PS-PLLA - Www2.che.nthu.edu.tw

PS-PLLA - Www2.che.nthu.edu.tw

PS-PLLA - Www2.che.nthu.edu.tw

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

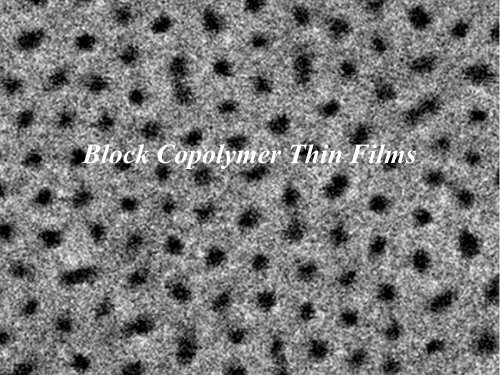

Block Copolymer Thin Films

Thin Film Morphologies of BCPs<br />

Thickness<br />

Air surface<br />

Substrate<br />

Size<br />

Shape<br />

Order<br />

Orientation<br />

@

Thickness Effect<br />

while t is small for a lamellar phase!<br />

FL: symmetric<br />

surface-parallel full<br />

lamella;<br />

AFL: anti-symmetric<br />

surface-parallel<br />

lamella;<br />

AHY: anti-symmetric<br />

hybrid structure;<br />

HL: half-lamella;<br />

HY: symmetric hybrid<br />

structure;<br />

PL: surfaceperpendicular<br />

lamellae.

At equilibrium, symmetric film systems exhibit a series of<br />

stable films when t = nL 0 (n = 1, 2, 3, 4), whereas antisymmetric<br />

films exhibit a similar series of stable films when t =<br />

(n + 1/2)L 0. It is highly possible to form the island-like<br />

textures for t being not equal to nL 0 and (n + 1/2)L 0.<br />

For symmetric surface energy, first, the domain orientation<br />

was film thickness dependent. In particular, PL gained stability<br />

when t = nL 0, and especially for t < L 0. Second, for neutral<br />

surface energetics, PL was stable for all film thicknesses.<br />

@

Phase diagram of thin film morphologies calculated<br />

with the following parameters: N=200, S 1 B = -0.3 kT,<br />

interaction parameter = 0.1, S 1 B /S2 B = R

For a<br />

cylinder<br />

phase

Surface Tension @

Substrate<br />

Effect

Grain boundary problem<br />

for thicker samples<br />

<strong>PS</strong>-PB AFM Morphology<br />

Defect free microdomain!<br />

van Dijk, M. A.; van den Berg, R. Macromolecules 1995, 28, 6773.

Large-scale Orientation of Microdomains<br />

Electric field-Induced Orientation<br />

Russell, U of Massachusetts<br />

Surface-Induced Orientation<br />

Russell, U of Massachusetts<br />

Shear-Induced Orientation<br />

Register, Princeton U<br />

■ Patterned Substrate-induced Orientation<br />

Nealey, U of Wisconsin<br />

■ Graphoepitaxy-induced Orientation<br />

Ross, MIT<br />

■ Photo-induced Orientation<br />

Iyoda, TIT

Electric field-Induced Orientation<br />

ε <strong>PS</strong> = 2.45<br />

ε PMMA = 6<br />

Russell, U of Massachusetts<br />

Russell, T. P. et al. Science, 1996, 273, 931.

Surface-Induced Orientation<br />

Neutral Surface<br />

Russell, T. P. et al. Science 1997, 275, 1458.; Russell, T. P. et al. Nature 1998, 395, 757.<br />

@

Shear-induced Orientation<br />

<strong>PS</strong>-PEP Cylindrical Morphology<br />

<strong>PS</strong><br />

@<br />

Register R. A. et al. Adv. Mater. 2004, 16, 1736.

Patterned Substrate for DSA<br />

(1) Nealey, P. F. et al. Nature, 2003, 424, 411.

Grephoepitaxy-induced Orientation<br />

Confinement effect<br />

Sibener. S. J. et al. Nano Lett. 2002, 4, 273.<br />

@

Photo-induced Orientation<br />

Chromophore molecule<br />

Iyoda, T. et al. J. Am Chem. Soc. 2006, 128, 11010.<br />

@

Evaporation-induced Orientation<br />

Spin Coating-induced Orientation<br />

for <strong>PS</strong>-PEO<br />

Russell, T.P. et al. Adv Mater 2002,<br />

14, 1373.<br />

Tapping-mode<br />

SPM phase images<br />

of the surfaces of<br />

a) solution cast; b)<br />

spin coated<br />

<strong>PS</strong>365-<strong>PLLA</strong>109<br />

(f <strong>PLLA</strong> v =0.24) thin<br />

films on glass<br />

slides.<br />

a)<br />

Solution casting<br />

<br />

spinning<br />

Degradable BCP for mesoporous materials!<br />

Spin-coating for oriented microdomains!<br />

b)<br />

Spin coating

Tapping-mode SPM height images for spin-coated <strong>PS</strong>365-<strong>PLLA</strong>109 (f <strong>PLLA</strong> v =0.24)<br />

thin films on glass slides a) before hydrolysis; b) after hydrolysis.<br />

a) b)<br />

before hydrolysis after hydrolysis<br />

Well-oriented, perpendicular HC nanochannel arrays!

