Evaluation of Resins in Energy Curable Offset Inks - CYTEC Industries

Evaluation of Resins in Energy Curable Offset Inks - CYTEC Industries

Evaluation of Resins in Energy Curable Offset Inks - CYTEC Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Evaluation</strong> <strong>of</strong> <strong>Res<strong>in</strong>s</strong><br />

<strong>in</strong> <strong>Energy</strong> <strong>Curable</strong><br />

<strong>Offset</strong> <strong>Inks</strong><br />

EBECRYL ® <strong>Res<strong>in</strong>s</strong> and<br />

ADDITOL ® Additives<br />

for Graphic Arts

About Us<br />

From def<strong>in</strong><strong>in</strong>g more efficient processes for m<strong>in</strong><strong>in</strong>g<br />

customers to develop<strong>in</strong>g new additives for polymerbased<br />

alternatives to wood and metals, the product<br />

l<strong>in</strong>es <strong>of</strong> Cytec Specialty Chemicals are unified <strong>in</strong><br />

their dedication to customer-driven <strong>in</strong>novation.<br />

Work<strong>in</strong>g closely with our customers, we develop<br />

revolutionary technologies that enable them to improve<br />

performance and productivity, enter new markets,<br />

and ref<strong>in</strong>e new applications. How to improve m<strong>in</strong>e<br />

pr<strong>of</strong>itability or coat<strong>in</strong>gs efficiency <strong>in</strong> the face <strong>of</strong><br />

important environmental concerns? How to develop<br />

polymers that really stand up to UV light? How to use<br />

phosph<strong>in</strong>es to create better, safer biocides and fumigants<br />

for agriculture? Our technology and sales teams work<br />

on-site with customers every day to address today’s<br />

bus<strong>in</strong>ess challenges and troubleshoot tomorrow’s.<br />

The applications are diverse, but the commitment<br />

is uniform: f<strong>in</strong>d<strong>in</strong>g better solutions for customers<br />

through cont<strong>in</strong>ual research, ongo<strong>in</strong>g collaboration<br />

and a passion for <strong>in</strong>novation.<br />

An Expansive Portfolio<br />

Cytec Specialty Chemicals is a complete solution<br />

provider for customers requir<strong>in</strong>g high-value surface<br />

technologies <strong>in</strong> <strong>in</strong>dustries that <strong>in</strong>clude <strong>in</strong>dustrial<br />

coat<strong>in</strong>gs, automotive, architectural, wood and paper,<br />

graphics, adhesives and opto-electronics.<br />

We <strong>of</strong>fer out customers advanced and diverse<br />

products and technologies for surfaces with an<br />

emphasis on environmentally friendly products such<br />

as UV/EB curable res<strong>in</strong>s and additives, powder<br />

coat<strong>in</strong>g res<strong>in</strong>s and additives, as well as waterborne<br />

and solventborne liquid coat<strong>in</strong>g res<strong>in</strong>s and additives.<br />

We are committed to work<strong>in</strong>g with our customers<br />

to develop environmentally advanced solutions and<br />

we are dedicated to open communication concern<strong>in</strong>g<br />

the safe handl<strong>in</strong>g, distribution, use and disposal <strong>of</strong><br />

the products we make.<br />

A Focus on Customer Satisfaction<br />

Cytec Specialty Chemicals operates a globally<br />

<strong>in</strong>tegrated set <strong>of</strong> order fulfillment IT systems and<br />

processes. All Spec Chem personnel <strong>in</strong> the order<br />

fulfillment processes are dedicated to deliver<strong>in</strong>g<br />

customer satisfaction through reliable and costeffective<br />

supply <strong>of</strong> products to our customers. Cytec<br />

Specialty Chemicals has specialized personnel <strong>in</strong><br />

Customer Service, Procurement, Manufactur<strong>in</strong>g,<br />

Plann<strong>in</strong>g and Logistics to achieve this goal. In<br />

addition to timely and accurate order fulfillment,<br />

there is an equally important focus on ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g<br />

safety and protect<strong>in</strong>g the environment at all steps <strong>in</strong><br />

the process, from the procurement <strong>of</strong> raw materials to<br />

the delivery <strong>of</strong> f<strong>in</strong>ished goods to the customer’s door.<br />

Dedication to Operational Excellence<br />

Cytec’s Spec Chem Manufactur<strong>in</strong>g Organization<br />

operates globally to provide superior service to our<br />

customers <strong>in</strong> all regions. Our vision <strong>of</strong> operational<br />

excellence br<strong>in</strong>gs value to our customers through on-<br />

go<strong>in</strong>g, cont<strong>in</strong>uous improvement <strong>in</strong>itiatives, <strong>in</strong>clud<strong>in</strong>g<br />

