Brochure - ABA Gas

Brochure - ABA Gas

Brochure - ABA Gas

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

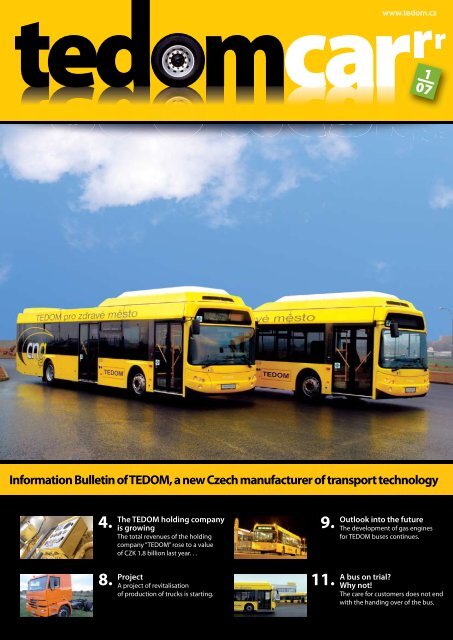

Information Bulletin of TEDOM, a new Czech manufacturer of transport technology<br />

4.<br />

8.<br />

The TEDOM holding company<br />

is growing<br />

The total revenues of the holding<br />

company “TEDOM” rose to a value<br />

of CZK 1.8 billion last year. . .<br />

Project<br />

A project of revitalisation<br />

of production of trucks is starting.<br />

9.<br />

11.<br />

www.tedom.cz<br />

Outlook into the future<br />

The development of gas engines<br />

for TEDOM buses continues.<br />

A bus on trial?<br />

Why not!<br />

The care for customers does not end<br />

with the handing over of the bus.

Content<br />

4.<br />

7.<br />

8.<br />

9.<br />

10.<br />

11.<br />

The TEDOM holding company<br />

is growing<br />

The total revenues of the holding<br />

company “TEDOM” rose to a value<br />

of CZK 1.8 billion last year. . .<br />

ČSAD Liberec<br />

The buses were subject to hard tests<br />

at our company.<br />

Project<br />

A project of revitalisation<br />

of production of trucks is starting.<br />

Outlook into the future<br />

The development of gas engines<br />

for TEDOM buses continues.<br />

15 years of experience with<br />

stationary engines<br />

Interview with Drahomír Jeleček,<br />

Technical Director<br />

A bus on trial?<br />

Why not!<br />

The care for customers does not<br />

end with the handing over of the<br />

bus.<br />

Dear Readers,<br />

You have received the first issue of the<br />

new magazine of the TEDOM holding.<br />

From a small company formed by several<br />

enthusiasts we have developed, in 15 years,<br />

into a firm which employs seven hundred<br />

people. Our annual turnover achieves<br />

approximately EUR 70 million. We are<br />

operating in several places in Europe. In the<br />

Czech Republic we have three production<br />

plants. We develop the production of buses<br />

and trucks, especially of vehicles using an<br />

alternative fuel, such as natural gas. We<br />

Edition Board:<br />

Eva Kijonková, Vlado Murár<br />

produce and operate environment-friendly<br />

energy sources and technologies for<br />

combined electricity generation and heat<br />

production. In all of these activities we will<br />

continue and we will foster our positions on<br />

both the domestic market and abroad.<br />

At the same time we would like to inform our<br />

business partners, customers, colleagues<br />

as well as public administration about our<br />

activities in an appropriate form. On the<br />

pages of this magazine we therefore bring<br />

a detailed view of one of the prospective<br />

production branch. Please make yourselves<br />

familiar with the product range of TEDOM<br />

buses and engines and with our intents in<br />

the field of production of TEDOM trucks.<br />

For myself as well as for my colleagues I can<br />

promise that we are ready to speak with you<br />

about everything what you deem interesting<br />

on the pages of our magazine.<br />

Josef Jeleček,<br />

General Manager of TEDOM, s.r.o.<br />

For TEDOM s.r.o. produced by:<br />

IanDerson Advertising, s.r.o.

