength properties <strong>of</strong> structural elements are in satisfactory accordance with<br />

<strong>the</strong> nominal values for S275 steel, whose yield strength fy <strong>and</strong> ultimate tensile<br />

strength fu are equal to 275 <strong>and</strong> 430 MPa respectively (Eurocode 3, 2001). The<br />

material performance generally meets <strong>the</strong> Codes requirements both for strength<br />

<strong>and</strong> deformation capacity: <strong>the</strong> ultimate elongation eu is greater than 20% <strong>and</strong> <strong>the</strong><br />

ultimate material ductility (eu/ey) achieves fairly <strong>high</strong> values. However, as far as<br />

strength limitation are concerned, in a few cases fy/ fy,nom was beyond <strong>the</strong> limit <strong>of</strong> 35<br />

per cent allowed by Eurocode 8 (2002) recommendation on <strong>the</strong> material<br />

overstrength. Moreover, <strong>the</strong> strength fmax/fy ratio very <strong>of</strong>ten exceeds <strong>the</strong> value <strong>of</strong>