FESEM micrographs of hydrolyzed <strong>PS</strong>-<strong>PLLA</strong> samples by viewing<br />

parallel to the cylindrical axes<br />

Top-view<br />

Fracture of substrate<br />

Cross-section view<br />

Spin-coated <strong>PS</strong>365-<strong>PLLA</strong>109 (f <strong>PLLA</strong> v =0.26) thin films on<br />

glass slides after hydrolysis. (50nm thickness)

Thin-film Thickness Control<br />

The plot of film thickness versus spin rate for spin-coated <strong>PS</strong>365-<br />

<strong>PLLA</strong>109 (f v<br />

<strong>PLLA</strong> =0.24) thin films on glass slides. Open circle<br />

indicates the sample thickness measured by SPM whereas open<br />

triangle indicates the thickness measured by depth profile.<br />

Thickness [nm]<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Surface Prfiler<br />

0 1000 2000 3000 4000 5000 6000 7000 8000<br />

Spin Rate [rpm]<br />

SPM

Tunable dimensions of nanostructures<br />

Varieties of synthesized <strong>PS</strong>-<strong>PLLA</strong> block copolymers having HC microstructures.<br />

Entry<br />

<strong>PS</strong>83-<strong>PLLA</strong>41<br />

<strong>PS</strong>198-<strong>PLLA</strong>71<br />

<strong>PS</strong>280-<strong>PLLA</strong>122<br />

<strong>PS</strong>365-<strong>PLLA</strong>109<br />

Mn, <strong>PS</strong><br />

[g/mol]<br />

[a]<br />

8900<br />

20700<br />

29400<br />

38200<br />

Mn, <strong>PLLA</strong><br />

[g/mol]<br />

[b]<br />

5900<br />

10200<br />

17500<br />

15700<br />

PDI<br />

1.15<br />

1.17<br />

1.21<br />

1.21<br />

0.66<br />

0.73<br />

0.69<br />

0.76<br />

[c]<br />

12.7<br />

25.8<br />

31.4<br />

34.1<br />

d-spacing [nm]<br />

[d]<br />

16.8<br />

28.4<br />

37.2<br />

39.7<br />

[e]<br />

20.8<br />

32.9<br />

35.5<br />

44.2<br />

[c]<br />

7.2<br />

10.7<br />

13.3<br />

17.0<br />

Diameter [nm]<br />

[a] measured from GPC analysis. [b] obtained from integration of 1 H NMR measurement. [c] obtained from<br />

calculation of TEM micrographs. [d] determined from first scattering peak of SAXS. [e] obtained from surface<br />

analysis of SPM.<br />

f <strong>PS</strong> v<br />

[d]<br />

12.0<br />

19.8<br />

25.6<br />

26.4<br />

[e]<br />

9.1<br />

19.7<br />

23.0<br />

20.9

Topographic <strong>PS</strong> Nanopattern<br />

Schematic illustration of <strong>PS</strong>-<strong>PLLA</strong> and <strong>PS</strong>-PLA nanopattern<br />

prepared by spin coating.<br />

Continuity and Uniformity of Thin Films<br />

Silicon wafer; Silicon oxide; glass; carbon; ITO glass;<br />

Light emitted diode; Aluminum ----<br />

Coated on various substrates

Spin-coated <strong>PS</strong>-<strong>PLLA</strong> thin films<br />

Perpendicular morphology<br />

SPM phase image TEM image<br />

100 nm<br />

40

Proposed Mechanism<br />

Solvent evaporation<br />

d<br />

funnel effect<br />

Step 1: well-ordered microphase separation<br />

Step 2: solvent permeate through specific microdomain<br />

fs<br />

41

Definition of Solvent<br />

Solvent Molar volume χ <strong>PS</strong>-solvent <strong>PLLA</strong>-solvent δ solvent<br />

