X - 経済産業省

X - 経済産業省

X - 経済産業省

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>経済産業省</strong>委託<br />

平成 23 年度<br />

経済連携提携促進のための産業高度化推進事業<br />

日本-インドネシア経済連携協定に係る<br />

国連相互認定協定(1958年協定)への加入支援事業<br />

成果報告書<br />

平成24年3月<br />

財団法人 日本自動車輸送技術協会<br />

自動車基準認証国際化研究センター(JASIC)

まえがき<br />

2007年8月、日本とインドネシアの両国政府は、首脳間において日本-インドネシア<br />

経済連携協定に署名し、2008 年 7 月に発効に至ったが、この協定において、自動車分野<br />

では、インドネシア側における完成車及び同部品輸入関税の段階的な削減及び撤廃を合<br />

意し、一方、日本側からは、自由化されたインドネシア自動車及びその裾野産業である<br />

同部品産業の国際競争力を向上させ、両国の経済連携を強化することを目的として、イ<br />

ンドネシア政府機関の研究開発機能強化、1958 年協定への加入支援、専門家によるイン<br />

ドネシア自動車部品企業への巡回型派遣の 3 分野の産業協力事業実施を合意した。この<br />

産業協力事業は、当初3年計画として進められたが、インドネシア側より更なる継続支<br />

援要請を受け、本年度も継続されることになった。<br />

JASIC では、この内、1958 年協定への加入支援を行う事業を、平成 20 年度、21 年度、<br />

22 年度に引き続き、本年度についても、<strong>経済産業省</strong>から受託し、インドネシアの実情に<br />

即した協定への理解促進活動、協定加入に向けたロードマップの策定や組織形勢に向け<br />

たアドバイス、人材育成・交流等を通じて、インドネシアの 1958 年協定加入の動きを<br />

促進する協力事業を行った。<br />

2<br />

平成24年3月<br />

財団法人 日 本 自 動 車 輸 送 技 術 協 会<br />

自動車基準認証国際化研究センター<br />

(JASIC)