Lean Manufactur<strong>in</strong>g, Six Sigma Pr<strong>in</strong>ciples, and Best<br />

Practice Eng<strong>in</strong>eer<strong>in</strong>g. Our value proposition is driven<br />

by excellence <strong>in</strong> our Safety, Environmental, Quality<br />

Systems and Employee Development Programs. We<br />

are structured by bus<strong>in</strong>ess technology, which enables<br />

our sites to work transparently with R&D, Customer<br />

Service and the Bus<strong>in</strong>ess, to share best practices across<br />

common processes. We also are able to ga<strong>in</strong> leverage<br />

from overall global manufactur<strong>in</strong>g synergies to most<br />

efficiently meet customer needs.<br />

Key Product L<strong>in</strong>es<br />

■ Liquid Coat<strong>in</strong>g <strong>Res<strong>in</strong>s</strong> and Additives<br />

■ M<strong>in</strong><strong>in</strong>g Chemicals<br />

■ Phosph<strong>in</strong>e and Phosphorus Specialties<br />

■ Polymer Additives<br />

■ Powder Coat<strong>in</strong>g <strong>Res<strong>in</strong>s</strong> and Additives<br />

■ RADCURE® UV/EB<br />

■ Specialty Additives

Provider <strong>of</strong> Innovative Solutions<br />

to the Graphics Industry<br />

We are committed to consolidat<strong>in</strong>g our<br />

leadership position as the preferred sup plier<br />

to the global energy-curable graphics <strong>in</strong>dustry.<br />

We shall cont<strong>in</strong>ue to deliver added value to our<br />

customers through <strong>in</strong>novative market-driven<br />

solutions based on technological and<br />

operational excellence.<br />

To fulfill our objective <strong>of</strong> deliver<strong>in</strong>g superior<br />

value to our customers, we have a dedi cated<br />

technical service team <strong>in</strong>vestigat<strong>in</strong>g <strong>in</strong>ks and<br />

varnishes requirements for all pr<strong>in</strong>t<strong>in</strong>g processes.<br />

Based on this, we have designed a full range <strong>of</strong><br />

UV/EB vehicles, b<strong>in</strong>ders and res<strong>in</strong>s that address<br />

the most str<strong>in</strong>gent needs <strong>of</strong> the energy-cur<strong>in</strong>g<br />

graphics market.<br />

With numerous plants, research and tech nical<br />

service centers around the world, we are <strong>in</strong> a<br />

strong position to satisfy the multidimensional<br />

requirements <strong>of</strong> our customers with unrivalled<br />

world-class levels <strong>of</strong> service.<br />

Cytec Specialty Chemicals

Table <strong>of</strong> Contents<br />

Introduction to <strong>Energy</strong> <strong>Curable</strong> <strong>Offset</strong><br />

General Pr<strong>in</strong>ciples <strong>of</strong> the Lithographic Process . . . . . . . . . . . . . . . . . . . . . . 1<br />

Types <strong>of</strong> <strong>Offset</strong> Lithographic <strong>Inks</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

Typical Properties <strong>of</strong> <strong>Energy</strong> <strong>Curable</strong> <strong>Offset</strong> <strong>Inks</strong> . . . . . . . . . . . . . . . . . . . . 3<br />

<strong>Offset</strong> Ink Parameters and Test Methods . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

Products for <strong>Energy</strong> <strong>Curable</strong> <strong>Offset</strong> <strong>Inks</strong><br />

Raw Materials Recommended for <strong>Energy</strong> <strong>Curable</strong> <strong>Offset</strong> <strong>Inks</strong> . . . . . . . . . 8<br />

General Properties <strong>of</strong> Raw Materials for <strong>Energy</strong> <strong>Curable</strong> <strong>Offset</strong> <strong>Inks</strong> . . . 13<br />

Standard Ink Formulations<br />

for <strong>Evaluation</strong>s <strong>of</strong> B<strong>in</strong>ders for <strong>Energy</strong> <strong>Curable</strong> <strong>Offset</strong> <strong>Inks</strong><br />

For Paper and Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14<br />

For Non-Porous Stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Introduction to <strong>Energy</strong> <strong>Curable</strong> <strong>Offset</strong><br />

