-Eng Mar 07 - BSP

-Eng Mar 07 - BSP

-Eng Mar 07 - BSP

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Mar</strong>ch 20<strong>07</strong> Published for employees of <strong>BSP</strong> / BLNG / BST / BSM<br />

Integrated Activity Planning<br />

demonstrates how<br />

“Together We Can Do So Much”<br />

We focus on the cross-business drive to improve Integrated<br />

Activity Planning (IAP) in <strong>BSP</strong>, which has the potential for<br />

significant savings, by eliminating wasted resources.<br />

CENTRESPREAD<br />

New Muara Supply<br />

Base Jetty<br />

The commissioning of the jetty will provide a strong<br />

boost for <strong>BSP</strong>’s business activities. Page 3<br />

Highlights<br />

Vendors Forum<br />

20<strong>07</strong><br />

More than 350 local contractors participated in this<br />

year’s Vendors Forum. Page 5<br />

Bruneianisation<br />

at BST<br />

Bruneians are today at the forefront of Brunei Shell<br />

Tankers LNG shipping operation. Page 9<br />

Editor - Azrina Taib (CEA/22) - 3375951 / Assistant Editor - Mohd Justin Satria bin Hj Mohd Jaapar (CEA/23) - 3374184 / Photographs - Mohd Zufri Mohd Bakhtiar (CEA/222) & James How (CEA/222X)

2 Salam, <strong>Mar</strong>ch 20<strong>07</strong><br />

Health, Safety, EnvironmentNews<br />

<strong>BSP</strong> focused its attention on hand and finger injury<br />

prevention at the first Safety Takes Priority Week<br />

held from 12 to 16 <strong>Mar</strong>ch 20<strong>07</strong>.<br />

At the launching for the event, <strong>BSP</strong>’s Managing<br />

Director, Grahaeme Henderson stressed the utmost<br />

importance of safety, including preventing hand and<br />

finger injuries. He said, “Our hands and fingers are the<br />

most used and exposed parts of our body. In 2006, a<br />

total of 13 out of the 18 lost time incidents resulted in<br />

hand and finger injuries. Unfortunately, we tend to<br />

under-estimate the risks involved when we use our hands<br />

and fingers especially doing even routine tasks with our<br />

hands and fingers. We simply have to put a stop to<br />

accidents involving hands and fingers, for the sake of<br />

our families.”<br />

He emphasised, “Safety is a shared responsibility.<br />

The company can do all it can in terms of tightening<br />

procedures, but every one of us has a responsibility to<br />

adopt the right attitude. You owe it to yourself, your<br />

family and friends to make the extra effort to put a stop<br />

to hand and finger injuries. I know that safety, and<br />

therefore our well being, is the top priority for everyone.<br />

So please let us work together to prevent hand and finger<br />

injuries.”<br />

Highlights during the launch involved a live stage<br />

drama with employees acting out the consequences of<br />

an employee losing one’s fingers and having to live life<br />

COMPLIANCE INTERVENTION ATTITUDE<br />

<strong>BSP</strong> and Contractors hold<br />

Safety Takes Priority Week<br />

<strong>BSP</strong>’s firemen<br />

assist in efforts<br />

to put out fire<br />

in Seria<br />

Haji Salleh Bostaman Haji Zainal Abidin was at the<br />

scene to lend moral support to our firemen<br />

<strong>BSP</strong>’s Firemen assisted in the efforts to put out a<br />

fire, which broke out at the government barracks<br />

in Lorong Tiga Selatan in Seria.<br />

Responding to a call just past midnight on 13<br />

<strong>Mar</strong>ch, <strong>BSP</strong>’s fire services team led by Chief Fire Officer<br />

(HSE/11), Mohammed Sham - Khiruddin, two<br />

fire officers and six firemen, responded immediately and<br />

arrived at the scene of the incident to support the efforts<br />

of the Government Fire & Rescue Department.<br />

The fire was successfully brought under control<br />

a short while later, and all the 16 families comprising<br />

more than 80 persons were safely evacuated.<br />

Also at the scene of the incident to lend moral<br />

support to our firemen were Asset Director, Haji Salleh<br />

Bostaman Haji Zainal Abidin and Head of Emergency<br />

Response & Security (HSE/1), Rosman Hj Abdul<br />

Rahman.<br />

Our hands and fingers are the most used and exposed parts of our body<br />

with the handicap as well as a short video with a real-life accident victim talking<br />

about how his life has changed due to his finger loss.<br />

Amongst some of the activities that were conducted throughout the week were<br />

site visits by joint <strong>BSP</strong> and Contractor teams to <strong>BSP</strong> and Contractor facilities, which<br />

focused on engagements with site personnel to increase general awareness on<br />

preventing hand and finger injuries. A <strong>BSP</strong> and Contractor Quarterly Safety Forum<br />

was also held on 16 <strong>Mar</strong>ch at the closing of Safety Takes Priority Week.<br />

Drilling Menang’s<br />

HSE Network<br />

leads campaign on<br />

hand and finger safety<br />

HAND and finger injuries accounted for 13 of the 18 safety incidents recorded<br />

in <strong>BSP</strong> in 2006. It is therefore the first of the key quarterly action themes<br />

highlighted in the 20<strong>07</strong> HSE Plan.<br />

Senior HSE Adviser, Uche Igbokwe, is driving a number of activities on hand<br />

and finger injury prevention within <strong>BSP</strong> and contractor communities at homes, offices<br />

and worksites. This includes awareness cascades and workshops, featuring different<br />

types of hand and finger PPE, and right and wrong practices. “Only strict compliance<br />

with company rules and procedures, intervention and bold correction of unacceptable<br />

practices as well as having the right attitude will help us prevent these injuries,” he<br />

said.<br />

The HSE Network Committee of the Drilling MENANG community took<br />

the lead with a hand and finger injury prevention workshop for more than 300<br />

drilling contractor representatives ,opened by <strong>BSP</strong>’s Finance Director, <strong>Mar</strong>cel Luijten.<br />

Contractor personnel were given awards for their outstanding HSE performances<br />

and contributions towards Compliance, Intervention and Attitude, with Azlan from<br />

Haliburton emerging as the best overall contributor.<br />

The <strong>Mar</strong>ine HSE Network is currently planning their own workshop on this<br />

theme while other departments cascade the communications package to their teams.