(MPa) 0.5<br />

Vapor Pressure<br />

(mmHg)<br />

Chlorobenzene 102.1 0.36 0.62 19.6 12<br />

benzene 89.4 0.34 0.81 18.6 70<br />

THF 81.7 0.35 0.6 19.4 176<br />

1,1,2-trichloroethane 100.4 0.36 < 0.5 19.6 17.1<br />

1,2-dichloroethane 79.2 0.42 0.44 20.4 61<br />

chloroform 80.7 0.34 < 0.5 19 159.6<br />

χ = χ H + χ S = V i (δ i –δ j ) 2 /RT + 0.34<br />

χ <strong>PS</strong>-solvent < 0.5 and χ <strong>PLLA</strong>-solvent >0.5 <strong>PS</strong> selective solvent<br />

χ <strong>PS</strong>-solvent < 0.5 and χ <strong>PLLA</strong>-solvent

<strong>PS</strong>-<strong>PLLA</strong> with Cylinder Morphology<br />

Table 1. Varieties of synthesized <strong>PS</strong>-<strong>PLLA</strong> block copolymers having HC microstructures.<br />

Entry<br />

Mn, <strong>PS</strong><br />

[g/mol]<br />

[a]<br />

Mn, <strong>PLLA</strong><br />

[g/mol]<br />

[b]<br />

PDI f <strong>PS</strong> v<br />

d-spacing [nm] Diameter[nm]<br />

[c] [d] [e] [c] [d] [e]<br />

<strong>PS</strong>83-<strong>PLLA</strong>41 8900 5900 1.15 0.65 12.7 16.8 20.8 7.2 12.2 10.1<br />

<strong>PS</strong>198-<strong>PLLA</strong>71 20700 10200 1.17 0.71 25.8 28.4 32.9 13.8 18.9 19.7<br />

<strong>PS</strong>280-<strong>PLLA</strong>97 29400 14000 1.21 0.72 31.4 37.2 35.5 16.7 23.5 20.0<br />

Control<br />

Molecular weight<br />

Control<br />

Size<br />

<strong>PS</strong>365-<strong>PLLA</strong>109 38200 15700 1.21 0.75 34.1 39.7 44.2 17.0 24.6<br />

.<br />

20.9<br />

[a] measured from GPC analysis.<br />

[c] obtained from calculation of TEM micrographs. [e] obtained from surface analysis of SPM.<br />

[b] obtained from integration of 1H NMR measurement. [d] determined from first scattering peak of SAXS.<br />

43

Evaporation Rate Effect<br />

Selective solvent<br />

131.5 mmHg 70 mmHg 12 mmHg<br />

Solvent Evaporation<br />

Vapor Pressure<br />

Evaporation Rate<br />

Time scale of microphase separation<br />

44

Selectivity Effect<br />

Neutral solvent<br />

160 mmHg 61mmHg 17.1 mmHg<br />

Solvent Evaporation<br />

Neutral solvent<br />

Segregation strength ~ χN<br />

45

Solution Casting<br />

Neutral solvent<br />

Crystalline <strong>PS</strong>-<strong>PLLA</strong> Amorphous <strong>PS</strong>-PLA<br />

46

Solution Casting<br />

Selective solvent<br />

Crystalline <strong>PS</strong>-<strong>PLLA</strong> Amorphous <strong>PS</strong>-PLA<br />

47

Molecular Weight Effect<br />

Selective Solvent with Low Evaporation Rate<br />

S83L41<br />

S198L71<br />

S280L97 S365L109<br />

Solvent evaporation<br />

Molecular weight<br />

Segregation strength ~ χN<br />

48

Bottom Morphology<br />

Before hydrolysis<br />

<strong>PS</strong> <strong>PLLA</strong><br />

Hydrophilic substrate<br />

After hydrolysis<br />

Interfacial energy of <strong>PS</strong>-hydrophilic substrate > Interfacial energy of <strong>PLLA</strong>-hydrophilic substrate<br />

49

Tg Effect<br />

Side view image of FESEM<br />

100 nm<br />

Phase image<br />

Spin-coated <strong>PS</strong>-<strong>PLLA</strong> thin films at the temperature above T g<strong>PLLA</strong><br />

but below T g<strong>PLLA</strong> (ca. 50 o C)<br />

50

<strong>PS</strong> <strong>PLLA</strong><br />

Hydrophilic substrate<br />

Spin coating at room temperature<br />

D <strong>PS</strong> (glass state) = D <strong>PLLA</strong> (glass state)<br />

S <strong>PS</strong>-<strong>PS</strong> selective solvnet > S <strong>PLLA</strong>-<strong>PS</strong>-selective solvent<br />

Permeation<br />

Diffusivity & Solubility<br />

Kinetic control & Dynamic control<br />

<strong>PS</strong> <strong>PLLA</strong><br />

Hydrophilic substrate<br />

Spin coating at 50 O C<br />

D <strong>PS</strong> (glass state) S <strong>PLLA</strong>-<strong>PS</strong>-selective solvent<br />