General Pr<strong>in</strong>ciples<br />

<strong>of</strong> the Lithographic Process<br />

Lithography is a planographic process, <strong>in</strong><br />

that the <strong>in</strong>k-carry<strong>in</strong>g image is <strong>in</strong> the same plane<br />

as the non-image areas. On the plate, areas <strong>of</strong><br />

different surface energy are created by chemical<br />

treatment. This process leads to the formation<br />

<strong>of</strong> image areas that are <strong>in</strong>k accept<strong>in</strong>g and water<br />

repellent, and non-image areas that are water<br />

accept<strong>in</strong>g.<br />

Usually, the plate is damped before it is <strong>in</strong>ked.<br />

The founta<strong>in</strong> solution - consist<strong>in</strong>g <strong>of</strong> water,<br />

buffer salts, surface active agents, and other<br />

additives and possibly isopropanol – forms a<br />

film on the non-image areas (water accept<strong>in</strong>g),<br />

but contracts <strong>in</strong>to t<strong>in</strong>y droplets on the image<br />

areas (water-repellent). (See Fig.1).<br />

Water Ink Ink Water<br />

α α<br />

IMAGE NON-IMAGE<br />

Ink<br />

Fig. 1: Lithographic pr<strong>in</strong>ciple.<br />

Water<br />

IMAGE NON-IMAGE<br />

When an <strong>in</strong>ked roller passes over the damped<br />

plate, the water film on the non-image areas<br />

prevents these be<strong>in</strong>g <strong>in</strong>ked up and pushes the<br />

<strong>in</strong>k towards the image areas. The water droplets<br />

present on the image areas are either removed or<br />

emulsified <strong>in</strong>to the <strong>in</strong>k. If the <strong>in</strong>k is too water<br />

repellent and this emulsification does not take<br />

place, an uneven “mottled” pr<strong>in</strong>t will result.<br />

Emulsifcation <strong>of</strong> too much water <strong>in</strong> the <strong>in</strong>k<br />

may lead to a loss <strong>of</strong> transfer and hence a loss<br />

<strong>of</strong> optical density <strong>of</strong> the pr<strong>in</strong>t.<br />

A proper “water w<strong>in</strong>dow” is necessary to be<br />

able to pr<strong>in</strong>t with vary<strong>in</strong>g levels <strong>of</strong> founta<strong>in</strong><br />

solution emulsified. It is important that when<br />

water is emulsified <strong>in</strong> the <strong>in</strong>k, the <strong>in</strong>k rheology<br />

undergoes a m<strong>in</strong>or change. This is necessary to<br />

obta<strong>in</strong> a constant <strong>in</strong>k transfer and thus stable<br />

press behavior.<br />

To pr<strong>in</strong>t correctly <strong>in</strong> lithography, the right<br />

balance between <strong>in</strong>k and founta<strong>in</strong> solution<br />

must be achieved, thus comes the term “<strong>in</strong>k<br />

water balance”.<br />

1

2<br />

Introduction to <strong>Energy</strong> <strong>Curable</strong> <strong>Offset</strong><br />

Plate<br />

cyl<strong>in</strong>der<br />

Blanket<br />

cyl<strong>in</strong>der<br />

Ink duct<br />

Impression<br />

cyl<strong>in</strong>der<br />

Fig. 2: <strong>Offset</strong> Lithographic Process.<br />

1<br />

2<br />

3<br />

Damp<strong>in</strong>g<br />

rollers<br />

Fount<br />

solution<br />

Feed<br />

substrate<br />

The process is called <strong>of</strong>fset lithography (see Fig. 2)<br />

because the <strong>in</strong>k is not transferred directly from<br />

the plate to the substrate, but is first “<strong>of</strong>fset”<br />

onto a rubber blanket cyl<strong>in</strong>der and is then<br />

transferred to the substrate.<br />

The <strong>of</strong>fset lithographic process dom<strong>in</strong>ates the<br />

graphic <strong>in</strong>dustry <strong>in</strong> a wide range <strong>of</strong> formats:<br />

from multiple color 8½" x 11" (Sheet-fed<br />

pr<strong>in</strong>t<strong>in</strong>g, see Fig. 3), to pr<strong>in</strong>t<strong>in</strong>g magaz<strong>in</strong>es and<br />

newspapers on a cont<strong>in</strong>uous web <strong>of</strong> paper<br />

(web <strong>of</strong>fset). This process is particularly suited<br />

to the production <strong>of</strong> lightweight packag<strong>in</strong>g,<br />

books, magaz<strong>in</strong>es, newspapers, brochures, maps,<br />

promotional posters and literature, bus<strong>in</strong>ess<br />

stationery, to name some examples.<br />

Fig. 3: Schematic presentation<br />

<strong>of</strong> a Sheet-fed <strong>Offset</strong> pr<strong>in</strong>t<strong>in</strong>g mach<strong>in</strong>e.