From The <strong>BSP</strong> MD’s Desk<br />

Dear Colleagues,<br />

I am pleased to be able to reach out to you again. First of all,<br />

a big thank you to the many of you who turned up for our staff<br />

cascade of 13 <strong>Mar</strong>ch. A big thank you also to our colleagues from<br />

Champion, Ampa and Fairley, who joined us via live video<br />

conferencing.<br />

Once again, I would like to say ‘very well done’ on our recordbreaking<br />

performance for last year, and a very huge thank you to<br />

everyone for your contributions. Your magnificent efforts have been<br />

aptly recognised with the announcement of a company bonus that<br />

you deserve.<br />

I am worried, however, that our joy could be temporary, and<br />

that we may be taking our success for granted. I’m sure you will be<br />

as worried as I am too, if you look at the not-so promising progress<br />

we have made so far this year.<br />

On Safety, our performance remains fragile, with a sharp<br />

increase in safety-related incidents, particularly hand and finger<br />

injuries in January and February alone. We really need to pause,<br />

and take a long and hard look at how we can put immediate stop to<br />

these incidents.<br />

We must always conduct hazard identification before we<br />

commence any activity, routine or non-routine. We must treat high<br />

potential incidents with a huge amount of respect. Please help bring<br />

home these safety messages to everyone you work with in <strong>BSP</strong> and<br />

contractor companies.<br />

On Performance, our figures for both oil production and gas<br />

sales, unfortunately, are below target at this stage. Again, we really<br />

need to pull ourselves strongly together, and work hard as never<br />

before to push up well delivery, cut down on unscheduled<br />

deferments, and optimise shutdowns.<br />

We can still recover and catch up with our target. To do that<br />

we must from now onwards push ourselves to safely ‘chase every<br />

barrel of oil’ and ‘every cubic metre of gas’ we can lay our hands on.<br />

While we continue to make significant progress in the area<br />

of People development, we have fallen behind in terms of filling up<br />

vacancies to support our operations. We are working in close<br />

collaboration with our government partners and Shell shareholders<br />

THE commissioning of the brand new Muara Supply Base Jetty will provide a strong boost<br />

for <strong>BSP</strong>’s business activities, especially its offshore operations for the next thirty years and<br />

beyond.<br />

The jetty was officially opened on 13 February by Yang Berhormat Pehin Orang Kaya Seri<br />

Utama Dato Seri Setia Awang Haji Yahya bin Begawan Mudim Dato Paduka Haji Bakar, the Minister<br />

of Energy at the Prime Minister’s Office and Chairman of <strong>BSP</strong>, Brunei LNG, Brunei Shell Tankers and<br />

Brunei Shell <strong>Mar</strong>keting.<br />

Giving welcoming remarks at the event, Grahaeme Henderson, Managing Director of <strong>BSP</strong> said,<br />

“I am absolutely confident that the new jetty will further catalyse the continuing dynamic pace of<br />

development of the company in particular, and the oil and gas sector in general.”<br />

Salam, <strong>Mar</strong>ch 20<strong>07</strong> 3<br />

Grahaeme Henderson speaks to staff on our record-breaking performance of last year and<br />

shares his concern over progress in the first quarter of this year<br />

to overcome this challenge quickly.<br />

There are huge expectations from our stakeholders for us to repeat our winning performance of<br />

last year. The bottom line simply is that ‘we are only as good as our last game’.<br />

This means that our success in the previous year will be seen as history, and we will be judged<br />

solely by our latest performance in 20<strong>07</strong>. We must perform as well or even better than last year, for us<br />

to retain our hard-earned reputation as a top performing company.<br />

Driving our performance forward will depend very much on the same key factors which brought<br />

us outstanding success last year, namely, aggressively focusing on our scorecard to deliver production<br />

safely, on time and on budget, and by working closely as one solid team.<br />

As shown by our results last year, we are indeed a great team. We need to prove it again. I know<br />

I can count on you to do it.<br />

As always, I look forward to your feedback and comments.<br />

Best regards<br />

Grahaeme Henderson<br />

New Muara Supply Base Jetty -<br />

a boost for <strong>BSP</strong> operations<br />

Yang Berhormat Pehin officially opens the Muara Jetty Supply Base, which houses 14 storage<br />

tanks for keeping essential materials for offshore drilling operations<br />

The Muara Jetty Supply Base measures 120 metres by 48<br />

metres and is equipped with three loading facilities. It is almost<br />

close to the size of the football pitch at Hassanal Bolkiah National<br />

Stadium. It is also embedded on a powerful foundation of 182 piling<br />

points, comprising hollow steel pipes of 28 inches and 32 inches in<br />

diameter and a 1-inch thick wall. These piles have been driven 43<br />

metres deep into the ground.<br />

There are 14 storage tanks for keeping essential materials for<br />

offshore drilling operations. These tanks, which were dismantled<br />

and relocated from the old jetty, are no ordinary tanks. Each tank<br />

can hold up to 250 tonnes of dry material. This means that together<br />

they can store in excess of 1,400 tonnes of cement, 1,000 tonnes of<br />

bentonites and 400 tonnes of barites.<br />

Grahaeme highlighted that the project stands out because of<br />

four notable achievements. These are:<br />

• Safety - The project was successfully completed with an<br />

outstanding safety achievement of 0.8 million hours<br />

Total Recordable Case (TRC) free and without Loss<br />

Time Injury<br />

• Teamwork - It was managed by a multi-disciplinary<br />

project team drawn from <strong>BSP</strong> and complemented by<br />

various government departments<br />

• Local talent - The <strong>BSP</strong> project team was entirely made<br />

up of, and led by, Bruneian engineers and technical<br />

professionals<br />

• Standards - Comprehensive and rigorous standards have<br />

been adopted by the team to measure and mitigate any<br />

potential impact that arises<br />

Yang Berhormat Pehin then officially opened the Muara Jetty<br />

Supply Base by cutting a ribbon and signing a commemorative<br />

plaque. The Minister of Enegy and other guests were subsequently<br />

taken on a guided tour to see the facilities at the jetty and later,<br />

viewed an exhibition.

4 Salam, <strong>Mar</strong>ch 20<strong>07</strong><br />

<strong>BSP</strong> celebrates Technology<br />

David Purvis highlights the seven technology<br />

themes illustrated in the diagram on the right<br />

FOR the whole month of <strong>Mar</strong>ch, Shell celebrated<br />

technology at all its exploration and production<br />

locations all around the world. Technology Month<br />

helped to explain what makes <strong>BSP</strong> and Shell in<br />

general, an industry leader in its field. <strong>BSP</strong> took<br />

part in the celebration and launched the event<br />

locally on 12 <strong>Mar</strong>ch 20<strong>07</strong>.<br />

David Purvis, <strong>BSP</strong>’s Technical Director was<br />

present to officially launch the event. Speaking at the<br />

event, David highlighted the seven technology themes<br />

being celebrated and the role, which <strong>BSP</strong> plays in some<br />

of the themes. These themes are illustrated in the slide.<br />

Prime Minister<br />

of Laos visits BLNG<br />

From left: The Minister of Health, Yang Berhormat Pehin Orang Kaya Indera<br />

Pahlawan Dato Seri Setia Haji Awg Suyoi bin Haji Osman in his capacity<br />

as Minister in Attendance, Mr Bouasone Bouphavanh, Fred Smeenk, Haji<br />

Matsatejo Sokiaw and the delegation from the Lao People’s Deomocratic<br />

Republic<br />

THE Prime Minister of Lao People’s Democratic Republic, Mr Bouasone<br />

Bouphavanh and his delegation paid a courtesy visit to Brunei LNG Sdn<br />

Bhd (BLNG) on 1 February 20<strong>07</strong>.<br />

BLNG’s Managing Director, Fred Smeenk and the BLNG management<br />

team welcomed the Prime Minister and his delegation where they were later invited<br />

to attend a briefing on the company’s general operation and achievements. The<br />

premier was then invited for a tour of the plant led by BLNG’s Senior General<br />