The Traditional Czech Brand LIAZ<br />

revives thanks to TEDOM<br />

The Jablonec engine plant of the former car manufacturing<br />

company Liaz successfully produces engines for TEDOM buses.<br />

Production of trucks<br />

based on the last<br />

development project<br />

of Liaz is growing<br />

again. The traditional<br />

Liaz engines whose<br />

history dates back to<br />

1906 have a strong<br />

successor. After<br />

approximately three<br />

years of efforts, the<br />

TEDOM holding<br />

company, having<br />

its headquarters<br />

in Třebíč, the<br />

Bohemian-Moravian<br />

Highlands, managed<br />

to fully revive the<br />

production of the<br />

engines based on<br />

the well-proven Liaz<br />

engine design.<br />

Salvation in the bankruptcy proceedings<br />

The purely Czech company “TEDOM”, whose<br />

annual turnover approaches to 2 billion Czech<br />

crowns purchased the Liaz engine plant for CZK<br />

27 million in 2003. In the situation when this part<br />

of the original Jablonec automotive plant was<br />

undergoing bankruptcy proceedings only a few<br />

people believed that it could still generate a profit<br />

sometimes in the future. Nevertheless, TEDOM<br />

had a clear vision when it entered into the engine<br />

production process. Since 1991 this company<br />

has been successfully dealing with development,<br />

production and sale of the so-called cogeneration<br />

units for the combined generation of electricity and<br />

heat production based on gas piston, combustion<br />

engines. The engine production plant of Liaz<br />

always manufactured just this type of engines,<br />

and thus it seemed to be useful to use especially<br />

their stationary version for an interesting power<br />

engineering branch in which TEDOM has already a<br />

good market position.<br />

“By purchasing the engine production operation<br />

plant we became a manufacturer of gas and<br />

diesel combustion engines as well as a supplier of<br />

original spare parts for all Liaz engines which were<br />

produced in the plant in past,” says Josef Jeleček,<br />

General Manager of TEDOM.<br />

Chance for success<br />

The company gradually started to deal also with the<br />

issue of further development of vehicle applications<br />

of the engines, and it built its core project on the<br />

presumption that it will manage to become one of<br />

the few world manufacturers of buses with its own<br />

gas engine, based on solid foundations of a long<br />

tradition. “We released dozens of millions of Czech<br />

crowns for development, in order not to take over<br />

just the existing know-how of Liaz, but to make<br />

further progress. Thus we currently have four types<br />

of top gas engines and 12 types of diesel engines<br />

in a vehicle version. All of them bear already the<br />

TEDOM brand and stand on the solid foundations<br />

of the Liaz engines,“ stated J. Jeleček. The TEDOM<br />

engines, as he continued, thus form a unified series<br />

of the four-stroke in-line six-cylinder engines with<br />

a power output of 152 to 300 kW in a diesel version<br />

and 152 to 210 kW in a gas version.<br />

Innovations built on tradition<br />

The company has managed to implement also<br />

a project of its own production of road vehicles.<br />

About the company<br />

In 2004, i.e. just one year after the takeover of<br />

the Jablonec engine plant, it presented ( at the<br />

Automotive Trade Fair “Autotec” in Brno) a new<br />

low-floor bus powered with its own, electronically<br />

controlled engine using compressed natural gas<br />

(CNG).<br />

The design of the vehicle was based on the Neoplan<br />

bus with the licence which TEDOM purchased from<br />

the Italian company “Mauri”. By the end of 2006 the<br />

Třebíč-based holding company manufactured and<br />

tested 16 buses. On the testing and perfection of<br />

the vehicles it directly cooperated with the operator<br />

of the city transit services. “The largest portion<br />

of cooperation was borne by ČSAD Liberec and<br />

recently also by ČSAD Semily,” stressed J. Jeleček.<br />

The result is given by the fact that into this year<br />

TEDOM has entered with its own VIN and with an<br />

integrated offer of four buses equipped with engines<br />

using CNG and diesel oil. “At the Automobile Show<br />

in Nitra held this year we will officially introduce a<br />

low-floor low-entry gas-powered bus,” announced<br />

General Manager Jeleček. The firm expects that<br />

still this year it will manage to sell the first five new<br />

low-entry buses and wants to deliver them, under<br />

markedly advantageous conditions again to major<br />

transport companies, with which it will cooperate<br />

again on further optimisation of the vehicle<br />

operation.<br />

The work will however focus also on further<br />

development of the gas engine “TEDOM” which<br />

should lead to the achievement of the emission<br />

limits as low as possible and to further reduction of<br />

fuel consumption. All is prepared by the company<br />

in such a way that it can be possible to apply the<br />

engine modifications to the vehicles in service as<br />

well.<br />

3.