目 次<br />

(概 要)-------------------------------------------------------------- 4<br />

(本 論)------------------------------------------------------------- 7<br />

Ⅰ.事業目的・概要 ----------------------------------------------------- 8<br />

I- 1. 事業背景・目的 ----------------------------------------------- 9<br />

I- 2. 事業概要 ---------------------------------------------------- 10<br />

I- 3. 事業日程 ---------------------------------------------------- 10<br />

II.事業結果 ----------------------------------------------------------- 12<br />

II-1. 現地ワークショップ開催結果 ----------------------------------- 13<br />

II-2. 日本側委員会設置とインドネシア側委員会との会議結果 ----------- 69<br />

III.考 察 ---------------------------------------------------------- 88<br />

Ⅳ.資 料 ------------------------------------------------------------<br />

IV-1. 現地会合及びワークショップ資料<br />

(第 1 回~第 6 回)---------------------------------------<br />

Agenda<br />

現地会合 Participant List<br />

現地ワークショップ Participant List<br />

現地会合資料<br />

現地ワークショップ資料<br />

IV-2. Sub-WG2 国内委員会資料 (第 1 回~第 3 回)-----------------<br />

委員名簿<br />

議事次第<br />

議事録<br />

3<br />

頁<br />

91<br />

92<br />

1077

概 要<br />

JASIC では、平成 20 年度、21 年度、22 年度に引き続き、今年度についても、インド<br />

ネシアの 1958 年協定への加入支援を行う事業を<strong>経済産業省</strong>から受託し、インドネシア<br />

の実情に即した協定への理解促進活動、協定加入に向けた組織形勢に向けたアドバイス<br />

等を通じ、インドネシアが自動車基準・認証制度の整備を進めるための支援を行った。<br />

これは、インドネシアの自動車基準・認証制度整備のためにインドネシア側と日本側<br />

それぞれに設立された共同作業グループ(以下、Sub-WG2 又は単に SWG2 と記載)の活動<br />

成果である。<br />

1. Sub-WG2 活動目的<br />

政府関係技術専門家を派遣することによって、インドネシアが UNECE 規則(国連欧<br />

州経済委員会が定める自動車の構造・装置に関する国際的な統一基準)のような国際<br />

的規則の採用や、1958 年協定(以下 58 協定)のような国際的協定に加入するために<br />

必要な試験の適合性に関する技術規則の更新を支援する。<br />

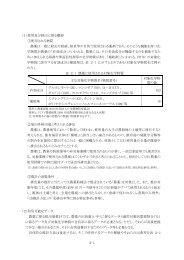

2. 日本-インドネシア経済連携協定支援事業のための Sub-WG2 の活動実績<br />

2008 年度 2009 年度 2010 年度 2011 年度<br />

準備段階 実行段階(1) 実行段階(2) 実行段階(3)<br />

インドネシアの 58 協<br />

定加入への課題、<br />

UNECE 規則採用のメリ<br />

ット、必要性等の理解<br />

を深めるセミナー実<br />

施。<br />

58 協定加入に向けた<br />

WP-29 のインドネシア<br />

国内検討チーム設立<br />

済み。<br />

主要試験機関<br />

(VTCC,B4T,CFC)の基<br />

礎調査を実施。自動車<br />

分野でのインドネシ<br />

ア側の要求や意見確<br />

認。<br />

58 協定加盟国間のの<br />

相互承認や国連 WP29<br />

及び GR 活動について<br />

のセミナー実施。<br />

官民協議の場として<br />

IASIG(Indonesia<br />

Automobile Standard<br />

Internationalizatio<br />

n Group)設立準備の<br />

ためのセミナーと新<br />

組織運営について意<br />

見交換。(2010 年 5<br />

月 IASIG 設立)<br />

現行 127 項目の UNECE<br />

規則からインドネシ<br />

アとして採用すべき<br />

75 項目を選定。認可当<br />

局及びテクニカルサ<br />

ービス候補試験機関<br />

を抽出。<br />

日本で主要な UNECE 規<br />

則 14 項目の技術要<br />

件・試験方法レクチャ<br />

ー実施。<br />

4<br />

欧州・日本でのハイレ<br />

ベル会合にて、WP29 活<br />

動、58 協定加入手続き<br />

についてより深い理<br />

解。<br />

IASIG から発展した新<br />

組織 IASIF(Indonesia<br />

Automobile Standard<br />

Internationalization<br />

Forum)の設立準備。<br />

(2011 年 6 月 IASIF 設<br />

立、IASIF ロードマッ<br />

プ公表)<br />

テクニカルサービス<br />

(試験機関)の能力向<br />

上のため、各試験機関<br />

(CFC,B2TKS,VTCC,B4T<br />

)に於ける9項目の<br />

UNECE 規則のレクチャ<br />

ー実施(認証手続き、<br />

生産の法規適合性チェ<br />

ックを含む)。<br />

ASEAN が推進する相<br />

互承認第一優先の 19<br />

項目の UNECE 規則中、<br />

インドネシアが優先<br />

する主要 5 項目<br />

(R13,13H,49,83,51)<br />

につき、現行国内法と<br />

比較し、採用に当たっ<br />

ての課題明確化。<br />

UNECE 規則ベースと<br />

した将来の型式認証<br />

制度設置についての<br />

アドバイス実施。<br />

インドネシア政府幹<br />

部への 58 協定加入、<br />

UNECE 規則採用に向<br />

けた IASIF 提案書作<br />

成を支援。<br />

インドネシア UNECE<br />

規則採用計画明確化<br />

のための IASIF ワー<br />

クシートを提案。<br />

IASIF 自身による検<br />

討開始。<br />

2011 年度の活動は、過去 3 年度の活動を通じて 2011 年 6 月設置に至った官民協<br />

力の協議体 IASIF の活動を支援し、58 協定加入への課題やメリット、必要性につ

いて、理解を深めるとともに、今年度末までに、インドネシアが 58 協定に加入し、<br />

UNECE 規則を順次導入していくための手順を公に宣言してもらうことを狙いとし<br />

た。<br />

3. 2011 年度 Sub-WG2 活動結果<br />

日本側事情により、当初計画日程の一部見直しをしたが、最終的には以下の日程に<br />

従って、活動を実施した。<br />

ここでは、まず(1)の現地ワークショップの結果を報告し、(4)の日本側に設置した<br />

検討委員会、(2)のインドネシア政府関係者との会議(SWG2)及び SWG2/SWG3 合同会<br />

議について報告する。<br />

3.1 現地ワークショップ開催結果<br />

(1) 第一回現地ワークショップ<br />

2011年9月14・15 日の両日、「インドネシアの車両型式認証制度改善のための<br />

UNECE 規則の選定及び採用計画作り」をテーマに、インドネシア運輸省傘下の車両<br />

認証試験センター(VTCC)会議室にて、一日目 28 名、二日目 23 名の参加者を得て<br />

開催した。<br />

(2) 第二回現地ワークショップ<br />

2011 年 10 月 5・6 日の両日、「現行インドネシア法規・規格に対する UNECE 規則<br />

採用による影響について(含む R13、R13H の精査)」をテーマに、インドネシア工<br />

業省会議室にて、一日目 24 名、二日目 21 名の参加者を得て開催した。<br />

5

(3) 第三回現地ワークショップ<br />

2011 年 11 月 2・3 日の両日、「改訂後採用すべき UNECE 規則(含む R49、R83 の<br />

精査)」をテーマに、インドネシア工業省会議室にて、一日目 21 名、二日目 22 名<br />

の参加者を得て開催した。<br />

(4) 第四回現地ワークショップ<br />

2011 年 12 月 14・15 日の両日、「UNECE 規則採用の国連通告手続きについて(含<br />

む R51 の精査)」をテーマに、インドネシア工業省会議室にて、一日目 16 名、二<br />

日目 20 名の参加者を得て開催した。<br />

(5) 第五回現地ワークショップ<br />

2012年1月25・26 日の両日、「2011 年度活動総括及び今後の活動について」を<br />

テーマに、インドネシア運輸省傘下の車両認証試験センター(VTCC)会議室にて、<br />

一日目 13 名、二日目 16 名の参加者を得て開催した。<br />

4. 今後の Sub-WG2 活動計画についての提案<br />

2012 年 1 月に開催された第 5 回 SWG2 ワークショップ及び 3 月に開催の第 6 回 SWG2<br />

会合にて、それまでの都合 4 回のワークショップ結果を総括し、インドネシアの 58<br />

協定加入のための準備日程及び UN 規則採用検討の方向及び今後の SWG2 活動計画を確<br />

認した。<br />

また、インドネシア側からは、今後の Sub-WG2 の活動について、日本からの支援継<br />

続について要望が出された。<br />

6

(本論)<br />

7

Ⅰ.事業目的・概要<br />

8

Ⅰ.事業目的・概要<br />

平成 22 年度経済連携提携促進のための産業高度化推進事業(日本-インドネシア経<br />

済連携協定に係る国連相互認定協定(1958 年協定)への加入支援事業)の実務概要は<br />

以下の通りである。<br />

I-1.事業背景・目的<br />

日本-インドネシア両国政府は、2007年8月20日に首脳間において日インドネシア経<br />

済連携協定(以下、「日尼EPA」という。)に署名。2008年7月1日に発効がなされ<br />

た。<br />

日尼EPAにおいて、自動車分野ではインドネシア側における完成車及び同部品輸<br />

入関税の段階的な削減及び撤廃を合意。一方、日本側からは、自由化されたインドネ<br />

シア自動車及び裾野産業である同部品産業の国際競争力を向上させ、両国の「WIN-WIN」<br />

の経済連携を強化することを目的として、3分野(①尼機関の研究開発(R&D)機<br />

能強化に向けた実現可能性調査(F/S、Feasibility Study)及び調査結果を踏まえ<br />

ての専門家派遣等による協力、②国連相互認定協定(1958年協定)(以下、「58協定」<br />

という。)への加入支援のための政府関係者の専門家派遣による協力、③専門家によ<br />

るインドネシア自動車部品企業への巡回型派遣事業の延長)の産業協力事業の実施を<br />

合意。当該産業協力事業の実施については、日本<strong>経済産業省</strong>及びインドネシア工業省<br />

間で合意された「Initiative for Manufacturing Industry Development Center」の<br />

主要部分を占めるものに位置付けられている。<br />

今回の委託事業は、上記3分野の産業協力事業のうち、②の 58 協定への加入支援と<br />

して、58 協定への理解促進活動、58 協定加盟に向けたロードマップの策定や組織形成<br />

に向けたアドバイス、人材育成・交流等を通じて、インドネシアの 58 協定加盟を促進<br />

することを目的としている。<br />

9

I-2.事業概要<br />

(1) 事業の内容及び実施方法<br />

本委託事業は、現地セミナーの開催やインドネシア政府関係者等の招聘を通じ、<br />

58協定への理解促進活動、58協定加入及び加入後の認証制度整備に向けたロード<br />

マップの策定や組織形成に向けたアドバイス、試験機関の人材育成、各種交流等<br />

を行う。<br />

具体的な事業内容は以下のとおり。<br />

① 58協定加入及び加入後の認証制度整備に向けたインドネシア側のロードマッ<br />

プ(方針や日程)に基づき、インドネシアの58協定加入後の認証制度整備の<br />

ためのワークショップを開催する(5回程度。1回当たり2日程度、現地政府関<br />

係者等も含め計35名程度の参加を想定。英尼通訳費、会議費等を計上するこ<br />

と)。専門家(3名程度)も同行し、インドネシアのUNECE規則をベース<br />

にした型式認証制度の構築に向けた具体的な作業に対する支援及びUNEC<br />

E規則の採用計画について意見交換を行う。派遣に関する渡航費、宿泊費等<br />

を計上すること。<br />

② インドネシアの58協定加入に向け、日本において検討委員会を設置して<br />

日本からの支援についてより具体的な検討を行う(3回程度検討委員会を開<br />

催することを想定)。委員会は、専門家や大学教授等により構成され、委<br />

員長1名及び委員6名程度を想定。<br />

③ インドネシア側との間に設置されているWG等を開催し、事業の進捗を適宜<br />

報告するなどインドネシア側と事業の継続や方向性について協議する。<br />

※WG等については5回程度(①のワークショップ併せて開催。1日程度。専門<br />

家3名程度も参加。)を想定。派遣に関する渡航費、宿泊費等を計上すること。<br />

④ 報告書の作成<br />

①~③の事項につき、報告書を作成する。<br />

I-3.事業日程<br />

事業実施期間は、委託契約締結日から平成 24 年3月30日までとする。具体的なスケ<br />

ジュールは、以下の通りである。<br />

10

Ⅱ.事業結果<br />

12

Ⅱ.事業結果<br />

Ⅱ-1.現地ワークショップ開催結果<br />

(1) 本年度事業開始前のインドネシアとの事前会合<br />

6 月 15 日ジャカルタで開催された第 3 回 MIDEC セミナーにて、過去 3 年実施して<br />

きた日本-インドネシア経済連携協定に係る自動車基準調和活動成果と本年度の活<br />

動計画概要につき報告した。また、事前に、6 月 13 日 SWG2 のインドネシア側主要<br />

メンバーと今後の活動計画詳細について打ち合わせた。<br />

(a) SWG1 及び SWG2 合同事前会合(6 月 13 日 14:00~17:00 インドネシア工業省会<br />

議室)<br />

〔出席者〕:<br />

日本側出席者:経産省松田係長、JICE 伊藤氏(SWG1 関係)、JARI 船崎主任研<br />

究員、鈴木研究員(SWG3 関係)、JASIC 土井<br />

インドネシア側:尼工業省(MOI)Sprijanto 課長、Rudiyono 課長補佐、M. Ihsan<br />

氏、Andreas A.S.氏、Agust Juvenly Purba 氏、Subriyanto<br />

氏、Yunita M. Lating 氏、Ari Gunawan 氏、BPPT Prawato 氏、<br />

尼自工会(GAIKINDO)Budi P. Susilo 氏、尼二輪車工業会(AISI)<br />

Haru Sutanto 氏、尼部工会(GIAMM)Hadi Surjadipradija 氏、<br />

JETRO ジャカルタ事務所 市川氏、Arif 氏<br />

通訳:Doni 氏<br />

〔SWG1 活動について〕:<br />

・ 経産省松田係長より、SWG1(カイゼンリーダーの養成)の本年度計画につ<br />

いて説明。6 月末に開始し、12 月完了予定。尼側企業 9 社から 9 名のカイ<br />

ゼンリーダー選定し、事前に準備会合を尼で開催の上、9 月に日本に招聘<br />

予定。今回は、カイゼンリーダーに加え、企業トップにも参加願う予定。<br />

この受け入れ業者として、これまでの AOTS(海外技術者研修協会)ではな<br />

く、JICE(日本国際協力センター)ともう一社が応募中。日本側専門家と<br />

しては、実績のある中嶋氏を考えているが、JETRO の選定次第。<br />

・ 尼側出席者より、日本での訪問企業プロフィールにつき、事前情報提供の<br />

要請があり、訪日の 1 週間前までに提供が約された。その他、日程詳細に<br />

つき、日尼双方の都合につき、確認あり。最終的には、日程表につき、尼<br />

側修正案につき、GAIKINDO が纏め、提示することになった。<br />

〔SWG2 活動について〕:<br />

・ 経産省松田係長より、SWG2(58 協定加入支援)は、インドネシアの 58 協<br />

定加入が目的であるが、尼側作成のロードマップによれば、本年内にも 58<br />

協定加入の宣言がされる見込みになっており、支援に携わって来た一人と<br />

して同慶の至り。但し、協定加入後、尼側が自主的に活動を継続していく<br />

ため、一定の期間日本側として支援するとの経産省方針が説明あり。<br />

・ JASIC 土井より、SWG2 の本年度計画につき説明。6 月 9 日発行の尼運輸省<br />

13

局長通達により設立された IASIF のロードマップに沿った支援を行う提案<br />

を行った。具体的には、ACCSQ-APWG が第一優先採用項目として推奨してい<br />

る UNECE 規則 19 項目の中から、本年度は4~5 項目を取り上げ、法規要件<br />

を精査・検討するための支援を実施したい。特に、IASIF ロードマップの<br />

中で、現行国内法との比較検討も実施し、場合によっては将来 UNECE 規則<br />

の改訂をインドネシアが提案出来るように、日本の経験についても本年度<br />

実施のワークショップの中で説明したい旨説明した。<br />

・ JASIC 案として、UNECE 規則精査項目については、R16(シートベルト)、R30<br />

(乗用車用タイヤ)、R43(安全ガラス)、R83(排出ガス)を提案したが、<br />

尼側は 6 月 15 日の MIDEC セミナー以降、関係者打ち合わせの上、6 月 16<br />

日までに JASIC に回答通知したいとして、この場での回答を保留した。(そ<br />

の後、尼側より、R13(商用車用ブレーキ)、R13H(乗用車用ブレーキ)、R49<br />

(ディーゼル排気)、R83(排出ガス)、R51(騒音)の 5 項目を希望すると<br />

の連絡あり、JASIC もこれを了承。)<br />

・ 都合5回のワークショップ日程について、意見交換の結果、第1回目のワ<br />

ークショップについては、8月 29 日~9 月 3 日尼政府は連休予定につき、<br />

JASIC 案(9 月 6 日~8 日)を一週間程度延期して欲しい旨要請あり。上記、<br />

精査項目回答を考慮の上、6 月末までに回答を約した。<br />

(b) 第3回 MIDEC ハイレベルセミナー(6月15日インドネシア工業省二階<br />

Rajawali 会議室)<br />

〔PLENARY SEMINAR〕(9:10~9:40 同省同会議室)<br />

1) インドネシア側挨拶その1(MOI Achdiat Atmawinata 特別補佐官)<br />

・MIDEC 事業は当初計画された 13 の分野の内、既に 12 の分野で活動を実施中<br />

で、インドネシアの産業競争力強化の一助になりつつある。<br />

・本日のセミナーでは8分野について 2010 年~11 年についての活動実績及び<br />

今後の予定について、日本側より説明頂き、インドネシア側からコメント<br />

する予定。<br />

2) 日本側挨拶その 1(在ジャカルタ日本大使館 前田公使)<br />