Permeation (P=DXS)<br />

Diffusivity (D) ~ T g<br />

Solubility (S)<br />

51

Substrate Effect<br />

Glass slide Carbon film<br />

ITO Silicon wafer<br />

52

Thickness Effect<br />

160 nm 80 nm 50 nm<br />

53

Proposed Mechanism<br />

Segregation strength and time scale Permeation (P=DXS)<br />

Selectivity (selective and neutral solvent) Diffusivity (Tg effect)<br />

Evaporation rate Solubility<br />

Molecular weight<br />

Solvent evaporation<br />

Step 1: well-ordered microphase separation<br />

Step 2: solvent permeate through specific microdomain<br />

d<br />

fs<br />

@

Solvent-induced Orientation<br />

SPM phase images<br />

Spin-coated thin film Solvent-annealed thin film<br />

<strong>PS</strong>-PEO with cylindrical microdomain<br />

Russell, T. P. et al. Adv. Mater. 2004, 16, 226.<br />

39

Nanopatterning for Lamellar Nanostructures<br />

Composition profile<br />

Chemical nanopattern<br />

Height profile<br />

Topographic nanopattern

What is Epitaxy-induced Orientation?<br />

Crystallizable solvent<br />

T max =150 o C<br />

80 o C<br />

T m, BA ≒ 123 o C<br />

Cooling<br />

Benzoic acid (BA)<br />

PLM image<br />

b BA

Large-Scale Orientation for <strong>PS</strong>-<strong>PLLA</strong> Lamellae<br />

Spin-coated lamellar thin film<br />

O<br />

C<br />

Induced by<br />

Crystallizable solvent<br />

O [ CH2 C H ] n<br />

O<br />

Oriented lamellar thin film<br />

H C<br />

3<br />

H C<br />

3<br />

CH 3<br />

CH 3<br />

Hydrolysis of <strong>PLLA</strong><br />

O<br />

Trench-like<br />

topographic nanopattern<br />

N [ C C ] m<br />

Semicrystalline copolymer: <strong>PS</strong>-<strong>PLLA</strong><br />

O<br />

H<br />

CH<br />

3<br />

<strong>PS</strong> <strong>PLLA</strong><br />

O H<br />

Amorphous and non-degradable Crystalline and degradable

Strongly Segregated <strong>PS</strong>-<strong>PLLA</strong><br />

Quench from melt<br />

S14-L15<br />

Lamellar morphology<br />

250nm<br />

Strongly Segregated <strong>PS</strong>-<strong>PLLA</strong><br />

RuO 4 staining (dark: <strong>PS</strong> and bright: <strong>PLLA</strong>)

Directional eutectic solidification<br />

Strongly Segregated <strong>PS</strong>-<strong>PLLA</strong><br />

500 nm<br />

Homogeneous mixture of substrate and polymer<br />

Quenching<br />

Directional eutectic solidification<br />

for strongly segregated <strong>PS</strong>-<strong>PLLA</strong><br />

Glass slide<br />

<strong>PS</strong><br />

<strong>PLLA</strong> Eutectic liquid<br />

Crystalline substrate<br />

Glass slide

Crystallization-Induced Orientation<br />

Strongly Segregated <strong>PS</strong>-<strong>PLLA</strong><br />

200 nm<br />

Homogeneous mixture of substrate and polymer<br />

Crystalline <strong>PLLA</strong><br />

Directional eutectic solidification<br />

for strongly segregated <strong>PS</strong>-<strong>PLLA</strong><br />

Non-lattice matching substrate (HMB)<br />

<strong>PS</strong><br />

Glass slide<br />

<strong>PS</strong><br />

<strong>PLLA</strong> Eutectic liquid<br />

Crystalline substrate<br />

Glass slide<br />

Isothermal<br />

crystallization<br />

Crystalline substrate

Lattice Matching Effect<br />

Strongly Segregated <strong>PS</strong>-<strong>PLLA</strong><br />

100 nm<br />

500 m<br />

Homogeneous mixture of substrate and polymer<br />

Crystalline <strong>PLLA</strong><br />

Directional eutectic solidification<br />

for strongly segregated <strong>PS</strong>-<strong>PLLA</strong><br />

<strong>PS</strong><br />

Glass slide<br />

<strong>PS</strong><br />

<strong>PLLA</strong> Eutectic liquid<br />

Crystalline substrate<br />

Glass slide<br />

Isothermal<br />

crystallization<br />

Crystalline substrate<br />

Lattice matching substrate (BA)<br />

Lattice matching improve nanostructure orientation !!