4.<br />

Current news<br />

The TEDOM holding company is growing<br />

The total revenues of TEDOM rose to CZK 1.8 billion last year.<br />

TEDOM is a manufacturer of buses and trucks, a manufacturer<br />

of a complete product range of engines based on the Liaz<br />

engines and at the same time it is an important supplier of<br />

power engineering technologies and operator of the sources for<br />

electricity generation and heat production.<br />

The profit of the TEDOM company for 2006 was<br />

approximately CZK 140 million before taxation.<br />

The share of export in revenues achieved about<br />

30 per cent, which represents approximately<br />

CZK 0.5 billion. The holding company which<br />

was established with exclusively Czech capital<br />

background in 1991, was exporting into 30<br />

countries last year. Among other successes it<br />

managed to penetrate into the American market<br />

with production of gas engines “TEDOM” which<br />

travel through the partner firm “CGP Resources LLC”<br />

from Texas to the market of the U.S.A. and Canada.<br />

The export will continue this year as well. This<br />

concerns specially modified stationary engines,<br />

four-stroke in-line six-cylinder engines which are<br />

designed mainly for the use in the oil industry,<br />

e.g. for compressor and pumping stations or as a<br />

power unit of the hydraulic systems.<br />

But TEDOM is engaged in other countries of Europe as well.<br />

For example in Istanbul and Bursa, Turkey, together with<br />

its contractual partner (Gürbey Mechanics Ltd.) installed,<br />

during the last two years, four cogeneration units which<br />

ensure a trouble-free operation of luxurious hospitals.<br />

At present other joint projects are under preparation<br />

for the Turkish market. The production of co-generation<br />

units is closely interconnected to the development and<br />

production of piston combustion engines. They form<br />

a connection element for TEDOM between its power<br />

engineering division and road vehicle production. In the<br />

field of power engineering, the holding company develops<br />

stationary use of especially gas engines for cogeneration,<br />

while in TEDOM buses and Fox trucks the company follows<br />

up to the development line of the traditional Liaz engines<br />

whose production it purchased and took over, including<br />

production of spare parts for all the types of vehicles<br />

which are still driving with the Liaz engines.<br />

The TEDOM holding company currently employs<br />

more than 700 people in all its divisions. Production<br />

background facilities of the firm are deployed in Třebíč,<br />

the Bohemian-Moravian Highlands, where bus production<br />

is concentrated, in Hořovice, Central Bohemia, where<br />

production of cogeneration technologies is centralised<br />

and in Jablonec nad Nisou, engine production centre.<br />

Apart from the Czech Republic TEDOM operates through<br />

its subsidiaries and business representations also in<br />

Hungary, Latvia, Russia and China.<br />

In terms of ownership structure, TEDOM is traditionally<br />

controlled by Czech capital.<br />

The owners of the holding company are four domestic<br />

natural persons.<br />

Technical innovations will help drivers.<br />

City low-floor buses TEDOM C12G and TEDOM C12D<br />

have undergone, during approximately the last six<br />

months, several principal technical innovations. The<br />

increase in total reliability of gas and diesel oil vehicles,<br />

which took into consideration all the comments<br />

generated from a trial operation, brings an advantage<br />

for the owner and operator and compliance with all<br />

certification requirements.