・今週、ユドヨノ尼大統領が訪日され、東日本大地震の被災地訪問予定と聞<br />

いている。インドネシアの多くの方々からお見舞いを多数受け、大変感謝<br />

している。<br />

・インドネシアは ASEAN の議長国としてリーダーシップを発揮。本年は日本<br />

との間の EPA にて9つの分野に付き産業協力が開始されることになった。<br />

また、本 MIDEC の協力事業では大きな成果を上げつつあり、本セミナーの<br />

開催により、両国の理解が更に深まることを期待。<br />

3) 日本側挨拶その2(経産省通商政策局参事官 山口琢磨氏)<br />

・東日本大地震及び津波被害に対するインドネシアからの沢山のお見舞い、<br />

支援ありがとうございます。この震災により日本の生産活動自体に大きな<br />

支障を来たし、インドネシアにもご迷惑をお掛けし、申し訳ない。日尼 EPA<br />

の一環として来日されている看護師さんが被災地でも活躍。経産省も勇気<br />

14

付けられている。今回の震災を通じ、日尼 EPA による絆の重要性を改めて<br />

痛感した。<br />

・JICA 専門家の MOI 駐在(1 名)に加え、MOC 駐在(2名)追加が実現し、日<br />

尼 EPA の心強い窓口になっている。<br />

・本日はお忙しい中、MIDEC セミナーへの参加に感謝。<br />

4)インドネシア挨拶その 2(MOI Riyanto 氏)<br />

・今回の MIDEC セミナーでは、2010 年~2011 年の活動実績及びこんごの予定<br />

につき報告願う。日尼 EPA の一環として行われている日本からの支援は非<br />

常に有効であり、ASEAN の 2015 年市場統合に備え、インドネシアの産業競<br />

争力強化に役立つものになると信じる。<br />

〔PARALEL SEMINAR - Seminar 1 金属加工、溶接、自動車、電子分野〕」(9:50~<br />

13:30 同省同会議室)<br />

金属加工、溶接、自動車、電子関係について、それぞれ活動報告あり。ここ<br />

では自動車関係のみ記載。<br />

1) R&D 体制強化支援活動について<br />

JARI 船崎氏より報告。2011 年度としては、大気質改善のため、日本での解<br />

析手法研修、専門家派遣による大気質戒厳や燃費についてのワークショップ<br />

開催を計画。代替燃料として、天然ガスを使用する自動車の安全性につきワ<br />

ークショップ開催予定。プラスチックやゴムについては材料評価技術につい<br />

て日尼間でクロスチェック予定。<br />

2) UN/ECE 1958 年協定加入支援活動について<br />

JASIC 土井より報告。2011 年度は、インドネシアに専門家を派遣し、都合<br />

5回程度のワークショップを開催する計画。ACCSQ-APWG が第一優先採用項目<br />

として推奨している UNECE 規則 19 項目の中から、本年度は4~5 項目を取り<br />

上げ、法規要件を精査・検討予定。また、インドネシアの UNECE 規則の採用<br />

項目検討や UNECE 規則をベースにした車両型式認証制度構築のための法整備<br />

について日本の経験を説明し、役立てたもらう予定。<br />

3) 「カイゼン」手法訓練による産業支援について<br />

経産省 松田係長より報告。<br />

【インドネシア側 GAIKINDO BudiP.S.氏コメント】<br />

・ 自動車関係の3分野の支援は、2015 年 ASEAN 市場統合に向けた非常に意味<br />

のある活動であると評価している。<br />

・ SWG3 の大気質改善については、インドネシア人自身が考えて行くためにな<br />

る基盤を与えるものと評価している。プラスチックとゴムについては、研究<br />

センター中心で産業側への波及はあまり明確でない。<br />

・ SWG2 について、WP29 活動、UNECE 規則採用の方向について説明してもらっ<br />

たが、1958 年協定加入、予算獲得を含め、IASIF の仕事が残っている。今後、<br />

型式認証、部品認証についてインドネシアの現行法規と如何につなげていく<br />

か提案願いたい。タイヤ、ガラスを含め、75 項目の UNECE 規則を選定した<br />

15

が、SWG2 として、改訂された UNECE 規則を政府、試験機関、産業がフォロ<br />

ーすることが大事。<br />

・ SWG1 のステップ 3 については、特にコメントなし。各社の代表が参加する<br />

TOT(Training of Trainers)活動に期待。上手くいかない場合のサポート<br />

についても考えて貰いたい。<br />

・ ロジェスティクスマスター制度の話があったが、その後どうなっているの<br />

か?<br />

(JETORO の市川氏より、ARI と KARI が制度発足を目指したが、カイゼンマ<br />

スターと同種と受け止めている。既に活動は終了しているとの回答あり)。<br />

【インドネシア側 MOI Rudiyono 課長補佐コメント】<br />

・プラスチックとゴムの産業との関わりについては、SWG1 と SWG3 に関係する<br />

が、自分もまだ理解できていないので、説明して欲しい。プラスチックや<br />

ゴム部品の試作品のテストを研究センターにお願いすることは、非常に良<br />

い方法と思うが、そのためのフィージビリティスタディー(FS)はこれか<br />

ら行う必要はないのではないか?<br />

(経産省の松田係長より、FS は既に昨年度終了済。今後どう進めるかは、<br />

JARI が詳しい資料を作っているので、別途説明したいと回答)<br />

(2)第1回現地ワークショップ結果<br />

2010年9月23・24日、インドネシアにて、「車輌型式認証のための法規および<br />

制度について」をテーマに、第一回現地ワークショップを開催した。<br />

(a) 第 1 回ワークショップ1日目<br />

「IASIF ロードマップ及びインドネシアの車輌型式認証制度改善について」<br />

をテーマに第1回ワークショップを開催した。<br />

〔日 時〕:2010 年 9 月 14 日(水) 9:00~16:30<br />

〔場 所〕:VTCC (尼名:BPLJSKB)会議室(ベガシ)<br />

〔出席者〕:<br />

16

日本側:JASIC 秋葉主査、吉沢委員、薩摩、土井、山田、通訳 Ms. Ziaini<br />

(6 名)<br />

インドネシア側:Mohammad Malawat, Irwan Arifianto (MOT/DGLT), Toto<br />

Noewitjaksono, Juliaman P., Hakim, Awaludin Yoda<br />

S.S. (MOT/VTCC), Budi Haryono. S.,Rudi C.N.(BTMP),<br />

Mehammed Nomesi (B4T), Fanani Hamzah ,Lintong<br />

S.H.(CFC), Juwono Andrianto, Hidayatol Ichsans,<br />

Tri Widobu, Abdur Rahim, Emjunan Sihite, Muawiyah<br />

I., Nur Haryono, Susanto K.P., Prasedyo, Anna W.,<br />

Eddy S., Tri Wiborn , Yeti I., (GAIKINDO), Heru<br />

Susanto, Rudi Prayitno, Alan Buchari , Girisa A.,<br />

(AISI)(28 名)<br />

1) 開会挨拶<br />

a) インドネシア側開会の挨拶(DGLT /VTCC 所長 Toto Noewitjaksono 氏)<br />

インドネシアの 58 協定加盟も近い。IASIF が設立されたので、これ<br />

までの活動を振り返りつつ、今後、UNECE 規則の採用計画、インドネシ<br />

アの VTA 制度の改善のため取り組んでいかねばならない。<br />

b) インドネシア業界を代表して(GAIKINDO 事務局長 Juwono Andrianto 氏)<br />

本日は業界からも多数参加頂き、感謝。本日も日本の専門家に来てい<br />

ただいているので、活発な議論に期待。<br />

c) JASIC を代表して(JASIC 秋葉主査)<br />

今回のワークショップでは、インドネシアの VTA 制度を改善するため<br />

に、日本から有益と考えられる情報をインプットしたい。尼側関係者の<br />

積極的な参加をお願いする。<br />

2) IASIF ロードマップ(VTCC Toto 所長)<br />

a) IASIF ロードマップ:IASIF の活動計画を、IASIF ロードマップの形で<br />

纏めた。IASIF は、本年 6 月の MOT/DGLT の局長通達により設立されたが、<br />

インドネシアの 58 協定加入、WP29 活動への参画、インドネシアが採用<br />

すべき UNECE 規則の選定、テクニカルサービスの能力向上等多くの課題<br />

を抱えている。ロードマップの実行に当たっては、更に詳細な活動計画<br />

が必要と考えている。<br />

b) IASIF 設立の DGLT 局長通達(6 月 9 日付):参加者にその内容を披露。<br />

・ 通達本文<br />

・ IASIF ロードマップ(3 ケ年計画)<br />

・ IASIF 組織<br />

<br />

・インドネシアは何時 WP29 に加盟し、58 協定に加入するのか?(JASIC)<br />

17

→オペレーションレベルでは、直ぐにも協定加入は可能ではないかと考<br />

えるが、国内でそれを socialize するために十分な時間が必要。<br />

(VTCC Toto 氏)<br />

・IASIF の各活動には何時までに何を行うという目標設定が必要。UNECE<br />

規則 19 項目の採用についても何時その規則を採用するのか明確にすべ<br />

きである。(JASIC)<br />

→インドネシアとしては、まず最初に安全ガラス、シートベルト、・・・、<br />

排出ガスの4項目を採用する予定。(DGLT/VTCC)<br />

・UNECE 規則 19 項目の採用で終了するのではなく、並行してインドネシア<br />

の将来の VTA 制度を考えると、順次採用項目を増やす必要がある。最終<br />

的には、コンポーネントに終わるのではなく、Whole Vehicle Type<br />

Approval に繋がるものにすべきである。(JASIC)<br />

・WP29 でインドネシアが採用した UNECE 規則が改定された場合、どのよう<br />

にインドネシア国内法をその改定に合わせ変更すれば良いのか?<br />

(GAIKINDO)<br />

→インドネシアの法体系に則って、国内法を切り換えていかねばならな<br />

い。(DGLT/VTCC)<br />

→EU(欧州連合)では、非常に賢い方法を取っている。基本的な法は変更<br />

せず、その下に Annex として技術要件が添付された法体系となってい<br />

る。(JASIC)<br />

・ 業界としては、各 UNECE 規則の採用の利益は一体何なのかを明確にする<br />

必要がある。(GAIKINDO)<br />

→そのために、IASIF が設立された。各 UNECE 規則採用に当たっては、<br />

官民共同で Analysis することが必要。(JASIC)<br />

・UNECE 規則採用により、ある部品がコストアップになるようなケースが<br />

起こる。インドネシアの自動車・部品メーカーの多くは日系メーカーな<br />

ので、JAMA、JAPIA からその必要性を日本の親会社に説明して貰えれば<br />

非常に助かる。(AISI)<br />

→コストアップだが、フルモデル・チェンジのタイミングに新法規を対<br />

応すれば、(法規内容にもよるが)コストを抑えることが可能。従っ<br />

て法規導入の際には適切なリードタイム設定が肝要。(JASIC)<br />

→ 日本でも、UNECE 規則採用に当たって、各メーカーのトップマネージ<br />

メントは、全く違う意見を持つことがある。その場合、粘り強く、UNECE<br />

規則採用のメリットを説明する必要がある。UNECE 規則を一種のビジ<br />

ネスツールと考えてもらう必要がある。(JASIC)<br />

3) 2011 年度 SWG2 活動について(JASIC 土井)<br />

a) 活動の狙いと方法<br />

b) 年間スケジュール<br />

c) 各 SWG2 会合及びワークショップの概要<br />

18

・インドネシアの状況をベースに現行の UNECE 規則改定ができるのか?<br />

(GAIKINDO)<br />

→58 協定加入していなくても、国連加盟国ならば、改定提案できる。<br />

勿論、その提案については、WP29 の中で他の加盟国と意見交換さ<br />

れる。但し、UNECE 規則を改定したい場合は、改定理由、参考デー<br />

タ等を添付して提出する必要がある。WP29 で 2/3 の加盟国の賛同<br />

があれば、改正される。(JASIC)<br />

・ インドネシアの自動車メーカーは、輸出のことは殆ど考えていない。<br />

UNECE 規則採用は、輸出する場合は役立つが、国内市場が未成熟で、<br />

これからという国では当面 UNECE 規則採用は急ぐ必要はないという<br />

のが、大半である。(GAIKINDO)<br />

→インドネシアが現状に満足するのであれば、UNECE 規則採用の必要<br />

はないが、既に同じ ASEAN 諸国の中には、タイやマレーシアのメー<br />

カーのように、欧州に輸出をしているところもあり、将来の ASEAN<br />

諸国間の競争を考えれば、UNECE 規則採用は避けて通れない道であ<br />

る。(JASIC)<br />

→ECE 規則採用は、事故削減・環境保全という政府 MOT/MOE にとって<br />

安全・環境面の視点もある。従って、政府・業界間の立場のバラン<br />

スを考えることも重要(JASIC)。<br />

4) インドネシアの部品・コンポーネント認証及び VTA 制度の現状<br />

a) 自動車部品のための SNI 認証(B4T の Mehammed Nomesi 氏)<br />

・SNI のための法規及び位置づけ<br />

・義務付け SNI<br />

・SNI 認証のプロセス及び流れ<br />

・車両コンポーネント認証(タイヤ、チューブ、ホィール、2 輪用ヘ<br />

ルメット、ガラス)<br />

b) インドネシアの自動車法規の調和(DGLT の Mohammad Malawat 氏)<br />

・道路交通・運送に関するインドネシアの法律(N0.22/2009)に基づく<br />

型式認証について;車両の技術要件、道路運行上の要件、車両検査<br />

(型式認証と定期車検)、VTCC による物理的な試験と構造設計検討、<br />

改造車の型式認可<br />

・IASIF 設置について;IASIF 設立についての DGLT 通達と IASIF の役<br />

割、メンバー構成、将来のテクニカルサービスとしての VTCC<br />

19

図 IASIF 設置とその役割(MOT/GDLT)<br />

・採用すべき UNECE 規則;ACCSQ-APWG 推奨の 19 項目、インドネシア<br />

の現状<br />

<br />

・11 項目の SNI 規格があり、これらはマンダトリーとの説明があったが、<br />

road worthiness とは大きな関わりはない。Road worthiness の観点<br />

から自動車基準が必要。(JASIC)<br />

→SNI 規格は、貿易上、マーケティング上の観点からタイヤやホィー<br />

ルの規格を義務付けているもの。(B4T)<br />

・ 現行の VTA では、これらの SNI 規格については、どのように扱ってい<br />

るのか?(JASIC)<br />

→例えば、車両の認証時には、ガラスの上に SNI 規格の合格証が貼付<br />

されているかはチェックしている。(VTCC)<br />

・ R43 は、既に ASEAN-MRA の対象に上げられている。今後、R43 により<br />

テストレポートが ASEAN 加盟国から持ち込まれたら、インドネシアは<br />

受け入れる準備はできているのか?(JASIC)<br />

→ SNI マークに変えて、E マークが必要になるかどうかは、インドネ<br />

シア政府の判断。インドネシアの VTA は、コンポーネントではなく、<br />

自動車の性能を中心に考えられている。(DGLT)<br />

→各部品に、E マークが必要かどうかはこれから考えねばならない。<br />

(VTCC)<br />

→誤解してもらいたくないので言っておきたい。B4T や CFC は、単な<br />

20

る試験機関ではなく、認可を与える認証機関である。(CFC)<br />

・ 輸出専用の自動車用ガラスにも、SNI マークが義務付けられているの<br />

か?(JASIC)<br />

→マレーシア以外については、その通り。複数のマークがガラスには<br />

入れられている。(CFC)<br />

→ASEAN-MRA が始まると、SNI マークが必要というのは問題になる。<br />

(JASIC)<br />

・ CBU の状態で輸入された自動車にも VTA が必要になると、その車にも<br />

SNI マークの部品が必要というのは、確かに問題である。(AISI)<br />

・ “Refer”というのは、VTA 上はどのような意味か?(JASIC)<br />

→テスト方法をその UNECE 規則から流用しているが、基準値はインド<br />

ネシアの事情で設定している。(DGLT)<br />

・ R39(Speedometer)は、二輪車のみか?(JASIC)<br />

→ASEAN-MRA の対象になっているのは、二輪車のみ。他のカテゴリー<br />

には要求なし。(AISI)<br />

・ ASEAN-MRA の対象になっている R46(Rearview mirror)は部品のみ<br />

ならず、自動車の間接視界を規定したもの。SNI で Rearview mirror<br />

の要件があるが、ミラー単独で SNI 規格を満足していても、車として<br />

OK かどうかは、別の問題である。(JASIC)<br />

5) インドネシアの VTA 制度改善の方向について(JASIC 秋葉)<br />

a) 活動の方向について<br />

図 インドネシア VTA 制度改善の方向<br />

b) 58 協定について<br />

c) WVTA 法規<br />

・将来の車両型式認可(WVTA)法規の構成<br />

21

・Annex としての技術要件リスト<br />

22

・認可当局とテクニカルサービス<br />

・最終ゴール<br />

<br />

・IWVTA について言及あったが、もっと詳しく IWVTA の考え方、検討状<br />

況について教えてほしい。<br />

→IWVTA の考え方を簡単に言うと、予めカテゴリー毎に必要な技術要<br />

件を決めておき、各要件の認可証があれば、どの加盟国が発行した<br />

ものであっても受け入れ、車両認可の一部分として認めるというも<br />

の。本年 11 月の WP29 にて、ECE R0 として提案される見込み。現<br />

在、OICA が ECE R0 の提案を準備中。(JASIC)<br />

・ その OICA のドラフトは入手可能か?<br />

→OICA メンバーである GAIKINDO なら、入手可能である。(JASIC)<br />

・ インドネシアは、テスト設備も不十分な状況。IWVTA 等の提案書が<br />

JASIC の website でオープンにされると良い。<br />

→既に、WP29 の website に掲載せれており、WP29 の website は JASIC<br />

の website からリンクされているので利用されたい。(JASIC)<br />

(b) 第1回ワークショップ(2日目)<br />

〔日 時〕:2011 年 9 月 15 日(木) 9:00~16:00<br />

〔場 所〕:VTCC 会議室<br />

〔出席者〕:<br />

日本側:秋葉主査、吉沢員、薩摩氏、土井・山田、通訳: Ms. Ziarini(6 名)<br />

インドネシア側:Irwan Arifianto (MOT/DGLT), Toto Noewitjaksono, Juliaman<br />

P., Suci Hakiman, Awaludin Yoda S.S., Arham S. (MOT/VTCC),<br />

M. Tafku S., Rudi C.N.(BTMP), Fanani Hamzah (CFC), Juwono<br />

