Components for Gasoline Direct Injection Systems - Denso

Components for Gasoline Direct Injection Systems - Denso

Components for Gasoline Direct Injection Systems - Denso

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Powertrain Control<br />

<strong>Components</strong> <strong>for</strong> <strong>Gasoline</strong> <strong>Direct</strong> <strong>Injection</strong> <strong>Systems</strong><br />

Afamiliar technology<br />

in diesel engines, direct<br />

injection is beginning to<br />

appear in gasoline powertrains.<br />

The technology requires<br />

extremely sophisticated<br />

engine management systems.<br />

DENSO supplies a large and<br />

growing line of products <strong>for</strong><br />

those systems.<br />

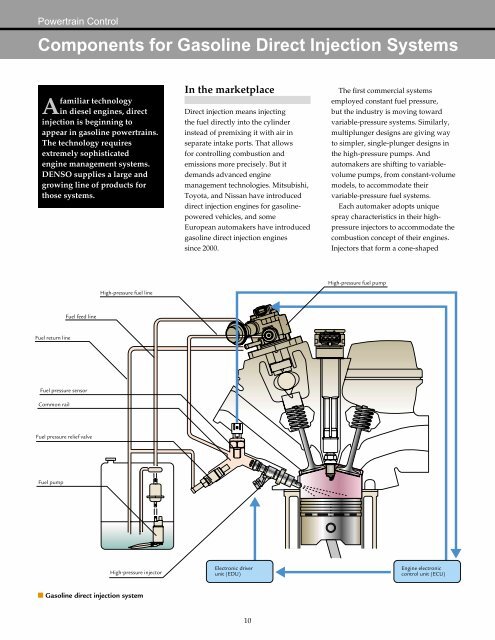

Fuel return line<br />

Fuel feed line<br />

Fuel pressure sensor<br />

Common rail<br />

Fuel pressure relief valve<br />

Fuel pump<br />

High-pressure fuel line<br />

High-pressure injector<br />

■ <strong>Gasoline</strong> direct injection system<br />

In the marketplace<br />

<strong>Direct</strong> injection means injecting<br />

the fuel directly into the cylinder<br />

instead of premixing it with air in<br />

separate intake ports. That allows<br />

<strong>for</strong> controlling combustion and<br />

emissions more precisely. But it<br />

demands advanced engine<br />

management technologies. Mitsubishi,<br />

Toyota, and Nissan have introduced<br />

direct injection engines <strong>for</strong> gasolinepowered<br />

vehicles, and some<br />

European automakers have introduced<br />

gasoline direct injection engines<br />

since 2000.<br />

Electronic driver<br />

unit (EDU)<br />

10<br />

The first commercial systems<br />

employed constant fuel pressure,<br />

but the industry is moving toward<br />

variable-pressure systems. Similarly,<br />

multiplunger designs are giving way<br />

to simpler, single-plunger designs in<br />

the high-pressure pumps. And<br />

automakers are shifting to variablevolume<br />

pumps, from constant-volume<br />

models, to accommodate their<br />

variable-pressure fuel systems.<br />

Each automaker adopts unique<br />

spray characteristics in their highpressure<br />

injectors to accommodate the<br />

combustion concept of their engines.<br />

Injectors that <strong>for</strong>m a cone-shaped<br />

High-pressure fuel pump<br />

Engine electronic<br />

control unit (ECU)

spray are most common, though<br />

Toyota has begun using a fan-shaped<br />

spray.<br />

We began limited production of<br />

components <strong>for</strong> gasoline direct<br />

injection engines in 1996 and have<br />

been mass-producing them since 1997.<br />

In 2000, we supplied components <strong>for</strong><br />

about 120,000 gasoline direct injection<br />

engines. We strengthened our product<br />

line during the year by introducing<br />

lighter-weight, higher-per<strong>for</strong>mance<br />

components.<br />

Injector<br />

High-pressure pump<br />

Nozzle<br />

configuration<br />

Spray<br />

■ High-pressure injection<br />

Slit nozzle<br />

Front view Side view<br />

In comparison with<br />

competitors<br />

The low drive torque in our highpressure<br />

pumps is significantly lower<br />

than in competing products. And the<br />

single-plunger design makes the<br />

pumps smaller and less expensive<br />

than multiplunger models.<br />

Our slit nozzles produce the first<br />

fan-shaped spray in the automobile<br />

industry. And our experience in<br />

mass-producing both slit and swirler<br />

nozzles equips us to satisfy a full<br />

range of automakers’ needs.<br />

Combining components in hybrid<br />

ICs has simplified and reduced the<br />

size of our electronic driver units <strong>for</strong><br />

injectors. Our units are about 40%<br />

lighter than competing products.<br />

Electronic driver unit<br />

11<br />

Swirler nozzle<br />

Fan-shaped Cone-shaped<br />

Issues and outlook<br />

<strong>Gasoline</strong> direct injection can help<br />

reduce the environmental impact of<br />

internal combustion power. By 2005,<br />

we expect more than 20% of the<br />

gasoline-powered new vehicles sold<br />

in Japan to have direct injection.<br />

Reducing cost is a pressing issue in<br />

making direct injection available in a<br />

broadened range of vehicle models.<br />

We will cultivate economies of scale<br />

by standardizing component designs<br />

and installation methods <strong>for</strong> different<br />

engines.<br />

Technical highlights<br />

Our common rail circuits allow <strong>for</strong><br />

controlling the fuel-delivery amount<br />

to generate the fuel pressure required<br />

by the engine. Electronic control<br />

adjusts the amount of fuel delivery<br />

with reference to a fuel pressure<br />

sensor in the common rail.<br />

We use a single-plunger design in<br />

our high-pressure injection pumps to<br />

provide high volumetric efficiency at<br />

low drive torque and at low cost. Our<br />

pumps have a built-in electromagnetic<br />

control valve, and the control function<br />

varies the fuel-delivery amount by<br />

adjusting the timing of the drive<br />

pulses sent to the valve. The drive<br />

torque and pulsation inside the highpressure<br />

lines are minimal, since our<br />

pumps supply only as much fuel as<br />

the engine actually requires.<br />

Our high-pressure injectors are<br />

available with different nozzles <strong>for</strong><br />

different spray configurations. We<br />

offer a swirler nozzle to produce a<br />

cone-shaped spray and a slit nozzle<br />

<strong>for</strong> a fan-shaped spray. Ultraprecise<br />

machining helps ensure a fine, highquality<br />

spray. We optimize injector<br />

per<strong>for</strong>mance with electronic driver<br />

units that incorporate original ICs.