Also the drivers of both the bus types<br />

should be satisfied. “Even though the<br />

modifications did not affect the general<br />

design of the bus and therefore are not<br />

obvious at first sight , they are essential,”<br />

states Vlado Murár, Marketing Manager of<br />

TEDOM. The firm came up with a complete<br />

renovation of the driver’s workplace during<br />

which there were created four new storage<br />

areas. One of them is situated above the<br />

driver’s head in a lockable box. The second<br />

one can be found by the driver in a form<br />

of a shaped pocket at the door of their<br />

workplace. The third one was designed by<br />

technicians in a form of a pocket integrated<br />

into the cover of the side control panel.<br />

And the fourth storage area is formed by<br />

the cabinet serving for the placement of<br />

the first-aid box in the new dashboard.<br />

Another principal innovation which<br />

is also focused on the driver’s work is<br />

the modification of the blowing of the<br />

windscreen, including the left side window<br />

at the driver’s place and glass in the front<br />

door. The system is currently formed by<br />

new heating channels integrated into the<br />

dashboard, blower and heating with a<br />

capacity of 13 kW.<br />

“The modification finally concerned also<br />

the name of our bus. We have decided to<br />

simplify it and to delete the word “Kronos”,<br />

which referred to the name under which<br />

these vehicles were produced at our<br />

company for the Italian market. That is<br />

why at present all the buses are already<br />

identified in an unambiguous manner as<br />

TEDOM,” added V. Murár.<br />

The manufacturer builds its strategy also on<br />

solid, robust buses.<br />

According to experts, the TEDOM buses are<br />

characterised with one of the longest warranty<br />

periods on the bus market. In the case of<br />

gas engines, the manufacturer guarantees<br />

an eight-year warranty period. The engines<br />

feature a high capacity and dynamics. They<br />

have long servicing intervals set to 40,000 km.<br />

An interesting aspect is also the warranty for<br />

the body frame, where the warranty period is<br />

even 12 years.<br />

The reason for which the manufacturer can<br />

afford such a generous warranty period is the<br />

fact that it trusts in high-quality components<br />

and a robust design of vehicles. It is based<br />

on the use of stainless steel materials as<br />

the main element, which is complemented<br />

with aluminium and plastic materials. In<br />

combination with the perfect workshop<br />

processing it is possible to achieve a reliable<br />

vehicle, which is a counterweight of light,<br />

subtle buses. A robust design furthermore<br />

provides sureness that even in the case of sale<br />

of a used bus from the fleet of the public transit<br />

companies it will be possible to receive good<br />

prices. Stainless steel materials increase the<br />

value of the vehicle which does not decrease<br />

so quickly during operation.<br />

Engines in vehicle versions to be exported<br />

as well.<br />

More than one hundred engines for buses<br />

operated within the City public transport<br />

in Bratislava have been delivered by<br />

TEDOM to Slovakia so far. The public transit<br />

operator in the Capital City of Slovakia is<br />

the largest operator of buses rebuilt to<br />

natural gas power (CNG), and at the same<br />

Current news<br />

time, thanks to the historical links to Czech<br />

suppliers it uses, in a decisive extent, the<br />

Karosa buses in which the original Liaz<br />

(now TEDOM) engines are installed. The<br />

Bratislava operator has 240 Karosa buses.<br />

There are more than one hundred CNG<br />

buses. With regard to the fact that TEDOM<br />

purchased the engine production plant<br />

of Liaz and took over also the production<br />

of spare parts, servicing and overhauls of<br />

the Liaz engines, the cooperation of the<br />

Třebíč-based holding company with its<br />

Slovak partners was initiated just with the<br />

deliveries of overhauls and replacements of<br />

old Liaz engines with new ones, i.e. with the<br />

TEDOM identification. Thanks to the design<br />

follow-up of Liaz and TEDOM, the client<br />

did not have any difficulties with servicing<br />

and did not have to replace servicing tools<br />

or the basic skills of its staff members. Last<br />

year TEDOM exported to Bratislava thirty<br />

CNG engines of its production. This year the<br />

company expects a continuation of exports<br />

to Slovakia. Nevertheless, the number<br />

of foreign contracts will be rising in new<br />

territories as well. The renovations of buses<br />

for CNG engines and overhauls of older<br />

engines are under preparation in Poland.<br />

The export to Rumania, Russia, Baltic<br />

countries and Bulgaria starts to develop,<br />

and TEDOM would like to renovate the<br />

buses serving for transport of inhabitants<br />

of capital cities of these countries for the<br />

CNG technology. The most exotic country<br />

where the TEDOM engines could travel still<br />

this year should be Indonesia.<br />

5.

6.<br />

Production<br />

New plant with top<br />

equipment will employ<br />

200 people within two years<br />

The TEDOM buses have been produced since January in the halls<br />

with top equipment in the middle of the industrial zone in Třebíč. The<br />

company plans to invest altogether CZK 160 million into this new plant.<br />

From this year on, the production of the TEDOM<br />

buses has a generous modern background in<br />

the newly constructed halls in the industrial<br />

zone in Třebíč in the Highlands Region. On<br />

a three-hectare plot of land which was<br />

purchased by the TEDOM holding company<br />

in August 2005, the company constructed a<br />

factory and an administrative building with a<br />

total area of 7,500 square metres during the<br />

last year, in the period from April to October.<br />

These premises currently form the main seat<br />

of the holding company and they include<br />

complete technologies for production of<br />

TEDOM buses. The total capital expenditures<br />

into the plant should achieve CZK 160 million,<br />

which means that it will be one of the most<br />

up-to-date automotive production plants in<br />

the Czech Republic and probably the only<br />

modern factory of this scale owned by purely<br />

Czech capital.<br />

The owners presuppose that during the first<br />

phase the factory whose official operation was<br />

commenced this year in January will produce<br />

approximately 300 buses per year. “This<br />

means that in two years we should employ<br />

approximately two hundred qualified people,”<br />

added Josef Jeleček, General Manager of the<br />

TEDOM holding company.<br />

The production background facilities in the<br />

Třebíč industrial zone resolved the difficulties<br />

of the holding, which were arising with regard<br />

to the fragmented production in Hořovice,<br />

Central Bohemia, and Jablonec nad Nisou,<br />

North Bohemia. “We needed to centralise<br />

all what concerns production of the TEDOM<br />

buses and to increase capacities for their<br />

mass production. For Třebíč we decided after<br />

a proper analysis, and one of the reasons<br />

supporting this decision was the fact that the<br />

parent holding company has had its registered<br />

office there traditionally since 1991 and that<br />

we believed in the skills of local people as well<br />

as in a sufficient supply of qualified labour<br />

on the labour market,“ explained the General<br />

Manager.<br />

TEDOM obtained also an investment incentive<br />

for the construction of the new factory for<br />

buses, which it can draw up to an amount of<br />

CZK 89 million.<br />

Nevertheless, the company will only obtain<br />

this amount in a form of a tax relief after the<br />

completion of the total capital expenditures<br />

planned. This means after completion of the<br />

construction of the entire production facility<br />

which should include, in its final stage, 1.5<br />

hectares of the built-up area. Neither the<br />

operations in Hořovice, where cogeneration<br />

units are manufactured, nor the engine<br />

plant in Jablonec nad Nisou, which is the<br />

centre of the TEDOM Engines division, will<br />

remain abandoned by the company. On the<br />

other hand, extensive capital expenditures<br />

will be fuelled into these divisions as well.<br />

Especially into the machinery equipment<br />

and upgrade of technologies. For example,<br />

the production capacity of the Engines<br />

division was extended last year with the new<br />

machining centre “Deckel-Maho-Gildemeister”<br />

which makes it possible to machine products<br />

with dimensions of metre times metre times<br />

metre. In the Jablonec plant it is thus possible<br />

to use universal machinery equipment for the<br />

production of TEDOM engines, overhauls as<br />

well as liabilities taken over with regard to the<br />

deliveries of spare parts of original engines<br />

“Liaz”. The Jablonec operations furthermore<br />

make it possible to perform the development<br />

and production of the TEDOM trucks, whose<br />

design is based on the last project of the<br />

development centre of the Liaz company and<br />

is ideal for the municipal operation.