Andrianto, Tri Widobu, Abdur Rahim, Eko Rudianto, Imran<br />

Haris W., Eddy S., Emjunan Sihite, Muawiyah S, Nur<br />

Haryono, Arif Setyawan (GAIKINDO), Heru Susanto, Rudi<br />

Prayitno, Girisa A., Susanto K.R., (AISI)(23 名)<br />

1) 日本の UNECE 規則の現状と将来(JASIC 吉沢委員)<br />

23

a) 日本の UNECE 規則採用の歴史<br />

b) WP29 活動への日本の貢献<br />

c) UNECE 規則の国内採用のための検討・精査手順について<br />

<br />

・ 日本が UNECE 規則を採用するために、日本から WP29 に改定提案したものはど<br />

24

んな項目があるのか?<br />

→R13 以外にも R93、94、70 等数多い。大部分、インフォーマルドキュメント<br />

として提案しているので、WP29 の website で確認されたい。(JASIC)<br />

・ 自国に試験設備がない場合、その UNECE 規則は採用できないのか?<br />

→ルクセンブルグのように試験設備を自国に持たないテクニカルサービスで<br />

も、メーカーラボで使いテストを行い、そのレポートで認可証を発行してい<br />

るケースもある。但し、テクニカルサービス自身は、自分が発行したテスト<br />

レポートの内容に責任がある。(JASIC)。<br />

・ テクニカルサービスとしての資格は、誰が認めるのか?<br />

→WP29/1059 という文書にテクニカルサービスの資格要件が規定されている。<br />

試験設備が自国内にないケースも認められている。(JASIC)<br />

・ASEAN-MRA のドラフトには、テクニカルサービスの資格要件については、<br />

WP29/1059 をそのまま引用しているので、問題無いのではないか?<br />

→ASEAN-MRA は、飽くまで ASEAN 域内では通用するが、そのまま 58 協定加盟国<br />

向けに通用するものではない。即ち、欧州、日本、オーストラリア向けには<br />

使えないということ。(JASIC)<br />

・ ASEAN が市場統合のお手本にしている EU の EU-WVTA では、それまでの欧州地域<br />

法規 EU directive から、国連 UNECE 規則を使うように方向転換している。<br />

(JASIC)<br />

・ 日本とインドネシアでは、UNECE 規則の採用について、基本的な違いがある。<br />

インドネシアの多くの自動車メーカーは、日本の親会社の意向で、対応可能か<br />

決まる。UNECE 規則の採用によって、自動車の安全性が向上し、排出ガス性能<br />

が向上すると言っても、コストアップが避けられなければ、反対される。イン<br />

ドネシアのローカルな会社には決定権がない。(GAIKINDO)<br />

→ASEAN の市場統合、ASEAN-MRA を考慮しなければならない。インドネシアの<br />

自動車メーカー、自動車部品メーカーもその生き残りを考えるのであれば、<br />

インドネシアの国内市場のみならず、広く ASEAN 市場、更にはそれ以外の市<br />

場も視野に入れていく必要がある。すでに、タイやマレーシアでは、それを<br />

始めている。(JASIC)<br />

・日本は、WP29 に IWVTA の提案をしたが、その進捗はどうか?<br />

→本年 3 月、IWVTA のインフォーマルグループが立ち上げら、それから既に6<br />

回のインフォーマルグループの会合がパリで開催された。この中で、ロード<br />

マップの作成や 58 協定見直しについて検討がされている。11 月の WP29 に<br />

ロードマップ案、58 協定見直し案が提示される見込み。既に、WVTA を規定<br />

する ECE R0 が OICA より提案されているが、M1 カテゴリーから WVTA に必要<br />

な技術要件リストが作成される予定。58 協定見直しについては、インドか<br />

らも積極的な提案が提出されている。(JASIC)<br />

・インドの提案というのは、どんなものか?<br />

→票決方法や技術要件リスト等多岐に亘っている。詳しくは、WP29 の website<br />

で IWVTA のインフォーマルグループの審議状況が報告されているので、そち<br />

25

らを見られたい。(JASIC)<br />

2) IASIF の UNECE 規則採用と ASEAN-MRA 対応について<br />

・VTCC の Juliaman 氏より、昨年 11 月、本年 4 月の ACCSQ-APWG 出席報告あり。<br />

ASEAN-MRA について、T/F よりドラフトが提案され、また各国が採用を考えてい<br />

る UN 規則の version について報告あり。また日本 MLIT/JASIC が開催したワー<br />

クショップから ECE のバージョン違い、VTA、COP 等について話題提供あり。<br />

・インドネシアの対応案につき、GAIKINDO の Eko 氏より、2015 年の ASEAN-MRA<br />

のイメージが紹介され、AAC(ASEAN AuromobileCommittee)の下に幾つかの WG<br />

を設置し、MRA する UN 規則をレビューして行く仕組みについて検討中であると<br />

の説明あり。<br />

図 ASEAN-MRA のイメージ(GAIKINDO)<br />

なお、UN 規則のテクニカルサービス候補の認証テスト能力評価区分では、評価<br />

が「試験設備なし」、「認定なし」が大部分で、その準備はこれからのところば<br />

かりであった。<br />

表 現在のインドネシアの部品認証能力評価(GAIKINDO)<br />

26

・ ASEAN-MRA のインドネシア対応、特にインドネシアの現状分析については、も<br />

っと詳細な分析が必要と思うが、その分析結果について是非 IASIF 内で認識の<br />

共有化を図られたい。また、ASEAN で各規則の採用検討につき、Technical WG<br />

を設置し、検討する方法が提案されているが、非常に良い方法と考えられる。<br />

各国がそのリーダーを分担することも可能。そこで ASEAN10 としての意見や提<br />

案を WP29 や GR に提出することを真剣に考えられたい。(JASIC)<br />

3) パネル討議「IASIF の必要性について」<br />

司会:JASIC 秋葉<br />

パネリスト:Juliaman(VTCC), Tufku(BTMP), Fanani(CFC)、Eko(GAIKINDO)、<br />

Heru(AISI)、吉沢、薩摩(JASIC)<br />

各パネリストの意見は、次の通り。<br />

〔58 協定加入、UNECE 規則採用の利益について〕<br />

・UNECE 規則採用に当たっては、経済的な影響を十分に考慮するべきである。<br />

(BTMP)<br />

・過去、JASIC 官民会議でも、このテーマで多くの議論が行われた。UNECE 規則採<br />

用によって、自動車の安全性が向上し、自動車事故による死傷者数が減る。排<br />

出ガス性能が向上し、大気汚染が減少すると言う説明がされたが、これらの議<br />

論には、経済性が判る人達、Marketing people が参画していない。(GAIKINDO)<br />

・安全保全には、車両の仕様、交通インフラ、ドライバー教育の 3 要素全てが重<br />

要であるが、技術基準の採用は車両側で安全確保を行う事である。安全性向上<br />

のためコストアップが発生する場合もあるが、一部はメーカーで吸収し、一部<br />

はお客様に負担頂くことになろう。但し新車開発時から法規要件を織り込めば、<br />

最小限に抑えることも可能である。自動車メーカーは既に世界的な競争に晒さ<br />

れており、一定のレベルの車両安全性、環境性能を市場が要求するのであれば、<br />

これに応えるのが自動車産業の役割だ。(JASIC)<br />

・部品メーカーの立場から言うと、ECE 規則の採用によるデメリットが存在するこ<br />

とも事実である。ローカルの中・小部品メーカーは技術開発、生産設備のコス<br />

トアップが問題となる。一方でコストは生産量に大きく依存する。統一した仕<br />

様で大きな生産量を確保できればコストは下がり、また国際規則に基づく仕様<br />

なので海外へ輸出することも可能となる。事故原因が推定できる交通事故分析<br />

データが提供されれば、必要な UNECE 規則を採用するときのプライオリティ判<br />

断ツールになる。(JASIC)<br />

・58 協定加盟加入により、貿易上の手続きが簡素化でき、MOI や MOF にとっても<br />

利益がある。(JASIC)<br />

〔UNECE 規則採用に当たってのインドネシアの VTA 制度の問題について〕<br />

・現在のインドネシアの VTA 制度は 80 年代に設けられたもので、ASEAN-MRA を実<br />

27

行可能にするためにも、一刻も早く改善する必要がある。(GAIKINDO)<br />

・VTA 制度をまず ASEAN-MRA の対象 19 項目から始め、徐々に段階的に強化してい<br />

くべきである。(GAIKINDO)<br />

図 ASEAN-MRA の将来(GAIKINDO)<br />

〔IASIF は何をおこなうべきか?〕<br />

・IASIF は 10 名のメンバーにより構成された組織であるが、他の業務のため欠席<br />

者も多い。事務局の専任者もいない。(VTCC)<br />

・IASIF 事務局を GAIKINDO に移したらどうか?(GAIKINDO)<br />

・JASIC 事務局のように、自動車メーカーや部品メーカーからある一定期間(2<br />

年とか3年)専任者を出してもらうことも考えてみたら。(JASIC)<br />

・すべてがインドネシアにとって複雑なので、これを整理するため、IASIF は Group<br />

を速やかに設立し、誰がその Group に参加すべきか明らかにする必要がある。<br />

(GAIKINDO)<br />

・今度の FAMI チェンマイ会議で、2 輪関係は 16 項目の UNECE 規則について調和<br />

していく方向を確認。AISI としてはタイムスケジュールを考えたが、政府はま<br />

だ話し合う用意が出来ていない状況。IASIF が出来て、話し合える機会が出来た<br />

ことは歓迎できる。ASEAN 諸国の間では既に競争が始まっており、インドネシア<br />

が現状に留まっている余裕はない。(AISI)<br />

・ACCSQ-APWG の T/F に参加しているインドネシアの業界からの参加者が他の国に<br />

比べ、極端に少ない。もっと出るべき。(VTCC)<br />

・そのためには、事前に IASIF 内で、官民で協議すべき。(GAIKINDO)<br />

・IASIF 内の議論の透明性の確保が大事で、その結果を公表することを考えるべ<br />

き。<br />

①国内法を UNECE 規則と整合をとること。<br />

②UNE CE 規則採用項目の提案と公表<br />

③コメント募集・結果の公表、<br />

④新型車・継続生産車への適切な適用リードタイム<br />

(JASIC)<br />

28

(3)第2回現地ワークショップ結果<br />

「車輌型式認証のための法規および制度について」をテーマに第2回ワークシ<br />

ョップを開催した。<br />

(a) 第 2 回ワークショップ(1日目)<br />

〔日 時〕:2011 年 10 月 5 日(水) 9:30~15:30<br />

〔場 所〕:MOI 会議室(ジャカルタ)<br />

〔出席者〕:<br />

日本側:JASIC 秋葉主査、石原氏、松原氏、土井、山田、通訳: Ms. Ziaini<br />

(6 名)<br />

インドネシア側:Ruiyono(MOI), Irwan Arifianto (MOT/DGLT), M. Harsono,<br />

T. Renh(MOE), Iman Alamsyah, S. Hakiman (MOT/VTCC), Hari<br />

S.(BTMP), Heru Munadhir (CFC), Rizki Irawati (BSN),<br />

Juwono Andrianto, Arif S., Eddy (GAIKINDO), Adi Ahjadi,<br />

Rudi P., Endang (AISI), Aji Wibono, Riwi, M. Yoga P.,<br />

Kharui Babri、Herry Rinden, Ardyoron P.(GIAMM), Hardpen,<br />

Irwan D.(APBI,タイヤ協会), Ruddy H. (Tuv Rheinland)(24<br />

名)<br />

1) 開会の挨拶(MOI Rudiyono 氏)<br />

JASIC から R13H、R13 の専門家に参加頂いたので、インドネシアへのこれ<br />

らのブレーキ法規の採用についてどのように進めたらよいか議論したい。<br />

IASIF で検討を開始したインドネシアの 58 協定加盟、UNECE 規則採用のため<br />

の具体的な議論の足掛かりになると考えられるので、積極的な討議に期待す<br />

る。<br />

2) UNECE 規則<br />

a) R13H(乗用車用ブレーキ)の概要(JASIC 石原氏)<br />

・GRRF の概要(組織、目標、担当規則及び法規)<br />

・UNECE 規則の一般外観(原則、構造)<br />

・R13H(その歴史と現状、関連情報、技術要件)<br />

・GRRF のブレーキに関するトピックス<br />

29

表 R13H の概要<br />

図 乗用車用ブレーキ法規の歴史<br />

b)R13(商用車用ブレーキ)の概要(JASIC 松原氏)<br />

・R13 の対象車両カテゴリー<br />

30

・R13 の構成<br />

・R13 の概要(トラック・バスについての技術要件を中心に)<br />

・その他の要件(ABS、EBS、EVSC、EVSC 等)<br />

EVSC(Electronic Vehicle Stability Contorol)装着効果デモンスト<br />

レーションビデオ紹介<br />

<br />

・乗用車用ブレーキの法規の歴史について説明があったが、白地と青地で区<br />

分されているのはどういう意味か?<br />

→白地で表現したのは古い法規であり、青地で表現したのが新しい法規。<br />

・日本の場合、なぜ R13H を二段階で採用することになったのか?<br />

→欧州や米国との国際的な基準調和のため、R13H の採用を決めたが、一部<br />

条項については採用に時間が掛かるとの判断から、1994 年 4 月に取りあ<br />

えず可能な範囲での調和を図り、十分なリードタイムを経て、1998 年<br />

11 月から完全に R13 を採用するという二段階を踏むことになった。<br />

・R13H の採用をしている国々の説明があったが、ASEAN の中の状況はどうか?<br />

→公式には、マレーシアが採用。タイが採用検討中の状況。<br />

→マレーシアが採用というのは、公式には採用の形になっているが運用は<br />

未決定が実態である。<br />

・MFDD というのは、何の略か?<br />

→後程詳しく説明するが、Mean Fully Developed Deceleration の略であ<br />

31

る。ブレーキの基本要件である MFDD と停止距離は、いずれか一方が判<br />

れば導きだされるものである。<br />

・ ABS と BAS の違いは何か?<br />

→ABS は、滑り易い路面でもタイヤがロックしないようにして、車両安定<br />

性と操舵性の向上を図るもの。BAS は、急に障害物が現れたようなとき<br />

の緊急ブレーキ時の制動力を増加指せるもの。但し、BAS 装着の前提条<br />

件として、ABS がある。<br />

図.ABS と BAS<br />

・ 1987 年に 85 年型の乗用車に乗っていて、ひどい雨模様の中で左折しよう<br />

としてブレーキをかけた時に、突然車が制御できなくなったことがある。<br />

これは一体何が起こったのか?<br />

→おそらく4輪ともロックしてしまったのではないだろうか。タイヤがロ<br />

ックしてしまうとハンドルを切りすぎると全く制御できないことがあ<br />

る。車全体がそのまま滑ってしまったのだろう。ブレーキペダルを一旦<br />

離し、ハンドルを滑る方向に向けるとロックから逃れ、そのハンドルの<br />

向いている方向に車両が進み始める事になる。ABS を装着すれば、その<br />

ようなロックが防げる。<br />

・2003 年型の ABS 装着の欧州製車に乗っていて、黄色のワーニングが点灯し、<br />

一旦エンジンキーを切っても、また入れるとワーニングがついたままだっ<br />

32

た。これは一体どういうことなのか?<br />

→おそらく ABS 自身に何等かの問題があったのではないか。R13H の法規上<br />

は故障が続く限り再スタート時も警報すべきとなっている。<br />

・ RBS というのは、ABS とは違うのか?<br />

→RBS は Regenerative Braking System のことで、主にハイブリッド車や<br />

電気自動車で使われる再生ブレーキのことを言う。ABS はブレーキ時の<br />

タイヤのロックを防ぐもので、従来のエンジン車にも搭載されているも<br />

の。<br />

・ブレーキ試験に使われるテスト路面の摩擦係数についての規定はあるの<br />

か?<br />

→十分な粘着力が有る事となっており特に具体的に規定されていない。ブ<br />

レーキ試験については、正常時要件で 6.43m/s 2 が要求されているが、そ<br />

れが実現できる路面においては路面摩擦係数の試験への影響は無い。通<br />

常のアスファルト路面で、摩擦係数は、0.9 程度であり問題ない。<br />

3) インドネシアのブレーキ法規の現状について(VTCC Mr. Iman)<br />

a) 車両試験の法的根拠<br />

b) タイプテストと定期テスト<br />

c) 主ブレーキ及び駐車ブレーキの技術要件(乗用車用、トラック・バス用)<br />

<br />

・インドネシアでは、車両のカテゴリーの定義は何によって決めているのか?<br />

→M、N、O、L は Law No.14, 1992 年で定義されている。従って、MOI、MOT<br />

33

間で定義が異なることはない。<br />

・ 定期車検は、商用車のみ義務付けられているとの説明であったが、どのよう<br />

に商用車と定義しているのか?<br />

→黄色のナンバープレートが商用車。<br />

・ 車両型式についての法規やデクリーがないのであれば、早急に発行する必要<br />

がある。<br />

→MOI 標準課でドラフトが準備されているが、まだ発行されていない。<br />

4) UNECE 規則の国内採用の仕方について<br />

a) 日本で採用検討中の R13 のケースについて(JASIC 石原氏)<br />

R13 の日本の採用検討を例に、UNECE 規則をインドネシアが採用していけ<br />

ばよいかについて、その手順や考え方について説明。<br />

b) インドネシアへの R13H 及び R13 採用について(討議)<br />

<br />

・インドネシアが 58 協定の加盟国になったら、インドネシアで R13H のテスト<br />

を行い、インドネシア政府から認可証を得たら、日本でも受け入れるのか?<br />

(GAIKINDO)<br />

→Yes.<br />

・日本は R13H と R10(EMC)について採用したとの説明があったが、それらの<br />

試験設備を同時に導入するのは難しい。どうしたらよいのか?(Tuv<br />

Reinland)<br />

→127 項目ある UNECE 規則の中から、どの規則を採用し、どの規則を採用し<br />

ないのかを明確にし、どの規則をまず採用し、次にどの規則を採用する<br />

かを考えていくべきである。同時に採用する必要は全くない。段階的な<br />

採用を計画する必要がある。<br />

→R13H についてインドネシア内で試験するには、規定の車両スピードから<br />

減速し、停止距離を計測するために必要な試験路を確保する必要がある。<br />

現在、インドネシアではダイナモ上のテストを実施しているが、試験路<br />

の確保が必須である。R10 についても専用の電磁波試験装置が必要。<br />

34

・インドネシアの試験機関に十分な試験設備がない場合、どうしたらよいの<br />

か?(GAIKINDO)<br />

→インドネシアがある UNECE 規則の採用を決めたら、それから認可当局がテ<br />

