Prisma Plus PH System - Schneider Electric

Prisma Plus PH System - Schneider Electric

Prisma Plus PH System - Schneider Electric

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Low Voltage electrical distribution<br />

<strong>Prisma</strong> <strong>Plus</strong><br />

<strong>PH</strong> <strong>System</strong><br />

Catalogue<br />

2010

General contents Contents<br />

Contents<br />

401F_E0010TDM.indd<br />

Presentation<br />

General presentation<br />

<strong>Electric</strong>al switchboards 2<br />

up to 3200A 2<br />

Characteristics 4<br />

The forms according to IEC 61439-2 5<br />

Catalog numbers<br />

Functional units<br />

Switchgears 6<br />

Distribution<br />

Horizontal busbars 7<br />

up to 1600A 7<br />

Lateral Linergy busbars 10<br />

up to 1600A 10<br />

Lateral flat busbars 12<br />

up to 1600 A 12<br />

up to 3200 A 14<br />

Form 2 partitioning 16<br />

Form 3 partitioning 20<br />

Enclosures<br />

Cubicles, frameworks 21<br />

IP55 cover panels 23<br />

Plinth, gland plates 24<br />

Accessories 25<br />

Dimensions<br />

Cubicles 26<br />

version: 1.0 - 06/2010<br />

1

Index<br />

Index<br />

Index<br />

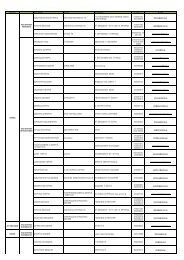

Cat. no. Designation Module<br />

03000<br />

03583 Universal angle brackets (6) 401E22905/6<br />

04000<br />

04502 Linergy vertical busbar, 630 A 401E22215/2<br />

04503 Linergy vertical busbar, 800 A 401E22215/2<br />

04504 Linergy vertical busbar, 1000 A 401E22215/2<br />

04505 Linergy vertical busbar, 1250 A 401E22215/2<br />

04506 Linergy vertical busbar, 1600 A 401E22215/2<br />

04516 Vertical busbar with holes, 60x5mm 401E22315/2<br />

04518 Vertical busbar with holes, 80x5mm 401E22315/2<br />

04525 Vertical busbar with holes, 50x10mm 401E22315/4<br />

04526 Vertical busbar with holes, 60x10mm 401E22315/4<br />

04528 Vertical busbar with holes, 80x10mm 401E22315/4<br />

04536 Horizontal busbar without holes, 60x5mm 401E22110/1<br />

04538 Horizontal busbar without holes, 80x5mm 401E22110/1<br />

04545 Horizontal busbar without holes, 50x10mm 401E22110/3<br />

04546 Horizontal busbar without holes, 60x10mm 401E22110/3<br />

04548 Horizontal busbar without holes, 80x10mm 401E22110/3<br />

04550 Horizontal busbar without holes, 100x10mm 401E22110/3<br />

04634 Connection plate for 5mm horizontal bar to lateral Linergy busbar, 1000A 401E22215/3<br />

04635 Connection plate for 5mm horizontal bar to lateral Linergy busbar, 1600A 401E22215/3<br />

04636 Connection plate for 10mm horizontal bar, 1600A 401E22215/3, 401E22315/5<br />

04637 Connection plate for 10mm horizontal bars to vertical flat bar, 3200A 401E22315/5<br />

04640 Joint for 50/60mm horizontal busbars 401E22110/1, 401E22110/3<br />

04641 Joint for 80/100mm horizontal busbars 401E22110/1, 401E22110/3<br />

04642 Mounting hardware for joint > 80mm 401E22215/3, 401E22315/5<br />

04645 20 screws for vertical / horizontal busbars connections 401E22315/3<br />

04651 Support for lateral vertical Linergy busbars 401E22215/3<br />

04662 Free support for 5/10mm busbars 401E22110/1, 401E22110/3, 401E22315/2,<br />

401E22315/4<br />

04664 Support for 5/10mm horizontal busbars 401E22110/1, 401E22110/3<br />

04671 Support mounting hardware for bars > 80mm 401E22110/3<br />

04678 5/10 mm busbar free support, 115 mm spacing 401E22315/2, 401E22315/4<br />

04901 Form 3 horizontal partition 401E22905/6<br />

04911 Inter-cubicle partition, D = 400 mm 401E22905/4<br />

04924 Form 2 restoration kit for side barrier cut-out 401E22905/3<br />

04943 Rear support for Form 3 partition 401E22905/6<br />

04955 Form 3 vertical partition for rear connection, 3 or 4 modules 401E22905/6<br />

04956 Form 3 vertical partition for rear connection, 5 or 6 modules 401E22905/6<br />

06000<br />

06461 20 bolts, M6 401E23120/2<br />

06501 2 uprights H2000 401E23110/2<br />

06502 2 adaptated uprights H2000 401E23110/2<br />

06503 2 uprights+intermediary H2000 401E23110/2<br />

06512 2 frames + roof W300 D500 401E23110/2<br />

06513 2 frames + roof W300 D800 401E23110/2<br />

06514 2 frames+ roof + flange W700 D500 401E23110/2<br />

06515 2 frames+ toit + flange W700 D800 401E23110/2<br />

06522 Plain door W300 401E23110/4<br />

06524 Plain door W700 401E23110/4<br />

06525 Transparent door W700 401E23110/4<br />

06533 Rear panel W300 401E23110/4<br />

06535 2 side panels D500 401E23110/4<br />

06537 Rear panel W700 401E23110/4<br />

06538 2 side panels D800 401E23110/4<br />

06540 Form 2 front back barrier W300 401E22905/4<br />

06543 Form 2 side barrier ext. to D800 401E22905/3<br />

06545 Side barrier form 2 D500 401E22905/3<br />

06555 Inter-cubicles cover D500 401E22905/4<br />

401F_E0012TDM.indd version: 1.0 - 05/2010<br />

1

Index<br />

Index<br />

Index<br />

Cat. no. Designation Module<br />

06560 Form 2 horiz. cover W300 D500 401E22905/5<br />

06563 Form 2 horz. cover W300 D500+300 401E22905/5<br />

06570 Form 2 horz. cover W700 D500 401E22905/5<br />

08000<br />

08566 Front plate support frame, W=650mm 401E23110/3<br />

08911 Earthing wire, 6mm² 401E23120/2<br />

NSY<br />

NSYAS500 Bottom support for lateral vertical busbar D500 401E22315/2, 401E22315/4<br />

NSYAS800 Bottom support for lateral vertical busbar D800 401E22315/2, 401E22315/4<br />

NSYAS800L Bottom support for lateral vertical busbar D800, 115mm spacing 401E22315/2, 401E22315/4<br />

NSYBHS500 Horizontal busbar support W300, D500 401E22110/1, 401E22110/3<br />

NSYBHS800 Horizontal busbar support W300, D800 401E22110/1, 401E22110/3<br />

NSYBHS800L Horizontal busbar support D800, 115mm spacing 401E22110/1, 401E22110/3<br />