Manager (Plant), Haji Matsatejo Sokiaw.<br />

The delegation toured the power plant project and the Main Cryogenic<br />

Heat Exchanger (MCHE) train 5 areas and the jetty. The visit ended with a<br />

luncheon, hosted by Fred Smeenk, at the Liang Lumut Recreation Club.<br />

David also said, “I hope all of you will find the events and activities to be of great interest and if anything<br />

else, it should inspire you to create technologies that will be key enablers to our future.”<br />

Locally, <strong>BSP</strong> held three technology talks throughout the month, which highlighted several achievements<br />

made by <strong>BSP</strong>. The first was a presentation on Powering Ahead with Microturbines by William Voon, Head of<br />

Electrical <strong>Eng</strong>ineering. In his capacity as one of Shell’s Principal Technical Experts in the area of Electrical Power<br />

Generation, William shared his expertise on the application of Microturbines for<br />

generating electrical power in remote and normally unmanned installations offshore.<br />

The application of Microtubines has been successfully implemented at several offshore<br />

locations under Sarawak Shell Berhad.<br />

The second technology talk was by Peter Slaiby, <strong>BSP</strong>’s East Asset Manager on<br />

the topic of Champion West: Leading the Way in Smart Field Technology. <strong>BSP</strong>’s<br />

Champion West Facility is one of the most technically advanced offshore facilities in<br />

the world. The flexibility of the snake well, applied here, means the drill can snake<br />

through all of the hidden oil pockets from a single offshore platform and with smart<br />

field technology, engineers can monitor productivity via remote control. We have<br />

become the pioneer of the 58 smart wells available in the whole of Shell and 55% of<br />

them are available right here in Brunei.<br />

The last talk was Seria North Flank: Getting Connected by Al-Khadhuri<br />

Shaikhan Mohamed, Conductor-Connector Wells Senior Production Technologist<br />

and Hamoud Alriyami, Senior Well <strong>Eng</strong>ineer (Conductor-Connector Project).<br />

Connector-Conductor Wells technology has been succesfully completed. It involved<br />

drilling a connector well onshore to connect with an existing well offshire in the Seria<br />

North Flank field. The objective of the project was to prove the concept for wider<br />

implementation in Champion West. The Connector-Cundoctor wells project is a<br />

great success and is the first of its kind worldwide.<br />

A Shell Business View video on Smart Fields was shown during the launch<br />

of Technology Month

Salam, <strong>Mar</strong>ch 20<strong>07</strong> 5<br />

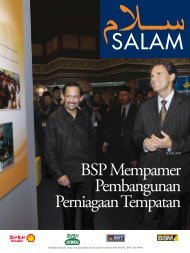

Contractors attend forum<br />

Grahaeme Henderson presents a momento to Yang<br />

Berhormat Pehin, who spoke at and officiated Vendors Forum<br />

20<strong>07</strong><br />

MORE than 350 local contractors, registered with <strong>BSP</strong>,<br />

BLNG, BST and BSM, participated in this year’s Vendors<br />

Forum, which was held at the International Convention<br />

Centre on 14 <strong>Mar</strong>ch 20<strong>07</strong>.<br />

The objective of the forum, which carried the theme ‘Building<br />

Brunei Business’ was to provide up-to-date information on the<br />

existing process and procedures of contracting and procurement in<br />

the four joint venture companies.<br />

Speaking at the event, Grahaeme Henderson, Managing<br />

Director of <strong>BSP</strong> said, “Through our Local Business Development<br />

(LBD) initiatives, we will positively support the work of the<br />

Government of Brunei Darussalam to establish a strong and resilient<br />

local business community. In addition, we also hope that the LBD<br />

provides opportunities to grow the number of globally competitive<br />

Bruneian companies venturing out into overseas markets.”<br />

“I am very pleased to share with you that just last year alone,<br />

90 percent of all our business transactions were through Bruneianowned<br />

and managed companies. More than half of all our contracts<br />

by value in 2006 were awarded to local contractors,” Grahaeme<br />

said.<br />

In essence, LBD is a structured partnership between our<br />

companies and our contractors, who support us by delivering<br />

essential goods and services to drive our business. At the forum,<br />

<strong>BSP</strong> disclosed three key local business development initiatives that<br />

will be implemented in the immediate future.<br />

The three initiatives are the new format of its annual Vendor<br />

Forum, the push for the inclusion of technical and vocational skill<br />

development and to further step up and institutionalise measures<br />

to enhance the capabilities of the contractors, which include their<br />

ability to compete in the international marketplace.<br />

Yang Berhormat Pehin Orang Kaya Seri Utama Dato Seri<br />

Setia Awang Haji Yahya bin Begawan Mudim Dato Paduka Haji<br />

Bakar, Minister of Energy at the Prime Minister’s Office also the<br />

Chairman of <strong>BSP</strong>, BLNG, BST and BSM was the guest of honour<br />

where he spoke and officiated the forum.<br />

In officiating the event, Yang Berhormat Pehin said, “I am<br />

particularly pleased that companies like <strong>BSP</strong>, BLNG, BST and BSM<br />

have been at the forefront of private-sector efforts to complement<br />

the government’s initiatives to strengthen local business<br />

development, including the SMEs sector.”<br />

He added, “The LBD programme has helped to nurture the<br />

development of a dynamic Bruneian contractor community in the<br />

energy sector. The programme has also created clear and widening<br />

business opportunities for many SMEs and Bruneian citizens now<br />

occupy the majority of top management positions in companies<br />

contracted to <strong>BSP</strong>”.<br />

There was an exhibition held in conjunction with the forum<br />

as well as booth sessions on topics of highly specialist business, future<br />

Bumi business, developing Bumi business, minimum effort Bumi<br />

business and registering for business with the four Shell JV<br />

companies.<br />

An exhibition as well as booth<br />

sessions were also held during<br />

the event<br />

Another presentation revolved around the financing for SMEs from the Islamic and Conventional<br />

Financing by the Associations of Banks Brunei and knowledge sharing on critical success factors by<br />

Schlumberger Overseas S.A.(B), SKSWoods Sdn Bhd, P.T.A.S Sdn Bhd and Hackna Company.<br />

The forum was wrapped with a question and answer session which was conducted by the <strong>BSP</strong><br />

Tender Board key members led by Awg Haji Zainal Abidin bin Hj Mohd Ali, Deputy Managing<br />