Lattice Matching<br />

<strong>PLLA</strong> -PCL<br />

0.514 nm<br />

1.07 nm<br />

Crystalline <strong>PLLA</strong> lamellae<br />

b<br />

a<br />

<strong>PLLA</strong><br />

a<br />

BA<br />

2b<br />

Amorphous <strong>PLLA</strong> and PCL domain<br />

axis mismatch<br />

b <strong>PLLA</strong> - a BA<br />

a BA<br />

a <strong>PLLA</strong> - 2b BA<br />

2b BA<br />

= 7%<br />

= 4%<br />

Ho, R.M. et al., Macromolecules 2003, 36, 9085.<br />

2D Lattice Matching

<strong>PS</strong>128LLA106 diblock copolymer: Lamellar morphology<br />

Epitaxy-induced Morphology<br />

Phase-separated Morphology<br />

500nm<br />

Area > 150μm 2 !<br />

<strong>PLLA</strong>(200)<br />

<strong>PLLA</strong>(110)<br />

500nm

Mechanisms<br />

1.Homogeneous mixture<br />

of solvent and polymer<br />

<strong>PS</strong> <strong>PLLA</strong><br />

Polymer-crystallizable solvent solution<br />

Crystalline substrate<br />

Glass-slide<br />

2.Directional crystallization<br />

of crystallizable solvent<br />

T m, solvent<br />

1<br />

2<br />

L+<br />

5<br />

6<br />

Liquid<br />

+<br />

L+<br />

0 0.5 1<br />

Weight fraction of block copolymer<br />

3.Directional eutectic solidification<br />

for strongly segregated <strong>PS</strong>-<strong>PLLA</strong><br />

T m, <strong>PLLA</strong> block<br />

T e<br />

T C, <strong>PLLA</strong> block<br />

T ODT<br />

: Crystalline substrate<br />

: <strong>PS</strong>-<strong>PLLA</strong><br />

4.Isothermal crystallization<br />

Ho, R.-M. et al. Macromolecules 2006, 39, 7071.

Nanopatterning<br />

Nanopattern: pattern with nanoscale features (1~100 nm)<br />

Height profile<br />

Topographic nanopattern<br />

Composition profile<br />

Substrate<br />

Chemical nanopattern

Methods for Nanopatterning<br />

Photolithography?<br />

Excimer Laser Micro-processing?<br />

Soft Lithography?<br />

Scanning Probe Lithography<br />

Electronlithography<br />

Self-assembly of Living Cells, Surfactant,<br />

Dendrimer and Polymer<br />

Bottom-up methods<br />

@Top-down methods<br />

External forces!

Electronlithography<br />

Write with electron beam<br />

Martin, J.I.; Velez, M.; Morales, R. J. Magn. Mater. 2002, 249, 156.

Soft Lithography<br />

Whitesides, G. M. et. al.<br />

J. Mater. Chem. 1997, 7, 1069<br />

Stupp, S. I. et. al.<br />

Nano Lett. 2007, 7, 1165

Nanoimprint Lithography<br />

PMMA film<br />

PMMA film<br />

Au dots<br />

Au lines<br />

Chou, S. Y. et. al. Science 1996, 272, 85

Scanning Probe Lithography<br />

Atomic force microscope tip as a “pen”<br />

A solid-state substrate as “paper”<br />

Molecules with a chemical affinity for<br />

the solid-state substrate as “ink”<br />

Transport of the molecules from the<br />

AFM tip to the solid substrate<br />

Mirkin, C. A. et. al. Science, 1999, 283, 661

Why Degradable Block Copolymers ?<br />

Polyesters: degradable<br />

characteristics for<br />

mesoporous materials<br />

Substrate<br />

Bio-degradation<br />

Chemical degradation<br />

Zalusky, A. S.; Olayo-Valles, R.; Taylor, C.; Hillmyer, M. A.<br />

J. Am. Chem. Soc. 2001, 123, 1519.<br />

Degradable blocks<br />

Non-degradable blocks<br />

Height profile<br />

Substrate<br />

Topographic nanopattern<br />

Nanopatterned template

Advantages and Disadvantages<br />

Electronlithography<br />

PMMA<br />

van Blaaderen, A. et al. Nature 1997, 385, 323.<br />

Require precise manufacturing<br />

(expensive!)<br />

Topographic pattern only<br />

Limitation in pattern area<br />

Creative features<br />

Block copolymer<br />

<strong>PS</strong>-<strong>PLLA</strong><br />

Ho, R.-M. et al. US24265548A1<br />

Large-scale orientation<br />

Easy to prepare (cheap!)<br />

Quick!<br />

Available for topographic and<br />

chemical nanopatterns<br />

Flexibility

Degradation of Block Copolymer<br />

Dry Pyrolysis<br />

<strong>PS</strong>-PB <strong>PS</strong>-PMMA <strong>PS</strong>-PDMS<br />

O3 ; RIE<br />

UV O3 ; RIE<br />

Russell T. P. et al. Adv. Mater.<br />

2000, 12, 787.<br />

Park M, Harrison C, Chaikin P. M., Register R. A.,<br />

Adamson D. H. Science 1997, 276, 1401.<br />

Ross, C.A. et al. Nano. Lett.<br />

2007, 7, 2046.