Interview<br />

ČSAD Liberec: The buses<br />

were subject to hard tests<br />

at our company<br />

ČSAD Liberec, a.s., is one of the largest passenger carrier in<br />

the Liberec Region. On its regular lines it makes, within the<br />

framework of the public service liability, about four million km<br />

per year, and for several years it has been operating also the<br />

public city transit in Liberec and the surroundings, where it<br />

makes one million km per year.<br />

Since 2004, the<br />

firm has been<br />

cooperating, thanks<br />

to many years<br />

of experience<br />

with an intensive<br />

operation, on the<br />

development and<br />

testing of TEDOM<br />

buses. Interview<br />

about cooperation<br />

with the Head<br />

of the City Public<br />

Transit Division of<br />

ČSAD Liberec, Mr.<br />

Martin Oumrt.<br />

ČSAD Liberec was the first company which decided<br />

to buy the TEDOM bus. What led us to the decision<br />

of buying a product from quite an unknown<br />

manufacturer at that time?<br />

There were several reasons for such a decision. We<br />

considered the design of the low-floor bus with<br />

a platform for the entry of people with impaired<br />

mobility or mothers with baby carriages to be quite<br />

interesting. In our opinion, also the design with a<br />

natural gas power system was interesting because<br />

we want to opt for environment-friendly, statesubsidised<br />

transport.<br />

At present we operate four gas buses from TEDOM<br />

and we do not let them have a rest at all.<br />

Liberec has a filling station for compressed natural<br />

gas and you have a possibility to decide for diesel or<br />

gas drive systems while purchasing a new vehicle.<br />

What are in your opinion the strengths and<br />

weaknesses of gas buses?<br />

I will not deny that the state policy in the support of<br />

the use of natural gas is advantageous for us. If you<br />

buy a gas (i.e. CNG) bus you obtain a modern new<br />

means of transport at which you know that it will pay<br />

in the end thanks to the type of engine and low costs<br />

of maintenance and repairs.<br />

Of course, new vehicles were not free of defects at<br />

the beginning. Did you have also other agreements<br />

with TEDOM, apart from bus contracts, such as<br />

agreements on defect removal or similar? If yes,<br />

how did this cooperation develop?<br />

Apart from the purchase of buses, we have made an<br />

agreement about the handover of knowledge from<br />

the operation of buses. All comments are handed<br />

over to individual responsible persons at TEDOM. It<br />

assesses the same and responsible staff members<br />

suggest changes which are transferred into buses in<br />

a very short term. The cooperation between us and<br />

TEDOM is very useful and is reflected in a continual<br />

improvement of buses, for example platforms for<br />

wheelchair users, driver’s cabins, vibration absorbers,<br />

front axle, bars in the vehicle interior, etc.<br />

Liberec is situated in a rather hilly area. How did the<br />

new buses cope with this complicated operation<br />

profile?<br />

It is true that all buses with an automatic gearbox<br />

must necessarily go here with winter tyres in winter.<br />

But we do not have any problems with the power<br />

output of the TEDOM buses. And we use them twice<br />

more often than other vehicles. This means that they<br />

make about eight thousand km per month and they<br />

can do so without difficulty.<br />

At various discussion forums people often discuss<br />

what the TEDOM buses are actually like. You are<br />

the company which has most experience with their<br />

operation. What characteristics of the TEDOM bus<br />

do you appreciate best?<br />

We surely appreciate their technical standard. It<br />

is excellent that the buses are equipped with an<br />

engine which is based, in terms of design, on the<br />

well-proven concept of Liaz. The frame of the bus is<br />

very modern, the combination of stainless steel and<br />

aluminium minimises the possibility of corrosion.<br />

TEDOM furthermore provides in the basic version<br />

what many other manufacturers provide as abovestandard<br />

configurations only. E.g. the vehicle height<br />

control system, known as ECAS. An advantage is<br />

also formed by an eight-year warranty period for the<br />

engine, or alternatively the mileage of 400,000 km.<br />

This is also four times more than the values offered<br />

by competitors. Of course, we like the low floor of the<br />

bus and the entry platform, i.e. the aspects which will<br />

be appreciated by passengers.<br />

Could you sum up at the end, whether you consider<br />

the purchase of other TEDOM vehicles after the<br />

existing experience?<br />

Our company will organise a tender for procurement<br />

of low-floor CNG buses very soon and we expect the<br />

TEDOM company to take part in this tender.<br />

7.

8.<br />

Truck<br />

The truck production<br />

revival project is starting<br />

The TEDOM Truck company became last year the successor and<br />

continuator of the traditional production of trucks after the Jablonecbased<br />