クニカルサービスの資格要件を決めることが出来る。その資格要件に基<br />

づき、テクニカルサービスを認定する。外国の試験機関でもテクニカル<br />

サービスに認定することが出来る。(JASIC)<br />

→インドネシアでは、試験機関(例えば VTCC)は MOT/DGLT の直轄であり、<br />

これを無視して海外のテクニカルサービスを認定することは考えられな<br />

い。(MOI)<br />

→どこをテクニカルサービスに認定するかはその認可当局の政策で決めて<br />

よいと思う。大事なことはその決定の透明性を確保することだ。(JASIC)<br />

(b) 第2回 SWG2 ワークショップ(2日目)<br />

〔日 時〕:2011 年 10 月 6 日(木) 9:00~16:00<br />

〔場 所〕:MOI 会議室(ジャカルタ)<br />

〔出席者〕:<br />

日本側:秋葉主査、石原氏、松原氏、土井、山田、通訳: Ms. Ziarini(6 名)<br />

インドネシア側:Irwan Arifianto (MOT/DGLT), Toto Noerwitjaksono, Iman<br />

Alamsyah, S. Hakiman (MOT/VTCC), M. Harsono, T.<br />

Renh(MOE), Hari S.(BTMP), Ni Made P.(B4T), Juwono<br />

Andrianto, Arif Setyawan, Eddy, Rita Erita, Emjunan<br />

Sihite, Nur Haryano (GAIKINDO), Heru S., Adi Ahjadi,<br />

Rudi P., Endany (AISI), Aji Wibono, Riwi S. (GIAMM),<br />

Ruddy H. (Tuv Rheinland)(21 名)<br />

1) IASIF の運営の有り方についての前回ワークショップの討議結果について<br />

a) 前回ワークショップの討議結果の紹介(JASIC 土井)<br />

第 2 回 SWG2 ワークショップ(9/15)のパネル討議結果を以下の区分で<br />

纏めてみた。<br />

・58 年協定加入及び UNECE 規則採用による利益<br />

・UNECE 規則採用に当たってのインドネシア VTA 制度の問題<br />

・IASIF は何を行うべきか?<br />

b) インドネシア政府幹部のための IASIF 提案書案(VTCC Toto 氏)<br />

前回ワークショップでのパネル討議結果を基に、UNECE 規則採用につい<br />

ての閣議提案のために、MOI、MOT 両局長宛 IASIF 報告書案を纏めた。 以<br />

下の構成になっているが、追加・修正の意見があれば、聞きたい。<br />

・背景<br />

・利益<br />

・必要なインフラ<br />

・必要なステップ<br />

35

・フォローすべき事項<br />

<br />

・ IASIF のロードマップが作成されたが、その活動実行はこれからである。<br />

(VTCC)<br />

・ インドネシアの自動車産業の現状について言えば、4輪関係は今後輸出の<br />

可能性もあるが、二輪関係は非常に限られるのではないか。国内で開発・<br />

設計を行っていないインドネシアの自動車メーカーにとって、UNECE 規則<br />

採用によって得られるメリットは大きくない。利益があるのは日本の親会<br />

社ではないか。(AISI)<br />

→現状はその通りかも知れないが、すでに日本の多くの自動車メーカー、<br />

部品メーカーは、ブローバルに開発・生産を始めており、インドネシア<br />

のメーカーが UNECE 規則の様なグローバルな基準に基づいた製品の生産<br />

が可能かどうかは重要なことである。UNECE 規則導入は、インドネシア<br />

の日系の自動車メーカーよりも地元資本の部品メーカーの方が対応は<br />

大変だと思う。MOI がこれらのメーカーの競争力強化を図ることが大事<br />

だと思う。(JASIC)<br />

・ 現状のみを考えるのではなく、将来を考えて、世界的に競争力のある製品<br />

を作っていく必要がある。(GIAMM)<br />

・ インドネシア国内には、58 年協定加入によるリスクがあると考えている。<br />

(GAIKINDO)<br />

→ジュネーブやパリでの WP29 事務局のラモス氏や WP29 のゴバーン議長の<br />

説明の通り、58 協定加入によってインドネシアの利益が損なわれること<br />

はない。UNECE 規則採用はインドネシアの状況に合わせて検討していく<br />

ことが出来る。それが今回のワークショップの課題のひとつだ。<br />

36

(JASIC)<br />

・ASEAN 諸国の中でも、タイは 58 年協定に加入したが、UNECE 規則を1件も<br />

採用していない。一方、マレーシアは、多くの UNECE 規則を短期間に採用<br />

しようとしている。(GAIKINDO)<br />

→タイの場合、国家標準化機構の TISI と運輸省陸運局の DLT の二つの監督<br />

官庁があり、DLT 傘下では車両認証法規が乗用車に関しては整備されて<br />

いないことが大きな問題。一方 TISI は製品規格として TIS 強制規格の<br />

運用の歴史が長い。この状況下では当面、UNECE 規則採用は難しいと聞<br />

いている。(JASIC)<br />

・先ほど R13H の日本での採用に当たって、最終的に義務付けするまでに、5<br />

~6年も掛けている。(GAIKINDO)<br />

・インドネシアの副大統領が、将来は UNECE 規則が義務付けになるだろうと<br />

の声明を発表しており、方向性は明確だ。(VTCC)<br />

・将来というのは、どの位先のことか?(JASIC)<br />

→2020 年とか 2030 年とか言うレベル。(VTCC)<br />

・採用した UNECE 規則の国連本部への通告は、大変重要。マレーシアは加盟<br />

直後に手続きを間違えたが、現在、これを是正しており、インドネシアの<br />

良い競争相手になるだろう。(JASIC)<br />

・UNECE 規則採用による利益の一つとして、規則に適合していない自動車や部<br />

品のダンピングによる輸入を防ぐバリアになる。インドネシアの市場の保<br />

護にも効果があるのではないか?(GAIKINDO)<br />

→市場を保護するという言葉は、あまり使いたくないが、粗悪品から消費<br />

者を守るという意味であれば、その通りであろう。(JASIC)<br />

・ UNECE 規則採用によって、海外からインドネシアへの投資を活性化する働<br />

きもあるのではないか?<br />

・UNECE 規則採用によって、ローカルな部品メーカーへの影響はどうだろう<br />

か?(JASIC)<br />

→タイヤやシートメーカーは、規模も大きく、すでに輸出志向で、殆ど問<br />

題ないと考えられる。それ以外については問題がある。(AISI)<br />

・UNECE 規則採用が決定すれば、規模の大きなメーカーは、テクニカルサービ<br />

ス並みの試験設備を備えることになる。これらの設備は、認証テストに使<br />

えるので、メリットの3番目に記入されたい。(Tuv Reinland)<br />

・小さなメーカーでは問題かも知れないが、UNECE 規則採用決定によって、品<br />

質管理システム改善が余儀なくされるので、品質レベルも上がるだろう。<br />

(JASIC)<br />

・「背景」の中に、安全・環境面でインドネシアのイメージアップにつながる<br />

というのも、追記されたい。(Tuv Reinland)<br />

・「利益」の中に、中小企業がグローバル基準を満足する製品を作れるように<br />

指導することができるという文章を追加されたい。(B4T)<br />

37

2) IASIF の UNECE 規則採用計画作成にはどのような準備が必要か?<br />

a) インドネシアの WVTA 制度改善の方向について(JASIC 秋葉)<br />

i) 活動の方向について<br />

ii) WVTA 法規について<br />

・WVTA 法規の改善(WVTA の基本要素の理解、現行 WVTA と理想的 WVTA<br />

の比較、IASIF 活動ロードマップ)<br />

・インドネシア WVTA 法規の付則として UNECE 規則を中心とする技術<br />

要件候補検討<br />

まず、127 項目を A,B,C に色分けし、更に A,B を表1、2、3 に区分。<br />

1から 6 の要素について評価し、インドネシア固有の法規の今後の<br />

有り方検討。<br />

b) UNECE 規則採用計画検討のためのワークシート提案(JASIC 秋葉)<br />

ワークシートの空欄を埋めることで、計画が完成するプロセス説明。<br />

c) 自由討議「IASIF の UNECE 規則採用計画作成にはどのような準備が必要<br />

か?」<br />

<br />

・基本的にインドネシアの VTA 法規本文そのものを変更する必要はなく、本<br />

文には「Annex 4.を参照せよ。」という字句のみを追加すればよい。Annex<br />

4 は、法規本文ではないので改定が容易に出来ると考えている。協定加盟<br />

国として UNECE 規則が年間 120 件以上も改定され、採用した規則の改定フ<br />

ォローを如何にスムースにできるかが大事なことになる。<br />

因みに、インドネシアの VTA 制度のために採用すべき UNECE 規則を選ん<br />

でみたので、これを参考に IASIF で議論されたい。(JASIC)<br />

→JASIC より提示されたワークシートを埋める作業は、完成までに何年も<br />

38

かかるのではないか。日本では、UNECE 規則に基づいた VTA 法規になっ<br />

ているのか?(VTCC)<br />

→日本は、採用 UNECE 規則の改定フォローに多くの工数がかかるなどの<br />

苦い経験がある。加盟後に法規の改良などを実施しているが、この経<br />

験を踏まえて、インドネシアでは最初から考えておく方が良いと考え、<br />

ここで提案している。(JASIC)<br />

・現在の IASIF は、専従スタッフもおらず、主要スタッフとして名前の挙が<br />

っている人ですら今回のワークショップに出席していない現状から、作業<br />

実行は大変困難で挑戦的である。(VTCC)<br />

・IASIF の現状は理解するが、僅かずつでもよいので、このワークシートを<br />

埋める作業を開始してほしい。最初の作業はラフなクラス分けから始める<br />

のでそれ程詳しい専門家は不要だと思う。昨日の議論があったのでここに<br />

示すように個人的な作業をしてみた。この程度の作業なら直ぐ出来ると信<br />

じているし、そのためにこのワークショップを通じてサポートをしていき<br />

たい。(JASIC)<br />

・二輪関係については、AISI は既に ACCSQ/APWG の作業を通じてクラス分け<br />

を実施して居るので 16 項目の UNECE 規則採用の必要な理由を記述するこ<br />

とができる。(AISI)<br />

・先ほどの説明の中で、将来は IWVTA を目指すべきとの説明があったが、<br />

ASEAN で現在進めている ASEAN-MRA については、どう考えればよいのか?<br />

(GAIKINDO)<br />

→ASEAN-MRA は、WVTA ではなく、一部部品の MRA を図ろうというもの。<br />

1958 年協定下での調和基準を使用した認証の相互承認とも違うし、<br />

WVTA の国際的な調和を図る IWVTA とは異なる。地域的な新しい規則を<br />

作ろうとしているだけなので、将来、1958 年協定を考慮した相互承認<br />

に進むときには再び重複した作業が発生する。(JASIC)<br />

・ワークシートについては、今後ワークショップの都度、進捗を確認させて<br />

頂きたい。(JASIC)<br />

→簡単に行くとは考えられないが、関係団体で内容を検討してコメント<br />

して欲しい。IASIF として作業を開始したい。(VTCC)<br />

(4)第3回現地ワークショップ結果<br />

「排出ガスに関する UN 規則とインドネシア法規の違いは何か?」をテーマに、<br />

第 3 回ワークショップを開催した。<br />

39

(a) 第3回 SWG2 ワークショップ(1日目)<br />

〔日 時〕:2011 年 11 月 2 日(水)9:00~16:00<br />

〔場 所〕:MOI 会議室(ジャカルタ)<br />

〔出席者〕:<br />

日本側:JASIC 秋葉主査、掛川氏、加藤氏、土井、山田、通訳: Ms. Ziaini<br />

(6 名)<br />

インドネシア側:Ruiyono, M. Ihsan (MOI), Irwan Arifianto (MOT/DGLT),<br />

M. Harsono (MOE), Toto Noerwitjaksono (MOT/VTCC), M.<br />

Taufik, Mouhtar, Yogi, Agus W.(BTMP), Juwono Andrianto,<br />

Anna W., U. Eruon, Girisa, Januar, Endang, Dedy<br />

Kristiadi, Hidopatol I. S. (GAIKINDO), Juli P., Srko<br />

S., Asep H.S., Heru S.(AISI),(21 名)<br />

1) 開会の挨拶(MOI Rudiyono 氏)<br />

JASIC から排出ガス規則の専門家に参加頂いたので、インドネシアへ<br />

のこれらの排出ガス法規の採用についてどのように進めたらよいか議<br />

論したい。また、インドネシアの 1958 年協定加盟、UN 規則採用につい<br />

てのワークシートが提案されているので、積極的に議論されたい。<br />

2) インドネシアの車両認証制度(WVTA)改善のためのプロセスについて<br />

(JASIC 秋葉氏)<br />

a) WVTA 改善の最終目標<br />

40

) 何故 WVTA の改善が必要か?<br />

c) WVTA 法規の構成<br />

d) 認証手順<br />

e) 関係者・組織のより良い理解のために(IASIF は今後何をすべきか?)<br />

<br />

・WVTA 改善の最終目標として上げられた IWVTA の Technical Requirement<br />

とはどのようなものか?(VTCC)<br />

→A,B,C という国が 58 協定加盟国であるとして、同じ WVTA の認証書、即<br />

ち WVTA のためのセットになった Technical Requirement の認証書を要<br />

求している。ここでいう Technical Requirement というのは、各 UN 規<br />

則で定めるブレーキ、シート、シートベルト、騒音、排出ガスといっ<br />

た個別の要件を指す。(JASIC)<br />

→インドネシアの車両型式認証法規上は、Road worthiness に分類されて<br />

いる。(VTCC)<br />

→用語の定義が同じではないようなので、注意されたい。(JASIC)<br />

・アセアン MRA として、19 項目の UN 規則を採用する計画であるが、IWVTA<br />

との関係はどのように理解すれば良いのか?(GAIKINDO)<br />

→アセアン MRA は、あくまで部品についてのテストレポート及び認証書<br />

を相互承認しようというもので、IWVTA へ進む途中段階と考えるべき。<br />

インドネシアもアセアン MRA に留まらず、58 年協定に加入し、将来は<br />

IWVTA を目指して欲しい。(JASIC)<br />

→昨日、SWG2 会合で、JASIC より、インドネシアの 58 協定加入の公式宣<br />

言は何時になるのか聞かれたが、IASIF としてはまだその準備が出来て<br />

いないと答えた。今後、関係業界、官庁を含め、コンセンサス作りが<br />

必要である。(VTCC)<br />

・日本は、Euro 5 を採用していないと聞いたが、何故か?(GAIKINDO)<br />

→後程のセッションで詳しく説明があるはずであるが、基本的には国連<br />

で IWVTA が合意されたら、それに添付される Technical Requirements<br />

41

list に記載される要件を排出ガスについても適用する考え。(JASIC)<br />

3) インドネシアの排出ガス法規及び BTMP の試験設備の現状について(BTMP<br />

Mr. Taufik)<br />

a) インドネシアの排出ガス法規の現状<br />

2009 年発行の MOE 法規 No.4(新型車の排出ガス規制値)適用。<br />

・L カテゴリーは、R40、R47、Euro2 レベル<br />

・M 及び N カテゴリーは、R83、ガソリン車、ディーゼル&ガスエン<br />

ジン車は Euro2 レベル<br />

・M、N、O カテゴリーのディーゼル車:R24<br />

・M、N、O カテゴリーのディーゼル&ガス(CNG/LPG)車:R49、Euro<br />

Ⅱレベル<br />

b) BTMP の車両排出ガス試験能力<br />

c) Euro4 対応準備状況<br />

2011 年内に Euro 4 テストが可能な 4WD シャシダイナモ試験設備が<br />

完成し、2012 年 2 月からテストサービス開始予定。<br />

d) BTMP のエンジン排出ガス試験設備及び試験能力<br />

42

e) 課題<br />

・市場燃料と試験燃料の品質の違い<br />

・何時インドネシアで Euro 3 又は Euro 4 を実施するのか?<br />

・COP<br />

<br />

・BTMP では、Euro 4 のテストも可能なのか?(GAIKINDO)<br />

→試験燃料さえ確保されれば、テストは可能。<br />

・インドネシアの Euro4 導入のため、燃料側の準備はできているのか?<br />

(JASIC)<br />

→Euro 4 用燃料のスペックは、現行 Euro 2 のそれに比べ、格段に厳し<br />

く、特に燃料中の硫黄分を非常に低くする必要がある。現在、<br />

GAIKINDO も参画し、議論をしているが、石油会社は反対しており、<br />

政府(MOE 等)の明確な判断が必要である。GAIKINDO としては、Euro<br />

4 導入は、2012 年からとすべきと主張している。(GAIKINDO)<br />

・BTMP 等の試験機関をテクニカルサービスに認定した場合の独立性につ<br />

いて、どう担保すればよいのか?(MOI)<br />

→政府から予算を得ながら、テクニカルサービスとしての独立性を維<br />

持する例は、例えば、英国の VCA 等、世界でも多くの例がある。<br />

(JASIC)<br />

・WP29 に日本の代表を派遣する場合、JASIC で意見を纏められると聞い<br />

ているが、どの様に行っているのか?(GAIKINDO)<br />

→事前に、JASIC 内の Technical Committee 及び Sub-committee で協議<br />

し、WP29 に派遣される政府代表をサポート。政府代表者をサポート<br />

する要員も JASIC の名の基に業界や試験機関から派遣している。<br />

(JASIC)<br />

4) UN 規則 No.49 と現行インドネシアの排出ガス法規の比較(JASIC 掛川氏)<br />

a) ディーゼル燃焼及び排出ガス低減技術<br />

43

) UN 規則 No.49<br />

44

c) 市場燃料品質リコメンデーション<br />

d) EURO VI についての提案<br />

e) UN 規則 No.24(ディーゼルスモーク)<br />

<br />

・R49 では、10~16 万 km の排出ガス耐久性を要求しているが、日本の排出<br />

ガス法規の排出ガス耐久走行距離はいくらか?耐久パターンはどうなっ<br />

ているか?(GAIKINDO)<br />

→日本の場合、距離については中型車と大型車では同じだが、小型車は<br />

R49 に比べ短い。パターンは小型に準じ MLIT が定めた耐久サイクルを<br />

走らせる。(JASIC)<br />

・国連では EuroⅣまでの推奨市場品質が決まったとのことだが Euro V や<br />

Euro VI ではどうなるのか?自動車業界は S50ppm を受け入れ可能か?<br />

(VTCC)<br />

→Euro V 以降は 10ppm が必要というのが業界のスタンスで、欧州でも EU<br />

は EuroⅤにあわせ 10ppm 化している。技術的にもサルフェート排出や<br />

触媒信頼性の確保の問題から 50ppm では難しい。(JASIC)<br />