NSYBVS500 Vertical lateral busbar support D500 401E22315/2, 401E22315/4<br />

NSYBVS800 Vertical lateral busbar support D800 401E22315/2, 401E22315/4<br />

NSYBVS800L Vertical lateral busbar support D800, 115mm spacing 401E22315/2, 401E22315/4<br />

NSYEC351 Entry cable gland plate W300 D500 401E23110/5<br />

NSYEC381 Entry cable gland plate W300 D800 401E23110/5<br />

NSYEC751 Entry cable gland plate W700 D500 401E23110/5<br />

NSYEC781 Entry cable gland plate W700 D800 401E23110/5<br />

NSYEL166D8 Earthing lead, 6mm² section, 160mm length, 8.3mm terminal 401E23120/2<br />

NSYEL3525D8 Earthing lead, 25mm² section, 350mm length, 8.3mm terminal 401E23120/2<br />

NSYSFBK19 Swing 19" rack coupling kit 401E23110/3, 401E23120/2<br />

NSYSFEB 4 lifting eyes M12 401E23120/2<br />

NSYSFELB 4 lifting brackets 401E23120/2<br />

NSYSPF3100 Front plinth 100x300 401E23110/5<br />

NSYSPF3200 Front plinth 200x300 401E23110/5<br />

NSYSPF7100 Front plinth 100x700 401E23110/5<br />

NSYSPF7200 Front plinth 200x700 401E23110/5<br />

NSYSPS5100 2 Plinth side panels 100x500 401E23110/5<br />

NSYSPS5200 2 Plinth side panels 200x500 401E23110/5<br />

NSYSPS8100 2 Plinth side panels 100x700 401E23110/5<br />

NSYSPS8200 2 Plinth side panels 200x700 401E23110/5<br />

2<br />

version: 1.0 - 05/2010 401F_E0012TDM.indd

PD391265b_SE<br />

PD391266b_SE<br />

PD391267b_SE<br />

General presentation <strong>Electric</strong>al switchboards<br />

up to 3200A<br />

Presentation<br />

The <strong>Prisma</strong> <strong>Plus</strong> functional<br />

system<br />

2<br />

PD391264b_SE<br />

The <strong>Prisma</strong> <strong>Plus</strong> functional system can be used for all types of low-voltage<br />

distribution switchboards (main, subdistribution and final) up to 3200 A, in<br />

commercial and industrial environments.<br />

Switchboard design is very simple:<br />

A metal structure<br />

The switchboard is made up of one or more frameworks combined side-by-side or<br />

back-to-back, on which a complete selection of cover panels and doors can be<br />

mounted.<br />

A distribution system<br />

Horizontal busbars or vertical busbars positioned in a lateral compartment or at the<br />

rear of the cubicle are used to distribute electricity throughout the switchboard.<br />

Complete functional units<br />

Each device is part of a functional unit comprising:<br />

b dedicated mounting plate for device installation<br />

b front plate to block direct access to live parts prefabricated busbar connections<br />

b<br />

devices for on-site connections.<br />

Each functional unit contributes to a function in the switchboard. The functional units<br />

are modular and are arranged rationally, one on top of another, within the enclosure.<br />

The system includes everything required for functional unit mounting, supply and<br />

onsite connection. The components of the <strong>Prisma</strong> <strong>Plus</strong> system and those of the<br />

functional units in particular have been designed and tested taking into account<br />

device characteristics. This design approach ensures a high degree of reliability in<br />

system operation and optimum safety for personnel.<br />

version: 1.0 - 06/2010 401F_E10020.indd

PD391269b_SE<br />

PD391270b_SE<br />

PD391271b_SE<br />

General presentation <strong>Electric</strong>al switchboards<br />

up to 3200A<br />

Presentation<br />

Advantages of <strong>PH</strong> system<br />

switchboards<br />

PD391268b_SE<br />

A safe electrical installation<br />

The total compatibility of <strong>Schneider</strong> <strong>Electric</strong> devices with the <strong>PH</strong> system is a key<br />

advantage in ensuring a high level of installation dependability.<br />

An upgradeable electrical installation<br />

Thanks to modular design, <strong>PH</strong> switchboards can be modified easily to integrate new<br />

functional units as needed. Maintenance operations, carried out with the<br />

switchboard de-energised, are fast and straight-forward due to easy access to<br />

devices.<br />

Total safety for personnel<br />

Work in a switchboard must be carried out by authorised persons in compliance with<br />

all applicable safety regulations. To increase the safety of personnel, devices are<br />

installed behind protective front plates; only the operating handles are accessible.<br />

Additional internal protection (partitions, barriers) is available to create form 2 or 3<br />

separation to protect against direct contacts with live parts.<br />

Terminal shields are mandatory for installation of Compact NSX and INS/INV<br />

devices in <strong>PH</strong> system enclosures.<br />

<strong>Electric</strong>al switchboards built using the <strong>Prisma</strong> <strong>Plus</strong> functional system and<br />

<strong>Schneider</strong> <strong>Electric</strong> recommendations fully comply with international standard<br />

IEC 61439-2.<br />

401F_E10020.indd version: 1.0 - 06/2010<br />

3

General presentation<br />

Presentation<br />

4<br />

PD391272b_SE<br />

Characteristics<br />

<strong>Electric</strong>al characteristics<br />

Use of the components in the <strong>Prisma</strong> <strong>Plus</strong> functional system ensures the creation of<br />

switchboards complying with standards IEC 50298, EN 50298, IEC 61439-2 and<br />

EN 61439-2, as well as local versions with the following electrical characteristics:<br />

b rated insulation level of main busbars: 1000 V<br />

b rated operational current Ie: 3200 A<br />

b rated peak withstand current Ipk: 187 kÂ<br />

b rated short-time withstand current Icw: 85 kA rms/1 second<br />

b frequency: 50/60 Hz.<br />

Mechanical characteristics<br />

b Steel sheet metal.<br />

b Electrophoresis treatment + hot-polymerised polyester epoxy powder.<br />

b White colour RAL 9001.<br />

b Can be dismantled.<br />

b Can be combined side-by-side and back-to-back.<br />

b Degree of protection: IP55.<br />

b Degree of protection against mechanical impacts: IK10 with door.<br />

b Framework dimensions:<br />

v two widths:<br />

- W 300: cable compartment<br />

- W 700: device compartment or cable compartment<br />

v two depths: 500, 800 mm<br />

v height: 2000 mm<br />

b Indoor cubicles.<br />

version: 1.0 - 06/2010 401F_E10020.indd

E33522<br />

E33523<br />

General presentation<br />

Presentation<br />

Decisions concerning the Form of separation and the<br />

degree of protection are the subject of an agreement<br />

between the manufacturer and the user.<br />

Form 2b.<br />

Form 3b.<br />

The forms according<br />

to IEC 61439-2<br />

In most installations, <strong>Prisma</strong> <strong>Plus</strong> cubicles do not require partitioning. In this case,<br />

the switchboard is a Form 1.<br />

Safety being one of its foremost goals, <strong>Schneider</strong> <strong>Electric</strong> offers options and features<br />