Types <strong>of</strong> <strong>Offset</strong> Lithographic <strong>Inks</strong>:<br />

<strong>Offset</strong> lithographic <strong>in</strong>ks are <strong>of</strong>ten characterised<br />

accord<strong>in</strong>g their dry<strong>in</strong>g method:<br />

• Absorption: cold-set <strong>in</strong>ks (eg. newspaper<br />

<strong>in</strong>ks)<br />

• Evaporation: heat-set <strong>in</strong>ks<br />

• Oxidation: conventional sheet-fed <strong>in</strong>ks<br />

• <strong>Energy</strong> cur<strong>in</strong>g (UV/EB)<br />

<strong>Energy</strong> <strong>Curable</strong> <strong>Offset</strong> <strong>in</strong>ks are used <strong>in</strong> sheet-fed<br />

and web-fed applications. The sett<strong>in</strong>g and the<br />

dry<strong>in</strong>g <strong>of</strong> the <strong>in</strong>k occur <strong>in</strong> approximately 0,1 s.<br />

by transform<strong>in</strong>g the wet b<strong>in</strong>der <strong>in</strong>to an <strong>in</strong>soluble<br />

dry <strong>in</strong>k film through a polymerisation reaction.<br />

The polymerisation is <strong>in</strong>duced by UV light (or<br />

electron beam).<br />

<strong>Energy</strong> curable <strong>in</strong>ks ma<strong>in</strong>ly consist <strong>of</strong>:<br />

• Acrylated res<strong>in</strong>s (oligomers):<br />

basic coat<strong>in</strong>g properties<br />

• Monomers (di- to hexa acrylates): viscosity<br />

reduction, flexibility (mon<strong>of</strong>unctional);<br />

crossl<strong>in</strong>k<strong>in</strong>g (multifunctional<br />

• Pigments and fillers<br />

• Additives: performance f<strong>in</strong>e tun<strong>in</strong>g<br />

• Photo<strong>in</strong>itiator package: free radical<br />

generation to <strong>in</strong>itiate polymerisation<br />

Typical Properties <strong>of</strong> <strong>Energy</strong> <strong>Curable</strong><br />

<strong>Offset</strong> <strong>Inks</strong>:<br />

• Immediate dry<strong>in</strong>g (surface and <strong>in</strong>-depth)<br />

• On-l<strong>in</strong>e process<strong>in</strong>g<br />

• No spray powder needed <strong>in</strong> sheet-fed <strong>of</strong>fset<br />

• Increased productivity<br />

• No solvents used<br />

• No dry<strong>in</strong>g <strong>of</strong> <strong>in</strong>k on the pr<strong>in</strong>t<strong>in</strong>g press<br />

(less clean<strong>in</strong>g)<br />

• Low energy level required (vs heat dry<strong>in</strong>g)<br />

• Ability to pr<strong>in</strong>t on a wide variety <strong>of</strong><br />

substrates with the same <strong>in</strong>k<br />

• Pr<strong>in</strong>t<strong>in</strong>g on heat-sensitive substrates<br />

• Reduced space required (vs heat dry<strong>in</strong>g)<br />

• High gloss<br />

• High chemical resistance<br />

<strong>Offset</strong> Ink Parameters<br />

and Test Methods<br />

Ink Parameters<br />

<strong>Inks</strong> used for the lithographic <strong>in</strong>dustry must<br />

fulfil a number <strong>of</strong> requirements:<br />

• Suitable Viscosity (expressed <strong>in</strong> Pa.s or poise)<br />

• Low tack (at 1200 RPM, 90° F)<br />

• Low mist<strong>in</strong>g<br />

• Good <strong>in</strong>k-water balance<br />

• Good reactivity<br />

Dur<strong>in</strong>g the last decades, a number <strong>of</strong> methods<br />

have been developed to evaluate properties<br />

<strong>of</strong> wet <strong>in</strong>ks and pr<strong>in</strong>ted (dried) <strong>in</strong>ks. We have<br />

chosen the follow<strong>in</strong>g laboratory methods to<br />

assess the above characteristics.<br />

3

4 Introduction to <strong>Energy</strong> <strong>Curable</strong> <strong>Offset</strong><br />

Lithographic <strong>Inks</strong> <strong>Evaluation</strong> Capabilities at Cytec Specialty Chemicals, Americas<br />

