Hydraulic Hoses, Fittings and Equipment - Brammer

Hydraulic Hoses, Fittings and Equipment - Brammer

Hydraulic Hoses, Fittings and Equipment - Brammer

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

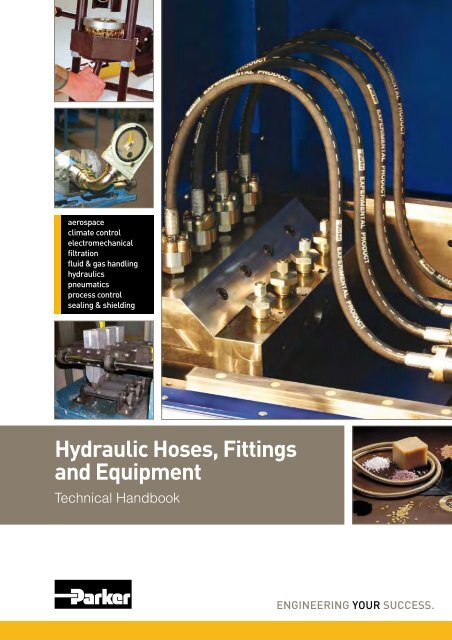

aerospace<br />

climate control<br />

electromechanical<br />

filtration<br />

fluid & gas h<strong>and</strong>ling<br />

hydraulics<br />

pneumatics<br />

process control<br />

sealing & shielding<br />

<strong>Hydraulic</strong> <strong>Hoses</strong>, <strong>Fittings</strong><br />

<strong>and</strong> <strong>Equipment</strong><br />

Technical H<strong>and</strong>book

Parkrimp No-Skive <strong>and</strong> ParLock System<br />

Along with the ever-growing<br />

power <strong>and</strong> efficiency of<br />

construction, agriculture <strong>and</strong><br />

other machinery <strong>and</strong> increasing<br />

working pressures <strong>and</strong> flow<br />

Parkrimp No-Skive system<br />

is based on no-skiving technology (without<br />

removing the rubber cover before assembling)<br />

Each of the two concepts has its<br />

indisputable advantages – which<br />

concept should be selected<br />

depends on the particular<br />

conditions of the application.<br />

rates of their hydraulic systems,<br />

multispiral hose is gaining an<br />

increasingly important role in<br />

machine design.<br />

Parker Hannifin, as the world<br />

ParLock system<br />

uses external or internal <strong>and</strong> external<br />

skiving (Interlock) technology<br />

leader in the hydraulic hose<br />

market, responds to these highly<br />

dem<strong>and</strong>ing requirements with<br />

2 comprehensive systems –<br />

Parkrimp No-Skive <strong>and</strong> ParLock.<br />

Each of the Parkrimp No-Skive<br />

<strong>and</strong> ParLock systems consists of<br />

integrated ranges of hose, fittings<br />

<strong>and</strong> assembling equipment <strong>and</strong><br />

know-how, all of which are:<br />

• Designed <strong>and</strong> developed<br />

together<br />

• Tested <strong>and</strong> approved together<br />

• Produced <strong>and</strong> supplied<br />

together<br />

This way Parker Hannifin can<br />

guarantee:<br />

• The highest quality <strong>and</strong> safety<br />

<strong>and</strong> the longest service life of<br />

the final product – to the end<br />

users, <strong>and</strong> at the same time:<br />

• The easiest, most efficient <strong>and</strong><br />

safe production process – to<br />

the assemblers.<br />

In this way Parker Hannifin<br />

also meets the requirements of<br />

SAE J1273 <strong>and</strong> ISO 17165-2,<br />

which pay particular attention<br />

to matching the hose with the<br />

fittings <strong>and</strong> to their compatibility<br />

proven by the manufacturer.

Parkrimp No-Skive<br />

The easy to operate crimp system<br />

from textile to 6 spiral high tensile steel wire<br />

Parkrimp No-Skive is synonymous<br />

with the best solution for<br />

assembling hydraulic <strong>and</strong> related<br />

hose <strong>and</strong> fittings from both the<br />

technical <strong>and</strong> the manufacturing<br />

points of view!<br />

Throughout the progressive<br />

rubber <strong>and</strong> metal compression<br />

during the crimping process the<br />

reinforcement always remains<br />

intact. The meticulous design,<br />

Parkrimp No-Skive<br />

hose <strong>and</strong> fittings<br />

the system for fast<br />

<strong>and</strong> leak-free assemblies<br />

• For crimping Parkrimp<br />

No-Skive fittings only<br />

• No skiving tool needed<br />

• No need to remove the cover<br />

• Quick <strong>and</strong> easy: no gauges to<br />

set on the machine<br />

• Portable machines for field<br />

repair<br />

• Meets EN safety regulations<br />

Parkrimp No-Skivee hose <strong>and</strong> fittings the system with the perfect match<br />

The perfect match<br />

The complete system from one<br />

source. No-Skive hose, No-Skive<br />

fitting <strong>and</strong> crimping machine<br />

with world-wide guarantee<br />

<strong>and</strong> availability.<br />

testing <strong>and</strong> manufacturing processes<br />

of Parkrimp No-Skive<br />

hose <strong>and</strong> fittings, combined with<br />

the approved crimping diameters<br />

provide an excellent mechanical<br />

connection between the hose<br />

<strong>and</strong> the fitting. This absolutely<br />

leak-free connection gives long<br />

service life even with the highest<br />

pressures associated with 4- <strong>and</strong><br />

6-spiral hose assemblies.<br />

Parker’s colour-coded die sets<br />

No loose parts to mismatch or<br />

misplace – die set segments<br />

linked together. Die sets provide<br />

360° evenly applied crimping<br />

forces for an ideal crimp result.<br />

The smartly designed <strong>and</strong> timetested<br />

Parkrimp No-Skive assembling<br />

equipment combined with<br />

Parker‘s assembling know how<br />

allow the safest, most efficient<br />

<strong>and</strong> mistake-proof assembly<br />

process. The Parkrimp equipment<br />

allows cost <strong>and</strong> time savings to<br />

the assembler <strong>and</strong> guarantees a<br />

defect-free, reliable <strong>and</strong> durable<br />

final product to the end-user.<br />

Parkalign ®<br />

Parker’s exclusive Parkalign ®<br />

positions the fitting in the dies<br />

perfectly every time.

ParLock<br />

The system for extremely dynamic pressure applications<br />

Applications requiring the ParLock system<br />

• Hydrostatic transmissions<br />

(combine harvesters, large<br />

tractors, excavators, etc.)<br />

• Vibratory hammers<br />

Gripping zone<br />

• superb mechanical<br />

grip for safety <strong>and</strong><br />

impulse life<br />

Sealing zone<br />

• superb sealing<br />

performance<br />

• high compression<br />

• rubber friendly<br />

shapes<br />

For manufacturing the ParLock hose assemblies Parker Hannifin offers<br />

• Skiving machines for<br />

external <strong>and</strong> internal skiving<br />

• Large injection moulding<br />

machines<br />

• Tunnelling machines<br />

• Forestry machines<br />

• Universal crimping machines<br />

with adjustable crimping<br />

diameter<br />

tions with extremely dynamic pressure<br />

ressure surges <strong>and</strong> peaks, as well as<br />

tions with intense vibrations <strong>and</strong> hose<br />

(bending), especially when close to the<br />

, a strong mechanical grip by the fitting<br />

the hose is paramount.<br />

opular method accepted by the market of<br />

eving this mechanical grip in such aptions<br />

is to use hose fittings that „lock“<br />

etal reinforcement of the hose directly<br />

en the metal shell <strong>and</strong> nipple – for which<br />

er of the hose has to be removed both<br />

• Large material h<strong>and</strong>ling<br />

machines (container h<strong>and</strong>ling)<br />

• Excavator booms<br />

• Blow-out preventers<br />

in oil <strong>and</strong> gas<br />

Transition zone<br />

• gradual takeup<br />

of bending<br />

forces <strong>and</strong><br />

reinforcement<br />

<strong>and</strong> hose<br />

movements<br />

• weather seal<br />

• Detailed assembling<br />

instructions (see further<br />

in this catalogue)<br />

externally <strong>and</strong> up to a certain<br />

length also internally (a concept<br />

generally called „Interlock“).<br />

As a response to the market requirement<br />

for an „Interlock“ hose<br />

fitting system, Parker has developed<br />

the Parlock program. This<br />

range consists of a specific range<br />

of hose, fittings <strong>and</strong> assembly<br />

equipment combined with<br />

Parker crimping know-how.