Nanopatterning from Degradable BCPs<br />

(a)<br />

staining with OsO4 (b) (c)<br />

Spin-coated film<br />

<strong>PS</strong>-PB m n<br />

O 3<br />

Spin-coated film<br />

with annealing<br />

unstained<br />

Spin-coated film with<br />

annealing<br />

exposure to ozone<br />

@<br />

Register, R. A. et. al. Science, 1997, 276, 1401<br />

Register, R. A. et. al. Appl. Phys. Lett. 2000, 12, 787

Nanopatterning from Degradable BCPs<br />

<strong>PS</strong>-PMMA<br />

UV<br />

O O<br />

Height image Phase image<br />

m<br />

n<br />

Top-view FESEM<br />

Cross-section-view FESEM<br />

Russell, T. P. et. al. Adv. Mater. 2000, 12, 787<br />

@

Nanopatterning from Degradable BCPs<br />

Methanol 40 V<br />

NaOH+H2O (0.5M) 60 V<br />

<strong>PS</strong>-PLA bulk Nanoporous bulk<br />

Degradation solution<br />

Hillmyer, M. A. et. al. J. Am. Chem. Soc. 2001, 123, 1519<br />

@

<strong>PS</strong>-<strong>PLLA</strong>, Degradable Diblock Copolymers<br />

O<br />

C<br />

<strong>PS</strong><br />

O [ CH2 C H ] n<br />

O<br />

H C<br />

3<br />

H C<br />

3<br />

Non-degradable block<br />

CH 3<br />

CH 3<br />

O<br />

<strong>PLLA</strong><br />

chiral center<br />

N [ C C ] m<br />

O<br />

*<br />

H<br />

CH<br />

3<br />

O H<br />

Degradable block

Synthetic routes of <strong>PS</strong>-<strong>PLLA</strong> block copolymers<br />

O<br />

Ph O<br />

Ph<br />

O N<br />

m<br />

<strong>PS</strong>-TEMPO-OH<br />

Living free radical polymerization<br />

Living ring-opening polymerization<br />

OH<br />

Toluene<br />

O O<br />

Li TEMPO-<strong>PS</strong><br />

O<br />

Li<br />

Li<br />

Li<br />

Li<br />

O<br />

Li TEMPO-<strong>PS</strong><br />

O O<br />

Lithium Alkoxide Macroinitiator<br />

OEt 2<br />

O C<br />

Li<br />

O<br />

Li<br />

Li<br />

Li<br />

Li<br />

C<br />

Li<br />

O O<br />

OO<br />

<strong>PS</strong> H OO<br />

O<br />

3<br />

C<br />

O N O<br />

O<br />

H<br />

O N O<br />

O<br />

H<br />

Ph O<br />

O<br />

P h O<br />

O<br />

C O [ C H C ]<br />

2<br />

H<br />

n<br />

O<br />

Ph<br />

O<br />

P h m<br />

O<br />

*<br />

m n n<br />

Non-biodegradable H Biodegradable<br />

<strong>PS</strong>-<strong>PLLA</strong>3<br />

C CH 3<br />

P S - P L L A<br />

CH 3<br />

O<br />

N O [ C C H O ]<br />

m<br />

H<br />

CH 3<br />

+<br />

Lin, C.-C. et al. J. Am. Chem. Soc. 2001, 123, 7973-7977.<br />

n L-LA/ CH 2Cl 2, 0 o C<br />

<strong>PLLA</strong><br />

Poly(styrene)-block-Poly(L-lactide) (<strong>PS</strong>-<strong>PLLA</strong>)<br />

O -<br />

O -<br />

t-Bu<br />

=<br />

t-Bu<br />

t-Bu<br />

O- O- t-Bu

Log(I)<br />

Various nanostructures of <strong>PS</strong>-<strong>PLLA</strong> block copolymers<br />

<strong>PS</strong>198-<strong>PLLA</strong>28 (f <strong>PLLA</strong> v =0.14)<br />