that go well beyond the recommendations of the standard.<br />

The protection of life and property is a standard feature due to:<br />

b front plates that require a tool to be removed<br />

b keylocks on doors, some of which provide access to live parts<br />

b the systematic installation of terminal shields on Compact NSX circuit breakers<br />

and Interpact INS and INV switch-disconnectors<br />

b covering of the upstream and downstream terminals on the incoming device so<br />

that operators are perfectly safe at all points in the switchboard when the incoming<br />

device is off (open).<br />

What is more, <strong>Prisma</strong> <strong>Plus</strong> offers different levels of partitioning to create separations<br />

inside the cubicles and thus create Form 2, 3 electrical switchboards.<br />

<strong>Electric</strong>al switchboards must meet the degree of protection IP2X to comply with<br />

standard IEC 61439-2<br />

Form 2<br />

<strong>PH</strong> <strong>System</strong> offers Form 2 cubicles<br />

It is a physical separation of horizontal, vertical busbars from the functional units,<br />

complying with standard IEC 61439-2<br />

Form 3b<br />

<strong>PH</strong> <strong>System</strong> offers Form 3b cubicles. They are achieved by separating from one<br />

another the functional units of a Form 2 switchboard.<br />

Device must be equipped of downstream terminal shields.<br />

401F_E10020.indd version: 1.0 - 06/2010<br />

5

DD384395<br />

Functional units<br />

Catalogue numbers<br />

Intermediaire uprights.<br />

2<br />

Switchgears<br />

Upgraduable <strong>Prisma</strong> <strong>Plus</strong> functional units<br />

Functional units include switchgear mounting plates, front plates, connectors,<br />

connections, connection supports, barriers...<br />

Switchgear Cat. no.<br />

Masterpact NW 08 to NW 32 400E21100<br />

Masterpact NT 06 to NT 16 400E21110<br />

Compact NS up to 1600 400E21120<br />

Compact NS from 630 to 1600 400E21130<br />

Compact NSX up to 630 400E21150<br />

Interpact INS-INV250-630 400E21200<br />

Interpact INS-INV630-2500 400E21210<br />

Source changeover systems Compact/Masterpact 400E21160<br />

Source changeover systems Interpact INS 400E21250<br />

Acti 9 400E21400<br />

Accessories 400E21500-<br />

400E21600<br />

version: 1.0 - 06/2010 401F_E21000.indd

DD384396<br />

DD384397<br />

DD384398<br />

Distribution<br />

Catalogue numbers<br />

The bars are secured by insulated supports attached to<br />

the framework.<br />

The tables opposite indicate:<br />

b the number and size of the bars to be used,<br />

depending on the permissible current level in the<br />

busbars<br />

b the number of busbar supports for each type of<br />

framework, depending on:<br />

v the size of the busbars<br />

v the rated short-time withstand current Icw.<br />

For more information on busbar calculations, see<br />

DESW016.<br />

The modularity of the busbar is 3 modules.<br />

Fixed support and free support.<br />

Joints.<br />

NYBSHS500<br />

DD381226<br />

Horizontal busbars<br />

Up to 1600 A<br />

Flat copper bars 5 mm thick<br />

Busbar calculation<br />

Number and size of copper busbars<br />

Permissible current (A) No. of bars/phase<br />

IP55<br />

750 1 bar 60 x 5<br />

900 1 bar 80 x 5<br />

1250 2 bars 60 x 5<br />

1600 2 bars 80 x 5<br />

Note: the permissible current values for the busbars are given for an ambient temperature of<br />

35 °C around the switchboard.<br />

Number of supports<br />

Framework width Size of bars (mm) No. of supports lcw (kA rms/1 s)<br />

(mm)<br />

y 15 y 25 y 30 y 40 y 50<br />

W 700 mm 1 bar 60 x 5<br />

1 bar 80 x 5<br />

2 bars 60 x 5<br />

2 bars 80 x 5<br />

2 3<br />

W 300 mm All sizes 1 2<br />

Busbar selection<br />

Flat busbars, W 2000 mm<br />

Designation Cat. no.<br />

Copper bar without holes, 60 x 5 04536<br />

Copper bar without holes, 80 x 5 04538<br />

Busbar supports<br />

Two fixed supports for 700 mm wide frameworks and one fixed support for 300 mm<br />

wide frameworks are mandatory. If more supports are required, use free supports.<br />

Designation Cubicle W 700 Cubicle W 300<br />

D 500 D 500 D 800<br />

Distance between busbar centres 75 75 75<br />

Fixed support for horizontal bars 04664 NSYBHS500 NSYBHS800<br />

Free support (additional) 04662 04662 04662<br />

04664 04662<br />

Joints<br />

Designation Cat. no.<br />

1 joint for bars W 60 mm 04640<br />

W 80 mm 04641<br />

Note: when installed at the bottom of cubicles, the busbars must be partitioned, see<br />

page 401F22905.indd/2.<br />

401F_E22110.indd version: 1.0 - 06/2010<br />

1<br />

DD381225

DD384396<br />

Distribution<br />

Catalogue numbers<br />

The bars are secured by insulated supports attached to<br />

the framework.<br />

The tables opposite indicate:<br />

b the number and size of the bars to be used,<br />

depending on the permissible current level in the<br />

busbars<br />

b the number of busbar supports for each type of<br />

framework, depending on:<br />

v the size of the busbars<br />

v the rated short-time withstand current Icw.<br />

For more information on busbar calculations, see<br />

DESW016.<br />

The modularity of the busbar is 3 modules.<br />

2<br />

Horizontal busbars<br />

Up to 3200 A<br />

Flat copper bars 10 mm thick<br />

Busbar calculation<br />

Number and size of copper busbars<br />

Permissible current (A) No. of bars/phase<br />

IP55<br />

1080 1 bar de 50 x 10<br />

1250 1 bar de 60 x 10<br />

1600 1 bar de 80 x 10<br />

1850 2 bars de 50 x 10<br />

2000 2 bars de 60 x 10<br />

2500 2 bars de 80 x 10<br />

2900 2 bars de 100 x 10<br />

Note: the permissible current values for the busbars are given for an ambient temperature of<br />