Technical H<strong>and</strong>book<br />

<strong>Hydraulic</strong> <strong>Hoses</strong> <strong>and</strong> <strong>Fittings</strong><br />

<strong>Hoses</strong> <strong>and</strong> <strong>Fittings</strong> Terminology – The basics Aa-2 – Aa-8<br />

Safe Hose Assemblies in 8 Steps Aa-9<br />

1 Application Aa-9<br />

2 Pressure Aa-10<br />

3 Size Aa-10<br />

4 Temperature Aa-11<br />

5 Fluid Compatibility Aa11<br />

6 Hose <strong>Fittings</strong> Aa-11<br />

7a Working Steps for One-Piece Parkrimp No-Skive <strong>Fittings</strong> Aa-12 – Aa-14<br />

7b Working Steps for Two-Piece ParLock <strong>Fittings</strong> Aa-15 – Aa-16<br />

8 Routing, Installation, Environmental influences Aa-17 – Aa-19<br />

How to Order (Part number description) Aa-20 – Aa-21<br />

<strong>Hoses</strong> <strong>and</strong> <strong>Fittings</strong> Storage Aa-22 – Aa-23<br />

Safety Precaution Aa-24 – Aa-25<br />

Proactive Maintenance Programme Aa-26<br />

Technical Data<br />

Hose Overview Ab-2 – Ab-3<br />

Hose <strong>Fittings</strong> Overview Ab-4 – Ab-7<br />

Hose <strong>Fittings</strong> Pressure Ratings Ab-8 – Ab-10<br />

Hose <strong>Fittings</strong> Nomenclature Ab-11 – Ab-14<br />

Classification Bodies Ab-15<br />

Classification Body Type Approvals Ab-16 – Ab-17<br />

Conversion Chart Ab-18<br />

Temperature / Pressure Chart Ab-19<br />

Flow Capacity Nomogram Ab-20<br />

The Correct Method to Fit Female Swivel Ends Ab-21<br />

Chemical Resistance Table Ab-22 – Ab-30<br />

Identifying Fitting Types Ab-31 – Ab-41<br />

Safety Guide Ab-42 – Ab-45<br />

A-Index<br />

Index<br />

Catalogue 4400/UK

<strong>Hoses</strong> <strong>and</strong> <strong>Fittings</strong> Terminology<br />

– The basics!<br />

<strong>Hydraulic</strong> hose is a full-value part of the hydraulic<br />

system transmitting the hydraulic power – not just<br />

conveying a fluid – <strong>and</strong> deserves adequate attention,<br />

just like the other hydraulic components which generate,<br />

consume or control that power. Furthermore,<br />

it is just hydraulic hose assemblies that are usually<br />

most exposed to various extreme conditions in<br />

which they have to retain full functionality <strong>and</strong> assure<br />

serviceability of the hydraulic system <strong>and</strong> safety<br />

of the operators.<br />

Aa-2<br />

In spite of that, the importance of the hydraulic hose<br />

is often overlooked <strong>and</strong> underestimated.<br />

This catalogue is to provide guidelines to correct<br />

hoses <strong>and</strong> fittings selection <strong>and</strong> hose assembly<br />

manufacturing <strong>and</strong> to highlight the most important<br />

safety aspects for its service in the field.

<strong>Hydraulic</strong> Rubber <strong>Hoses</strong><br />

Tube – inner layer of rubber compound<br />

with chemical <strong>and</strong> physical<br />

properties to be long-term resistant<br />

to the fluid <strong>and</strong> working conditions.<br />

Reinforcement – 1 or 2 (exceptionally<br />

3) layers of braided textile fibre or<br />

highly tensile steel wire or 4 or 6 layers<br />

of spiralled very highly tensile steel<br />

wire to bear high pressure but allow<br />

flexibility of the hose.<br />

Cover – outer layer of rubber compound<br />

with chemical <strong>and</strong> physical<br />

properties to protect the reinforcement<br />

against ambient conditions <strong>and</strong><br />

mechanical damage.<br />

Depending on the pressure level we classify the<br />

hydraulic hoses in this catalogue into 4 groups:<br />

• Push-Lok<br />

– low-pressure hoses<br />

with self-grip connection to fittings<br />

• Low pressure <strong>and</strong> Transportation<br />

– 1 <strong>and</strong> 2 textile yarn braided <strong>and</strong><br />

1 steel wire braided hoses<br />

• Medium pressure<br />

– 1 <strong>and</strong> 2 steel wire braided hoses <strong>and</strong><br />

suction hoses<br />

• High pressure<br />

– 3 steel wire braided hoses <strong>and</strong><br />

4 or 6 spiral steel wire braided hoses<br />

– 4 spiral steel wire braided compact hoses<br />

Insulation/<br />

Separation layer<br />

Inside tube<br />

Aa-3<br />

Hose <strong>and</strong> <strong>Fittings</strong> Terminology<br />

Cover<br />

Steel wire braided<br />

reinforcement<br />

Depending on the method of hose <strong>and</strong> fittings<br />

assembling we offer 2 basic product concepts<br />

(integrated product lines of hoses, fittings,<br />

assembling equipment <strong>and</strong> know-how):<br />

• Parkrimp No-Skive<br />

– complete range of braided <strong>and</strong> spiralled hose,<br />

not needing removing (skiving) of the hose<br />

cover before assembling.<br />

• ParLock<br />

– specific range of 4 <strong>and</strong> 6 spiral hose for extreme<br />

applications which require skiving of the cover<br />

<strong>and</strong> for bigger sizes also of the inner tube.

Hose <strong>and</strong> <strong>Fittings</strong> Terminology<br />

Hose <strong>Fittings</strong><br />

Nipple (insert etc.) – the inner part of the fitting<br />

of which, one end is coupled to the counterpart of<br />

a hydraulic component (termination end), while the<br />

other end is inserted into the hose (tail end).<br />

To assure compatibility <strong>and</strong> leak-free sealing of the<br />

hose fitting with the other connectors, designs of<br />

termination ends are st<strong>and</strong>ardized according to<br />

numerous national <strong>and</strong> international st<strong>and</strong>ards.<br />

The main role of the tail end is to provide durable<br />

sealing between fitting <strong>and</strong> hose.<br />

Shell (socket, ferrule etc.) – the outer part of<br />

the fitting provides mechanical connection of the<br />

fitting with the hose. To assure a strong hold of the<br />

hose reinforcement, shells are generally crimped on<br />

to the hose during assembly.<br />

The design of the tail end <strong>and</strong> the shell profile is the<br />

sole responsibility of the respective manufacturer.<br />

Due to this reason many different designs are found<br />

in the market (only the design of the termination end<br />

<strong>and</strong> the functionality of the enitire hose assembly is<br />

specified in the international st<strong>and</strong>ards.<br />

In this catalogue we offer 3 kinds of fittings:<br />

• Push-Lok<br />

– special nipples connectable to<br />

Push-Lok hose without any shells.<br />

• 1-piece fittings<br />

– pre-crimped shells on nipples make the assembling<br />

of hose with fittings easier, more<br />

effective <strong>and</strong> reliable.<br />

• 2-piece fittings<br />

– for extreme applications requiring full metalto-metal<br />

connection of the hose reinforcement<br />

with the shell or even with the nipple (external<br />

or external plus internal skiving).<br />

Aa-4<br />

Note<br />

Parker Hannifin also offers a limited range of<br />

2-piece Parkrimp No-Skive fittings but being<br />

special products they are not included in this<br />

catalogue. For more information about 2-piece<br />

fittings, please contact our Division Helpdesk<br />

(HPDE_Helpdesk@parker.com)<br />

Except Push-Lok, all fittings in this catalogue<br />

are crimped <strong>and</strong> include:<br />

• All Parker 1-piece fittings<br />

– suitable for the<br />

Parkrimp No-Skive e product line<br />

• All 2-piece fittings in this catalogue<br />

– suitable for the<br />

ParLock product line

Hose Assembly<br />

It is the interplay between the fitting tail <strong>and</strong> shell<br />

designs <strong>and</strong> the hose design with its material<br />

properties that primarily determine performance,<br />

service, durability <strong>and</strong> safety of the final hose<br />

assembly. Yet compatibility of hose <strong>and</strong> fitting<br />

cannot be just theoretically projected. It requires<br />

exhaustive <strong>and</strong> repetitive laboratory <strong>and</strong><br />

field tests <strong>and</strong> further tuning of the designs.<br />

Non-compatibility of hose with fittings or even<br />

the combination of hose <strong>and</strong> fittings from different<br />

manufacturers, do not just only influence the performance<br />

of the hose assembly, they often<br />

lead to hose failure with serious health or<br />

life-threatening consequences! For this<br />

reason the main international st<strong>and</strong>ards<br />

ISO 17165-2 <strong>and</strong> SAE J1273 strictly<br />

warn not to mix hose with fittings from different<br />

manufacturers without their approval.<br />

Parker Hannifin has not approved products of<br />

any other manufacturer for combination with<br />

Parker hoses <strong>and</strong>/or Parker fittings <strong>and</strong> guarantees<br />

full compatibility, reliability <strong>and</strong> safety only<br />

for combinations of genuine Parker parts selected<br />

<strong>and</strong> assembled in accordance with the guidelines<br />

included in this catalogue!<br />

Pressure Rating<br />

Aa-5<br />

Hose Hint<br />

Never mix & match one manufacturer’s<br />

fittings with hoses from<br />

another manufacturer.<br />

Parker hoses, fittings, assembling<br />

equipment <strong>and</strong> know-how are<br />

designed as an integrated system.<br />

Only this ensures optimum product<br />

performance, reliability <strong>and</strong><br />

safety!<br />

<strong>Hydraulic</strong> hose is a component transmitting hydraulic power <strong>and</strong> the pressure is obviously the main physical<br />

quantity determining the hydraulic power. For hydraulic hoses the following pressure ratings are used:<br />

Working Pressure – the pressure for which the<br />

hose assembly is designed to operate over its<br />

whole service life - provided the other<br />

parameters (temperature in particula<br />

stay within reasonable limits.<br />

For apparently static applications<br />

(e.g. with h<strong>and</strong> pumps or water<br />

jetting) consult the Working Pressure<br />

with your Parker Field Representative<br />

or with our Technical Support<br />

(HPDE_Helpdesk@parker.com).<br />

Hose <strong>and</strong> <strong>Fittings</strong> Terminology<br />

Burst Pressure – the pressure which statically<br />

applied causes destruction of the hose. Technical<br />

st<strong>and</strong>ards for hydraulic hoses define the burst<br />

pressure to be equal to or higher than 4 times the<br />

working pressure (safety factor 4). This rule <strong>and</strong><br />

the burst pressure in general serve<br />

to hose manufacturers for design<br />

<strong>and</strong> testing of the<br />

hose only! If you 4 x =<br />

happen to know<br />

the burst pressure of certain<br />

hose, never use this rule backwards<br />

to deduce its working pressure!