Director of <strong>BSP</strong> in his capacity as the Chairman of Tender Board for the companies.<br />

<strong>BSP</strong> hosts Global<br />

Lawyers Conference<br />

OVER eighty lawyers from all over the world joined <strong>BSP</strong>’s Legal Department for a week of<br />

sharing best practices on legal developments in the upstream oil and gas industry. This gathering<br />

was part of the bi-annual Shell Global Exploration & Production Lawyers Conference held<br />

on 13 February 20<strong>07</strong>.<br />

Grahaeme Henderson, <strong>BSP</strong>’s Managing Director, delivered the keynote address where he<br />

welcomed the guests. Grahaeme said, “We are absolutely delighted to welcome so many Shell lawyers<br />

from all over the world to Brunei. There is an unlimited variety of legal risks surrounding our core<br />

exploration activities, which require daily<br />

management and as such legal input is<br />

instrumental to meeting deliverables.”<br />

“Apart from the knowledge and experience<br />

this conference brings to <strong>BSP</strong>, it clearly<br />

demonstrates that Brunei is maturing as a topnotch<br />

location for learning and development<br />

opportunities, an initiative <strong>BSP</strong> is actively<br />

pursuing.”<br />

Head of the Legal Department at <strong>BSP</strong>,<br />

Ingrid de Jong added, “Conferences such as these<br />

enable us to provide continued high quality<br />

services to the company in today’s complex legal<br />

environment. Although Seria may seem a quiet<br />

place, the international dynamics of the energy<br />

business demand us to up our game every day.”<br />

Grahaeme Henderson welcomes the<br />

delegates to Brunei and presented an<br />

overview of our business<br />

Over 80 lawyers from all over the world converged in Brunei for the Shell Global EP Lawyers<br />

Conference

6 Salam, <strong>Mar</strong>ch 20<strong>07</strong><br />

Business Improvement In Action<br />

Integrated Activity Planni<br />

demonstrates how<br />

“Together We Can Do So M<br />

Activity execution work being carried out<br />

THIS is the second in a series of articles highlighting the achievements of<br />

<strong>BSP</strong> people driving bottom-line business improvements. In this article, we<br />

focus on the cross-business drive to improve Integrated Activity Planning<br />

(IAP) in <strong>BSP</strong> which has the potential to save $30 million by eliminating wasted<br />

resources.<br />

IAP is recognised across Shell and the industry as a critical activity to eliminate inefficient processes<br />

and use of resources. It focuses on standardising and integrating the planning for people, processes and<br />

tools across departments to improve delivery. The power of IAP is based on its capacity to combine the<br />

knowledge and resources of all staff levels, departments and disciplines to develop the most efficient<br />

solutions for the overall business.<br />

IAP Business Improvement Team Lead and <strong>BSP</strong> Head of Production and Maintenance Excellence,<br />

Paul Rijks said, “Put simply, it’s about taking waste out of the system to help the people on the front<br />

Integrated Activity Planning meetings are held on a regular basis<br />

line do their job better.”<br />

“Let me give you an example of what successful IAP looks like. I see on<br />

to go to a platform. When he arrives, he goes to the control room, where hi<br />

materials are in the ‘barang’ box, and the scaffold is in place, so he can<br />

successfully completes the task, signs off his permit, and moves to anothe<br />

When that task is complete, the boat is there waiting for him at 4pm, to ge<br />

“You can see that if we enable everyone to work like that, we get the<br />

and, most importantly, time and resources are not wasted,” he said. “Mak<br />

because the people who are working on materials, boats, maintenance and<br />

planning their work. We’re working hard to standardise and integrate plann<br />

The Business Improvement Priorities (BIP) analysis conducted in<br />

performance:<br />

♦ Clarity of roles, responsibilities and accountability for activit<br />

♦ Ensuring compliance with existing processes and systems<br />

♦ Improving the quality of data that is provided for planning p<br />

Detailed diagnostics identified potential savings of an estimated $30<br />

teams over the past 18 months. “We have made improvements but there is<br />

One major change being introduced by IAP has been a shift away fr<br />

engineers and others submitting data to analyse the sequence of activities an<br />

“This integrates the planning for areas from design, procurement, fab<br />

what’s needed earlier in the process,” Paul said. “Crucially, this tells us whe<br />

work delivered in the same time-frame. It helps us understand critical delive<br />

we can anticipate how things are best done.<br />

One of the most significant successes of IAP has been to help reduce<br />

enabled the IAP team to pre-analyse the scope and implications of shut-do<br />

planned shut down windows, which of course immediately translates to ba<br />

The alignment of shut-downs between <strong>BSP</strong> and BLNG also played<br />

“We’ve always had a level of co-ordination with BLNG, but now BLNG repre<br />

Paul said. “We’ve got the right people in the room to maximise the efficien<br />

“Improving decision-making is key to planning across the board. In th<br />

diffused decision-making. The IAP work on accountabilities is helping us u<br />

“We’ve also made good progress in convincing staff to improve the qu<br />

develop standardised templates for Primavera and SAP systems. Primavera<br />

implemented to help us standardise our work. As soon as it can talk to SAP,<br />

to the execution of our activities.<br />

“Along with the systems and processes, we are encouraging behaviour c<br />

co-operation. At the outset, IAP can look like more administration and pap<br />

mak<br />

brea<br />

deliv<br />

colle<br />

supp<br />

a com<br />

little<br />

got a<br />

func<br />

imp<br />

The<br />

2006<br />

The<br />

beyo<br />

intro<br />

This

ng<br />

ch”<br />

e of our people getting on a boat at 8am<br />

s permit and toolbox are ready, the right<br />

start straight away. He then safely and<br />

job where he is equally well-prepared.<br />

t him back to shore on time.<br />

most value out of people and resources,<br />

The Planning Community meet weekly to review progress and actions<br />

ing it happen is a challenge, of course,<br />

scaffolding all work to different systems and have different approaches to<br />

ing to overcome that.”<br />

2006 identified three key strands of activity to improve IAP and overall<br />

ies across departments<br />

urposes<br />

illion, and each of the three strands has been progressed by cross-business<br />

still a way to go,” Paul said.<br />

om planning data that was based purely on cost-estimation. IAP now asks<br />

d the capabilities required to deliver their end result.<br />

rication right through to installation, so we have a more accurate picture of<br />

n to start, how jobs fit together and how to combine activities to get more<br />

y issues such as clashes with other activities, shutdowns and weather so that<br />

scheduled deferment. The innovative ‘Shut-down on Paper’ approach has<br />

wns. “This helped avoid clashes with other activities and has taken days of<br />

rels in the tank.”<br />

an important role in the achievement of record gas production in 2006.<br />

sentatives actually participate in key Integrated Activity Planning meetings,”<br />

ies between the businesses.<br />

e past, there have been up to 40 people in one room which resulted in slow,<br />