35 °C around the switchboard.<br />

Number of supports (distance between centres: 75 mm)<br />

Framework width<br />

(mm)<br />

Size of bars<br />

(mm)<br />

No. of supports Icw (kA rms/1 s)<br />

y 25 y 30 y 40 y 50 y 60 y 65 y 75 y 85<br />

W 700 mm 1 bar de 50 x 10<br />

1 bar de 60 x 10<br />

1 bar de 80 x 10<br />

3<br />

4<br />

2 bars de 50 x 10<br />

2 bars de 60 x 10<br />

2 bars de 80 x 10<br />

2 bars de 100 x 10<br />

2<br />

W 300 mm All sizes 1 2<br />

Number of supports (distance between centres: 115 mm)<br />

Framework width<br />

(mm)<br />

Size of bars<br />

(mm)<br />

No. of supports Icw (kA rms/1 s)<br />

y 25 y 30 y 40 y 50 y 60 y 65 y 75 y 85<br />

W 700 mm 1 bar de 50 x 10<br />

1 bar de 60 x 10<br />

1 bar de 80 x 10<br />

2 bars de 50 x 10<br />

2 bars de 60 x 10<br />

2 bars de 80 x 10<br />

2 bars de 100 x 10<br />

2<br />

3 4<br />

W 300 mm All sizes 1 2<br />

version: 1.0 - 06/2010 401F_E22110.indd

DD384397<br />

DD384398<br />

Distribution<br />

Catalogue numbers<br />

Fixed support and free support.<br />

Joints.<br />

NYBSHS500<br />

DD381226<br />

Horizontal busbars<br />

Up to 3200 A<br />

Flat copper bars 10 mm thick<br />

Busbar selection<br />

Flat busbars, W 2000 mm<br />

Designation Cat. no.<br />

Copper bar without holes 50 x 10 04545<br />

Copper bar without holes 60 x 10 04546<br />

Copper bar without holes 80 x 10 04548<br />

Copper bar without holes 100 x 10 04550<br />

Busbar supports<br />

Two fixed supports for 700 mm wide frameworks and one fixed support for 300 mm<br />

wide frameworks are mandatory. If more supports are required, use free supports.<br />

Designation Bar width Cubicle W 700 Cubicle W 300<br />

Distance between<br />

busbar centres<br />

Fixed support for<br />

horizontal bars<br />

Free support<br />

(additional) for<br />

bars<br />

D 500 D 800<br />

75 75 75<br />

y 80 mm 04664 NSYBHS500 NSYBHS800<br />

> 80 mm 04664 +<br />

04671<br />

401F_E22110.indd version: 1.0 - 06/2010<br />

3<br />

DD381225<br />

NSYBHS500 +<br />

04671<br />

y 80 mm 04662 04662 04662<br />

> 80 mm 04662 +<br />

04671<br />

Designation Bar width Cubicle W 700<br />

D 800<br />

Distance between<br />

busbar centres<br />

Fixed support for<br />

horizontal bars<br />

Free support<br />

(additional) for<br />

bars<br />

04662 +<br />

04671<br />

115 115<br />

NSYBHS800 +<br />

04671<br />

04662 +<br />

04671<br />

Cubicle W 300<br />

D 800<br />

y 80 mm NSYBHS800L NSYBHS800L<br />

> 80 mm NSYBHS800L<br />

+ 04671<br />

y 80 mm 04678 04678<br />

> 80 mm 04678 +<br />

04671<br />

04664 04662<br />

Joints<br />

NSYBHS800L<br />

+ 04671<br />

04678 +<br />

04671<br />

Designation Cat. no.<br />

1 joint for bars Width 50 and 60 mm 04640<br />

Width 80 and 100 mm 04641<br />

Note: when installed at the bottom of cubicles, the busbars must be partitioned, see<br />

page 401F22905.indd/5.

PD391273b_SE<br />

Distribution<br />

Catalogue numbers<br />

The table opposite indicates:<br />

b the catalogue numbers of the bars to be used,<br />

depending on the permissible current level<br />

in the busbars<br />

b the number of supports required, depending<br />

on the rated short-time withstand current<br />

(Icw in kA rms/1 s).<br />

For more information on other ambient temperatures,<br />

see DESW016.<br />

Busbars up to 1600 A.<br />

The bottom support also maintains the bars in position.<br />

2<br />

DD381233<br />

DD381236<br />

Lateral Linergy busbars<br />

up to 1600 A - depth 500 mm<br />

Busbar calculation<br />

Linergy<br />

busbars<br />

Cat. no. Permissible<br />

current<br />

at 35 °C for<br />

switchboard<br />

DD381234<br />

DD381237<br />

No. of supports Icw (kA rms/1 s)<br />

IP55 y 25 y 30 y 40 y 50 y 60 y 65 y 75 y 85<br />

Linergy 630 04502 590<br />

Linergy 800 04503 760<br />

Linergy 1000<br />

Linergy 1250<br />

Linergy 1600<br />

04504<br />

04505<br />

04506<br />

950<br />

1170<br />

1480<br />

3<br />

4 5<br />

7 8<br />

Note: The permissible current values for the busbars are given for an ambient temperature of<br />

35 °C around the switchboard. The bottom support also maintains the bars in position. Each<br />

catalogue number represents one bar.<br />

Busbar selection<br />

Linergy busbars, W 1670 mm<br />

Cat. no. selection: see the table below.<br />

Each bar is supplied with a stop for the bottom support:<br />

Bar 630 A.<br />

Cat. no. 04502<br />

Bar 1250 A.<br />

Cat. no. 04505<br />

Bar 800 A.<br />

Cat. no. 04503<br />

Bar 1600 A.<br />

Cat. no. 04506<br />

version: 1.0 - 06/2010 401F_E22215.indd<br />

DD381235<br />

Bar 1000 A.<br />

Cat. no. 04504

DD384399<br />

DD384400<br />

DD384401<br />

Distribution<br />

Catalogue numbers<br />

Single Linergy busbars up to 1600 A.<br />

Connection 04635 to horizontal busbars, 5 mm thick.<br />

Connection 04636 to horizontal busbars, 10 mm thick.<br />

06502<br />

04651<br />

DD380741<br />

Lateral Linergy busbars<br />

up to 1600 A - depth 500 mm<br />

Busbar supports<br />

Supports are used to install busbars to the left or right of the device zone. They are<br />

supplied with 8.8 class mounting hardware.<br />

Designation Cat. no.<br />

Busbar supports 04651<br />

401F_E22215.indd version: 1.0 - 06/2010<br />

3<br />

DD380742<br />

Busbar supports. Each bar is supplied with a stop for installation<br />

on the bottom support.<br />

Horizontal-busbar connections<br />

These connections are used to connect horizontal busbars, 75 mm centre distance,<br />

5 or 10 mm thick, to lateral Linergy busbars.<br />

Supplied with mounting hardware.<br />

Designation Cat. no.<br />

Connection to horizontal busbars,<br />

5 mm thick<br />

Connection to horizontal busbars,<br />

10 mm thick<br />

1000 A connection 04634<br />

1600 A connection 04635<br />

width of horizontal bars y 80 mm 04636<br />

width or horizontal bars > 80 mm 04636 + 04642

DD384402<br />

DD384403<br />

Distribution<br />

Catalogue numbers<br />

The bars are secured by insulated supports. Three<br />

fixed supports, attached to the framework, are<br />

mandatory.<br />

If necessary, additional free supports may be used.<br />

The bars rest on a bottom support.<br />

The table opposite indicates:<br />

b the number and size of the bars to be used,<br />

depending on the permissible current level in the<br />

busbars<br />

b the number of supports required in a cubicle,<br />

depending on the rated short-time withstand current<br />

(Icw).<br />

The bars are secured by three mandatory fixed supports and<br />

two free supports.<br />

2<br />

NSYBVS500<br />

NSYAS500<br />

04662<br />

DD383350<br />

DD383352<br />

Lateral flat busbars<br />

up to 1600 A<br />

Busbars 5 mm thick<br />

Busbar calculation<br />

Permissible current<br />

for switchboards<br />

No. of bars/phase No. of supports Icw (kA rms/1 s)<br />

IP55 y 15 y 25 y 30 y 40 y 50<br />

750 1 bar de 60 x 5<br />

900<br />

1250<br />

1 bar de 80 x 5<br />

2 bars de 60 x 5<br />

3<br />

5<br />

7<br />

1600 2 bars de 80 x 5<br />

Note: The permissible current values for the busbars are given for an ambient temperature of<br />