Hose <strong>and</strong> <strong>Fittings</strong> Terminology<br />

Remember the working pressure<br />

1. The hose assembly working<br />

the weakest “link in the chai<br />

of the working pressures of<br />

fittings. Do not forget to chec<br />

sure of the fittings when sele<br />

for a hose assembly<br />

(see pages Ab-8 to Ab-10 of<br />

2. The real hydraulic system o<br />

is not given by the system<br />

components setup but by the<br />

which introduces into the sys<br />

<strong>and</strong> surges or by the functio<br />

system itself (rapid closing o<br />

induces spikes <strong>and</strong> pulses. S<br />

are detectable only by sensit<br />

sure gauges <strong>and</strong> are usually<br />

all filtered out by safety or relief valves <strong>and</strong> exert<br />

excessive strain on the hydraulic system – hoses<br />

<strong>and</strong> tubes first of all!<br />

3. The hose assembly working pressure must<br />

always be equal to or higher than the real<br />

hydraulic system operating pressure incl. all<br />

peaks, surges, spikes <strong>and</strong> pulses!<br />

Hose Hint<br />

Working pressure is a dynamic<br />

parameter, burst pressure is<br />

a static parameter. High burst<br />

pressure does not mean high<br />

working pressure!<br />

4x =<br />

Aa-6<br />

of<br />

s MPa<br />

(Mega Pascal) – used also in this catalogue. In the<br />

US <strong>and</strong> in Anglo-Saxon markets also psi (pounds<br />

per square inch) is officially used <strong>and</strong> many European<br />

producers, users <strong>and</strong> even technical st<strong>and</strong>ards<br />

still also use bar.<br />

For the conversion chart of various units of measure<br />

see page Ab-18.<br />

In order to assure mutual compatibility, producers<br />

of hydraulic equipment, producers of machines<br />

<strong>and</strong> also international technical st<strong>and</strong>ards profess<br />

certain preferred pressure levels:<br />

MPa 21 28 35 42<br />

bar 210 280 350 420<br />

psi 3000 4000 5000 6000<br />

Hose Hint<br />

For highly dem<strong>and</strong>ing applications<br />

(dynamic pressure, high number of pressure<br />

cycles, high temperature etc.):<br />

• Select hose with much higher working<br />

pressure than officially requested<br />

• Select multispiral hose instead of braided or<br />

ParLock instead of Parkrimp No-Skive<br />

• Select all of that in order to increase service life<br />

<strong>and</strong> safety!

Hose Size<br />

The other parameter determining the hydraulic<br />

power in direct proportion is the flow rate – i.e. the<br />

fluid velocity. However, too high fluid velocity gives<br />

rise to turbulence, pressure drops <strong>and</strong> heating up<br />

of the fluid, causing excessive ageing of hoses <strong>and</strong><br />

other components or even their damage. To keep<br />

the fluid velocity below certain limits but achieve the<br />

required flow rate, the size of the hose has to be<br />

defined appropriately (see Flow Capacity Chart on<br />

page Ab-20).<br />

As the first technical st<strong>and</strong>ards for hose came<br />

from the USA, dimensions of hose are defined in<br />

inches <strong>and</strong> hose sizes are expressed in inches or<br />

from inch-derived units. Global companies – such<br />

as Parker – use dash sizes (-1 = 1/16”), while the<br />

European st<strong>and</strong>ards use DIN-based DN (diameter<br />

nominal) sizes.<br />

Note<br />

SAE 100 R5 hydraulic hose, SAE J1402 air-brake<br />

hose <strong>and</strong> SAE J2064 air-conditioning hose use sizes<br />

equivalent to corresponding metal tube I.D. – different<br />

from the other hydraulic hoses (see datasheets<br />

of these hoses in this catalogue).<br />

Aa-7<br />

I.D.<br />

Ambient <strong>and</strong> Fluid Temperature<br />

Temperature is one of the factors which most<br />

negatively affect rubber characteristics <strong>and</strong> so<br />

it deserves particular attention of the hydraulic<br />

system designers <strong>and</strong> hose users!<br />

High temperature causes degradation of rubber<br />

<strong>and</strong> accelerated ageing of the hose – an<br />

effect which can be yet further intensified by the<br />

chemical impact of the fluid. That is why the upper<br />

temperature limits specified in this catalogue<br />

refer to the fluid temperature <strong>and</strong> why they differ<br />

for various media. However, permanent or longterm<br />

use at temperatures close to the upper<br />

limit would considerably shorten the hose service<br />

life in any case <strong>and</strong> if it cannot be avoided<br />

the hose should be replaced more frequently<br />

once it shows first symptoms of deterioratioin<br />

(stiffness, hard cover <strong>and</strong> cracks).<br />

Hose <strong>and</strong> <strong>Fittings</strong> Terminology<br />

dash inch DN mm<br />

-3 3/16 05 4.8<br />

-4 1/4 06 6.4<br />

-5 5/16 08 7.9<br />

-6 3/8 10 9.5<br />

-8 1/2 12 12.7<br />

-10 5/8 16 15.9<br />

-12 3/4 19 19.1<br />

-16 1 25 25.4<br />

-20 1.1/4 31 31.8<br />

-24 1.1/2 38 38.1<br />

-32 2 51 50.8<br />

Size Inch mm DN<br />

-6 6/16 6/16 * 25,4 = 9,525 10<br />

<br />

-6 3/8 9,5 10<br />

°C<br />

Hose Hint<br />

The combination of high temperature<br />

<strong>and</strong> high pressure<br />

reduces the hose service life.<br />

Pay attention to regular inspection<br />

of such hoses <strong>and</strong><br />

their preventive replacement if<br />

the cover is brittle or cracked!<br />

Low temperature, on the other h<strong>and</strong>, affects<br />

mainly physical properties of rubber – making<br />

t more fragile – <strong>and</strong> so at extremely low temperatures<br />

hose being bent may crack in tube<br />

or cover which can cause immediate or later<br />

eakage, burst or reinforcement damage. As<br />

there are not many hydraulic fluids which flow<br />

at or below -40 °C, the lower temperature limits<br />

specified in this catalogue refer rather to ambient<br />

temperature below which the hose should<br />

not be bent or otherwise hit from outside (while<br />

staying passively in it does not cause serious<br />

problems).

Hose <strong>and</strong> <strong>Fittings</strong> Terminology<br />

Hose Bend Radius<br />

Small bend radius<br />

The role of hydraulic<br />

hose is to provide<br />

a connection of relatively<br />

movable parts of the circuit<br />

<strong>and</strong> so its bending is a natural<br />

state the hose is designed for. However,<br />

the layout of the reinforcement wire or fibre inside<br />

a bent hose may shift to less appropriate positions.<br />

The tube <strong>and</strong> cover are stretched <strong>and</strong> become thin-<br />

Aa-8<br />

Large bend radius<br />

Remember<br />

In order not to displace the hose reinforcement <strong>and</strong>/or damage<br />

its tube or cover, hydraulic hoses must never be bent below<br />

the min. bend radius specified in this catalogue<br />

Recommended Fluids<br />

As the power transmitting – not fluid conveying –<br />

element, hydraulic hose should be first of all used<br />

for the primary applications <strong>and</strong> with the recommended<br />

fluids specified in this catalogue!<br />

– even without any pressure or even in bulk<br />

when stored or packed!<br />

Hose Hint<br />

Bend radius <strong>and</strong><br />

are<br />

ings!<br />

rently<br />

(with<br />

orce)<br />

bent<br />

min.<br />

dius!<br />

ner <strong>and</strong> so the pressure<br />

resistance of a<br />

bent hose considerably<br />

decreases. For this reason<br />

working pressure <strong>and</strong> bend<br />

radius are negatively interdependent<br />

parameters <strong>and</strong> the max. working pressures specified<br />

in this catalogue are conditioned by respecting<br />

the min. bend radii.<br />

For low pressure applications with various<br />

non-hydraulic fluids see our catalogue<br />

“4401 Industrial <strong>Hoses</strong>”.<br />

If for required higher pressure or for any other<br />

reason you cannot use industrial hoses, follow<br />

the instructions in this catalogue (pages Aa-9 –<br />

Application, Aa-11 – Fluid Compatibility <strong>and</strong><br />

Ab-22 to Ab-30 – Chemical Resistance Table).