Liaz automotive company which was wound up, but for the<br />

time of its existence produced almost 350,000 vehicles.<br />

The TEDOM Holding<br />

company, which has<br />

managed to save, during<br />

the last three years,<br />

the production of the<br />

traditional Liaz engines<br />

and to follow up to it<br />

by means of its own<br />

development of engines<br />

and construction of buses,<br />

initiates a similar project<br />

of revival also<br />

for production of trucks<br />

after the Liaz company<br />

wound up.<br />

Since last year there has been a separate<br />

subsidiary known as “TEDOM Truck, s.r.o.” with a<br />

registered office in Jablonec nad Nisou, which<br />

purchased all the rights for production of<br />

trucks of the 300 and 400 series, including the<br />

documentation, technologies and production<br />

equipment. The last truck under the Liaz brand<br />

was manufactured in September 2003. “We are<br />

the only lawful successor of the production of<br />

vehicles designed on the basis of the design<br />

documentation from Liaz. The core programme<br />

is production and development of Czech trucks,”<br />

said Martin Macík, Executive Head of TEDOM<br />

Truck.<br />

The firm which maintains its background<br />

facility in Jablonec nad Nisou, is currently a<br />

manufacturer of trucks known as TEDOM. Its<br />

product range is currently formed, including<br />

superstructure variants, altogether by 22 trucks.<br />

The design of the TEDOM trucks is based on<br />

the last project of the development centre of<br />

the Liaz automotive company, which however<br />

was unable to implement it before it has been<br />

wound up. Now TEDOM Truck wants, according<br />

to M. Macík, to continue in the tradition of the<br />

high reputation of production of Czech trucks<br />

and to supply to the market a reliable comfort<br />

truck designated for a wide range of use in<br />

municipal operations.<br />

“The trucks manufactured by our company<br />

TEDOM-G TEDOM-D<br />

which we have been newly producing since<br />

last year bear the TEDOM-D and TEDOM-G<br />

identifications and it is typical of them that<br />

they combine a long lifetime of the completely<br />

galvanised chassis frames with the possibility of<br />

an easy installation of almost any superstructure,<br />

comfortable cabin with a long lifetime of the<br />

aluminium-composite design and a possibility<br />

of incorporation of virtually any driving unit from<br />

world manufacturers of engines,“ explained the<br />

Engines Division Director, Mr. Vlastimil Vildman.<br />

The fact that the actual design of the chassis<br />

platform is adapted for an easy installation and<br />

use of any superstructure, such as a firm or tilting<br />

body, self-collection system, spreading and<br />

sub-base system body, tank vehicle, municipal<br />

waste superstructure and others, should form,<br />

according to the TEDOM Truck management,<br />

a basis for the possibility of sale of the TEDOM<br />

vehicles on the domestic market. An essential<br />

role should be played also by the fact that the<br />

production programme includes also trucks<br />

using an alternative fuel – natural gas. In the<br />

future it is expected that the TEDOM holding<br />

could provide a comprehensive solution for<br />

the situation of communities and towns in the<br />

transition of the city public transit system and<br />

municipal services to natural gas, as Vlastimil<br />

Vildman, a partner in the TEDOM Holding<br />

company says.<br />

Pressure cylinders for compressed natural gas on the TEDOM vehicle.

Outlook into the future<br />

The development of gas engines for TEDOM buses continues.<br />

TEDOM focuses especially<br />

on the development<br />

and production of gas<br />

engines which it uses<br />

for its own cogeneration<br />

units and for municipal<br />

and prepared intercity<br />

buses. We asked Jiří Piller,<br />

Designer of the TEDOM<br />

engines, to describe<br />

the latest news on the<br />

development workplaces<br />

and in the engine testing<br />

room.<br />

In the design for the automotive industry the<br />

company offered in the past a version of the<br />

CNG engine with a simple method of control<br />

and mixing. On the basis of the continually<br />

increasing requirements relating to the decrease<br />

in emission limits, a decision was made about<br />

the development of the new design of the<br />

CNG engine with a full engine management<br />

system, because only an engine controlled<br />

this way is capable of mastering not only the<br />

requirements on emission limit reduction, but<br />

also the requirements concerning the engine<br />

control within the entire operating range. The<br />

development of this engine (marked as TG 210<br />

AH TA 04) started in autumn 2003. And already<br />

at the beginning of June 2004, the engine<br />

was successfully certified from the viewpoint<br />

of emissions according to the limits “EURO 4”.<br />

At the same time the first bus into which this<br />

engine was incorporated was completed. After<br />

driving tests and approval, the bus was put into<br />

operation at the beginning of 2005.<br />

In the years 2005 and 2006, the main part of<br />

the development of the engine in the vehicle<br />

was taking place, which meant especially the<br />

knowing of an operation reliability from the<br />

viewpoint of the components used, both for<br />

the gas installation of the engine and the parts<br />

of the engine management.<br />

The result of the development in this period is<br />

given by certain structural changes in favour of<br />

Bus<br />

the company and functionality. The area of the<br />

control of the engine management underwent<br />

some modification especially in the form of a<br />

change in software and communication with<br />

control elements of the vehicle. Together with<br />

the development in the vehicle there continued<br />

various work in the engine testing room, in<br />

particular the verification of the change in the<br />

components designed, as well as preparatory<br />

work on the new version of the engine.<br />

At the beginning of 2007, there were<br />

commenced the tests of the version of the<br />

engine for the compliance with the future<br />

limits EURO 5 and EEV. Successful fulfilment of<br />

these requirements represents certain design<br />

changes and changes in the method of engine<br />

control. This version of the engine presupposes<br />

two capacity levels, 210 and 245 kW. The tests<br />

focused on verification of the changes in the<br />

components designed continues.<br />

The core point of the work consisting in the tests<br />

of the engine in the vehicle was transferred into<br />

the tests whose aim is to reduce the operation<br />

consumption of fuel. These tests will serve as<br />

a basis for the treatments and settings of the<br />

driving regimes of the vehicle, both in the<br />

control unit of the gearbox and in the control<br />

unit of the engine. The reliability and function<br />

tests will continue.<br />

9.