nderstand who needs to be in each meeting to get the best result.<br />

ality of the data they submit. Our experiences from 2006 are helping us to<br />

is the new global Shell integrated activity planning tool, which is being<br />

it improves transparency and means that financial results are linked directly<br />

hanges and improved interfunctional and departmental understanding and<br />

er. However, our people are coming to see that better planning is going to<br />

e their jobs easier and deliver better results.<br />

“In the past, we’ve recognised the heroes who fix things quickly when they<br />

k. We now want to really recognise and reward the people who comply and<br />

er with what they originally planned, and work most effectively with<br />

agues across all levels and departments. It will take time, but we’ve got good<br />

ort from across the business.<br />

“It is impossible for any one person to deliver the optimal solution in such<br />

plex operating environment,” he said. The principle of ‘alone we can do so<br />

, together we can do so much’ applies 100% to IAP.”<br />

“I’m confident about the long-term benefits we can deliver because we’ve<br />

talented, diverse team working on IAP issues, with representatives from the<br />

tions, assets, business planning and representatives from business<br />

ovement.”<br />

Delivering Business Improvement in 20<strong>07</strong><br />

The success of IAP is part of the <strong>BSP</strong> Business Improvement Programme.<br />

aim of the 20<strong>07</strong> programme is to consolidate the significant gains made in<br />

, sustain momentum and continue to align activities to the <strong>BSP</strong> strategy.<br />

programme is now led by the <strong>BSP</strong> Leadership Team, and has been extended<br />

nd the eight original themes to cover all improvement initiatives in <strong>BSP</strong>.<br />

<strong>BSP</strong> Business Improvement Manager, David Taylor said,“IAP is<br />

ducing important cross-business efficiencies that cut waste out of the system.<br />

is vital to sustain the success of the business in 20<strong>07</strong> and the years ahead.”<br />

Activity execution work being carried out<br />

Activity execution work being carried out<br />

Salam, <strong>Mar</strong>ch 20<strong>07</strong> 7

8 Salam, <strong>Mar</strong>ch 20<strong>07</strong><br />

Learning Centre<br />

scores another first<br />

Practical exercises in the class were carried out to enhance participants understanding about certified<br />

equipment including Equipment Inspection Exercise<br />

THE Brunei Asia Pacific Shell Learning Centre, formerly known as the Learning and Development<br />

Centre (LDC) scored another first when it conducted a learning event to a third party, Petronas, Malaysia<br />

LNG (MLNG) Plant in Bintulu, Sarawak from 22 January - 8 February 20<strong>07</strong>.<br />

The three-day learning event was entitled ‘Certified Equipment for Hazardous Area’ and was conducted by<br />

the Learning Centre’s Electrical Learning Adviser, Manggau Galawing. A total of 48 employees from MLNG<br />

engineering/ technical front line attended the course including staff from Shell Philippines Exploration BV (SPEX),<br />

Learning and<br />

development<br />

for MPM<br />

THE Brunei Asia Pacific Shell Learning Centre (formerly LDC) organised<br />

Learning and Development days at various <strong>BSP</strong> site locations throughout the<br />

month of <strong>Mar</strong>ch. Major Projects (MPM) held its Learning and Development<br />

session on 15 February at the Sutera Biru building in Kuala Belait.<br />

Gary Young, Head of Learning and Development at LDC gave an introduction<br />

where he said, “LDC has been evolving into a regional learning centre since 2005,<br />

which means that global programmes are becoming more accessible to our staff.<br />

The event triggered energy amongst staff by stimulating discussion and<br />

sharing experiences on training<br />

Che Baharum Che Busu, MLNG Senior Electrical<br />

Manager, receives a momento from Manggau<br />

Galawing from LDC<br />

Brunei LNG, Sarawak Shell Berhad (SSB) and Shell<br />

Malaysia Exploration and Production (SMEP).<br />

This course aims to enhance the front line staff<br />

to maintain facility asset integrity. Other subjects covered<br />

include:<br />

• Principle of protection for various type of<br />

Ex certified equipment, including “live”<br />

demonstration where possible<br />

• Design and construction for various type of<br />

Ex certified equipment including motors,<br />

lightings, junction boxes, etc<br />

• Inspection and maintenance practices<br />

including practical/ hand-on sessions<br />

• Pre and post training assessment for<br />

participants<br />

Overall, the course was beneficial for the<br />

participants and certificates were presented on<br />

completion of the course.<br />

Learning and Development days aimed to emphasise commitment to training<br />

and development by <strong>BSP</strong> and to increase awareness of the numerous training<br />

and development opportunities being offered<br />

Innovative learning processes such as blended and workplace learning are becoming<br />

the norm and there are tremendous benefits from mixing participants from <strong>BSP</strong>, the<br />

region and worldwide. “<br />

Learning and Development days were golden opportunities to showcase many<br />

of the offerings available to <strong>BSP</strong> staff and the key processes used to make learning<br />

happen. It aimed to emphasise the commitment to training and development by<br />

<strong>BSP</strong> and to increase awareness among staff of the numerous training and development<br />

opportunities in <strong>BSP</strong> and across Shell.<br />

Rob Brouwer, <strong>BSP</strong>’s Major Projects Manager (MPM) reiterated the<br />

commitment to training. He emphasised the importance of learning on the job,<br />

career planning and career ladders in learning. Rob said, “It is important to make use<br />

of the Competence Based Development (CBD) tool to identify gaps and to set work<br />

targets to close the identified gaps.”<br />

Altogether, some 60 members of staff from MPM and <strong>Eng</strong>ineering Services<br />

(SEN/1) attended the event. Staff were presented with an overview of learning<br />

programmes in <strong>BSP</strong>, EP Asia Pacific and Shell, including Shell Open University and<br />

Shell Project Academy. These included technical, project engineering, personal<br />

development and leadership development courses.<br />

The event triggered energy amongst the participants by stimulating discussion<br />

and sharing experiences on training. To seal staff commitment to training, staff were<br />

requested to fill in their training requirements for 20<strong>07</strong> at the end of the event.