Safe Hose Assembly in 8 Steps<br />

1. Application<br />

There are so many operational factors affecting<br />

the functionality <strong>and</strong> service life of hydraulic rubber<br />

hoses <strong>and</strong> there is such a wide variety of external<br />

circumstances they have to work in that some few<br />

basic parameters such as pressure, size <strong>and</strong> fitting<br />

types cannot provide a sufficient basis for selecting<br />

<strong>and</strong> producing the proper product.<br />

The only unfailing way is to start … from the end<br />

– to learn <strong>and</strong> thoroughly underst<strong>and</strong> the application<br />

the hose assembly will work in.<br />

Hose Hint<br />

You do not always need additional sleeve to protect<br />

the hose against abrasion!<br />

Parker high <strong>and</strong> extremely high abrasion resistant<br />

<strong>and</strong> versions with<br />

80-times <strong>and</strong> 450-times higher abrasion resistance<br />

do the same, but better <strong>and</strong> cheaper!<br />

Metal-to-Hose Abrasion<br />

Resistance Comparison<br />

Levels of Abrasion Resistance<br />

St<strong>and</strong>ard<br />

Rubber Cover<br />

Tough Cover<br />

(TC)<br />

80<br />

Times<br />

450<br />

Times<br />

Aa-9<br />

Main operational factors:<br />

– Market<br />

(agriculture, construction, marine, mining, …)<br />

– Machine / equipment type<br />

– <strong>Hydraulic</strong> system pressure<br />

– Static / dynamic<br />

– Extreme pulses (frequency, amplitude)<br />

– Surges, peaks, spikes<br />

– Suction strains<br />

– Flow rate<br />

– Ambient / fluid temperature<br />

(permanent, peak)<br />

– Biodegradable oil<br />

– Other fluid – liquid / gaseous<br />

– Bend radius<br />

– etc.<br />

Main external circumstances:<br />

– Extreme environmental conditions<br />

– Ultraviolet light / sunlight<br />

– Ozone / smog / salt water<br />

– Restricted space<br />

– Abrasives / sharp-edged objects<br />

– Mechanical loads (strain , stress, torsion)<br />

– Mechanical vibrations<br />

– <strong>Fittings</strong> heated<br />

– <strong>Fittings</strong> under voltage / current<br />

– Electrical / magnetic field<br />

– Heat exposure<br />

– Flame / fire exposure<br />

– etc.<br />

Other requirements:<br />

– Certificate / approval needed<br />

– Special (OEM) specification<br />

– Environmental requirements<br />

– Work safety requirements

Safe Hose Assembly in 8 Steps<br />

2. Pressure<br />

Working pressures of both hose<br />

<strong>and</strong> fittings must be equal to or<br />

higher than the real hydraulic<br />

system operating pressure incl.<br />

all surges, peaks, spikes <strong>and</strong><br />

pulses!<br />

For hose working pressure rates see pages Ab-2 to<br />

Ab-3 Hose Overview.<br />

For fittings working pressure rates see pages Ab-8<br />

to Ab-10 Hose <strong>Fittings</strong> Pressure Ratings.<br />

For the absolute majority of hydraulic applications<br />

incl. for the highest pressure 4- <strong>and</strong> 6-spiral hoses<br />

we advise to use the Parkrimp No-Skive product<br />

line. It provides really supreme solutions for hydraulic<br />

<strong>and</strong> related hoses <strong>and</strong> fittings from both the technical<br />