*<br />

q<br />

*<br />

2q<br />

*<br />

3q<br />

*<br />

4q<br />

*<br />

5q<br />

*<br />

6q<br />

*<br />

7q<br />

BCC<br />

*<br />

9q<br />

0.3 0.4 0.5 0.6 0.7 0.8<br />

q(nm -1 )<br />

Similar to <strong>PS</strong>-PLA!<br />

Log(I)<br />

<strong>PS</strong>280-<strong>PLLA</strong>97 (f <strong>PLLA</strong> v =0.29)<br />

*<br />

q<br />

*<br />

3q<br />

*<br />

4q<br />

*<br />

7q *<br />

9q<br />

HC<br />

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8<br />

q(nm -1 )<br />

Log(I)<br />

<strong>PS</strong>125-<strong>PLLA</strong>167 (f <strong>PLLA</strong> v =0.57)<br />

*<br />

q<br />

*<br />

2q<br />

*<br />

3q<br />

*<br />

4q<br />

Lamellae<br />

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8<br />

q(nm -1 )<br />

Ho, R.-M. et al. J. Am. Chem. Soc. 2004, 126, 2704.<br />

100nm<br />

Hillmyer, M. A. et al. J. Am. Chem. Soc. 2002, 124, 12761.

Nanotemplate (i.e., Nanoreactor)<br />

A convenient way to generate organic or inorganic nanostructure!<br />

Substrate<br />

Substrate<br />

(1) Spin-coating<br />

Substrate<br />

(2) Self-assembly<br />

Self-ordering<br />

Substrate<br />

Substrate<br />

Substrate<br />

(3) Hydrolysis<br />

(4) Sol-gel reaction; Porefilling;<br />

Electroplating;<br />

CVD etc.<br />

(5) Remove template<br />

regularly sized and spaced features

Sol-gel Process for NanoTemplates<br />

One example: Nanoreactor for nanoarrays<br />

High-efficiency photocatalysis!<br />

TiO 2 nanoarrays<br />

FESEM Images<br />

Particle array Diameter:20~30nm(sol particle size

Pore-filling for Nanotemplates<br />

Capillary force driven from the<br />

tunable wetting property of<br />

solution for the templates<br />

H 2S vapor<br />

tubular-like<br />

cylinder-like<br />

Ho, R.-M. et al. Macromolecules, 2007, 40, 2621.

air-block releasing<br />

directed capillary force (method 1)<br />

directed capillary force (method 2)

TEM : Air-block releasing<br />

Nanoporous template<br />

Vacuum<br />

Injection<br />

Cd(Ac) 2/methanol<br />

Pump<br />

Vacuum<br />

R<strong>edu</strong>ction by H 2S (g)<br />

inefficient filling<br />

CdS nanocrystals

TEM : directed capillary force (method 1)<br />

Nanoporous template<br />

from hydrolysis by<br />

<strong>PS</strong>-<strong>PLLA</strong> thin film<br />

(b)<br />

H 2O solution<br />

Water<br />

lack of wetting capability for<br />

driving of capillary force<br />

grid<br />

Small area !!<br />

grid<br />

Cd(Ac) 2/ X solution<br />

Methanol solution<br />

R<strong>edu</strong>ction by H 2S (g)<br />

partial filling of<br />

going-through solution

TEM : directed capillary force (method 2)<br />

Nanoporous template<br />

Large area !!<br />

Cd(Ac) 2/methanol/water<br />

Cd(Ac) 2/methanol/water<br />

R<strong>edu</strong>ction by H 2S (g)

PL and UV spectra<br />

Exciting length is at 450 nm<br />

a greater density of<br />

CdS nanocrystals<br />

residing in the<br />

template!<br />

No QDE: CdS<br />

nanoparticles > 6<br />

nm).

Confocal Microscopy Observation<br />

CdS solid state<br />

exciting at 454nm and detected from 480nm~600nm<br />

200 μm 200 μm 200 μm<br />

air-block releasing<br />

directed capillary force<br />

The emission intensity of the CdS nanoarray can be<br />

modulated by pore-filling process.

Electroplating of Metallic Materials<br />

Nanoarrays of Catalytic Materials<br />

Ni nanoarrays embedded<br />

in the template of <strong>PS</strong><br />

matrix<br />

Eletroplating for the growth of Ni<br />

The exploitation of carbon<br />

nanotubes (CNTs) for display and<br />

lighting purposes require<br />

controlled size, special spacing,<br />

and layout of patterns.<br />

Ni nanoarrays<br />

thermal CVD at<br />

500 o C for CNT<br />

growth<br />

CNT nanoarrarys<br />

Ho, R.-M. et al. Adv. Mater.,<br />

2007, 19, 3584-3588.