10.<br />

Interview<br />

We are using the 15 years<br />

of our experience with<br />

stationary engines . . .<br />

. . . says Drahomír Jeleček, Technical Director.<br />

The TEDOM brand is a<br />

newcomer on the Czech<br />

market of road vehicle.<br />

Mr. Drahomír Jeleček,<br />

Production and Technical<br />

Director, however stresses<br />

in his interview that<br />

the word “new” does<br />

not mean the same as<br />

“inexperienced”.<br />

It is clear that the TEDOM buses did not<br />

arise somewhere in a home workshop and<br />

overnight. But still they featured a relatively<br />

fast start into operation. Could you explain<br />

this situation, please?<br />

TEDOM is a new entrant among the bus<br />

manufacturers, it is true, but it has long years<br />

of experience with gas engines because it<br />

uses them for its cogeneration units. We have<br />

produced more than 1500 applications of<br />

these technologies since 1991, and we are<br />

selling them to more than 30 countries of all<br />

the world. We were using the Liaz engines,<br />

whose production we purchased in the<br />

spring 2003, for long years for the drive of<br />

cogeneration units and we co-participated in<br />

their development as well. From the purchase<br />

of the engine production plant, there was<br />

only a small step to the finishing of the<br />

development of the electronically controlled<br />

gas engine and for the purchase of the Italian<br />

licence for bus production. Buses for the<br />

Italian client (for the Mauri company) were<br />

manufactured in the Czech Republic already<br />

in previous years. TEDOM performed design<br />

modifications on them, necessary for the inbuilding<br />

of a new engine and for operation in<br />

the Czech Republic. In the case of our buses<br />

thus the matter concerns a vehicle which is<br />

well-proven in the operation and is equipped<br />

with well-proven Czech engines which are<br />

based on the last type of LIAZ M1.2C.<br />

How does the structure of the vehicle look<br />

now, after three years of perfection? How<br />

is it like from your, i.e. technician’s point of<br />

view?<br />

The structure of the bus is formed by thin-wall<br />

stainless steel profiles, the shell is formed by<br />

aluminium sheet, the roof (including the front<br />

and rear faces) is made of fibreglass. We have<br />

selected these materials intentionally in order<br />

to guarantee a long lifetime of the buses for<br />

the carriers, and thereby also savings with<br />

regard to possible repairs. The bus in a gas<br />

version is powered with a new, modern, gas,<br />

electronically controlled engine “TEDOM”<br />

with the exact dispensing of natural gas to<br />

individual suction valves. In the diesel oil<br />

version we offer well-proven engines usual<br />

for such buses as Iveco Cursor or Renault and<br />

complying with the Euro 4 emission limits.<br />

We are also able to offer a limited quantity of<br />

vehicles with a TEDOM diesel engine with the<br />

Euro 3 emission limits.<br />

The in-line vertical water-cooled six-cylinder<br />

engine with a capacity of 12 litres is installed in<br />

the left rear part. The engine is supercharged<br />

by a turbocharger and its power output<br />

is 210 kW. The gearbox is fully automatic,<br />

with a torque changer and with an in-built<br />

retarding system. Three or four pressure<br />

composite tanks with an aluminium core<br />

and with a total volume of 960 to 1280 litres<br />

are installed on the roof of the bus, under an<br />

aerodynamic cover, and they provide a bus<br />

operating range of 450 to 650 km. Fuel is<br />

replenished through an easy accessible filling<br />

flare.<br />

And what about the comfort of travellers,<br />

what can be perceived also by a nonprofessional<br />

passenger?<br />

Passengers are sure to appreciate the large lowfloor<br />

area without any steps and stairs, as well<br />

as the wide glazed door. We have furthermore<br />

equipped the vehicle with a special platform<br />

for the entry of people with impaired mobility<br />

and mothers with baby carriages. The floor is<br />

coated with an anti-skidding PVC cover which<br />

increases the safety when people are moving<br />

inside the vehicle. For the purpose of holding,<br />

the bus is equipped with classical grab handles<br />

and suspension attachments. For summer<br />

operation it is also important to have a<br />

ventilation regulation system. The upper parts<br />

of windows can therefore be opened easily,<br />

the roof window is controlled electrically,<br />

from the driver’s workplace. What is less easy<br />

to see but what also increases the comfort of<br />

passengers is the ECAS electronic system. It<br />

controls the height of the vehicle and allows<br />

its tilting for an easier entry and exit. A diligent<br />

observer is sure to have noticed it. I suppose<br />

that also the attractive design of our buses<br />

will be perceived positively already at first<br />

sight. It is based on the Italian modification<br />

of the original design of NEOPLAN, and<br />

our cooperation with the Italian designers<br />

continues also for the development of other<br />

types of buses.