<strong>and</strong> the manufacturing points of view!<br />

For applications with extremely pulsing dynamic pressure,<br />

pressure surges <strong>and</strong> peaks, as well as for applications<br />

with intense mechanical vibrations <strong>and</strong> hose<br />

flexing (bending), especially close to the fittings, we<br />

recommend using the ParLock k product line.<br />

3. Size<br />

To avoid turbulence <strong>and</strong> their negative consequences<br />

for hose <strong>and</strong> other components in the hydraulic<br />

circuit, certain limits for fluid velocity have been set<br />

based on long-term experience with hydraulic systems.<br />

The limits differ for pressure, return <strong>and</strong> suction<br />

lines, as the hydraulic flow tends to turbulences<br />

the more the lower the pressure.<br />

Max. recommended fluid velocity:<br />

• Pressure lines – ca. 6.1 m/sec<br />

• Return lines – ca. 3 m/sec<br />

• Suction lines – ca. 1.2 m/sec<br />

However, there is no need to calculate the velocity.<br />

Depending on the flow rate <strong>and</strong> kind of hydraulic<br />

line in which the hose is intended to serve (pressure<br />

/ return / suction) you can assign the required hose<br />

size in the Flow Capacity Nomogram on page Ab-20.<br />

Aa-10<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

- -<br />

- -<br />

-<br />

- -<br />

-<br />

-<br />

s -<br />

s -<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

s -<br />

- -<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

- -<br />

- -<br />

-<br />

-<br />

-<br />

- -<br />

- -<br />

-<br />

-<br />

- -<br />

-<br />

-<br />

- -<br />

-<br />

-<br />

-<br />

- -<br />

-<br />

-<br />

-<br />

-<br />

-<br />

Size<br />

<br />

Temp. Construction St<strong>and</strong>ard Page<br />

-3 -4 -5 -6 -8 -10 -12 -16 -20 -24 -32<br />

24 24 21 21 21 14 40/+100 1braid fibre<br />

<br />

EN854-R3 SAE100R3<br />

EN854-R6<br />

EN854-2TE<br />

EN854-R6<br />

EN854-2TE<br />

SAE100R5 SAEJ1402AII<br />

SAE100R5 SAEJ1402AII<br />

SAEJ1402AI<br />

SAEJ1402AI<br />

SAEJ1527TypR3<br />

SAEJ2064TypC<br />

ISO1436-1-1SN/R1AT SAE100R1AT<br />

ISO1436-1-1SN/R1AT SAE100R1AT<br />

EN853-2SN SAE100R2AT<br />

ISO1436-1-2SN/R2AT SAE100R2AT<br />

O11237-1-R16 SAE100R16<br />

O11237-1-R17 SAE100R17<br />

EN857-1SC ISO11237-1-1SC<br />

EN857-2SC ISO11237-1-2SC<br />

EN853-2SN ISO1436-1-2SN(R2AT<br />

SAE 100 R19<br />

<br />

O11237-1-R17 SAE100R17<br />

N857-2SC ISO11237-1-2SC<br />

N857-2SC ISO11237-1-2SC<br />

<br />

N857-1SC ISO11237-1-1SC<br />

N857-2SC ISO11237-1-2SC<br />

SAE100R1AT<br />

SAE100R16<br />

EN857-2SC ISO11237-1-2SC<br />

SAE100R2AT<br />

SAE100R1AT<br />

ISO1436-1-1SN/R1AT SAE100R1AT<br />

O11237-1-R16 SAE100R16<br />

<br />

436-1-1SN/R1AT SAE100R1AT<br />

els EN853-2SN EN856-2SC<br />

els EN853-2SN EN856-2SC<br />

Excels SAE100R17<br />

Excels SAE100R17<br />

SAE100R4<br />

SAE100R4<br />

<br />

N856-4SP ISO3862-1-4SP<br />

N856-4SH ISO3862-1-4SH<br />

13 ISO3862-1-R13 SAE100R13<br />

13 ISO3862-1-R13 SAE100R13<br />

<br />

O3862-1-R15 SAE100R15<br />

<br />

12 ISO3862-1-R12 SAE100R12<br />

13 ISO3862-1-R13 SAE100R13<br />

O3862-1-R15 SAE100R15<br />

O3862-1-R15 SAE100R15<br />

12 ISO3862-1-R12 SAE100R12<br />

ISO 18752-DC<br />

ISO 18752-DC<br />

ds EN856-4SP ISO3862-1-4SP<br />

ds EN856-4SH ISO3862-1-4SH<br />

13 ISO3862-1-R13 SAE100R13<br />

O3862-1-R15 SAE100R15<br />

ds EN856-4SP ISO3862-1-4SP<br />

ds EN856-4SH ISO3862-1-4SH<br />

<br />

13 ISO3862-1-R13 SAE100R13<br />

O3862-1-R15 SAE100R15<br />

ds EN856-4SP ISO3862-1-4SP<br />

ds EN856-4SH ISO3862-1-4SH<br />

O3862-1-R15 SAE100R15<br />

ds EN856-4SH ISO3862-1-4SH<br />

<br />

<br />

<br />

<br />

<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

- -<br />

- -<br />

-<br />

- -<br />

-<br />

-<br />

s -<br />

s -<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

s -<br />

- -<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

- -<br />

- -<br />

-<br />

-<br />

-<br />

- -<br />

- -<br />

-<br />

-<br />

- -<br />

-<br />

-<br />

- -<br />

-<br />

-<br />

-<br />

- -<br />

-<br />

-<br />

-<br />

-<br />

-<br />

Size<br />

<br />

Temp. Construction St<strong>and</strong>ard Page<br />

-3 -4 -5 -6 -8 -10 -12 -16 -20 -24 -32<br />

2.4 2.4 2.1 2.1 2.1 1.4 -40/+100 1braid,fibre<br />

1.6 1.6 1.6 1.6 1.6 -40/+80 1braid,fibre<br />

2.4 2.0 2.0 2.0 2.0 -40/+100 1braid,fibre<br />

1.6 1.6 1.6 1.6 1.6 1.4 -40/+100 1braid,fibre<br />

16 16 16 16 16 -40/+100 1braid fibre<br />

<br />

EN854-R3 SAE100R3<br />

EN854-R6<br />

EN854-2TE<br />

EN854-R6<br />

EN854-2TE<br />

SAE100R5 SAEJ1402AII<br />

SAE100R5 SAEJ1402AII<br />

SAEJ1402AI<br />

SAEJ1402AI<br />

SAEJ1527TypR3<br />

SAEJ2064TypC<br />

ISO1436-1-1SN/R1AT SAE100R1AT<br />

ISO1436-1-1SN/R1AT SAE100R1AT<br />

EN853-2SN SAE100R2AT<br />

ISO1436-1-2SN/R2AT SAE100R2AT<br />

O11237-1-R16 SAE100R16<br />

O11237-1-R17 SAE100R17<br />

EN857-1SC ISO11237-1-1SC<br />

EN857-2SC ISO11237-1-2SC<br />

EN853-2SN ISO1436-1-2SN(R2AT<br />

SAE 100 R19<br />

<br />

O11237-1-R17 SAE100R17<br />

N857-2SC ISO11237-1-2SC<br />

N857-2SC ISO11237-1-2SC<br />

<br />

N857-1SC ISO11237-1-1SC<br />

N857-2SC ISO11237-1-2SC<br />

SAE100R1AT<br />

SAE100R16<br />

EN857-2SC ISO11237-1-2SC<br />

SAE100R2AT<br />

SAE100R1AT<br />

ISO1436-1-1SN/R1AT SAE100R1AT<br />

O11237-1-R16 SAE100R16<br />

<br />

436-1-1SN/R1AT SAE100R1AT<br />

els EN853-2SN EN856-2SC<br />

els EN853-2SN EN856-2SC<br />

Excels SAE100R17<br />

Excels SAE100R17<br />

SAE100R4<br />

SAE100R4<br />

<br />

N856-4SP ISO3862-1-4SP<br />

N856-4SH ISO3862-1-4SH<br />

13 ISO3862-1-R13 SAE100R13<br />

13 ISO3862-1-R13 SAE100R13<br />

<br />

O3862-1-R15 SAE100R15<br />

<br />

12 ISO3862-1-R12 SAE100R12<br />

13 ISO3862-1-R13 SAE100R13<br />

O3862-1-R15 SAE100R15<br />

O3862-1-R15 SAE100R15<br />

12 ISO3862-1-R12 SAE100R12<br />

ISO 18752-DC<br />

ISO 18752-DC<br />

ds EN856-4SP ISO3862-1-4SP<br />

ds EN856-4SH ISO3862-1-4SH<br />

13 ISO3862-1-R13 SAE100R13<br />

O3862-1-R15 SAE100R15<br />

ds EN856-4SP ISO3862-1-4SP<br />

ds EN856-4SH ISO3862-1-4SH<br />

<br />

13 ISO3862-1-R13 SAE100R13<br />

O3862-1-R15 SAE100R15<br />

ds EN856-4SP ISO3862-1-4SP<br />

ds EN856-4SH ISO3862-1-4SH<br />

O3862-1-R15 SAE100R15<br />

ds EN856-4SH ISO3862-1-4SH<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

I.D.<br />

Technical H<strong>and</strong>book<br />

<br />

Hose Hint<br />

Don’t try to save your<br />

own or your customer’s<br />

money by downsizing<br />

the hose!<br />

It would cost your customer<br />

more to replace<br />

damaged hoses, other<br />

components <strong>and</strong> oil,<br />

<strong>and</strong> it will cost you more<br />

as you may lose your<br />

customer!<br />

The size of the hose is directly included in the hose part<br />

number: e.g. 302-6 – ISO 1436 / DIN EN 853 2SN hose<br />

size -6 (3/8”- DN10)<br />

Fitting<br />

end<br />

connection<br />

92. B1. B2.<br />

B4. B5<br />

EA, EB, EC<br />

91, D9<br />

01<br />

02<br />

03, 33<br />

Description<br />

BSP<br />

swivel female<br />

BSP<br />

swivel female<br />

with O-ring<br />

BSP<br />

male<br />

NPTF<br />

male<br />

NPTF<br />

female<br />

SAE (JIC) 37°<br />

male<br />

Metric tube size in mm<br />

Maximum working pressure (MPa) – safety factor 4:1<br />

4 5 6 8 10 12 16 20 24 32<br />

63.0 55.0 43.0 37.5 35.0 28.0 25.0 21.0 21.0<br />

40.0 40.0 35.0 35.0 31.5 25.0 20.0 16.0 12.5<br />

63.0 55 0 43 0 35 0 28 0 25 0 21.0 21.0<br />

3 0 14.0<br />

3 0 14.0<br />

4 0 17.0<br />

04 SAE 45° male 4 0 17.0<br />

05<br />

06/68,37/3V,<br />

39/3W, L9,<br />

41/3Y<br />

93<br />

07<br />

08, 77, 79<br />

1L<br />

S2<br />

0G, 0L<br />

28, 67, 69<br />

SAE male<br />

with O-ring<br />

SAE (JIC) 37°<br />

swivel female<br />

Female SAE (JIC) 37°<br />

90° Elbow<br />

Female<br />

NPSM-pipe swivel<br />

Female SAE 45°<br />

swivel<br />

Male NPTF<br />

pipe swivel<br />

90° Elbow<br />

Female NPTF<br />

pipe swivel<br />

Male SAE<br />

O-Ring<br />

SAE Male<br />

inverted<br />

45° swivel<br />

15, 16, 17, 18,<br />

SAE flange<br />

19, 26, 27, 89,<br />

Code 61<br />

X5, X7, X9<br />

4A, 4N, 4F<br />

SAE flange<br />

5000 psi<br />

6A, 6E, 6F, 6G, SAE flange<br />

6N, XA, XF, XG, Code 62<br />

XN, X5, X7, X9 6000 psi<br />

4 0 17.0<br />

4 0 17.0<br />

4 0 17.0<br />

3<br />

4 0 17.0<br />

2 0 8.0<br />

2 0 8.0<br />

21.0 21.0 21.0 21.0 19.0 15.5 14.0 11.0 9.0 8.0<br />

19.0 17.0 15.0 14.0<br />

34.5 34.5 34.5 34.5 27.5 21.0 21.0<br />

Ab-3.1<br />

Hose <strong>Fittings</strong> Pressure Ratings<br />

34.5 34.5 34.5<br />

41.0 41.0 41.0 41.0 41.0 41.0<br />

Catalogue 4400/UK

High Temperature<br />

For high temperature hoses choose the<br />

part numbers ending in “6”<br />

– e.g. 436-12 - SAE 100R16<br />

High Temperature hose size -12<br />

Low Temperature<br />

For extremely low temperature hoses choose the<br />

part numbers ending in “LT” –<br />

e.g. 461LT-16 – DIN EN 857-2SC<br />

Low Temperature Hose size -16<br />

5. Fluid Compatibility<br />

You can find recommended fluids for Parker hoses<br />

in the datasheet of each hose type in this catalogue.<br />

If the required fluid is not mentioned in the<br />

Recommended Fluids Chart <strong>and</strong> if due to<br />

higher pressure or for any other reason you<br />

cannot use Parker industrial hoses (see<br />

Parker catalogue “4401 Industrial <strong>Hoses</strong>”)<br />

pay the highest attention to obtain as much<br />