Salam, <strong>Mar</strong>ch 20<strong>07</strong> 9<br />

Bruneianisation success at BST<br />

BRUNEIANS are today at the forefront of Brunei Shell Tankers’s internationally<br />

respected LNG shipping operation. Hajah Normawati Dato Paduka Haji Othman<br />

from Brunei Gas Carriers Sdn Bhd (BGC) explains how the success of BST’s<br />

Bruneianisation Programme was achieved.<br />

How it began<br />

The history of BST has undoubtedly been a<br />

successful one. Established in 1986, the seven vessels,<br />

in BST’s B-Class Fleet was subsequently chartered<br />

by BLNG to secure cargo deliveries to Japan.<br />

In spite of Brunei having these LNG tankers<br />

under its flag, very few nationals manned these vessels<br />

at the outset. BST began its Bruneianisation<br />

Programme in 1990 with the aim of manning its<br />

tankers with nationals in Master and Chief <strong>Eng</strong>ineer<br />

positions. BST assisted the Jefri Bolkiah College of<br />

<strong>Eng</strong>ineering by training <strong>Mar</strong>ine students onboard its<br />

vessels in 1990. Three of these students later joined<br />

BST as <strong>Eng</strong>ineering Officers in 1998.<br />

BST accelerated the Bruneianisation<br />

Programme in 2002 by sponsoring 14 cadets to<br />

undertake further studies at the Warsash <strong>Mar</strong>itime<br />

College, in the United Kingdom. The Programme<br />

was expanded in 2002 through a vigorous campaign<br />

to introduce Bruneian ships’ ratings covering activities<br />

i.e. machinists, deck and catering categories.<br />

The success that followed<br />

In September 2003, the success of BST’s<br />

<strong>Mar</strong>ine Cadets Year 2000 Intake was commemorated,<br />

with His Royal Highness Duli Yang Teramat Mulia<br />

Paduka Seri Pengiran Muda Mahkota Pengiran Muda<br />

Haji Al-Muhtadee Billah ibni Kebawah Duli Yang<br />

Maha Mulia Paduka Seri Baginda Sultan Haji<br />

Hassanal Bolkiah Mu’izzaddin Waddaulah, the<br />

Crown Prince and Senior Minister at the Prime<br />

Minister’s Office, graciously attending and witnessing<br />

this historic occasion.<br />

This graduation of thirteen of the Brunei<br />

<strong>Mar</strong>ine Cadet Officers marked a new beginning for<br />

the provision of highly trained, competent locals on<br />

BLNG vessels. Following completion of their studies<br />

and their achievement of internationally recognised<br />

qualifications, these Cadets progressed into positions<br />

of Third Deck Officers and Fourth <strong>Mar</strong>ine <strong>Eng</strong>ineers<br />

aboard the BLNG B-Class Fleet and BGC’s, Abadi.<br />

What was more pleasing was the outstanding<br />

achievement of one Bruneian Cadet, Ak Nor Hazman<br />

bin Pg Haji Abdul Hamid. Out of the 36 international<br />

students at Warsash <strong>Mar</strong>itime College, he was<br />

awarded the Best National Vocation Qualification<br />

(“NVQ”) Portfolio by the <strong>Mar</strong>ine Society of the<br />

Haji Ibrahim Haji Md Yassin, the Managing Director of BGC (centre) pictured<br />

alongside catering staff during his visit onboard the Abadi<br />

United Kingdom.<br />

A total of 31 Cadets have been sponsored through<br />

the Bruneianisation Programme, and the number of<br />

Brunei nationals has increased steadily against targets<br />

in all ranks in BST. By January 20<strong>07</strong>, there were 325<br />

BST employees - 79 officers and 246 ratings.<br />

Senior ranks in the Machinist section were held<br />

by the first Bruneian Machinists, Suhardi bin Rahiman<br />

and Arbi bin Haji Ibrahim in November 2003, and Haji<br />

Md Akinorbaishu bin Haji Suhaili was promoted as the<br />

first Bruneian Chief Cook in December 2003.<br />

In 2006, Belais was the second Brunei LNG vessel<br />

after Abadi to be manned fully by Bruneian ratings. This<br />

followed promotion of five capable fellow Bruneian<br />

Able-Seamen that have been trained as Bosuns.<br />

Bruneians have also held the key onshore position of<br />

Manning Officer since 2005.<br />

Strong performances continue<br />

Strong performances by young Bruneians<br />

continue through the Programme. This includes:<br />

♦ Third <strong>Eng</strong>ineer Shamsul Othman became<br />

the first Bruneian officer to reach senior ship<br />

management level following his appointment<br />

as Gas <strong>Eng</strong>ineer in 2006<br />

♦ Third <strong>Eng</strong>ineer Ak Nor Hazman was<br />

seconded to IMR Office in Japan as Brunei’s<br />

first Support <strong>Eng</strong>ineering Superintendent in<br />

May 2006. Ak Nor Hazman will follow suit<br />

from Shamsul as the next Bruneian Gas<br />

<strong>Eng</strong>ineer in <strong>Mar</strong>ch 20<strong>07</strong>.<br />

♦ Third <strong>Eng</strong>ineer <strong>Eng</strong> Yih Chih commenced<br />

his Support <strong>Eng</strong>ineering Superintendent<br />

secondment to IMR Office early February<br />

20<strong>07</strong>.<br />

♦ Second Officer <strong>Mar</strong>tin Liew recently<br />

completed his assignment as Brunei’s first<br />

Support Operations Superintendent at<br />

STASCO Headquarters in London.<br />

♦ Chief Cook, Sardini Bin Hj Tajuddin<br />

commenced “hands-on” training with<br />

Catering Trainer Hendry Anderson to<br />

assume the role of the first Bruneian Catering<br />

Trainer following completion.<br />

Several training programmes have been<br />

implemented to consolidate the success of the<br />

<strong>Mar</strong>tin Liew being welcomed at the start of his<br />

superintendency training at STASCO<br />

Headquarters, UK<br />

Ak Nor Hazman<br />

during his<br />

superintendency<br />

training at IMR<br />

Office, Japan<br />

Programme. BST staff competency is further<br />

developed by having trainers for both officers and<br />

ratings onboard the ships. Safety training and<br />

awareness initiatives are of course a top priority in<br />

BST, and play a key role in the development of all<br />

staff<br />

A prosperous future<br />

The journey for Bruneian Masters or Chief<br />

<strong>Eng</strong>ineers to serve on Brunei LNG tankers is far from<br />

over, but the milestones achieved by this Programme<br />

stand as a testament that this vision will be attained.<br />

Bruneianisation is being sustained through a<br />

continuous process of recruiting talented nationals,<br />

providing them with educational and training<br />

opportunities, and actively supporting the<br />

development of their careers.<br />

The Bruneians in this Programme will continue<br />

to contribute not only to the Company, but also to<br />

the prosperity of Brunei Darussalam. Their<br />

achievements build on centuries of maritime tradition<br />

and strengthen the nation’s reputation of 35 years<br />

supply of LNG to customers.<br />

Brunei’s first Bosuns during their training aboard North West Eagle in 2006

10 Salam, <strong>Mar</strong>ch 20<strong>07</strong><br />

The Benchmarking (BM) Cycle:<br />

SCOT BM feedback and<br />

20<strong>07</strong> Upstream BM Review for West and East<br />

The team from OPM, West, HP, PCC and EP Asia Pacfic during the SCOT<br />

Benchmarking Feedback Session<br />

By Hajah Mahayon M Taha (OPM/53)<br />

THE Seria Crude Oil Terminal’s (SCOT) terminal benchmarking feedback<br />

session was held in the Learning and Development Centre in Seria in January<br />

