Enhanced Polymer Passivation Layer for Wafer Level Chip Scale ...

Enhanced Polymer Passivation Layer for Wafer Level Chip Scale ...

Enhanced Polymer Passivation Layer for Wafer Level Chip Scale ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1.4 Solder Joint Fatigue<br />

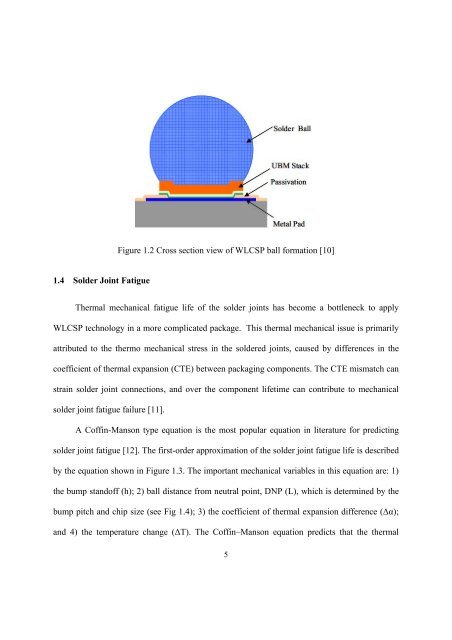

Figure 1.2 Cross section view of WLCSP ball <strong>for</strong>mation [10]<br />

Thermal mechanical fatigue life of the solder joints has become a bottleneck to apply<br />

WLCSP technology in a more complicated package. This thermal mechanical issue is primarily<br />

attributed to the thermo mechanical stress in the soldered joints, caused by differences in the<br />

coefficient of thermal expansion (CTE) between packaging components. The CTE mismatch can<br />

strain solder joint connections, and over the component lifetime can contribute to mechanical<br />

solder joint fatigue failure [11].<br />

A Coffin-Manson type equation is the most popular equation in literature <strong>for</strong> predicting<br />

solder joint fatigue [12]. The first-order approximation of the solder joint fatigue life is described<br />

by the equation shown in Figure 1.3. The important mechanical variables in this equation are: 1)<br />

the bump standoff (h); 2) ball distance from neutral point, DNP (L), which is determined by the<br />

bump pitch and chip size (see Fig 1.4); 3) the coefficient of thermal expansion difference (Δα);<br />

and 4) the temperature change (ΔT). The Coffin–Manson equation predicts that the thermal<br />

5