35 °C around the switchboard.<br />

For more information on busbar calculations, see DESW016.<br />

Busbar selection<br />

Flat busbars, W 1675 mm<br />

Designation Cat. No.<br />

Copper bar with holes 60 x 5 04516<br />

Copper bar with holes 80 x 5 04518<br />

Busbar supports<br />

Three fixed supports are required to maintain the busbars. If more than three<br />

supports are required, use additional free supports.<br />

Designation Cubicle W 300<br />

D 500 D 800<br />

Distance between<br />

busbar centres<br />

Fixed support for lateral<br />

flat busbars<br />

75 75 115<br />

NSYBVS500 NSYBVS800 NSYBVS800L<br />

Free support (additional) 04662 04662 04678<br />

NSYBVS500. 04662.<br />

Busbar chocks<br />

The bottom support maintains the bars in position. It is not considered a busbar<br />

support.<br />

Designation Cubicle W 300<br />

D 500 D 800<br />

Distance between<br />

busbar centres<br />

75 75 115<br />

Bottom support for lateral NSYAS500<br />

flat busbars<br />

NSYAS800 NSYAS800L<br />

NSYAS500.<br />

DD381650<br />

version: 1.0 - 06/2010 401F_E22315.indd

DD384405<br />

DD384406<br />

DD383399<br />

Distribution<br />

Catalogue numbers<br />

To satisfy safety clearances, the assembly points on adjacent<br />

bars must be staggered as shown above.<br />

401F_E22315.indd<br />

DD380512<br />

DD383398<br />

Lateral flat busbars<br />

up to 1600 A<br />

Busbars 5 mm thick<br />

Horizontal-busbar connections<br />

Direct connection (115 mm between centres)<br />

The connection between horizontal busbars, 5 mm thick, and lateral flat busbar is<br />

direct, after drilling the bars.<br />

Drilling diagram for horizontal busbars, 5 mm thick.<br />

Direct connection (75 mm between centres)<br />

For busbars with 75 mm between centres, the bars must fully overlap.<br />

Drilling diagram for horizontal busbars, 5 mm thick<br />

Number of assembly screws (04645)<br />

Horizontal bars (mm) Vertical bars (mm)<br />

50 60 80<br />

50 2 2 2<br />

60 - 2 2<br />

80 - - 3<br />

In case of direct connection (75 or 115 mm centre distance) with a horizontal<br />

busbars, bottom support part no. NSYAS500, NSYAS800 or NSYAS800L are not<br />

required.<br />

version: 1.0 - 06/2010<br />

3

DD384402<br />

DD384403<br />

Distribution<br />

Catalogue numbers<br />

The bars are secured by insulated supports. Three<br />

fixed supports, attached to the framework, are<br />

mandatory. If necessary, additional free supports may<br />

be used.<br />

The bars rest on a bottom support.<br />

The table opposite indicates:<br />

b the number and size of the bars to be used,<br />

depending on the permissible current level in the<br />

busbars<br />

b the number of supports required in a cubicle,<br />

depending on the rated short-time withstand current<br />

(Icw).<br />

Above 1600 A, the busbars must be doubled and<br />

installed in two busbar sections, side by side. In this<br />

case, they must be interconnected by three<br />

equipotential links.<br />

The bars are secured by three mandatory fixed supports and<br />

two free supports.<br />

Busbars up to 3200 A.<br />

4<br />

NSYBVS500<br />

NSYAS500<br />

04662<br />

DD381505<br />

DD383350<br />

DD383352<br />

Lateral flat busbars<br />

up to 3200 A<br />

Busbars 10 mm thick<br />

Busbar calculation<br />

Permissible current No. of bars/ No. of supports Icw (kA rms/1 s)<br />

for switchboards phase<br />

IP55 25 30 40 50 60 65 75 85<br />

1080 1 bar 50 x 10<br />

1250<br />

1600<br />

1 bar, 60 x 10<br />

1 bar, 80 x 10<br />

5 7<br />

9<br />

1850 2 bars, 50 x 10 3<br />

2000 2 bars, 60 x 10<br />

2500 2 bars, 80 x 10<br />

3200 2 bars, 100 x 10<br />

Note: The permissible current values for the busbars are given for an ambient temperature of<br />

35 °C around the switchboard.<br />

For more information on busbar calculations, see DESW016<br />

Busbar selection<br />

Flat busbars, W 1675 mm<br />

Designation Cat. no.<br />

Copper bar with holes 50 x 10 04525<br />

Copper bar with holes 60 x 10 04526<br />

Copper bar with holes 80 x 10 04528<br />

Busbar supports : directly fixed on frame (300 mm width duct)<br />

Three fixed supports are required to maintain the busbars. If more than 3 supports<br />

are required, use additional free supports.<br />

Designation Cubicle W 300<br />

D 500 D 800 D 800<br />

Distance between busbar<br />

centres<br />

Fixed support for lateral flat<br />

busbars<br />

75 75 115<br />

NSYBVS500 NSYBVS800 NSYBVS800L<br />

Free support (additional) 04662 04662 04678<br />

NSYBVS500. 04662.<br />

Busbar chocks<br />

The bottom support maintains the bars in position. It is not considered a busbar<br />

support.<br />

Designation Cubicle W 300<br />

D 500 D 800<br />

Distance between busbar<br />

centres<br />

Bottom support for lateral flat<br />

busbars<br />

NSYAS500.<br />

DD381650<br />

75 75 115<br />

NSYAS500 NSYAS800 NSYAS800L<br />

version: 1.0 - 06/2010 401F_E22315.indd

DD384404<br />

DD384405<br />

DD384406<br />

DD383399<br />

Distribution<br />

Catalogue numbers<br />

To satisfy safety clearances, the assembly points on adjacent<br />

bars must be staggered as shown above.<br />

401F_E22315.indd<br />

DD383367<br />

DD383400<br />

Lateral flat busbars<br />

up to 3200 A<br />

Busbars 10 mm thick<br />

Horizontal busbars connection<br />

Connection with a horizontal busbars, 10 mm thick.<br />

In this case, use the bottom support ref. NSYAS500, NSYAS800 or NSYAS800L.<br />

Designation Horizontal Vert. Cat. no.<br />

Busbars Busbars<br />

Connection vert. busbars (1 bar/phase) with W y 80 mm 50/60 mm 04636<br />

horizontal bars<br />

W > 80 mm 50/60 mm 04636 + 04642<br />

W y 80 mm 80 mm 04637<br />

W > 80 mm 80 mm 04637 + 04642<br />

Connection vert. busbars (2 bars/phase) with W y 80 mm 50/80 mm 04637<br />

horizontal bars<br />

W > 80 mm 50/80 mm 04637 + 04642<br />

Direct connection (115 mm centre distance)<br />

The connection between horizontal busbars, 10 mm thick, and lateral flat busbar is<br />