attended by the key benchmarking team from Production and Maintenance<br />

Excellence (OPM), Hydrocarbon Processing (HP), West asset and the EP<br />

Asia Pacific benchmarking team.<br />

The objective of the crude oil export terminal benchmarking review,<br />

which began in 2005, was to compare the operational performance of crude<br />

oil export terminals, on a worldwide basis, whilst taking into account the<br />

diversity of the facilities and their operating parameters.<br />

To facilitate the comparisons, a number of normalising factors were<br />

incorporated, the main one being the Mechanical Equivalency Factor and<br />

Barrel of Oil equivalent. The second part of the process was the analysis and<br />

understanding of performance gaps. This was followed by the most essential<br />

part of the process, which was the selection, and implementation of gap closure<br />

actions.<br />

A typical benchmarking process consists of eight phases, which involves<br />

familiarising with process parameters and Maintenance Equivalency Factor<br />

workbooks, training the staff, data collection, data validation, data processing,<br />

data analysis, reporting and finally the facility ‘gap analysis’ workshop. The<br />

benchmarking requires accurate process, timely submission and report timing<br />

preferably aligned to the business plan. The dimension of the benchmarking<br />

Part of the Benchmarking team at work in a ring-fenced system<br />

review requires inputs on:<br />

♦ Availability & utilization<br />

♦ Safety and environment<br />

♦ Operating costs<br />

♦ Maintenance and reliability<br />

♦ Personnel<br />

For the 20<strong>07</strong> benchmarking cycle, there are<br />

three <strong>BSP</strong> upstream facilities participating in the<br />

benchmarking review namely, West asset: Ampa,<br />

Fairley and East asset: Champion fields. OPM/5<br />

is the central focal point for data compilation and<br />

the team has now submitted the completed<br />

workbooks to SGSI on 28 February 20<strong>07</strong>.<br />

West and East are the two assets in their<br />

journey to top-quartile (TQ) and the<br />

benchmarking efforts will be used to support their<br />

TQ action plans. The top quartile assets will be<br />

benchmarked on a yearly cycle while the rest will<br />

be benchmarked on a two-yearly cycle.<br />

The view graphs show the benchmarking<br />

plan in the next 90 days and key milestone and<br />

deliverables as shown:

MORE than 70 government representatives, including officers from the<br />

Ministry of Defence and Ministry of Health, attended a briefing session<br />

organised by Brunei Shell <strong>Mar</strong>keting Co Sdn Bhd (BSM) for government<br />

departments on the new process improvements for government bulk purchases<br />

using fleetcard on 1 <strong>Mar</strong>ch 20<strong>07</strong>.<br />

The briefing session was jointly chaired by BSM’s Head of Business and<br />

Development (BMB), Siti Kurshiah Haji Anuar, Dk Hajah Noorasiah Pg Haji Hassan<br />

of Treasury Department and Haji Suhaimi Haji Hashim from Bank Islam Brunei<br />

Darussalam.<br />

The primary purpose of the session was to brief the various government<br />

departments on the newly-revised payment system from the government to BIBD<br />

using the Tafis System. Dk Hajah Noorasiah also discussed the impact on bulk<br />

Longservice<br />

30 YEARS<br />

Hj Salleh Bin Mohd Daud PCC<br />

Hung Kim Hwa STL111<br />

Mohamad Bin Hj Jimin ISM341<br />

Kapli Bin Hj Omar Ali SCO542<br />

25 YEARS<br />

Improving processes for<br />

government fuel purchases<br />

The purpose of the session was to brief the various government departments<br />

on the newly-revised system<br />

LiveWIRE launches<br />

sixth business awards<br />

LIVEWIRE Brunei launched its annual Business<br />

Awards competition for the year 2006 - 20<strong>07</strong> on<br />

27 February 20<strong>07</strong>. This is the sixth LiveWIRE<br />

Brunei Business Awards, which is organised and<br />

jointly sponsored by <strong>BSP</strong> and HSBC Brunei.<br />

The event, part of a continuous commitment to<br />

develop and promote young entrepreneurs in Brunei<br />

Darussalam, was officiated by the Permanent Secretary<br />

at the Ministry of Education, Dato Paduka Haji Sheikh<br />

Adnan bin Sheikh Mohammad. Also attending the event<br />

was the Chief Executive Officer of HSBC Brunei, Mr<br />

Guy Priestley. The award aims to encourage and recognise<br />

the achievement of young entrepreneurs in preparing<br />

for starting up a business.<br />

35 YEARS<br />

Jatali Bin Akun DOP124<br />

Khoo <strong>Eng</strong> Kiat OPS2<br />

Deputy Managing Director of <strong>BSP</strong>, Haji Zainal<br />

Abidin Haji Md Ali, in his capacity as the Chairman of<br />

the LiveWIRE Brunei Board said, “<strong>BSP</strong> hopes the<br />

LiveWIRE programmes will continue to contribute towards<br />

local business development and complement the<br />

government’s efforts to build a robust small-and-medium<br />

enterprise (SME) sector.”<br />

This year, LiveWIRE Brunei is introducing a new<br />

award category - the LiveWIRE Brunei Special Business<br />

Award - to recognise LiveWIRE participants who<br />

have been sustaining their business for at least three years.<br />

LiveWIRE Brunei will also run a series of dialogue<br />

sessions that focuses on coaching participants to<br />

develop business plans.<br />

Hjh Norsaripah Bte Hj M Noor FTR0<br />

Jaitun Bte Hashim HPD20<br />

Liaw Wei Fun HBS21<br />

Rusli Bin Haji Mokti ISM161<br />

Hee Kui Leng OPM55<br />

Chang Lee Lee DPE10<br />

Zamadi Bin Yusof SCM4321<br />

Chai Sut OPM6213<br />

Surayati Bte Samin MPS312<br />

Hamdan Bin Hj Pudin BMR6<br />

Foo Cheh Keng SCM1335<br />

Serimah Bte Awg Besar SCM127<br />

Chaw Nyet Hiong ISM225<br />

Fatimah Bte Hj Zainip EEN0<br />

20 YEARS<br />

Hj Osman Bin Hj Ladis ISM Tinggal Bin Hj Sulong POP111<br />

Salam, <strong>Mar</strong>ch 20<strong>07</strong> 11<br />

Representatives from various government departments at the roadshow<br />

purchases and procedures that were outlined for them during the cut-off period of<br />

the New Government Budget Roll out, which will start in mid-<strong>Mar</strong>ch towards early<br />

April. In addition, Haji Suhaimi further explained services offered by the bank<br />

pertaining to the Government Bulk Purchases using Fleet Card.<br />

The Kad Inden is a cooperation project between Bank Islam Brunei Darussalam<br />

and BSM to provide value-added services in partnership with the Ministry of Finance.<br />