・Euro IV から更に Euro V、Euro VI に規制レベルが厳しくなるとしたら、<br />

どのような試験設備が必要になるのか?(BTMP)<br />

→EuroⅤについては大幅な設備の変更は必要ない。EuroⅥではパティキ<br />

ュレートの質量を計測する精密天秤、その天秤を納めるエアコン付き<br />

の測定室、粒子数計測システムが必要で、希釈空気の清浄性確保のた<br />

45

めダイリューショントンネル入り口に大型のフィルタ等が必要になる。<br />

ダイリューショントンネルは、小型で比較的安価なマイクロトンネル<br />

も使用可能。(JASIC)<br />

→マイクロトンネルは、どこで取り扱っているのか?(BTMP)<br />

→設備メーカーなら取り扱っているはず。AVL に相談すればよい。<br />

(JASIC)<br />

・Euro IV から更に Euro V、Euro VI に規制レベルが厳しくなるとしたら、<br />

どのような対策が必要になるのか?OBD についてはどうか?(BTMP)<br />

→EuroⅤでは NOx 触媒または DPF のどちらか、EuroⅥでは両方が必要。<br />

他に Cooled EGR 量増加、コモンレール、電子制御ユニットインジェク<br />

ター、VGT 等が必要になるだろう。OBD は Euro V から必要になり、Euro<br />

VI では NOx センサーや PM センサーを用いて排ガスや粒子を計測・監視<br />

するシステムが必要になるだろう。(JASIC)<br />

(b) 第3回 SWG2 ワークショップ(2日目)<br />

〔日 時〕:2011 年 11 月 3 日(木)9:00~16:00<br />

〔場 所〕:MOI 会議室(ジャカルタ)<br />

〔出席者〕:<br />

日本側:JASIC 秋葉主査、掛川氏、加藤氏、土井、山田、通訳: Ms. Ziaini<br />

(6 名)<br />

インドネシア側:Ruiyono, M. Ihsan (MOI), Irwan Arifianto (MOT/DGLT),<br />

Toto Noerwitjaksono (MOT/VTCC), M. Taufik, Sifi<br />

Yubaidah, M. Agus W., Tedy I, Hamjotad, Aris Sukmomo<br />

(BTMP), Budi P.S., Emornan S., Eko R., Mianpyah, Anna<br />

W., Girisa, Endang, Dedy Kristiadi (GAIKINDO), Juli<br />

Pamunekas., Suko S., Asep H.S.(AISI), Hadi<br />

Sunjadipradjh(GIAMM)(22 名)<br />

1) UN 規則 No.83 とインドネシア法規との比較(JASIC 加藤)<br />

a) 世界及びインドネシアの排出ガス法規<br />

b) WLTP(Worldwide Light Duty Test Procedure)について<br />

c) UN 規則 No.83-S5<br />

・R83 の歴史<br />

46

・排出ガス規制値の歴史<br />

・排出ガスと燃料改善<br />

・R83-S5 の構成<br />

・R83-S5 の適用範囲<br />

47

・R83-S5 の型式認証テスト(Type I~Type VI テスト、OBD 要件)<br />

<br />

・ DBL というのは、何のことか?(VTCC)<br />

→Diurnal Breathing Loss のことで、一日に、気温が 20℃から 35℃位<br />

まで大きく変化する。この間の燃料蒸散ガス量を DBL という。<br />

(JASIC)<br />

・ キャニスターを搭載すれば、蒸散ガスはゼロになるのではないか?<br />

(GAIKINDO)<br />

→燃料タンクからの蒸散ガスは、キャニスターで吸収できても、燃料<br />

配管を含めた燃料系全体の蒸散ガス量を計測するので、ゼロにはな<br />

らない。(JASIC)<br />

・排出ガス耐久テストの方法をメーカーで選べるとの説明があったが、<br />

認可当局自身が認証試験を行う場合も、メーカーが選んだ方法が認め<br />

られるのか?(GAIKINDO)<br />

→その通り。(JASIC)<br />

・耐久テストパターンは高速走行の頻度が高いがその理由は?<br />

(GAIKINDO)<br />

→触媒は高温下で劣化し、その浄化性能が低下して来る。従って耐久<br />

テストは、高排気温を含んだパターンで実施し、その性能劣化を評<br />

価する。(JASIC)<br />

・OBD システムは、Useful life を越えても機能するはず。もしも、Useful<br />

を越えて、MIL が点灯したらどう判断すれば良いのか?(GAIKINDO)<br />

→後ほど、OBD システム搭載の修理等への利益について説明するので、<br />

Useful life を越えても OBD は使えることが理解してもらえるだろ<br />

う。(JASIC)<br />

・燃料のオクタン価が違っていたら、ノックセンサーは使いものになら<br />

ないのではないか?(GAIKINDO)<br />

→市場の燃料品質に対応できるように KNOCK センサーは付いている。<br />

(JASIC)<br />

・ハイブリッド車と従来エンジン車の OBD システムに違いがあるのか?<br />

(BTMP)<br />

→Euro OBD では、ハイブリッド車にも従来エンジン車と同じ項目が要<br />

求されているが、OBD システムについては、各メーカーの OBD 戦略<br />

があるのでメーカー毎に異なる。(JASIC)<br />

・バイオ燃料車については、どの法規に規定されているのか?(BTMP)<br />

→Euro OBD では、従来燃料車と同じ項目が要求されている。(JASIC)<br />

48

2) 自由討議「どのように環境法規を UN 規則に整合して行くか?」(司会:<br />

JASIC 秋葉氏)<br />

・数年前にインドネシア環境省は、ブルースカイポリシーを発表。厳しい<br />

排出ガス規制導入について議論が開始された。インドネシアでは、EU<br />

で採用されている Euro 4、Euro IV 規制を導入の方向である。(VTCC)<br />

・ステークホルダーである政府及び試験機関、業界からそれぞれ意見を貰<br />

いたい。(秋葉)<br />

→ジュネーブで、Type VI や Type VII の議論があっても、インドネシ<br />

アが参画してその活動に貢献できるか、甚だ疑問に感じる。インド<br />

ネシアでは、Type VI のようなテストは不要ではないか?(GAIKINDO)<br />

→58 協定の加盟国との MRA を行うためには、その UN 規則に定める全項<br />

目のテストを欠けることなく実施し、その認可証を発行しなければ<br />

ならない。但し、インドネシアの気候、インフラや燃料事情等から<br />

規則の一部テストを除外した法規を採用し、自国の WVTA の一部とし<br />

て実施することは可能である。(JASIC)<br />

・万一、インドネシア MOE が Euro4 導入を決めても、燃料品質が追いつか<br />

ない場合、どうすればよいのか?(GAIKINDO)<br />

→本日のワークショップに MOE からの参加なし。答えられない。(VTCC)<br />

・インドネシアが 58 年協定の加盟国になった時、他の加盟国のテストレ<br />

ポートや認可証を受け入れないといけないのか?インドネシアが認可<br />

証を発行する場合、排出ガスについては、MOT と MOE のどちらが発行で<br />

きるのか?(GAIKINDO)<br />

→勿論、インドネシア内で話し合わねばならないが、排出ガス、騒音<br />

は、MOE、部品は MOI、車両全体は MOT という考えが良いのではない<br />

か?(VTCC)<br />

→WVTA に関するものは、全て VTCC でテストし、MOT で認可証を発行す<br />

るというのがよいのではないか?(MOI)<br />

・日本では、どの省庁が発行しているのか?(GAIKINDO)<br />

→日本では、WVTA に使われるものは、全て NTSEL でテストし、認可は<br />

49

MLIT が与える。(JASIC)<br />

・JIS は使われていないのか?(MOI)<br />

→過去には、JIS を refer したものもあったが、現在の WVTA に関する<br />

限り、一切 JIS を refer していない。(JASIC)<br />

・マレーシアは、58 協定加入の際、UNECE 規則について全く Objection<br />

しなかったという話を聞いたが?(MOI)<br />

→その通り。マレーシアは一旦新規制定・改正の全ての UN 規則を採用<br />

した形になった。インドネシアが、58 協定加入の際、不採用の UNECE<br />

規則について国連本部に公式レターを提出する必要があるので注意<br />

されたい。(JASIC)<br />

2) 自由討議「UN 規則採用によって WVTA を改善するには、IASIF 活動を如何<br />

に進めればよいか?」(司会:JASIC 秋葉氏)<br />

・58 協定加入の政府決定前に、UN 規則をベースにした WVTA 制度確立を提<br />

案したい。複雑な WVTA 制度を持つ日本の例に従う必要はなく、より簡<br />

素に UN 規則の改廃をフォローできる WVTA 法規体系を持ったものにすべ<br />

きである。(JASIC)<br />

・WP29 は、年3回新規制定及び改正を審議・決定する。従って、これをフ<br />

ォローし、インドネシアの WVTA 法規に反映するには、その法規の Annex<br />

として、インドネシアが採用した UN 規則を並べる EU の WVTA 法規の構<br />

成を参考にすべきである。(JASIC)<br />

・現行のインドネシアの「2009 年道路交通と運輸に関する法律第 22 号」<br />

自身の構成は、UN 規則を採用し易いものではない。また、使われている<br />

term もその定義が異なっている。従って、UN 規則採用に当たっては、<br />

技術的な検討に併せ、リーガルな検討も必要。更に、WVTA 制度の方向や<br />

必要な人的資源やインフラの開発等についても関係組織間で論議が必<br />

要。(VTCC)<br />

50

・インドネシアの「1993 年車両とドライバーに関する政府規制第 44 号」<br />

の改正が必要と思う。GAIKINDO の中でも、コストの観点から、あるもの<br />

は反対、あるものは賛成ということがあり得る。IASIF で、政府を含め、<br />

協議し、明確な方向を決めるべきである。(GAIKINDO)<br />

→日本でも、一般に多くの UN 規則採用はコストアップの観点から反対<br />

が多かった。インドネシアの場合は、日本に親会社のあるメーカーは、<br />

技術的な面では大きな問題はないと考えられるが、ローカルなメーカ<br />

ーは対応が困難なところが出てくるだろう。(JASIC)<br />

・アセアン MRA は、最終的には 58 協定加盟国間の MRA が出来る IWVTA を目<br />

指すべきである。IASIF 内にいくつかのワーキンググループを作り、UN<br />

規則精査を行い、どの UN 規則を採用し、どの UN 規則は採用しないとい<br />

うような採用計画を明確にしていかねばならない。(JASIC)<br />

3) IASIF 活動の次のステップについて<br />

・関係するステークホルダーを参集し、IASIF 会合を開催する。<br />

→第 5 回 SWG2 会合及びワークショップまでに、JASIC から提案あったワ<br />

ークシートを埋める努力をすることを提案する。併せて、政府幹部に<br />

提出する IASIF レポートも完成させる。(GAIKINDO Eco 氏)<br />

・インドネシアの 58 協定加入への公式宣言を何時行うかという質問に対し<br />

て、まずは次回 SWG2 会合で進捗を報告できるようにしたい。(VTCC Toto<br />

氏)<br />

(5)第4回現地ワークショップ結果<br />

「騒音に関する UN 規則とインドネシア法規の違いは何か?」をテーマに、第<br />

4回ワークショップを開催した。<br />

(a) 第4回 SWG2 ワークショップ(1日目)<br />

〔日 時〕:2011 年 12 月 14 日(水)9:00~16:00<br />

〔場 所〕:MOI 会議室(ジャカルタ)<br />

〔出席者〕:<br />

日本側:JASIC 秋葉主査、掛川氏、加藤氏、土井、山田、通訳: Ms. Ziaini<br />

(6 名)<br />

インドネシア側:Ruiyono (MOI), Irwan Arifianto (MOT/DGLT), S. Hakiman,<br />

Iman Alameeyah, Aneludin Yoga S. (MOT/VTCC), Juwono<br />

Andrianto, Budi P.S., M. Erwin D., Dodop. S., Reza<br />

A.P., Dea F.P., Anna W.,(GAIKINDO), Hanggoro, Rudi,<br />

Jumdianzah (AISI), Hadi Srjadipradja (GIAMM) ( 16<br />

名)<br />

1) 開会の挨拶(MOI Rudiyono 氏)<br />

SWG2 のワークショップは、日尼 EPA の協力プロジェクトの一環として開催<br />

51

されたもので、これまで、58 年協定加入の利益は何かという点について多<br />

くの時間を割いて議論してきた。また、ACCSQ-APWG が ASEAN-MRA の対象と<br />

して推薦している第一優先の 19 項目の中から、5項目について今年度計画<br />

として取り上げ、日本の専門家よりインドネシアが採用する際の課題を指<br />

摘頂いている。今回、JASIC から騒音の専門家に参加頂いたので、インドネ<br />

シアへのこれらの騒音法規の採用についてどのように進めたらよいか議論<br />

したい。参加の皆様の積極的参加を期待する。<br />

2) インドネシアの車両認証制度(WVTA)改善について(JASIC 秋葉氏)<br />

既に、今年度都合3回のワークショップを終了。今回第 4 回目のワークシ<br />

ョップでは、日本の専門家より R51 規則について、その概要を説明し、イ<br />

ンドネシアの現行騒音法規と比較して頂く予定。<br />

また、前回に引き続き、インドネシアの WVTA 制度を今後どのように改善し<br />

て行けば良いのか、JASIC より、資料 ”Practical way to improve<br />

Indonesian WVTA system”に沿って具体的に提案したい。<br />

a) 58 協定加盟国としてのインドネシアの利益<br />

b) 最終ゴール<br />

c) 最終ゴールの前に:58 協定加入後の3段階、徐々に選択的に UN 規則施<br />

行<br />

d) WVTA 法規の内容:WVTA 法規の構成とサンプルとして M1 カテゴリーに対<br />

する技術要件リスト(59 項目の UN 規則)提案(図 2.参照)<br />

e) 関係者・組織のより良い理解のために<br />

図 2. M1 車の WVTA の技術要件リストのサンプル<br />

<br />

52

・58 協定加入の利益の一つとして、テクニカルサービスのビジネスチャ<br />

ンスが上げられているが、どういうことか?(AISI)<br />

→ここでいうビジネスチャンスというのは、58 協定に加入した国の試験<br />

機関が認可当局から信頼できるテクニカルサービスに認定され、他の<br />

58 協定加盟国のテクカルサービスとの競争に打ち勝って、始めて手に<br />

入れられるもので、自国に限らず、他の加盟国のメーカーから試験を<br />

受注できるようになるということ。従って、アドバンテージにもなる<br />

が、ディスアドバンテージにもなり得る。(JASIC)<br />

・現在、インドネシアの WVTA の一環として車両の寸法や重量等仕様の確<br />

認が行われているが、提案された EU 方式の WVTA 法規では、何処に規<br />

定されているのか?(MOT)<br />

→ 後ほど詳しく説明するが、重量・寸法等の基本的な仕様については、<br />

申請者であるメーカーから提出される申請用書類に記載が求められて<br />

おり、認可当局はその書類に記載の仕様通りか確認する権限を持って<br />

いる。(JASIC)<br />

・インドネシアが採用・施行すべき UN 規則選定のためのパラメーターは<br />

何か?(MOI)<br />

→ 交通事故防止等、自動車安全性を向上させるもの、排出ガス低減等に<br />

寄与するもの、試験機関の試験能力(設備面、人的資源)があるもの、<br />

しかもコスト効果の高いものを採用すべき。さらに、EU や日本などが<br />

どのような UN 規則を採用しているかを考えることも大事である。その<br />

一つの指針として先のプレゼンで説明した表などを参考にまず採用項<br />

目を前広に決めたらどうかと提案している。採用することと規則適用<br />

は別の議論であることをもう一度念を押しておきたい。(JASIC)<br />

・これまでも日本の専門家から、交通事故データ分析結果を反映した自動<br />

車安全性向上に有効との話があった。インドネシアは事故データが不<br />

足している。どうすればよいのか?(AISI)<br />

→徒に事故分析センター設置に投資せよと言っている訳ではない。詳しい<br />

データが無くとも、衝突事故が多いのであれば、極端に言えば、R94<br />

と R95 を採用すれば、衝突事故による死傷者数は激減する。更に、<br />

Passive Safety の要件については、R12、14、16、17、21、25 等パッ<br />

ケージで考えてはどうか。まず、第一にこれらの UN 規則の採用計画を<br />

明確にして、IASIF で適用時期について検討していくべきだと思う。こ<br />

ういう検討手順を踏めば適用に至るプロセスについても関係者全体の<br />

合意を得やすいし、透明性も増すと思う。(JASIC)<br />

・試験設備に必要なコストを、まず考えるべきではないか?(MOI)<br />

→コストを考えるのは、勿論重要である。同じコストを掛けても、それだ<br />

け利益がなければ意味がない。効果も並行して考える必要がある。<br />

ACCSQ ではこのような議論がなされていないのではないかと感じてい<br />

る。経験の少ない ACCSQ がクローズドの会議で議論することがおかし<br />

53

いし、もし求められればいつでもサポートする。JASIC から過去には何<br />

回か情報提供しているが、どう生かされているのか不明だ。インドネ<br />

シアの UN 規則採用、適用に当たっては ACCSQ のようなおかしなことは<br />

繰り返して欲しくない。このような議論を、是非 IASIF 内に設置する<br />

個別の作業グループで行って適用時期に至るプロセスを明確にしてほ<br />

しい。(JASIC)<br />

3) 騒音についての UN 規則 R51 の概要について(JASIC 白橋氏)<br />

UN 規則 R51 と現行インドネシア法規の違いについて、説明。また、インド<br />

ネシアの使用過程車の騒音チェック方法及び規制値案の考え方が、UN51-02<br />

と異なっていると指摘あり。<br />

a) UN 規則とインドネシア法規(加速騒音及び定置騒音)の比較<br />

b) UN 規則(R.E.3):使用過程車の定置騒音は相対値規制であり、型式認証<br />

値+5dB(A)のマージン許容のはず。ドラフトの規制値案では、新車での<br />

加速騒音値が合格でも、使用過程車の定置騒音値が不合格になり得る。<br />

また、試験エンジン回転数の定義が既に R51/02 の supplement 6 で改訂<br />

済にも拘らず、インドネシア法規には反映されていない。<br />

<br />

・今回指摘した問題について、どのように対処するつもりか?(JASIC)<br />

→使用過程車の騒音チェックの方法及び規制値の決定権は MOE にあり、<br />

MOE と話し合う必要がある。(GAIKINDO)<br />

・更に、新車の加速騒音テスト方法についても MOE に誤解を質す必要があ<br />

る。もし、MOT から試験方法についてテクニカルガイダンスを出すので<br />

54

あれば、その修正が可能ではないか?(JASIC)<br />

→MOT が出すテクニカルガイダンスは、あくまで騒音テスト方法のトレー<br />