direct, after drilling the bars.<br />

Drilling diagram for horizontal busbars, 10 mm thick.<br />

Direct connection (75 mm centre distance)<br />

For busbars with 75 mm between centres, the bars must fully overlap.<br />

Drilling diagram for horizontal busbars, 10 mm thick.<br />

Number of assembly screws no. 04645<br />

Horizontal bars (mm) Vertical bars (mm)<br />

50 60 80 100<br />

50 2 2 2 2<br />

60 - 2 2 2<br />

80 - - 3 3<br />

In case of direct connection (75 or 115 mm centre distance) with a horizontal<br />

busbars, bottom support part no. NSYAS500, NSYAS800 or NSYAS800L are not<br />

required.<br />

version: 1.0 - 06/2010<br />

5

Distribution<br />

Catalogue numbers<br />

2<br />

PD391274b_SE<br />

Form 2 partitioning<br />

Separation of busbars from the functional units. Configuration Form 2<br />

Form 2 partitioning is essential to ensure excellent protection for the installation and<br />

operators working in the switchboard.<br />

When added to standard protection features (terminal shields, prefabricated<br />

connections, etc.), it eliminates the risk of direct contacts with live parts. <strong>Prisma</strong> <strong>Plus</strong><br />

offers Form 2b.<br />

Form 2b provides much better safety than Form 2a, notably during connection,<br />

because the terminals are separated from the busbars.<br />

version: 1.0 - 06/2010 401F_E22905.indd

DD384407<br />

DD384408<br />

Distribution<br />

Catalogue numbers<br />

06545.<br />

06543.<br />

DD383356<br />

DD384441<br />

Form 2 partitioning<br />

Partitioning of lateral vertical busbars<br />

Lateral partitioning<br />

b<br />

b<br />

b<br />

v<br />

v<br />

b<br />

Vertical barrier made of insulating slats.<br />

Can be installed on both sides of Linergy and flat busbars.<br />

Made up of:<br />

five extruded slats that clip to the supports<br />

two metal plates at the top and bottom that can be cut out to pass a PE or PEN.<br />

The space between the slats is sufficient for prefabricated connections (one<br />

copper bar, 5 or 10 mm thick, or insulated flexible bars) or for cables up to 35 mm²,<br />

while maintaining the degree of protection IP2X compliance with standard IEC<br />

60695.2.1 concerning withstand to fire.<br />

Form 2 restoration for side-barrier cut-out<br />

This kit enables passage of the connection between a device > 1600 A (NW, INS)<br />

and lateral vertical busbars.<br />

It is made up of an insulated plate (six modules H 300 mm) that can be cut as<br />

required, supplied with supports and the necessary hardware.<br />

It can be installed at any height in the switchboard.<br />

Cat. no. selection<br />

Designation Cat. no.<br />

Form 2 side barrier for D 500 mm cubicle 06545<br />

Form 2 restoration kit 04924<br />

Partitioning extension<br />

For the <strong>PH</strong> system switchboards 800 mm depth (500 + 300), a partitioning extension<br />

for 300 mm depth is required.<br />

Designation Cat. no.<br />

Partitioning extension in 800 mm depth 06543<br />

401F_E22905.indd version: 1.0 - 06/2010<br />

3

DD384409<br />

DD384410<br />

Distribution<br />

Catalogue numbers<br />

06540.<br />

06555.<br />

4<br />

DD383360<br />

DD383362<br />

Form 2 partitioning<br />

Front and rear barrier<br />

Barrier, W 300 mm, from top to bottom of the cubicle.<br />

Can be installed in the front and rear of the busbar compartment.<br />

Protects against direct contact with the busbars.<br />

Front protection<br />

Is realized by the association of the door W 300 mm and this barrier. Metallic barrier,<br />

composed of 2 parts H 850mm, pre-cut at both ends.<br />

Rear protection<br />

A barrier is required at the rear of the busbar compartment in cubicles that are 800,<br />

1000 and 1300 mm deep.<br />

Cat. no. selection<br />

Designation Cat. no.<br />

Front or rear barrier for lateral vertical busbars W 300 mm 06540<br />

Inter-cubicle partitioning<br />

Metal partition, used to separate two adjacent cubicles.<br />

It is made up of two panels, each 850 mm high.<br />

The top and bottom ends have knock-outs for horizontal busbars.<br />

Supplied with the necessary supports and hardware, the partition is mounted on the<br />

framework and does not hinder installation of the functional mounting plates<br />

Cat. no. selection<br />

Designation Cat. no.<br />

Inter-cubicle<br />

partitioning<br />

D 500 mm 06555<br />

D 800 mm 04911 + 06543<br />

version: 1.0 - 06/2010 401F_E22905.indd

DD384412<br />

DD384411<br />

Distribution<br />

Catalogue numbers<br />

Form 2 partitioning<br />

Partitioning of horizontal busbars<br />

Set of two barriers (front and rear), plus a slotted rear panel for efficient natural<br />

convection in the switchboard.<br />

The set can be used to partition horizontal busbars installed at the top or bottom of<br />

the cubicle.<br />

The space required for the busbars is not increased.<br />

Cat. no. selection<br />

Designation Cat. no.<br />

W 300 mm D 500 mm 06560<br />

D 800 mm 06563<br />

W 700 mm D 500 mm 06570<br />

D 800 mm<br />

Note: when the busbars are at the bottom of the cubicle, gland plates are mandatory.<br />

401F_E22905.indd version: 1.0 - 06/2010<br />

5

DD384420<br />

DD384421<br />

Distribution<br />

Catalogue numbers<br />

04901 + 04943.<br />

6<br />

DD384422<br />

DD383396<br />

Form 3 partitioning<br />

Form 3 partitioning<br />

Front connection<br />

Presentation<br />

A horizontal metal partition can be used to physically separate functional units from<br />

one another.<br />

It is fixed at the rear by a support (two uprights) secured to the framework (500 mm<br />

deep) or to the intermediate uprights (800 mm deep frameworks).<br />

A set of brackets can be used to install partial Form 3 partitioning in the cubicle.<br />