Double-length-Scale Patterns<br />

(a)<br />

Conductive Micropatterning<br />

Conductive<br />

Ho, R.-M. et al. Adv. Mater.,<br />

2007, 19, 3584-3588.<br />

P02940028US; P02940028TW<br />

(composite micro- and nano-patterned)<br />

Spin-Coating<br />

<strong>PS</strong>-<strong>PLLA</strong> sol.<br />

Lithography<br />

Growing<br />

CNT<br />

Nanopatterning<br />

(b)<br />

Electroplating Template removal<br />

(c)<br />

Electroplating Ni<br />

Block Copolymer<br />

Templating<br />

Electroplating

Screening Effect<br />

High site density (>109 /cm2 )<br />

leading to small electrical<br />

enhancement at the tips. A site<br />

density of about 107 /cm2 (according to electrostatic<br />

calculation) has been<br />

calculated to be the right<br />

number for optimal electron<br />

emission properties in the<br />

sense of both emission site<br />

and current density.<br />

Appl. Phys. Lett., 76, 2071 (2000); Chem. Mater.,<br />

17, 237 (2005); J. Mater. Res., 16, 3246 (2001);<br />

Thin Solid Film, 405, 243 (2002).<br />

Patterns with both in micro-scale and nano-scale for the CNT<br />

arrays have been expected to reach high-field-emission<br />

capability and uniformity.

FESEM images of CNTs grown from <strong>PS</strong>/Ni composite films<br />

Patterned<br />

cross-section<br />

low magnification high magnification<br />

Non-patterned<br />

FESEM image of CNTs grown from Ni layer

Two-electrode field emission device<br />

Double-length-scale<br />

High current density with<br />

low threshold voltage and<br />

high field emission<br />

efficiency for patterned<br />

CNT arrays!<br />

Single-length-scale<br />

Ho, R.-M. et al. Adv. Mater.,<br />

2007, 19, 3584-3588.

Lighting<br />

DTC<br />

Phosphor (CRT)<br />

Ni on DC-206<br />

Patterning ITO<br />

substrate<br />

<strong>tw</strong>o-electrode field emission device<br />

Spacer 150μm<br />

Spacer<br />

FP-R-054-taping<br />

1000v<br />

二極結構

Drug-Eluting Stent for Atherosclerosis<br />

■ Sirolimus: immunosupressive agent with anti-<br />

inflammation and antiproliferation characteristics<br />

■ Metallic stent: prevent vascular recoil<br />

■ Local delivery for the sustained release of drug<br />

Stent implantation during percutaneous<br />

transluminal coronary angioplasty (PTCA)<br />

Mixture of drug and<br />

polymer coated<br />

on the stent for<br />

drug-eluting control<br />

SIBS

Pore-filling for Sirolimus<br />

Capillary force driven from the<br />

tunable wetting property of<br />

aqueous solution for the templates<br />

Ho, R.-M. et al. Macromolecules<br />

2007, 40, 2621.<br />

nanoscale releasing<br />

Ho, R.-M. et al. ACS Nano, 2009, 3, 2260.<br />

Water → enhance the surface<br />

tension for the deposition of<br />

the <strong>PS</strong> template<br />

Ethanol → wet the <strong>PS</strong> template<br />

for the driven capillary force

Pore-filling of Sirolimus<br />

Before pore filling After pore filling<br />

TEM images of templated sirolimus nanoarrays

Accumulative Accumulative release release (%) (%)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Drug-releasing profile <strong>PS</strong> AAO Sirolimus<br />

24 hr<br />

42 hr<br />

0<br />

0 50 100 150 200 250<br />

Macrostructure<br />

with burst relesae!!<br />

85 hr<br />

extended drugeluting<br />

duration<br />

Time (hr)<br />

Ho, R.-M. et al. ACS Nano, 2009, 3, 2260.

Pore-filling of hydrophilic Conjugated Polymers<br />

Conjugated Polymer<br />

PEO-PPV<br />

Hydrolysis<br />

Solvent<br />

Annealing<br />

14<br />

O<br />

n<br />

HF<br />

code<br />

Mn<br />

(g/mol)<br />

PVE3 10309 1.12<br />

PVE7 14866 1.10<br />

PEO-PPV<br />

Ho, R.-M. et al. Adv. Funct. Mater. 2011, 21, 2729.<br />

PDI Solvent<br />

Acetic<br />

acid<br />

Acetic<br />

acid

Nanoscale Spatial Effect<br />

PY/CM thin film<br />

templated PY/CM<br />

nanoarrays<br />

PVE3<br />

PVE7<br />

with nanoporous template without nanoporous template

PL result : in-situ solvent annealing<br />

PVE3<br />

solvent annealing<br />

PVE7

Chain Alignment Mechanism<br />

Solventannealing<br />

process<br />

Ho, R.-M. et al. Adv. Funct. Mater. 2011, 21, 2729.