It supports the initiative of His Majesty’s government towards e-Government through<br />

electronic payment and paperless office solutions. As of 31 July last year, all government<br />

departments are now required to subscribe to the system eliminating the need to use<br />

paper invoices.<br />

Dato Paduka Haji Sheikh Adnan bin Sheikh<br />

Mohammad launched the LiveWIRE Business<br />

Awards. He is seen here with Haji Zainal Abidin<br />

Haji Mohd Ali and Mr Guy Priestley<br />

Abd Zabar Bin Sion IAM21<br />

15 YEARS<br />

Bieseman T EPE6<br />

Dk Hjh Umi Kalthum P H Zainal EPO21D<br />

Hj Md Nur Zaim Abdullah Sutee SCO533<br />

Masliah Bte Hj Mohamad Ali TSX10<br />

Hasimewati Bte Sidek IWM417<br />

Abidin Bin Mohamad Zen HML4<br />

Hjh Normaya Hj Musri EPE31<br />

Meijs Van Der J FAC<br />

Pine B D EPE5<br />

10 YEARS

12 Salam, <strong>Mar</strong>ch 20<strong>07</strong><br />

<strong>BSP</strong> awards fabrication<br />

contract to local business<br />

Grahaeme also highlighted the immense spin-off opportunities for businesses that would be<br />

generated from this contract. “There will be more employment opportunities for sub-contracting<br />

activities to support this contract, starting with engineering work right through the chain to the local<br />

business community, including shops and restaurants.”<br />

The projects awarded under this contract are critical to <strong>BSP</strong>’s operations and its continued<br />

dynamic business growth. After achieving an outstanding performance record in 2006 in all key areas<br />

of the business, <strong>BSP</strong> intends to work hard at repeating the success this year and every year with the help<br />

of the local business community.<br />

Grahaeme Henderson and Yang Amat Mulia Pengiran Anak<br />

Haji Abdul Wadood Bolkiah signed the contract for major<br />

fabrication works including fabrication of the Mampak and<br />

Seria North Flank jacket<br />

IN a contract signing ceremony held at the Oil and Gas<br />

Discovery Centre on 2 <strong>Mar</strong>ch 20<strong>07</strong>, <strong>BSP</strong> awarded a local<br />

company Syarikat Kejuruteraan Sistematik (SKS) Sdn Bhd<br />

with a major project fabrication contract.<br />

The scope of the contract includes the fabrication of the<br />

Mampak and Seria North Flank jacket and topside module fabrication<br />

as well as other incoming <strong>BSP</strong> major projects. The fabrication<br />

of these structures will be carried out locally at <strong>BSP</strong>’s Campaign<br />

Operations Services (SCO) fabrication yard in Kuala Belait.<br />

Managing Director, Grahaeme Henderson, signed on behalf<br />

of <strong>BSP</strong> with Yang Amat Mulia Pengiran Anak Haji Abdul Wadood<br />

Bolkiah bin Pengiran Lela Cheteria Sahibun Najabah Pengiran Anak<br />

Haji Abdul Aziz, the Chairman of SKS Sdn Bhd, signing on behalf<br />

of SKS.<br />

Covering a period of five years, the contract awarded to SKS<br />

Sdn Bhd, a locally based Bruneian contractor, supports <strong>BSP</strong>’s sustainable<br />

development commitment, in nurturing the development<br />

of local Bruneian businesses and human capital.<br />

In his welcoming speech, Grahaeme noted, “SKS, is a wholly<br />

Bruneian-owned and managed company and its success story continues<br />

and builds on the proud tradition of many other Bruneian<br />

contractor companies, which are currently doing business with <strong>BSP</strong>.”<br />

He continued, “For us in <strong>BSP</strong>, local business development is<br />

integral to, and inseparable from, our business and social commitments<br />

in this country. <strong>BSP</strong> is a major contributor to the Government<br />

of Brunei Darussalam’s efforts to strengthen the small-andmedium<br />

enterprises, or SMEs, in the country.”<br />

The renewed sale agreement will see <strong>BSP</strong> continuing to supply Taiyo with up to 20,000<br />

barrels per day of SLEB until 2008<br />

BRUNEI Darussalam entered into another sales agreement with Japan when <strong>BSP</strong> signed the<br />

Crude Oil Sales Agreement for 20<strong>07</strong> with Taiyo Oil on 14 <strong>Mar</strong>ch.<br />

The agreement was signed between Grahaeme Henderson, Managing Director of <strong>BSP</strong> on behalf<br />

of <strong>BSP</strong> and Mr Yutaka Oka, President of Taiyo Oil on behalf of that company. The renewed sale<br />

agreement will see <strong>BSP</strong> continuing to supply Taiyo with up to 20,000 barrels per day of Seria Light<br />

Export Blend (SLEB) for the period 1 April 20<strong>07</strong> to 31 <strong>Mar</strong>ch 2008.<br />

In acknowledging Taiyo Oil’s continuing loyal support over the years towards <strong>BSP</strong> and Brunei<br />

Darussalam, Grahaeme said, “Taiyo Oil is definitely an important customer to Brunei Darussalam<br />

who has been with us for over three decades. Our mutual relationship is beyond the oil trade as it has<br />

grown strongly over these years and will continue to grow in the future.”<br />

Taiyo Oil, a refining company, links Brunei with the island of Shikoku, the smallest of the four<br />

main islands that made up Japan, the location of its refining complex. Its refinery has processed Brunei’s<br />

flagship crude export grade, SLEB for more than 35 years.<br />

The business tie with the Japanese refiner has withstood the test of time, which dates as far back<br />

as 1969, during which time the volume supplied has grown from 5,000 barrels per day to its current<br />

quantity of 20,000 barrels per day.<br />

<strong>BSP</strong> signs contract for<br />

Containerised Equipment Room<br />

Haji Salleh Bostaman and Haji Musa signed the contract for the development of a new CER<br />

for <strong>BSP</strong>’s Mampak project<br />

<strong>BSP</strong> renews oil trade<br />

with long term customer<br />

<strong>BSP</strong> held a contract signing ceremony for the future<br />

development of a new Containerised Equipment Room<br />

(CER) on 13 <strong>Mar</strong>ch 20<strong>07</strong>. The contract is for the<br />

development of a new CER for <strong>BSP</strong>’s Mampak Project, one<br />

of the key projects in <strong>BSP</strong>’s major project portfolio which is<br />

scheduled for completion in 2008.<br />

<strong>BSP</strong>’s Asset Director, Haji Salleh Bostaman Haji Zainal<br />

Abidin signed the contract on behalf of <strong>BSP</strong> along with Haji Musa<br />

Haji Adinin, Managing Director of Adinin Group of Companies,<br />

signing on behalf of Adinin Works and <strong>Eng</strong>ineering Sdn Bhd, in<br />

association with Emerson Process Management. Also in attendance<br />

at the ceremony was <strong>BSP</strong>’s Major Projects Manager, Rob Brouwer.<br />

The CER will be constructed locally with the contract falling<br />

in line in supporting <strong>BSP</strong>’s sustainable development commitment,<br />

in developing local Bruneian businesses and human capital.