ニング用。(MOT)<br />

→新車の加速騒音テスト方法についても、決定権は MOE にあり、MOE が誤<br />

りを理解し、是正しない限りは、これまで通りである。(GAIKINDO)<br />

・前回ワークショップでは、将来 R49 や R83 の排出ガス、R51 の騒音規則<br />

についての Approval authority は MOE ではなく、MOT とすべきという<br />

のが結論であった。何故、この問題を放置しているのか?何故、MOE は<br />

今回ワークショップに参加されていないのか?肝心なステークホルダ<br />

ーが参加していないワークショップは、何回開催しても無駄ではない<br />

か?(JASIC)<br />

→明日のワークショップには、MOE より参加願えるように要請する。<br />

(GAIKINDO)<br />

(電話にて、MOE ザカリア氏に参加要請。その場では快諾あったものの、<br />

当日会場には現れず)<br />

(b) 第 4 回 SWG2 ワークショップ(2日目)<br />

「UN 規則とインドネシア国内法及び規格を整合するために何をすべきか?」<br />

日 時:2011 年 12 月 15 日(木)9:00~16:00<br />

場 所:MOI 会議室(ジャカルタ)<br />

出席者:<br />

日本側:JASIC 秋葉主査、大野氏、白橋氏、土井、山田、通訳: Ms. Ziaini<br />

(6 名)<br />

インドネシア側:Ruiyono, M. Ihsan (MOI), Toto Noerwitjaksono, Irwan<br />

Arifianto (MOT/DGLT), S. Hakiman, Awaludin Yoga S.S.<br />

(MOT/VTCC), Budi P.S., M. Erwin D., Ludi H., Reza A.P.,<br />

Arif Setyawah, Eddy S., Endang, Anna W., Girisa A.<br />

(GAIKINDO), Hari Sasono, Heru S., Hanggoro,<br />

Jumdianzah(AISI), Hadi Sunjadipradja(GIAMM)(20 名)<br />

1) 日本の騒音法規の歴史及び R51 採用検討状況について(JASIC 大野)<br />

a) 日本の環境騒音の法体系<br />

b) 騒音についての環境基準<br />

c) 道路交通騒音改善のトレンド<br />

55

d) 車両騒音法規全面見直し提案<br />

e) JASIC の車両騒音規則改定提案<br />

・試験方法<br />

・サブカテゴリー<br />

<br />

・ 乗用車の速度と騒音パワーレベルの表があったが、どこで測定したデ<br />

ータか?(GAIKINDO)<br />

56

→ JARI の研究設備のある筑波市の沿道で測定されたデータ。(JASIC)<br />

・ JIS でサイレンサーについて規定されているのではないか?(AISI)<br />

→ JIS には規制値はなく、試験方法のみ規定している。昨年よりアフタ<br />

ーマーケット用マフラーについても型式認証テスト(実際に、当該マ<br />

フラーを装着した上で、車両加速騒音テスト)が要求されるようにな<br />

った。(JASIC)<br />

・インドネシアでは、二輪車を購入した顧客は、アフターマーケット用<br />

マフラーに交換するケースが多い。しかも、大部分はオリジナルマフ<br />

ラーより、騒がしく、場合によっては触媒もないものが多い。(AISI)<br />

→ 日本では、JAMA が 10 年以上に亘って、新車だけで無く交換用マフラ<br />

ー等の対策の必要性を機会あるごとに説明してきたが、昨年 4 月から<br />

マフラー事前認証制度が適用開始した。(JASIC)<br />

・通常、オリジナルマフラーと交換用マフラーの騒音は、どのように違<br />

うのか?(MOI)<br />

57

→二輪車メーカーとしては、オリジナルマフラーを推奨している。<br />

(AISI)<br />

・本日 MOE から出席があれば、今回新車及び使用過程車の騒音試験方法<br />

及び規制値の問題について話し合いたかったが、参加願えず、残念。<br />

来年3月に JAMA として来尼予定につき、その機会に直接面談したい。<br />

2) 自由討議「今後、どのように IASIF を運営して行けばよいか?」(司会:<br />

JASIC 秋葉氏)<br />

・今後の IASIF の進め方について、これまでのワークショップでの議論<br />

や IASIF 内での意見交換の結果を纏めると、以下の通りになる。<br />

(ア) 政策決定者のための判り易い報告書<br />

(イ) 外務省への 58 協定加入計画説明<br />

(ウ) IASIF としての定期会合<br />

(MOT)<br />

→JASIC も設立されてから約 20 年以上が経過したが、その活動が重要視<br />

されたのは、1958 年協定加盟の機運が高まってハイレベルの認識が高<br />

まってからである。IASIF 活動をより有効なものにするには、より高い<br />

レベルに対するアプローチが必要。(JASIC)<br />

→インドネシアの業界トップは依然国内市場拡大に注目しており、輸出<br />

振興に寄与する IASIF 活動は不要という雰囲気がある。(GAIKINDO)<br />

・MOT、MOI だけでなく、他の省庁も IASIF 活動に積極的に参画願う必要<br />

がある。特に、58 協定加入には、外務省の許可を得る必要がある。(MOT)<br />

→来年9月に 58 年協定に加盟するには、残された準備期間は、9 ヶ月し<br />

かない。この間に多くの課題を解決していく必要がある。(JASIC)<br />

・昨日、JASIC からのプレゼンにあった”Elements for this project”<br />

に上げられたタスクを着実に実行して行くことが必要。(GAIKINDO)<br />

→「判り易い報告書」で、全てを書きあげることは不可能。むしろ、当<br />

面の目標として 58 協定加入を取り上げて、何をすべきかを明確にすべ<br />

き。(MOT)<br />

・採用すべき UN 規則の仕分けを行うにも、各規則の内容が理解できる専<br />

門家が必要ではないか?(AISI)<br />

→各規則の名前から想起できる範囲でよいので、それ程多くの専門家は<br />

必要ない。すぐに実行に移すべきである。(JASIC)<br />

・58 協定加入を目標として、これを 9 ヶ月で何をすべきか要因分析を行<br />

い、効果的な方法を取るべきである。次回、ワークショップでは、JAMA、<br />

JAPIA から Administrative な問題の解決に詳しい専門家を派遣するつ<br />

もり。次回ワークショップの前に、まずインドネシアの 9 カ月間の行<br />

動計画を作ってほしい。それをベースに我々が何をサポートできるか<br />

議論したい。(JASIC)<br />

→了解した。Toto 氏が IASIF 事務局責任者として資料をまとめ、日本側<br />

58

に事前に送付するのでコメントをいただきたい。(MOT)<br />

(6)第5回現地ワークショップ結果<br />

「本年度の SWG2 活動成果と今後の IASIF 運営について」をテーマにワークショ<br />

ップを開催した。<br />

(a) 第 5 回 SWG2 ワークショップ(1日目)<br />

日 時:2012 年1月25日(水)9:00~16:00<br />

場 所:VTCC 会議室(べカシ)<br />

出席者:<br />

日本側:JASIC 秋葉主査、森本氏、佐々木氏、冨樫氏、土井、山田、通訳: Ms.<br />

Ziaini(7 名)<br />

インドネシア側:M. Ihsan (MOI), Irwan Arifianto, Santy Eka (MOT/DGLT),<br />

Dewant P., Suci Hakiman, Awaludin Yoga S.S. (MOT/VTCC),<br />

Dedy Y., M. Tasfiq (BTMP), Juwono Andrianto, Budi P.S.,<br />

Girisa A., (GAIKINDO), Heru Sutanto, Hanggoro, Alam<br />

B.(AISI)(13 名)<br />

1) 開会の挨拶(MOT/VTCC Dewant 所長)<br />

今回の SWG2 のワークショップは、第5回目に当たる。本日のワークショ<br />

ップでは、2011 年度の SWG2 活動を振り返り、また、58 協定加入に向け<br />

た準備を行うために、新たに設置された IASIF の今後の運営について議<br />

論する予定。参加者の積極的な議論を期待する。<br />

2) 2011 年度 SWG2 活動成果と今後の活動についてのアイデア(JASIC 土井)<br />

今年度の SWG2 の活動成果をスポンサーである経産省に報告するため、<br />

JASIC にて主な活動成果を、以下の通り整理してみた。昨日の SWG2 会合<br />

で、その内容につき議論したので、ここで紹介し、出席者の意見を聞く<br />

ことにした。また、来年度の活動についても、JASIC 案を説明した。<br />

a) 2011 年度 SWG2 活動計画の狙いと方法<br />

b) 最終計画日程及び各 SWG2 会合及びワークショップでの議事概要<br />

c) 2011 年度 SWG2 活動の主な成果<br />

①58 協定加入準備のための IASIF 活動報告書の作成<br />

②19 項目の UN 規則の認可当局及びテクニカルサービス候補の選定<br />

③インドネシアの車両型式認証制度改善のための法規見直しの方向<br />

確認<br />

④IASIF ロードマップの一部見直し(未完成)<br />

d) 今後の SWG2 活動のアイデア<br />

①2012 年度は SWG2 会合を4回、ワークショップを4回開催。<br />

②現行試験機関のテクニカルサービス化のための能力向上策を中心<br />

59

に議論。<br />

③ 要に応じ、UN 規則精査も実施。<br />

<br />

・今年度は、何故 19 項目の UN 規則から5項目を取り上げて、精査する<br />

ことのなったのか?その経緯を知りたい。(JASIC)<br />

→ASEAN-MRA の対象として、まず 19 項目の UN 規則が第一優先項目となっ<br />

たので、現行 SNI 規格を見直し、その一部に UN 規則を織り込むことに<br />

なった。一方、完成車の認証は、MOT の監督下で行われており、コンポ<br />

ーネント及び部品の認証は MOI の監督下で行うということで整理され<br />

た。(GAIKINDO)<br />

・SWG2 活動では、インドネシアが 58 協定に加盟し、UN 規則をベースに<br />

した WVTA 制度を構築することを狙いとしている。一方、SNI 規格は、<br />

製品の品質を確保し、更に高めることが目標と考えられるので、WVTA<br />

制度の構築を目標とする SWG2 活動とは基本的に別の目的を持っている。<br />

はっきりと区別して考えなければならないのではないか?(JASIC)<br />

→インドネシア通関時の取扱は、完成車(CBU)とコンポーネント・部品<br />

とでは、全く違う。即ち、完成車のみが WVTA 認可が必要とされるが、<br />

コンポーネント・部品はマンダトリーの SNI 規格適合チェックが要求<br />

される。通関上、完成車及びコンポーネント・部品については、HS コ<br />

ードによって明確に区分される。(GAIKINDO)<br />

→ 貿易上で必要な HS コードと WVTA 自身は、直接関係が無い。個別に要<br />

求されるべきものではないか?(JASIC)<br />

・日本では、通関上完成車と部品の区分はないのか?(GAIKINDO)<br />

→日本の場合は、完成車についてはその安全性や排出ガス等が一定の基<br />

準を満たしているか国土交通省が WVTA 制度の基に担当している。<br />

(JASIC)<br />

・試験機関の能力向上を考える上で、予算の問題を避けて通れないので<br />

はないか?(GAIKINDO)<br />

→コストを考えるのは勿論重要だが、現行の試験機関の状況やり方次第<br />

でそのコストも低減できる。まず、将来の WVTA をイメージしながら、<br />

127 項目の UN 規則から、どの UN 規則を採用すべきか検討すべきである。<br />

(JASIC)<br />

・我々の優先順位検討に当たっては、IASIF 内に小グループを設置し、討<br />

議する必要がある。JASIC 提案のワークシートを基に、UN 規則採用検<br />

討一覧表(A3 シート)の作成を開始した。例えば、ガラスについては、<br />

少し手を入れれば、CFC で R43 のテストが可能と判断している。<br />

(GAIKINDO)<br />

→日本の専門家の意見も同様であった。そのような議論を他の UN 規則、<br />

試験機関について早急に実施されたい。(JASIC)<br />

60

・R51 や R41 の騒音テストは、VTCC でテストできるようになるのか?<br />

(JASIC)<br />

→ISO 路面は未完成で、完成の目途が立っていない。(MOT/DGLT)<br />

・車両の安全性については、VTCC がテストし、MOT/DGLT が認可するのが<br />

自然な流れだ。(JASIC)<br />

・MOT/DGLT では、短期間で担当者が交替する。日本の国交省は、どうか?<br />

(MOT/DGLT)<br />

→国交省でも、1・2年で担当者は異動することが多いが、異動後も業<br />

務の継続性を確保されるように尽力している。(MLIT)<br />

3) 今後の IASIF の運営について<br />

JASIC にて IASIF の運営上の問題点を分析してみたので、今後の運営に役<br />

立てて貰うため、ここに照会し、その解決方法について、幾つか提案した。<br />

a) 現在の IASIF 活動は、何が問題か?<br />

図 58 協定加入準備のための IASIF 活動が不十分な原因<br />

b) その対策案は?<br />

表 JASIC が提案した四つの対策案<br />

61

c) 最低3ヶ年計画を立てて、毎年見直そう。<br />

<br />

・IASIF スタッフの不足が原因の一つに取り上げられているが、Permanent<br />

staff の不足ではないか? また、トップからの適切な指示不足もある<br />

と思うが、どうか?(GAIKINDO)<br />

→異論なし。但し、ここで取り上げたのは、一部の例なので、IASIF 自身<br />

で同様の分析を行い、必要な対策案についても自身で考えて欲しい。<br />

(JASIC)<br />

・先ほど、IASIF で UN 規則採用検討一覧表(A3 シート)の作成を開始し<br />

たとの報告があった。また、IASIF のロードマップの一部見直しの必要<br />

との意見もあった。非常に心強いことであるが、58 協定加入まで、残<br />

り8ヶ月しかなく、早急に作業を進められたい。(JASIC)<br />

→具体的タイムテーブルについては、2 月末を目標に IASIF 案を纏めたい。<br />

(MOT/DGLT、GAIKINDO)<br />

4) インドネシアの車両型式認証制度改善の実際的な方法について<br />

JASIC 秋葉より、これまでのワークショップにて何度か説明してきた改善<br />

策の要点につき、再度説明し、今後の進め方について提案した。<br />

a) IWVTA のコンセプト<br />

b) インドネシアが目指す最終目標<br />

c) 58 協定加盟国として取るべき2段階<br />

d) インドネシアの WVTA 制度改善の実際的な方法について<br />

① WVTA 法規の草案作成<br />

② 本年9月58協定加入に向けた IASIF 活動とは?<br />

62

・作業項目確定<br />

・作業日程決定<br />

・WVTA の構成案検討<br />

・新しい WVTA 法規案作成(具体的な法規案を例示)<br />

・上記活動のための二つの WG 設置(UN 規則運用検討 WG と WVTA 法規<br />

見直し WG)を提案<br />

図 2012 年 9 月までに 58 協定に加入するための IASIF 活動<br />

<br />

・これまでの JASIC 提案を基に、現行 127 項目の UN 規則について、A3<br />

の一覧表”Draft Template IASIF Preparation for UN Regulation<br />

Selection”の作成を開始した。この表をみてコメントがあれば聞き<br />

たい。(GAIKINDO)<br />

表 UN 規則採用検討表(ワークシート)<br />

63

・Technician の資格は、どのように規定するのか?(JASIC)<br />

→試験の種類によって違ってくると考えられるが、BTMP では、排出ガス<br />

試験を実施する Technician には、運転免許と共に日本や英国での訓<br />

練終了書の取得を要件にしている。(BTMP)<br />

→安全についての試験、例えば R14、16、17 等の衝突安全性テストを行<br />

う Technician には、共通する資格設定が可能ではないかと考える。<br />

(JASIC)<br />

・衝突試験用ダミーを取り扱う Technician には、特別な技能が必要で<br />

はないか?(GAIKINDO)<br />

・テスト設備のコスト見積もりが取り上げられているが、最新の高度な<br />

試験設備、言い換えれば高価な試験設備でなくとも、工夫次第で安価<br />

な設備でもテストが可能なことがある。また、127 項目の UN 規則の<br />

内、灯火器関係が 30~40 項目あるが、同じ試験設備で複数のテスト<br />

が可能なので、よく考慮されたい。(JASIC)<br />

(b) 第 5 回 SWG2 ワークショップ(2日目)<br />

「IASIF の今後の進め方について」<br />

日 時:2012 年1月26日(木)9:00~16:00<br />

場 所:MOI 会議室(ジャカルタ)<br />

出席者:<br />

日本側:JASIC 秋葉主査、森本氏、佐々木氏、冨樫氏、土井、山田、通訳: Ms.<br />

Ziaini(7 名)<br />

インドネシア側:Ruiyono, M. Ihsan (MOI), Toto Noerwitjaksono, Irwan<br />

Arifianto, Santy Eka (MOT/DGLT), Dewant P., Suci<br />

Hakiman, Awaludin Yoga S.S. (MOT/VTCC), Juwono<br />

Andrianto, Rita Evita, Nos Hariyono (GAIKINDO), Hari<br />

Sasono, Heru Sutanto, Hanggoro, Rudi, Alam<br />

B.(AISI)(16 名)<br />

1) 開会のあいさつ(MOI の Rudiyono 課長補佐)<br />

64

昨日は、排出ガス規制強化に備えるため、新しい燃料法規につき検討す<br />

る会議があり、ワークショップに参加できず、失礼した。<br />

UN 規則の導入について、58 年協定調印に向けて早急に取り組む必要があ<br />

り、本日のワークショップでもその方策について議論したい。<br />

2) IASIF comprehensive paper の現状について<br />

・ 昨日、Sudirman 課長に IASIF comprehensive paper 案を説明し、<br />

Director General に上程出来るか相談したが、現状では了解を得るに<br />

は不十分との判断であった。本日のワークショップで良い意見があれ<br />

ば、補強・修正して行きたい。(MOT/DGLT)<br />

図 尼政府政策決定者への提案書案<br />

→MOI の Suprijant 課長にも説明したのか?(JASIC)<br />

→既に説明済である。(MOT/DGLT)<br />

・ 特に、58 年協定加入準備のためには、Permanent staff が必要である<br />

ことを訴えるべき。(JASIC)<br />

→それは十分承知しているが、IASIF の事務局は VTCC なので、VTCC の新<br />

所長である Dewanto 氏よりすべき。Permanent staff を置くためには、<br />

その予算措置も必要なので、他のステークホルダーの協力も必要。<br />

(MOT/DGLT)<br />

→その意見に賛同する。これまでの IASIF を今後は IASIC として、<br />