It does not take up any useful space in the switchboard.<br />

Cat. no. selection<br />

Designation Cat. no.<br />

Horizontal metal partition, W 650 mm 04901<br />

Rear support for partitions, W 650 mm 04943<br />

6 universal angle brackets 03583<br />

Rear connection<br />

Presentation<br />

For rear connection, in addition to the horizontal partitions, vertical partitions are<br />

required at the rear of each functional unit.<br />

There are two heights:<br />

b 3 to 4 modules<br />

b 5 to 6 modules.<br />

Cat. no. selection<br />

Designation Cat. no.<br />

Vertical partitions (two cat. no. per<br />

functional unit)<br />

Vertical partitions for rear connected Compact NSX250.<br />

3 to 4 modules 04955<br />

5 to 6 modules 04956<br />

version: 1.0 - 06/2010 401F_E22905.indd

DD384414<br />

DD384413<br />

Enclosures<br />

Catalogue numbers<br />

06502 x 2 + 06514.<br />

06502 + 06503 + 06515.<br />

2<br />

Cubicles, frameworks<br />

700 mm wide, 500 mm deep framework<br />

Designation Cat. no.<br />

2 x 2 adapted uprights H 2000 06502 x 2<br />

2 frames + 2 flanges + 1 roof 06514<br />

b<br />

v<br />

v<br />

v<br />

v<br />

v<br />

b<br />

Composition of catalogue numbers:<br />

2 frames<br />

2 flanges<br />

mounting hardware<br />

4 uprights<br />

1 roof.<br />

Roof characteristics:<br />

- equipped with a factory-mounted polyurethane (PUR) gasket<br />

- supplied with mounting hardware<br />

- with markings for clear identificatuion of cable-running zones<br />

b<br />

b<br />

b<br />

The cables compartment can be mounted on the right or left.<br />

Can be combined side-by-side or back-to-back.<br />

Receive the IP55 cover panels.<br />

An earthing braid (NSYEL166D8 or NSYEL3525D8) must be installed between the<br />

roof and the frame.<br />

700 mm wide, 800 mm deep framework<br />

Designation Cat. no.<br />

2 adapted uprights H 2000 06502<br />

2 uprights + 2 intermediary uprights H 2000 06503<br />

2 frames + 2 flanges + 1 roof 06515<br />

b<br />

v<br />

v<br />

v<br />

v<br />

v<br />

b<br />

-<br />

-<br />

-<br />

b<br />

b<br />

b<br />

Composition of catalogue numbers:<br />

2 frames<br />

2 flanges<br />

mounting hardware<br />

4 uprights + intermediary uprights<br />

1 roof.<br />

Roof characteristics:<br />

equipped with a factory-mounted polyurethane (PUR) gasket<br />

supplied with mounting hardware<br />

with markings for clear identificatuion of cable-running zones.<br />

The cables compartment can be mounted on the right or left.<br />

Can be combined side-by-side or back-to-back.<br />

Receive the IP55 cover panels.<br />

An earthing braid (NSYEL166D8 or NSYEL3525D8) must be installed between the<br />

roof and the frame.<br />

version: 1.0 - 06/2010 401F_E23110.indd

DD384415<br />

DD384416<br />

Enclosures<br />

Catalogue numbers<br />

06501 x 2 + 06512.<br />

06501 + 06502 + 06512.<br />

401F_E23110.indd<br />

Cubicles, frameworks<br />

300 mm wide, 500 mm deep framework<br />

Designation Cat. no.<br />

2 x 2 uprights H 2000 06501 x 2<br />

2 frames + 1 roof W 300 D 500 06512<br />

b<br />

v<br />

v<br />

v<br />

v<br />

b<br />

Composition of catalogue numbers:<br />

2 frames<br />

mounting hardware<br />

4 uprights<br />

1 roof.<br />

Roof characteristics:<br />

- equipped with a factory-mounted polyurethane (PUR) gasket<br />

- supplied with mounting hardware<br />

- with markings for clear identificatuion of cable-running zones.<br />

b<br />

b<br />

b<br />

The cables compartment can be mounted on the right or left.<br />

Can be combined side-by-side or back-to-back.<br />

Receive the IP55 cover panels.<br />

An earthing braid (NSYEL166D8 or NSYEL3525D8) must be installed between the<br />

roof and the frame.<br />

300 mm wide, 500 mm deep framework for Linergy<br />

Designation Cat. no.<br />

2 uprights H 2000 06501<br />

2 adapted uprights H 2000 06502<br />

2 frames + 1 roof W 300, D 500 06512<br />

b<br />

v<br />

v<br />

v<br />

v<br />

b<br />

Composition of catalogue numbers:<br />

2 frames<br />

mounting hardware<br />

2 adapted uprights<br />

1 roof.<br />

Roof characteristics:<br />

- equipped with a factory-mounted polyurethane (PUR) gasket<br />

- supplied with mounting hardware<br />

- with markings for clear identificatuion of cable-running zones.<br />

b<br />

b<br />

b<br />

The cables compartment can be mounted on the right or left.<br />

Can be combined side-by-side or back-to-back.<br />

Receive the IP55 cover panels.<br />

An earthing braid (NSYEL166D8 or NSYEL3525D8) must be installed between the<br />

roof and the frame.<br />

300 mm wide, 800 mm deep framework<br />

Designation Cat. no.<br />

2 x 2 uprights H 2000 06501 x 2<br />

2 frames + 1 roof W 300, D 800 06513<br />

b<br />

v<br />

v<br />

v<br />

v<br />

b<br />

Composition of catalogue numbers:<br />

2 frames<br />

mounting hardware<br />

4 uprights<br />

1 roof.<br />

Roof characteristics:<br />

- equipped with a factory-mounted polyurethane (PUR) gasket<br />

- supplied with mounting hardware<br />

- with markings for clear identificatuion of cable-running zones.<br />

b<br />

b<br />

b<br />

The cables compartment can be mounted on the right or left.<br />

Can be combined side-by-side or back-to-back.<br />

Receive the IP55 cover panels.<br />

An earthing braid (NSYEL166D8 or NSYEL3525D8) must be installed between the<br />

roof and the frame.<br />

version: 1.0 - 06/2010<br />

3

DD384417<br />

DD384418<br />

DD384419<br />

Enclosures<br />

Catalogue numbers<br />

4<br />

Cubicles, frameworks<br />

Hinged front plate support frame<br />

Designation Cat. no.<br />

Hinged front plate support frame, W 700 mm 08566<br />

b Reversible for left or right-hand opening.<br />

b Secured at two points.<br />

b Can be mounted on 700 mm wide cubicles.<br />

Framework combinations<br />

The <strong>PH</strong> system frameworks can be combined side-by-side or back-to-back.<br />