A bus on trial?<br />

Why not!<br />

TEDOM has been cooperating during<br />

production and upgrading of buses with<br />

large as well as small operators already for<br />

the third year. This year, like in previous years,<br />

it will again offer various services exceeding<br />

the usual standard in a form of free lending<br />

of vehicles. This is followed up by a possibility<br />

that the customer purchases a trial vehicle<br />

and by doing so it will obtain a significant<br />

discount. The delivery terms for the handover<br />

of buses are currently four months only, and<br />

the manufacturer wants to keep this fast rate.<br />

An essential factor is also that TEDOM does<br />

not “abandon” its buses after they have left the<br />

gates of the plant, but is able to offer various<br />

levels of assistance services at guaranteed<br />

prices for 1 kilometre or operating hour. The<br />

assistance services may include the entire<br />

range of possibilities – from the training of<br />

assistance staff of the operator and delivery<br />

of spare parts within 24 hours up to the fullrange<br />

servicing, including e.g. the delivery of<br />

tyres, fuels and lubricants.<br />

We offer<br />

In the case of your interest in this service please call +420 568 837 232 or write to obchod@bus.tedom.cz<br />

The care for customers<br />

does not end with the<br />

handing over of the bus<br />

From this year on, the operators of the TEDOM<br />

buses have a possibility of using extended<br />

assistance services of the manufacturer. Apart<br />

from the dispatching centre, which deals<br />

with the registration of all requirements of<br />

our clients on a standard basis, deals with<br />

complaints and assistance servicing, the bus<br />

operators can use also two service centres of<br />

TEDOM in Třebíč and in Jablonec nad Nisou.<br />

“These specialised centres of our company are<br />

followed up by contractual service stations.<br />

Through them we ensure the coverage within<br />

the framework of the entire Czech Republic“,<br />

says Jozef Tuza, Operation Director of TEDOM<br />

and states that after-sale servicing is a matterof-course<br />

as far as the care for customers is<br />

concerned.<br />

The structure of the service department<br />

includes, apart from the dispatching centre,<br />

servicing specialists and contractual service<br />

stations, also the technical sections. This<br />

section deals, according to J. Tuza, with<br />

training, technical documentation, advisory<br />

services, technical support and possibly also<br />

distribution of spare parts. “The key task of the<br />

section is also the evaluation of defects and<br />

comments from operation and their feedback<br />

to the design and production departments. In<br />

other words, also our designers and production<br />

staff members know everything what happens<br />

with our buses,“ stressed J. Tuza.<br />

What is modified, changed or innovated on<br />

the TEDOM buses from the design point of<br />

view is subsequently in turn announced by the<br />

firm towards external parties, to the network<br />

of service stations and servicing centres,<br />

operators. The staff members of TEDOM’s own<br />

service centres furthermore make trips to<br />

service centres in order to perform there their<br />

service interventions to which the contractual<br />

service centre may not be authorised or<br />

equipped.<br />

“In general, however, it is true that for repairs<br />

and maintenance of the TEDOM buses it is<br />

sufficient to have tools, aids and diagnostic<br />

equipment which are used for the equipment<br />

of ordinary service stations for repairs of trucks<br />

and buses. No special equipment is required, “<br />

assured the Marketing Manager. TEDOM will<br />

maintain this advantage for its buses on a<br />

long-term basis.<br />

11.

LONG<br />

LIFETIME<br />

BODY<br />

The TEDOM buses have<br />

undergone a number of tests<br />

and trials in the demanding climatic<br />

conditions of the Jizerské Mountains<br />

and succeeded in both winter<br />

months and in the hot summer<br />

HIGH CAPACITY<br />

OF PASSENGER<br />

TRANSPORT<br />

BRAND<br />

DIESEL ENGINES<br />

in the centre of the towns.<br />

ECONOMICAL<br />

ENGINES RUN ON<br />

NATURAL GAS<br />

The heart of the buses is formed<br />

by the newly developed TEDOM engine<br />

combusting compressed natural gas.<br />

TEDOM s.r.o.<br />

Výčapy 195, 674 01 Třebíč<br />

Czech Republic<br />

QUIET<br />

OPERATION<br />

COST-EFFICIENT<br />

OPERATION<br />

BARRIER-FREE<br />

ACCESS<br />

tel.: +420 568 837 211<br />

fax.: +420 568 837 215<br />

ENVIRONMENT-FRIENDLY OPERATION<br />

The TEDOM buses form a new type<br />

of environment-friendly city low-oor buses,<br />

complying with all the demands imposed<br />

on modern means of transport.<br />

QUALITY<br />

BRANDS<br />

ASSISTANCE<br />

SERVICE 24 HOURS<br />

8-YEAR WARRANTY<br />

PERIOD<br />

FOR GAS ENGINE<br />

INFORMATION<br />

SERVICES<br />

A rm structure made of stainless-steel,<br />

aluminium and plastic materials ensures<br />

a long lifetime and cost-eciency<br />

connected with the operation.<br />

Annual savings achieved by the TEDOM<br />

bus oscillate in a magnitude of hundreds<br />

of thousands of Czech crowns.<br />

email: tedom@tedom.cz<br />

www.tedom.cz