permanent staff を置くことを提案したい。ITS program のように副大<br />

統領を招いて、政府の上層部の後押しを得るようなことも考えたい。<br />

(GAIKINDO)<br />

・ 予算を得るには、トップレベルの関心を得る必要がある。残念ながら<br />

IASIF の活動は、プライオリティが低い。(MOI)<br />

65

→MOT としても、交通混雑解消のような緊急性がないため、プライオリテ<br />

ィは低い。(MOT/DGLT)<br />

→プライオリティを上げるため、議会に提案することを提案したい。<br />

(MOI)<br />

・ 政府の上層部を動かすには、もっと大きなインパクトが必要と考える<br />

が、一体何がそのトリガーになるのか?(JASIC)<br />

→UN 規則導入は、単なる手段。それが、海外諸国との自由貿易に繋がり、<br />

インドネシア産の製品の輸出拡大に資することが重要。すでに、ダイ<br />

ハツやスズキのようにインドネシアを生産拠点として海外に積極的に<br />

輸出して行こうとする動きも出て来た。(AISI)<br />

→輸出促進だけでなく、生活の質向上も重要。(MOI)<br />

・ 一般論として、58 協定加盟及び UN 規則導入のメリットについてコメン<br />

トしたい。国際基準導入によって自動車の安全性、環境性能が向上し、<br />

自動車製品の流通促進によりメーカーのコストは抑えられ、結果、消<br />

費者は高い安全・環境性能を有する自動車をより安価に入手可能とな<br />

る。また、協定に加盟しているアジア諸国は未だ少数であるため、協<br />

定加盟によりインドネシアの国際的な認識が向上することも期待され<br />

る。(MLIT)<br />

→ご意見は、これまで何度も JASIC から言われたことで、我々は良く理<br />

解している。(MOT/DGLT)<br />

→この paper にそれを補強する説明資料を添付することを考えよう。<br />

(JASIC)<br />

・ すでに、JASIC としては必要と考えられる情報は全てインプットした。<br />

更に、何が必要なのか? 具体的に示してくれれば、準備したい。<br />

(JASIC)<br />

・ 業界トップの理解を得る必要がある。今回、JAMA 及び JAPIA からも代<br />

表者が参加頂いているので、彼等の支援が必要ならば、要請されたい。<br />

(JASIC)<br />

→GAIKINDO の中でも、インドネシアの 58 協定加入に対する意見は分かれ<br />

ている。ある日系メーカーの日本本社は Yes であるが、インドネシア<br />

の子会社のトップは No というところもある。(GAIKINDO)<br />

・ 何が幹部の決定を促すファクターか?(JASIC)<br />

→58 協定加入そのものと思う。(MOT)<br />

・ タイは、58 協定に加盟したが、UN 規則を全く採用していない。(AISI)<br />

→タイの型式認証制度そのものの不備も原因だ。TISI で運用している規<br />

格の方で UN 規則を参照している程度。(JASIC)<br />

・ タイは独自の型式認証制度を作ろうとしているのか?(MOI)<br />

→まだ、VTA ではなく、部品の認証段階。(AISI)<br />

→58 協定加入後のアクションが大事。(MOI)<br />

・ 58 協定加入のための具体的準備開始の打ち合わせを開くべき。VTCC の<br />

66

Dewanto 所長より招聘して欲しい。Dewanto 氏にとっても大事な議論を<br />

しているのに、中座したまま戻ってこないのはけしからん。(MOT/DGLT)<br />

→べカシは、関係者が集まるには不便。ジャカルタの方が良い。(AISI)<br />

→今回のワークショップでも、べカシでの開催なので、多くの人が集ま<br />

っていない。ジャカルタ市内の MOI か GAIKINDO の事務所で開催するこ<br />

とも可能。事務局で考えて欲しい。(MOI)(AISI)<br />

→GAIKINDO や AISI の会長、MOT の Sdilman 課長にも招聘し、58 協定加入<br />

そのものについて議論して貰いたい。(GAIKINDO)<br />

・ 昨日のワークショップで確認した内容について、本日の参加者に簡単<br />

に説明して欲しい。(JASIC)<br />

→JASIC 土井より、昨日のワークショップ概要につき、資料を基に説明。<br />

その結果、昨日の合意内容で今後の作業を進めることとした。<br />

3) 今後の SWG2 活動について<br />

下記のような協議の結果、次回 SWG2 会合及び SWG3 との合同会合をジャ<br />

カルタ MOI にて開催することで合意した。(日程は、3/19-20 を仮設定。<br />

SWG3 側とも調整することとした。)<br />

また、次回 SWG2 会合までに、IASIF にて以下を準備することになった。<br />

① UN 規則採用検討用一覧表(A3 形式)検討結果をまとめる。<br />

② 二つの作業 WG 設立案を検討する。<br />

<br />

・ 今後の活動のタイムテーブルを整理したい。(JASIC)<br />

・ 日本に帰国次第、JASIC より METI に今回ワークショップ結果を基に今<br />

年度成果及び来年度計画案について報告する。3月下旬、再度 SWG2 会<br />

合を開催し、来年度計画について具体案を検討したい。(JASIC)<br />

・ 昨日、IASIF より、127 項目の現行 UN 規則についての検討項目が提示<br />

あり、討議の結果、2 月末を目途に採用検討一覧表(A3 形式)を作成<br />

する作業を行うことになった。<br />

・ 本日、問題提起された通関上規定されている HS コードについては SWG2<br />

の議論とは切り離して検討されるべきである。(JASIC)<br />

・ 来年度計画については、SWG3 との関わりもあるので、SWG3 との合同会<br />

合も併せて開催願いたい。(JASIC)<br />

・ 来年度の計画の中に、インドネシアの Technician の教育訓練を追加<br />

することは、可能か?(VTCC)<br />

→今回プロジェクトの対象ではないので、新たに MOT や MOI を通じて、<br />

日本政府(MLIT や METI)に申し入れられたい。(JASIC)<br />

→例えば、JICA スキームによる教育訓練の可能性も考えられる。まずは<br />

インドネシア側から具体的なプロポーザルを提示することが必要。<br />

(MLIT)<br />

67

・IASIF ロードマップも見直しが必要ではないか?(JASIC)<br />

→マスターロードマップは、DGLT 局長通達に添付されたものにつき、変<br />

更不可。但し、その中で幾つかの点について、より実際的なタイムテ<br />

ーブルを作成する必要がある。(GAIKINDO)<br />

・ VTCC より要望のあった Technician の教育訓練については、今後の課題<br />

としたい。(MOI)<br />

・ 試 験 機 関 の 能 力 向 上 の 問 題 は 、 SWG3 と 話 し 合 う 必 要 が あ る 。<br />

(GAIKINDO)<br />

68

Ⅱ-2.日本側委員会設置とインドネシア側委員会との協議<br />

(1) 日本側委員会の設置<br />

JASIC では、本プロジェクトを<strong>経済産業省</strong>から受託するに当たって、主として JASIC<br />

関係団体及び学識経験者から成る国内委員会を設置することにした。最終的に設置さ<br />

れた委員会メンバーは、資料 IV-3 に記載の通りである。<br />

2011 年度としては、都合3回の会合を開催し、年度計画の審議やインドネシアで開<br />

催するワークショップ、欧州及び日本で開催するハイレベル会合等の行事についての<br />

企画につき、活発な議論をいただいた。<br />

特に、インドネシアで開催したワークショップでは、インドネシア側出席者にとっ<br />

て貴重な講演や情報提供を行った。<br />

(2) インドネシア側委員会との協議<br />

本プロジェクトの受託前から、JASIC はインドネシア側委員会と接触を持ち、2011<br />

年度活動計画について協議を重ね、今回報告の通り、一定の成果を上げた。<br />

この間、都合 5 回の会合を開催し、年度計画の審議やインドネシアで開催するワー<br />

クショップ、欧州及び日本で開催するハイレベル会合等の行事についての企画、運営、<br />

成果につき、活発な議論をいただいた。<br />

第 1 回 Sub-WG2 会合風景<br />

(2-1) 第1回 Sub-WG2 会合<br />

〔日 時〕:2011 年9月13日(火)9:00~12:30<br />

〔場 所〕:Ministry of Industry (以下 MOI)会議室<br />

〔出席者〕:<br />

日本側:JASIC 秋葉主査、吉沢委員、薩摩、土井、山田、南部(6 名)<br />

インドネシア側:M. Ihsan (MOI), Irwan Arifianto, Yanti<br />

69

Marliana(MOT/DGLT), Toto Noerwitjaksono, Awaludin<br />

Yoda S. S. (MOT/VTCC), Prawato (BTMP), Juwono Andrianto<br />

(GAIKINDO), Heru Susanto (AISI)(8 名)<br />

1) 2011 年度 SWG2 年間活動計画の確認<br />

本年度活動計画について、土井より説明。各 SWG2 会合及びワークショ<br />

ップ開催日程及び開催場所について、以下の通り確認。<br />

① 第 1 回ワークショップ:ベカシの VTCC にて開催。<br />

② 第 2 回ワークショップ:ベカシの VTCC で開催。事前に開催の第 2 回 SWG2<br />

会合は、ジャカルタの MOI にて開催。<br />

③ 第 3 回~第 5 回ワークショップ:VTCC での開催で良さそうであるが、<br />

尼側で相談の上、決定したい。<br />

2) IASIF のロードマップの確認<br />

IASIF は、6 月 9 日付け MOT/DGLT 局長通達により設立された。<br />

① 設立後、ラマダン・政府休暇等があり、IASIF として会合が開催できた<br />

のは、9 月 2 日の1回のみ。今後、月に 2 回程度の通常会合開催を考え<br />

ている。<br />

② IASIF 設立は、政府をサポートする組織であり、基準調和を推進するも<br />

のである。しかしながら、最近時発令されたインドネシア大統領命令<br />

Masterplan for the Acceleration and Expansion of Economic<br />

Development of Indonesia (MP3EI)は、経済発展計画であるため、58<br />

協定加盟/基準調和活動は含まれていない。従って、IASIF はプロポー<br />

ザルを政府上層部に提案が必要。<br />

③ IASIF ロードマップでは、58 年協定署名のための公式宣言は、本年 9<br />

月から 10 月になっているが現在この日程通りに行われるか不明。<br />

④ 国連本部への 58 年協定及び WP29 加盟手続きについては、ロードマッ<br />

プ上では、2013 年 7 月~8 月としている。このロードマップ自体も逐<br />

次見直す必要があると考えている。<br />

3) ASEAN-MRA への対応<br />

MOI の Rudiyono 課長補佐等は、米国サンフランシスコで開催の APEC 自<br />

動車ダイヤログに出席のため、今回会合には不参加。ACCSQ-APWG で提案さ<br />

れている ASEAN MRA ドラフトについては、10 月ブルネイで開催される APWG<br />

で話し合う予定。但し、まだ、3 月の時点で、Rudiyono 氏は、ASEAN-MRA<br />

は飽くまで reference であると考えているとのご発言であったが、他の<br />

IASIF メンバー(VTCC、AISI 等)は mandatory と理解しており、インドネ<br />

シア内でも一致していない模様。また、インドネシアはマレーシアと同様、<br />

最新の UNECE 規則を採用すべきとの JASIC コメントに対し、明確な回答な<br />

し。明日のワークショップで、MOT/VTCC の Juliaman 氏より、インドネシ<br />

アの対応状況につき報告頂くことにした。<br />

4) 第 1 回ワークショップ及び第 2 回ワークショップの内容及び日程の確認<br />

70

①第 1 回ワークショップは、JASIC 提案通りの日程でベガシの VTCC にて開<br />

催することを確認。第2回ワークショップも、VTCC 開催を打診したが、<br />

同所はリノベーション工事のため、MOI(ジャカルタ)で開催してほし<br />

いとの Toto 所長意向。MOI 開催について、Juwono 氏が確認の上、連絡<br />

頂くことにした。<br />

②第 2 回ワークショップで、ブレーキに関するインドネシアの国内法規と<br />

UNECE 規則(R13H 及び R13)について比較検討する予定であるが、特に、<br />

インドネシア国内法規は存在しない由。日本では、R13H は採用済みであ<br />

るが、R13 については現在採用のための精査が開始された状況であり、<br />

日本の精査作業の要点について JASIC より説明したい旨提案し、了承さ<br />

れた。<br />

③Juwono 氏より、現地日系自動車メーカー上層部に IASIF の活動(インド<br />

ネシアの 1958 年協定加入、UNECE 規則の採用支援)について十分理解さ<br />

れていない現状があるので、マザー・カンパニー(日本)からローカル・<br />

カンパニーに説明が必要。また、今回及び次回ワークショップでも論議<br />

したい旨提案あり。提案に沿ってアジェンダを修正した。<br />

(2-2)第 2 回 Sub-WG2 会合<br />

〔日 時〕:2011 年 10 月 4 日(火)9:00~15:00<br />

〔場 所〕:MOI 会議室(ジャカルタ)<br />

〔出席者〕:<br />

日本側:JASIC 秋葉主査、石原氏、松原氏、土井、山田(5 名)<br />

インドネシア側:Rudiyono, M. Ihsan (MOI), Irwan Arifianto (MOT/DGLT),<br />

Toto Noerwitjaksono, Iman Alamsyah, S. Hakiman<br />

(MOT/VTCC), John H.P. Tamton, Radmat U., M. Harsono(MOE),<br />

Juwono Andrianto, Arif S., Abdor Rahim, Hidayatol I.S.<br />

(GAIKINDO), Hari Sasono, Heru Sutanto (AISI)(15 名)<br />

1) 開会の挨拶(MOI Rudiyono 氏)<br />

本会合では、IASIF の運営や活動、政府内の方針決定者に対する判りやす<br />

い報告書案について話し合うことになっている。<br />

2) 挨拶(JASIC 秋葉)<br />

今回は、実際的な課題の解決方法についても、是非話し合いたい。特に、<br />

インドネシアのVTA制度の改善についてのワーキングシートを持参したので、<br />

これを用いてIASIFとしては何を何時までに実施して行くのかを議論したい。<br />

また、同時に、本活動について各企業のトップマネージメントにも理解を得<br />

られるようにするにはどうすればよいのかについても議論したい。<br />

3) IASIF の運営及び活動について<br />

・IASIF としては、第 1 回 SWG2 会合及びワークショップでの議論を基に、「58<br />

年協定加盟のための IASIF からの判りやすい報告書」(案)を作成した。最<br />

71

終的には、政府内の方針決定者(関係局長経由大臣を想定)に提出される<br />

文書としたい。(MOI Rudiyono 氏)<br />

・まだ、具体的な作業を開始するために必要と考えられるワーキンググルー<br />

プの組織化には至っておらず、これからである。(GAIKINDO Juwono 氏)<br />

・業界のトップマネージメントの理解を得るためにも、非常に重要な文書に<br />

なるものと考えられる。同時に、本文書に対する質問にも答えを用意し、<br />

粘り強く、その必要性を説いていく必要がある。(JASIC)<br />

・政府の中でも、ハイレベルの理解を得なければ、その活動のための予算獲<br />

得もできない。(MOI)<br />

・GAIKINDO、AISI、GIAMM 等業界団体も、メンバー会社のトップに理解を得<br />

るには、機会を捉えて、継続的な説明が必要である。(JASIC)<br />

・この活動は、短期的な利益を考えて行うのではなく、むしろ中・長期的な<br />

視野で考える必要がある。(JASIC)<br />

4) 第 2 回ワークショップ内容とスケジュール確認<br />

・ワークショップ1日目は、R13H、R13 のブレーキについての UNECE 規則の<br />

採用に当たっての検討課題や検討・精査の方法について、日本の専門家よ<br />

り、日本での経験をベースに説明をしてもらう予定。2日目に、今後イン<br />

ドネシアの VTA 制度を改善して行くために、どの様に活動を展開していけ<br />

ばよいのか、これも日本での進め方を参考に提案したい。インドネシア側<br />

出席者と議論の上、役に立つものにしたい。(JASIC)<br />

・説明の中で、活動のための重要な要素の一つとして、「技術的な決定や WP29<br />

及び GR 参画のために専門家が必須」との指摘があった。その必要性は理解<br />

するが、実際にインドネシアの各企業にそのような専門家は存在しないの<br />

ではないか?また、この活動の重要性を各企業のトップに理解してもらう<br />

には、インドネシアで言うよりも、日本からインドネシアに派遣される各<br />

社トップに、JAMA や JAPIA を通じて説明してもらう方が早いのではない<br />

か?(GAIKINDO)<br />

・日本の中でも、過去に同様の議論があった。その経験から言うと、日本、<br />

インドネシアの双方で、粘り強く説明を繰り返し、理解を得るほか方法は<br />

ないと考える。(JASIC)<br />

5) UNECE 規則採用検討のためのワークシートについて、説明。(JASIC 秋葉)<br />

・非常に有効なワークシートであるが、専従者のいない IASIF にとって、こ<br />

のシートを埋めるだけでも、大変な作業が予想される。(VTCC)<br />

・一辺に埋める必要はない。時間を掛けて、検討しつつ、埋めていけばよい。<br />

特に、採用や不採用、また、そのままでは採用できないが、このように改<br />

定できれば採用できる等の理由を関係者間で認識を共有できる良いツール<br />

になる。最初にラフな検討を行い UN 規則の採用に関するクラス分けをす<br />

べきだ。それから個々の UN 規則について作業を進めて行き、その過程で明<br />

確になったことを最初のクラス分け表にフィードバックしてこの表の完成<br />

度を高めていけばよいと思う。(JASIC)<br />

72

6) その他<br />

第 3 回、第 4 回ワークショップは、ジャカルタ開催。第 5 回ワークショ<br />

ップは、ジャカルタ以外での開催を検討してはどうかとの意見もあり。継続<br />

検討することになった。<br />

(2-3)第 3 回 Sub-WG2 会合<br />

〔日 時〕:2011 年 10 月 31 日(火)9:00~13:00<br />

〔場 所〕:MOI 会議室(ジャカルタ)<br />

〔出席者〕:<br />

日本側:JASIC 秋葉主査、掛川氏、加藤氏、土井、山田(5 名)<br />

インドネシア側:Rudiyono, M. Ihsan (MOI), Saiful Bachri, Irwan Arifianto<br />

(MOT/DGLT), Toto Noerwitjaksono, Suci Hakiman, Awaludin<br />

Yoea S.S. (MOT/VTCC), Juwono Andrianto, Anna Widiasih<br />

(GAIKINDO), Heru Sutanto (AISI), Herinito (GIAMM)(11<br />

名)<br />

1) 開会の挨拶(MOI Rudiyono 氏)<br />

本会合では、58 年協定加入準備状況、前回 JASIC より提案のあったワーク<br />

シート、今回のワークショップアジェンダについて確認することになってい<br />

る。<br />