A combination kit is required.<br />

Side-by-side or back-to-back (1) combination<br />

The mechanical connection between the two frames is realised with the combination<br />

kit , which comprises the IP55 sealing kit .<br />

Designation Cat. no.<br />

Swing 19” rack coupling kit NSYSFBK19<br />

(1) Back to back association must be shipped individually and combined during on-site<br />

installation.<br />

version: 1.0 - 06/2010 401F_E23110.indd

DD384423<br />

DD384424<br />

DD384425<br />

Enclosures<br />

Catalogue numbers<br />

06525.<br />

06537.<br />

06535.<br />

401F_E23110.indd<br />

IP55 cover panels<br />

Front panel<br />

W 700 mm door<br />

Designation Cat. no.<br />

Plain door W 300 mm 06522<br />

W 700 mm 06524<br />

Transparent door W 700 mm 06525<br />

b<br />

b<br />

b<br />

Equipped with a factory-mounted polyurethane (PUR) gasket.<br />

Reversible for left or right-hand opening.<br />

Equipped with a black handle and keylock (key 405).<br />

An earthing wire (08911) must be installed between the door and the frame.<br />

To connect it, a M6 captive nut from the set cat. no. 06461 is required.<br />

Rear panel<br />

Rear panel<br />

Designation Cat. no.<br />

Rear panel W 300 mm 06533<br />

W 700 mm 06537<br />

b<br />

b<br />

b<br />

Equipped with a factory-mounted polyurethane (PUR) gasket.<br />

Supplied with mounting hardware.<br />

One-piece, reinforced panel designed to ensure the degree of protection.<br />

An earthing braid (NSYEL166D8 or NSYEL3525D8) must be installed between the<br />

rear panel and the frame.<br />

Side panel<br />

Side panel<br />

Designation Cat. no.<br />

Set of two side panels D 500 mm 06535<br />

D 800 mm 06538<br />

b Equipped with a factory-mounted polyurethane (PUR) gasket.<br />

b Supplied with mounting hardware.<br />

An earthing braid (NSYEL166D8 or NSYEL3525D8) must be installed between the<br />

lateral panels and the frame.<br />

version: 1.0 - 06/2010<br />

5

DD384428<br />

DD384427<br />

Enclosures<br />

Catalogue numbers<br />

NSYSPF7100 + NSYSPS5100.<br />

NSYEC751.<br />

6<br />

Plinth, gland plates<br />

Plinth, H 100 mm and 200 mm<br />

The plinth is made up of two catalogue numbers:<br />

b one catalogue number comprising four corner posts + two cross-pieces (front and<br />

rear), that can be used in side-by-side combinations or stacked to form a plinth 200<br />

mm high (maximum)<br />

b one catalogue number comprising two side plates (500 or 800 mm).<br />

Each catalogue number is supplied with the necessary hardware.<br />

Width Depth Plinth H 100 Plinth H 200<br />

Front and<br />

rear crosspieces<br />

Lateral crosspieces<br />

Front and rear<br />

cross-pieces<br />

Lateral crosspieces<br />

300 500<br />

NSYSPF3100 NSYSPS5100 NSYSPF3200 NSYSPS5200<br />

800 NSYSPS8100 NSYSPS8200<br />

700 500<br />

NSYSPF7100 NSYSPS5100 NSYSPF7200 NSYSPS5200<br />

800 NSYSPS8100 NSYSPS8200<br />

Plain gland-plates (IP55)<br />

Designation Cat. no.<br />

Plain gland-plates, D 500 W 300 NSYEC351<br />

W 700 NSYEC751<br />

Plain gland-plates, D 800 W 300 NSYEC381<br />

W 700 NSYEC781<br />

version: 1.0 - 06/2010 401F_E23110.indd

DD384440<br />

Enclosures<br />

Catalogue numbers<br />

2<br />

DD383348<br />

DD383349<br />

Accessories<br />

Lifting rings<br />

Set of four lifting rings screwed to the framework.<br />

Use a set of lifting rings for each framework (W 700 mm) containing devices.<br />

When two cubicles with devices have been combined, use a lifting beam.<br />

Designation Cat. no.<br />

4 lifting rings NSYSFEB<br />

4 lifting brackets NSYSFELB<br />

Screws/Nuts<br />

Designation Cat. no.<br />

Set of 20 screws + M6 nuts 06461<br />

Earthing leads<br />

b Mandatory to ensure earth continuity of side panels, roof and door.<br />

b Material: terminal of brass and copper delivered with PVC cover, green and<br />

yellow.<br />

Length (mm) Section (mm²) Terminal (mm) Cat. no.<br />

160 6 8.3 NSYEL166D8<br />

350 25 8.3 NSYEL3525D8<br />

Note: composition set of 10 leads (nuts and washers not delivered).<br />

The wire is equipped with a 5 mm diameter lug at one end and a 6 mm diameter lug<br />

on the other.<br />

Designation Cat. no.<br />

Earthing wire, 6 mm² 08911<br />

The wire is equipped with a 5 mm diameter lug at one end and a 6 mm diameter lug<br />

on the other.<br />

The earthing wire is used to earth:<br />

b a door or wicket door with devices<br />

b a front-plate support frame equipped with switchgear in a cubicle.<br />

Coupling kit<br />

For coupling enclosures either side-by-side or back-to-back (1) :<br />

b Fixing system from the inside of the enclosure.<br />

b IP55 degree of protection.<br />

b Material:<br />

v flat flange: galvanised steel.<br />

v sealing gasket: EPDM.<br />

Designation Cat. no.<br />

Swing 19” rack coupling kit NSYSFBK19<br />

(1) Back to back association must be shipped individually and combined during on-site<br />

installation.<br />

version: 1.0 - 06/2010 401F_E23120.indd

Dimensions<br />

Dimensions<br />

DD384437<br />

D384438<br />

DD384439<br />

Cubicles<br />

Profile<br />

Cover panels<br />

401F_E31010.indd version: 1.0 - 05/2010<br />

1<br />

515<br />

815<br />

500<br />

800<br />

Plain or transparent door, lateral panels<br />

Fixing to floor<br />

500<br />

800

Dimensions<br />

Dimensions<br />

2<br />

DD384433<br />

DD384443<br />

Cubicles<br />

Gland plates<br />

500<br />

800<br />

Cubicle mounting.<br />

DD384442 Functional system in <strong>PH</strong> system switchboards<br />

50<br />

D 500.<br />

50<br />

Transparent<br />

door<br />

Transparent<br />

door<br />

D 600/800.<br />

500<br />

700<br />

500<br />

700<br />

DD384434<br />

500<br />

800<br />

version: 1.0 - 05/2010 401F_E31010.indd<br />

50<br />

50<br />

505<br />

605<br />

805<br />

Plain<br />

door<br />

Plain<br />

door

Dimensions<br />

Dimensions<br />

DD384429<br />

DD384431<br />

DD384430<br />

DD384432<br />

Cubicles<br />

Busbars mounting<br />

Lateral vertical busbars<br />

1600 A.<br />

2500 A.<br />

75<br />

75<br />

75<br />

2000 A.<br />

115<br />

115<br />

115<br />

3200 A.<br />

401F_E31010.indd version: 1.0 - 05/2010<br />

3<br />

500<br />

500<br />

800<br />

500<br />

1005<br />

1305

<strong>Schneider</strong> <strong>Electric</strong> Industries SAS<br />

35, rue Joseph Monier<br />

CS 30323<br />

F- 92506 Rueil Malmaison Cedex<br />

RCS Nanterre 954 503 439<br />

Capital social 896 313 776 €<br />

www.schneider-electric.com<br />

401E<br />

As standards, specifications and designs change from time to time, please ask for confirmation<br />

of the information given in this publication.<br />

This document has been printed on ecological paper.<br />

Publication: <strong>Schneider</strong> <strong>Electric</strong> Industries SAS<br />

Photos: <strong>Schneider</strong> <strong>Electric</strong><br />

Printed:<br />

09-2010<br />

© 2010 - <strong>Schneider</strong> <strong>Electric</strong> - All rights reserved