information as possible about the fluid (temperature,<br />

pressure, state – liquid or gaseous<br />

etc.) <strong>and</strong> about the working conditions of the<br />

hose (see par. 1. Application).<br />

Then check the compatibility of the fluid with<br />

the given hose <strong>and</strong> material of the fitting in the<br />

Chemical Resistance Table pages Ab-22 to Ab-30.<br />

Technical H<strong>and</strong>book<br />

I Medium II III IV V VI STEEL BRASS SS<br />

3M FC-75 A A A A 16 A A A A A<br />

A<br />

Acetic Acid X X X A 16 6 X X X A<br />

Acetone X X X A 16 AA X AA A AA<br />

Acetylene X X X X X - - - -<br />

AEROSHELL Turbine Oil 500 (See MIL-L-23699) X X F X X - A A A<br />

Air 1, 1, 1, A 1, 10 1, A A A A<br />

Air (dry)<br />

A, 10 10 A, 10 A, 10<br />

A, 10<br />

X F, 1, 10 F, 1, 10 A 1, 10 A, 1, 10 A A A A<br />

Alcohol F F F A 16 F - F A A<br />

(Methanol-Ethanol)<br />

Ammonia (Anhydrous) X X X X X - X X X<br />

Ammonium Chloride A A A A 16 AA A X X X<br />

Ammonium Hydroxide F F FF A 16 A X F X A<br />

Ammonium Nitrate A A A A 16 A - F X A<br />

Ammonium Phosphate A A A A 16 A - X X F<br />

Ammonium Sulfate A A A A 16 A - F X F<br />

Amoco 32 Rykon X A A F 15 X A A A A<br />

Ampol PE 46 X X X X A, 7 F A A A<br />

AMSOIL Synthetic ATF F A A A 16 X F A A A<br />

Amyl Alcohol X X X A 16 F - X A A<br />

Anderol 495,497,500,750 X X X A 16 X X A A A<br />

Aniline X X X A 16 A X A X A<br />

Animal Fats X F FF A 16 F - 6 6 A<br />

Aquacent Light, Heavy X A A X X A A A A<br />

Argon A A A A A A A A A<br />

Aromatic 100,150 X F F<br />

- X F A A A<br />

Arrow 602P A A A A 15 X A A A A<br />

Asphalt XX F FF F 15 X A F F A<br />

ASTM #3 Oil F F FF A 16 X - A A A<br />

ATF-M F A A A 15 X A A A A<br />

Automotive Brake Fluid X X X X - X X X X<br />

AW 32,46,68 F A A A 15 X A A A A<br />

B<br />

BCF F F FF F 16 - - A A A<br />

Benz Petraulic 32,46,68,100,150,220,320,460 F A A A 15 XX A A A A<br />

Benzene, Benzol X X X A 16 X F A A A<br />

Benzgrind HP 15 -- A A A 16 XX - A A A<br />

Benzine X X X F 16 X - A A A<br />

Biodegradable <strong>Hydraulic</strong> Fluid 112B X A A X - - A A A<br />

Biodiesel E20 X F X X X X - - -<br />

Biodiesel E100 X F X X XX - - -<br />

Biodiesel E60 X F X X X X - - -<br />

Biodiesel E80 X F X X X X - - -<br />

Borax F F F<br />

A 16 A - F A A<br />

Boric Acid A A A X A X X 6 A<br />

Brayco 882 X A A A 16 X - A A A<br />

Brayco Micronic 745 X X A F 15 X A A A A<br />

Brayco Micronic 776RP F A A F 15 X A A A A<br />

Brayco Micronic 889 X F FF - X - A A A<br />

Brine F F FF A 16 A - X F F<br />

Butane See 2 & 13 F A A A<br />

Butyl Alcohol, Butanol FF F FF A 16 F - F F A<br />

C<br />

Calcium Chloride A A A A 16 A - F F X<br />

Calcium Hydroxide A A A A 16 A - A A A<br />

Ab-19<br />

Catalogue 4400/UK<br />

The Chemical Resistance<br />

Table concerns solely the<br />

hose inner tube. <strong>Hydraulic</strong><br />

hoses should never be<br />

submerged in the hydraulic<br />

fluids! If you need to know<br />

the resistance of the hose<br />

cover, consult our<br />

Technical Support<br />

(HPDE_Helpdesk@parker.com)<br />

Aa-11<br />

Safe Hose Assembly in 8 Steps<br />

4. Temperature<br />

The main technical st<strong>and</strong>ards for hydraulic hoses<br />

specify the max - min temperature range usually<br />

(not always) as:<br />

• EN st<strong>and</strong>ards <strong>and</strong><br />

EN/DIN-based ISO st<strong>and</strong>ards<br />

-40 °C to +100 °C<br />

• SAE st<strong>and</strong>ards <strong>and</strong><br />

SAE-based ISO st<strong>and</strong>ards<br />

-40 °F to +250 °F / -40 °C to +121 °C<br />

For Parker hoses you can find the recommended<br />

temperature ranges for fluids <strong>and</strong> for water <strong>and</strong> air<br />

(when applicable) in the datasheet of each hose<br />

type in this catalogue.<br />

Besides a complete range of st<strong>and</strong>ard hoses Parker<br />

also offers a wide range of special types for low <strong>and</strong><br />

high temperatures – see pages Ab-2 to Ab-3 Hose<br />

Overview.<br />

6. <strong>Fittings</strong><br />

Hose Hint<br />

Although fittings are<br />

made of steel, their<br />

working pressure is<br />

often lower than that of<br />

hose! Don’t forget to<br />

check the working pressures<br />

of both fittings when<br />

selecting components for<br />

your hose assembly!<br />

Even if the fitting termination end<br />

is given by the other component<br />

in the hydraulic circuit or the<br />

hose assembly is just for replacement,<br />

you have to pay attention<br />

to choosing the correct fittings<br />

compatible with the given hose for<br />

the required working pressure <strong>and</strong><br />

fluid.<br />

To identify the corresponding termination<br />

end see pages Ab-31 to<br />

Ab-41 Identifying Fitting Types.<br />

For each type of hose the series of the compatible<br />

fitting is indicated in the hose datasheets in this<br />

catalogue – e.g. Parker hose 701 is to be assembled<br />

only with Parker <strong>Fittings</strong> Series 70.<br />

Always check the fitting work<br />

sure – see pages Ab-8 to Ab<br />

Hose <strong>Fittings</strong> Pressure Rating

Safe Hose Assembly in 8 Steps<br />

7a. Working Steps for<br />

1-Piece Parkrimp No-Skive <strong>Fittings</strong><br />

Cutting<br />

Tolerances for hose assemblies<br />

Length tolerance according to DIN 20066 <strong>and</strong> DIN EN 853 to DIN EN 857<br />

Hose assembly length up to DN25 from DN32 (size -20) from DN60<br />

(size -16) up to DN50 (size -32) (size -40)<br />

up to 630 +7 +12<br />

-3 -4<br />

over 630 up to 1250 +12 +20<br />

-4 -6 +25<br />

over 1250 up to 2500 +20 +25 -6<br />

-6 -6<br />

over 2500 up to 8000 +1,5 %<br />

-0,5 %<br />

over 8000 +3 %<br />

-1 %<br />

Cleaning<br />

after<br />

cutting<br />

Hose<br />

Air<br />

Aa-12<br />

Hose is cut to the desired length according to<br />

specifications. The correct hose cutting tool ensures<br />

a square, clean cut without damaging the pressure<br />

reinforcement. Depending on the hose type,<br />

different kinds of cutting blades must be used:<br />

1) Smooth cutting blade:<br />

for high tensile textile layer, return line hoses<br />

<strong>and</strong> steel wire braided hoses<br />

2) Serrated cutting blade:<br />

for hoses with 4 or 6 spiral layer of high<br />

tensile steel wire<br />

According to DIN EN 982,<br />

hose assemblies are<br />

not permitted to be<br />

manufactured from any<br />

components that have<br />

already been in use in other<br />

hose assemblies.<br />

After cutting it is recommended to clean the hose<br />

with compressed air from both sides.<br />

Please make use of Parker‘s Cleaning System TH6-7<br />

– A quick <strong>and</strong> simple system<br />

– Delivered with two plastic nozzles for hoses<br />

from size -4 up to -32.<br />

The hose is pressed against the nozzle <strong>and</strong> thereby<br />

opens a valve to allow the compressed air to blow<br />

through the hose <strong>and</strong> blow out loose particles.

Marking<br />

assemblies must be clearly <strong>and</strong> permanently<br />

marked. They must bear the following information:<br />

– Manufacturer’s identification<br />

– Date of production (year <strong>and</strong> month)<br />

– Maximum permissible working pressure limit<br />

of hose assembly<br />

Crimping 1-Piece Parkrimp No-Skive <strong>Fittings</strong><br />

Crimping is the safest, fastest <strong>and</strong><br />

most commonly used method of<br />

making a hose assembly. The Parker<br />

crimping systems ensure precise,<br />

leak-free <strong>and</strong> tear-proof assembly<br />

of hose <strong>and</strong> fitting. Reaching the<br />

exact crimping diameter is possible<br />

with Parkrimp crimping tools or<br />

adjustable crimping tools. When<br />

crimping, it is essential that hose,<br />

fitting <strong>and</strong> crimping tool (dies) match<br />

precisely. For crimping dimensions<br />

please refer our crimp charts on<br />

pages Ed-1 to Ed-11.<br />

26, 46, 48, 70, 71, 73, 76, 77, 78, 79, S6 series:<br />

Push the hose all the way into the coupling.<br />

Place the hose next to the fitting shell<br />

<strong>and</strong> mark the insertion depth or<br />

the length of the fitting onto the<br />

hose – (lubricate hose end if<br />

necessary), push the<br />

hose into the fitting<br />

until the mark on the<br />

hose is even with the<br />

end of the shell.<br />

Parker representatives<br />

can support you with<br />

training or advice !<br />

Aa-13<br />

Safe Hose Assembly in 8 Steps<br />

Furthermore, the insertion depth, a<br />

square cut hose, correct, burr-free<br />

<strong>and</strong> clean crimping are important to<br />

ensure a correctly formed <strong>and</strong> leakfree<br />

connection of hose <strong>and</strong> fitting.<br />

Using the ParKrimp hose crimpers<br />

or adjustable crimpers, the fitting is<br />

crimped onto the hose in one slow<br />

<strong>and</strong> smooth crimping procedure.<br />

A depth stop with automatic<br />

function ensures safe positioning<br />

of the fitting. This guarantees the<br />

correct crimping of hydraulic hose<br />

assemblies.<br />

Angle setting<br />

The displacement angle of a hose assembly<br />

is indicated only when two elbow fittings are<br />

assembled in a displaced way.<br />

The angle always has to be indicated clockwise<br />

looking from the elbow fitting at the back to the<br />

one in the front. Please also consider the natural<br />

bending of the hose.

Safe Hose Assembly in 8 Steps<br />

Testing (optional)<br />

Static test pressure depending on the hose type<br />

<strong>and</strong> application is applied to the finished hose<br />

assembly for a pre-defined period of time. The test<br />

procedure can be documented using a test logging<br />

unit. The test pressure for Parker hydraulic hose<br />

assemblies is 2 times the value of the dynamic<br />

operating overpressure.<br />

Cleaning<br />

The hydraulic systems have to reach<br />

a defined degree of cleanliness. For<br />

this purpose we use cleaning devices<br />

which ensure fast <strong>and</strong> efficient cleaning<br />

of hose assemblies.<br />

With the TH6-6 st<strong>and</strong>ard cleaning<br />

device, certain cleanliness classes can<br />

be achieved. This cleaning device first<br />

flushes the hose assembly with an<br />

anticorrossive emulsion <strong>and</strong> dries<br />

it afterwards with pre<br />

ISO<br />

4406<br />

NAS<br />

1638<br />

SAE<br />

749<br />

11/8 2<br />

12/9 3 0<br />

13/10 4 1<br />

14/11 5 2<br />

15/12 6 3<br />

16/13 7 4<br />

17/14 8 5<br />

18/15 9 6<br />

19/16 10<br />

20/17 11<br />

21/18 12<br />

Proof Pressure Test<br />

This test is typically carried out on customer<br />

request according to a method defined by the ISO<br />

1402 st<strong>and</strong>ard. The test should be done at normal<br />

ambient temperature with a proof test bench using<br />

water or another suitable liquid. The hose assembly<br />

should be pressurised for between 30 to 60<br />

seconds at twice the working pressure of the hose<br />

assembly. There should be no leakage or pressure<br />

drop. A complete test report should be provided<br />

together with the hose assembly to the customer.<br />

For permanent protection of the<br />

finished hose assembly against<br />

impurities we recommend using<br />

plastic caps.

7b. Working Steps for<br />

2-Piece ParLock <strong>Fittings</strong><br />

Cutting, cleaning after cutting <strong>and</strong> marking<br />

please see “Working Steps for 1-Piece Parkrimp No-Skive”<br />

Skiving<br />

For the skiving of hydraulic hose, one distinguishes<br />

between internal skiving <strong>and</strong> external skiving. This<br />

system is applied for hose types with 4 or 6 spiral<br />

reinforcement layers, the so-called Parker Parlock<br />

System or Interlock.<br />

Internal skiving tool<br />

a: Skiving knife<br />

D<br />

Skiving tool<br />

C<br />

a<br />

E<br />

A: Complete tool holder<br />

B: Skiving m<strong>and</strong>rel for internal skiving<br />

C: Supporting arm for skiving knife<br />

(short/long arm)<br />

D: Skiving knife for external skiving (2x)<br />

E: Skiving knife for internal skiving<br />

B<br />

Cleaning after skiving<br />

A<br />

Adjustment of tools<br />

for internal skiving<br />

Select the skiving<br />

tool according to<br />

the manufacturing<br />

documents <strong>and</strong> the<br />

hose size. Insert the<br />

knife for the internal<br />

skiving m<strong>and</strong>rel into<br />

the borehole of the<br />

m<strong>and</strong>rel provided for<br />

this purpose <strong>and</strong> mark<br />

it with a lock collar at<br />

the straight surface.<br />

When adjusting the<br />

knife, observe the<br />

marking on the internal<br />

skiving knife <strong>and</strong> insert<br />

the m<strong>and</strong>rel into the<br />

tool holder.<br />

Adjustment of tools for<br />

external skiving<br />

Attach the knives in the<br />

supporting arm. Select the<br />

supporting arm (long or short)<br />

depending on the hose size.<br />

Adjust the knives according to the Parker working<br />

instructions <strong>and</strong> insert the tools into the machine.<br />

Push the m<strong>and</strong>rel onto the hose until it is close to<br />

the tool (external or internal skiving knife).<br />

Adjustment of the sense of rotation of the<br />

machine<br />

Always skive into the direction of the spiral layers.<br />

Please observe the operation instructions of the<br />

machine.<br />

15<br />

Safe Hose Assembly in 8 Steps<br />

D C<br />

B<br />

A<br />

External skiving tool<br />

A: External skiving tool<br />

with two arms<br />

B: M<strong>and</strong>rel for<br />

external skiving<br />

C: Supporting arm<br />

for skiving knife<br />

(short/long arm)<br />

D: External skiving knife<br />

All hose types which have been skived externally<br />

or internally should be cleaned immediately after<br />

skiving. For this purpose we recommend using<br />

cleaning plugs which are shot through the hose<br />

using compressed air.<br />

(e.g. TH6-10-EL-7 or TH6-10-HL-9-2)<br />

In addition to this working step, the finished hose<br />

assembly must be cleaned from both ends using<br />

pressurised air after the completion of this working<br />

step.

Safe Hose Assembly in 8 Steps<br />

Crimping 2-Piece ParLock <strong>Fittings</strong><br />

Make sure that the hose<br />

ends are cut squarely.<br />

Push the ferrule onto<br />

the hose. The cut end of<br />

the hose must be clearly<br />

visible.<br />

Measurement 1<br />

in the plane of force<br />

For crimping<br />

ParLock fittings<br />

V4 series a minimum<br />

of 320 tons<br />

crimping force is<br />

recommended.<br />

Min. of 340 tons<br />

for V6 series.<br />

Push the nipple down<br />

into the hose until it<br />

reaches the stop on the<br />

lower groove (plastic<br />

ring, fitting shoulder or<br />

metal stop). Use Hoze-<br />

Oil, if required.<br />

Aa-16<br />

1) Select the appropriate crimping dies using the<br />

crimping diameter chart.<br />

2) Before crimping hoses <strong>and</strong> fittings it must be<br />

ensured that you have the most recent crimping<br />

dimensions. For crimping dimensions please<br />

refer our crimp charts on page Ed-12 to Ed-13.<br />

3) Insert the dies into the crimping press <strong>and</strong> set the<br />

crimping diameter.<br />

4) Place the pre-assembled hose assembly into the<br />

crimper <strong>and</strong> perform the crimping procedure.<br />

5) Please observe the operating instructions of the<br />

crimper.<br />

2-piece fittings must not be crimped on Parkrimp crimpers – only with adjustable crimpers.<br />

Measurement 2<br />

displaced by 90°<br />

The ferrule must bottom<br />

up against the plastic<br />

ring or metal stop.<br />

Checking for the correct crimping diameter<br />

In case of the ParLock System, the conicity is<br />

measured. It is measured at the beginning <strong>and</strong> the<br />

end of the ferrule in 2 measuring planes.<br />

Angle setting<br />

please see “Working Steps for<br />

1-Piece Parkrimp No-Skive”<br />

Measurement 1<br />

at the beginning <strong>and</strong> the<br />

end of the ferrule<br />

Testing <strong>and</strong> cleaning please see<br />

“Working Steps for 1-Piece Parkrimp No-Skive <strong>Fittings</strong>”<br />

After crimping, the<br />

ferrule must be located<br />

precisely in the groove<br />

of the nipple.<br />

e<br />

Measurement 2<br />

at the beginning <strong>and</strong><br />

the end of the ferrule<br />

(displaced by 90°)

8 Routing / Installation /<br />

Environmental Influences<br />

wrong right<br />

The routing of the hose assembly <strong>and</strong> the environment<br />

in which the hose assembly operates<br />

directly influence the service life of the hose<br />

assembly. The following diagrams indicate the<br />

correct routing of hose assemblies that will maximise<br />

its service life <strong>and</strong> assure a safe working<br />

functionality.<br />

When hose installation is straight, it must be<br />

assured that there is enough slack in the hose<br />

to allow for changes in length that occur when<br />

pressure is applied. When pressurized, hose that<br />

is too short may pull loose from its hose fittings<br />

or stress the hose fitting connections, causing<br />

premature metallic or seal failures.<br />

The hose length must be determined so that<br />

the hose assembly has enough slack to allow<br />

the system components to move or vibrate<br />

without creating tension in the hose.<br />

However, care needs to be taken not to allow<br />

too much slack <strong>and</strong> therefore introduce the risk<br />

of the hose snagging on other equipment or<br />

rubbing on other components.<br />

Mechanical straining of the hoses needs to be<br />

avoided, so the hose must not be bent below<br />

its minimum bend radius or twisted during<br />

installation. The minimum bending radii for<br />

each hose is stated in the hose tables in the<br />

catalogue.<br />

The plane of movement must also be considered<br />

<strong>and</strong> the hose routing selected accordingly.<br />

Hose routing also plays an important role<br />

on the selection of the hose fittings, as the<br />

correct fittings can avoid straining the hoses,<br />

unnecessary hose length or multiple threaded<br />

joints.<br />

Aa-17<br />

Safe Hose Assembly in 8 Steps

Safe Hose Assembly in 8 Steps<br />

wrong right<br />

Correct clamping (holding/supporting) of the<br />

hose should be exercised to securely route the<br />

hose or to avoid the hose contacting surfaces<br />

that will cause the hose damage.<br />

It is however, vital that the hose be allowed to<br />

keep its functionality as a “flexible-pipe” <strong>and</strong><br />

not be restricted from changing in length when<br />

under pressure.<br />

It should also be noted that hoses for high<strong>and</strong><br />

low-pressure lines shall not be crossed or<br />

clamped together, as the difference in changes<br />

in length could wear the hose covers.<br />

Hose should not be bent in more than one<br />

plane. If hose follows a compound bend, it shall<br />

be coupled into separate segments or clamped<br />

into segments that each flex in only one plane.<br />

<strong>Hoses</strong> should be kept away from hot parts as<br />

high ambient temperatures shorten hose life.<br />

Protective insulation may need to be used in<br />

unusually high ambient temperature areas.<br />

Whilst the importance of the functionality is<br />

primate the aesthetics <strong>and</strong> practicality of the<br />

installation should also be considered in the<br />

design.<br />

It should be considered that maintenance might<br />

be necessary at some stage in the future, so<br />

prohibitive design routings should be avoided.<br />

Aa-18

wrong right<br />

Pollution of hydraulic circuits<br />

Modern hydraulic equipment is becoming highly<br />

precise <strong>and</strong> as such more sensitive, so as a<br />

result the importance of a clean working fluid<br />

in the system is growing. Because as many as<br />

75 % of hydraulic system failures are caused by<br />

contamination of the fluid by solid particles, the<br />

initial cleanliness of hydraulic components, as the<br />

main source of these contaminates, is vital.<br />

With hose assemblies most of the pollution/<br />

contaminates enter the hose assembly during its<br />

production <strong>and</strong> mainly during the cutting (or skiving)<br />

process.<br />

In order to avoid system failures, all hose<br />

assemblies should be cleaned before use (cleaned<br />

<strong>and</strong> plugged before shipping) with suitable cleaning<br />

equipment such as the Parker TH6-6 machine.<br />

The level of contamination is defined in three<br />

popular norms: ISO4406, ISO4405 or NAS 1638.<br />

Most common however, is the ISO 4406, which<br />

describes the number <strong>and</strong> size of solid particles in<br />

the hydraulic system by means of a classification<br />

value e.g. 16/13.<br />

Abrasive influences<br />

In general care should be taken that the hose<br />

is not exposed to direct surface contact that<br />

will cause abrasive wearing of the outer cover<br />

(either hose to object or hose to hose contact). If<br />

however, the application is such that this cannot<br />

be avoided, either a hose with a higher abrasion<br />

resistant hose cover or a protective sleeve need<br />

to be used.<br />

Parker (TC) or (ST)<br />

covers offer 80 times or respectively 1000 times<br />

the abrasion resistance of st<strong>and</strong>ard rubber<br />

covers.<br />

Aa-19<br />

Safe Hose Assembly in 8 Steps<br />

ISO<br />

4406<br />

NAS<br />

1638<br />

SAE<br />

749<br />

11/8 2<br />

12/9 3 0<br />

13/10 4 1<br />

14/11 5 2<br />

15/12 6 3<br />

16/13 7 4<br />

17/14 8 5<br />

18/15 9 6<br />

19/16 10<br />

20/17 11<br />

21/18 12

How to Order<br />

To make ordering Parker products easier, we have itemized the order numbers on this page.<br />

This will be especially helpful when you order hose assemblies. You can find further useful hints on the<br />

following page.<br />

1. Hose<br />

Example: 436 6<br />

> Hose type<br />

436-6 > Hose inside diameter in size<br />

2. Hose <strong>Fittings</strong><br />

Example: 1 CA -6<br />

1 > Fitting<br />

Without suffix: steel, zinc plated<br />

B: brass<br />

C: stainless steel<br />

K: without a plastic ring<br />

SM: metric hexagon dimension<br />

4 No-Skive e<br />

1 CA 6 > End configuration nomenclature<br />

1 CA 48 > Fitting series<br />

1 CA 48 - 12 6 > Thread or tube size<br />

1 CA 48 - 12 -6 6 > Hose size<br />

<strong>and</strong><br />

hose fitting size<br />

I.D. = size -6<br />

I.D. = size -6<br />

The content of the hose crimping tables shows the st<strong>and</strong>ard part numbers. For the<br />

availability of non st<strong>and</strong>ard parts/materials please contact your local Parker service centre.<br />

All part numbers printed in bold in the respective price list are available ex-stock.<br />

Aa-20<br />

1 = Crimp<br />

3 = PushLok Pu Pus ushLo fitting ng<br />

K = Ni l t<br />

10<br />

( g<br />

( g )<br />

example: 100VS-8

3. Hose Assemblies<br />

Example: P436C AC F12106-1000-0-SG900<br />

P<br />

tio tion<br />

436 36<br />

pe<br />

CA<br />

43 436- 6-6 No-Skive<br />

CF<br />

12<br />

2<br />

onfig figura ratio ion<br />

43 436- 6-6 No-Skive H<br />

Aa-21<br />

ze<br />

Ho Hos ose se as ass sse semb mbl bly ly le leng ngt gth th in mm<br />

Ho<br />

Fi Fit itt tti ti<br />

10 6<br />

Ac y,<br />

e.<br />

-1000-0-S G900 900 9000<br />

P 4 3 6 C A C F 1 2 1 0 6 110 000 0 0 - 0 - SG S G 90 9 00 0 0<br />

R = Low Pressure Push-Lok <strong>Fittings</strong> Series 82<br />

P = Parkrimp No-Skive <strong>Fittings</strong> Series 26, 48<br />

D = Parkrimp No-Skive <strong>Fittings</strong> Series 46<br />

F = Parkrimp No-Skive <strong>Fittings</strong> Series 70, 71, 73, 76, 77, 78, 79 <strong>and</strong> S6<br />

E= Parlock Skive <strong>Fittings</strong> SeriesVS<br />

V= Parlock Skive <strong>Fittings</strong> SeriesV4<br />

S= Parlock Skive <strong>Fittings</strong> SeriesV6<br />

Ex Explanation xplanation of the ex exa example xam xample<br />

SG Spring Gu<br />

AG Armour Guard r<br />

AS/PS Partek Nylon protective sleeve v<br />

FS Fire Sleeves<br />

HG PolyGuard-Hose Protector<br />

PG ParKoil-Hose Protector<br />

mm.<br />

be<br />

fied for the t bent fitting in relation with h the hose curvature. A protection prote tection sleeve eeve as a spring guard rd in<br />

900 m

Hose <strong>and</strong> <strong>Fittings</strong> Storage<br />

It is a well-known fact that rubber properties<br />

deteriorate during the time of storage <strong>and</strong> service.<br />

A system of hose age control should be maintained<br />

to ensure that hose is used as long as it retains full<br />

capabilities for rendering the intended service.<br />

However, it is impossible to advise the ideal storage<br />

period <strong>and</strong> service life of rubber hose as it is subject<br />

DIN 20066<br />

Fluid power systems – Hose assemblies –<br />

Dimensions, requirements<br />

Specifies bulk hose shelf life <strong>and</strong> hose assembly<br />

storage period <strong>and</strong> service life:<br />

• The shelf life of bulk hose before assembling must<br />

not exceed 4 years.<br />

• The service life of a hose assembly, incl. any<br />

period of storage, must not exceed 6 years.<br />

• The period of storage of a hose assembly must<br />

not exceed 2 years.<br />

Bulk Hose<br />

Shelf life<br />

– max. 4 years<br />

Hose Assembly<br />

Service life – max. 6 years<br />

Storage<br />

max. 2 years<br />

ISO 17165-2 / SAE J1273<br />

<strong>Hydraulic</strong> fluid power – Hose assemblies<br />

– Recommended practices for hydraulic hose<br />

assemblies<br />

The specified max. shelf life of bulk hose or a hose<br />

assembly is 10 years (40 quarters) from the date of<br />

manufacture (vulcanization) of the hose, provided it<br />

has been stored in accordance with ISO 2230 (Rubber<br />

products - Guidelines for storage) <strong>and</strong> passes visual<br />

inspection <strong>and</strong> if need be also a proof pressure test.<br />

If visual inspection gives rise to any doubts as to the<br />

functionality of the hose (cracks in the cover or tube<br />

after hose flexing, excessive stiffness, reinforcement<br />

rust etc.), a proof pressure test should be carried<br />

out before use or the hose should be scrapped.<br />

Aa-22<br />

to a variety of factors which may affect the rubber<br />

characteristics <strong>and</strong> the suitability for use.<br />

That is also why various st<strong>and</strong>ardization committees<br />

take very different approaches to rubber hose<br />

storage period <strong>and</strong> service life. The main national<br />

<strong>and</strong> international st<strong>and</strong>ards defining rules for rubber<br />

hose storage are the following:<br />

BS 5244<br />

Recommendations for application, storage <strong>and</strong><br />

life expiry of hydraulic rubber hoses <strong>and</strong> hose<br />

assemblies<br />

Specifies tests needed for various storage periods<br />

of hose (in bulk or hose assembly):<br />

• Storage period does not exceed 3 years<br />

– no tests needed.<br />

• Storage period is between 3 <strong>and</strong> 5 years<br />

– proof pressure test needed.<br />

• Storage period is between 5 <strong>and</strong> 8 years<br />

– proof pressure, burst, impulse, cold flexibility<br />

<strong>and</strong> electrical tests needed.<br />

• Bulk hose or a hose assembly older than 8 years<br />

– must be scrapped.<br />

For hose assembly service life no explicit limits are<br />