Oligomer Viscosity<br />

■ Def<strong>in</strong>ition:<br />

Viscosity is def<strong>in</strong>ed as a fluid’s resistance<br />

to flow. There are a number <strong>of</strong> available<br />

<strong>in</strong>struments and methods to measure<br />

viscosity.<br />

■ Equipment:<br />

• Brookfield Rotational Viscometer,<br />

Model RVDV<br />

• Brookfield Thermosel Chamber or Small<br />

Cell Adapter<br />

• Electronic Temperature controller or<br />

programmable circulat<strong>in</strong>g water bath<br />

• Brookfield Sample Conta<strong>in</strong>er<br />

• Brookfield Sp<strong>in</strong>dles<br />

■ Material:<br />

• Oligomer sample<br />

■ Test<strong>in</strong>g Method:<br />

• Appropriate oligomer sample size is added<br />

to Brookfield sample conta<strong>in</strong>er<br />

• Select RPM and sp<strong>in</strong>dle number by<br />

select<strong>in</strong>g the appropriate button on the<br />

viscometer keypad<br />

• Measure and record viscosity<br />

Tack<br />

■ Def<strong>in</strong>ition:<br />

Tack is a relative measurement <strong>of</strong> the<br />

cohesion or stick<strong>in</strong>ess <strong>of</strong> an <strong>in</strong>k film. Tack<br />

is measured by measur<strong>in</strong>g the force required<br />

to split an <strong>in</strong>k film between two rollers. The<br />

tackier the <strong>in</strong>k, the higher the force required<br />

for film separation. Tack is recorded <strong>in</strong><br />

arbitrary units, depend<strong>in</strong>g on <strong>in</strong>strument<br />

used for measurement.<br />

■ Equipment:<br />

• Thw<strong>in</strong>g-Albert Electronic Inkometer<br />

(See Fig. 4)<br />

■ Material:<br />

• 0.2 cc <strong>in</strong>k<br />

■ Test<strong>in</strong>g Method:<br />

• Ink is applied to bottom vibrator<br />

roller and manually spread onto the<br />

other rollers<br />

• Initiate test<strong>in</strong>g at 1200 RPM, 90° F<br />

• Ink tack is recorded after 1 m<strong>in</strong>ute<br />

Fig. 4: Thw<strong>in</strong>g-Albert Electronic Inkometer.

Lithographic <strong>Inks</strong> <strong>Evaluation</strong> Capabilities at Cytec Specialty Chemicals, Americas<br />

Mist<strong>in</strong>g<br />

■ Def<strong>in</strong>ition:<br />

Ink mist<strong>in</strong>g is the f<strong>in</strong>e mist or spray <strong>of</strong> <strong>in</strong>k<br />

thrown <strong>of</strong>f rapidly mov<strong>in</strong>g rollers (See Fig. 5).<br />

■ Equipment:<br />

• Thw<strong>in</strong>g-Albert Electronic Inkometer<br />

• Spectrodensitometer<br />

■ Materials (<strong>in</strong>k mist<strong>in</strong>g is usually measured<br />

at the same time as <strong>in</strong>k tack):<br />

• 0.2 cc <strong>in</strong>k<br />

• Coated white paper (trimmed to fit <strong>in</strong>to<br />

bottom <strong>in</strong>kometer tray)<br />

■ Test<strong>in</strong>g Method:<br />

• A piece <strong>of</strong> coated white paper is placed<br />

<strong>in</strong> the tray beneath the bottom<br />

<strong>in</strong>kometer roller<br />

• Beg<strong>in</strong> test<strong>in</strong>g at 1200 RPM, 90° F, 1 m<strong>in</strong>.<br />

• After complet<strong>in</strong>g the tack test<strong>in</strong>g, the<br />

paper is removed and the <strong>in</strong>k area is<br />

divided <strong>in</strong>to quadrants (See Fig. 6)<br />

• In each quadrant, the total color<br />

difference (∆E) between unexposed paper<br />

and the test specimen is measured<br />

• The average <strong>of</strong> the four read<strong>in</strong>gs is reported.<br />

– Note: This is not an absolute value<br />

but <strong>in</strong>dicates an <strong>in</strong>k’s tendency to<br />

exhibit mist<strong>in</strong>g<br />

Roller<br />

Roller<br />

Fig. 5: Ink film splitt<strong>in</strong>g.<br />

Cavity<br />

formation<br />

Str<strong>in</strong>g<br />

formation<br />

Fig. 6: Example <strong>of</strong> mist<strong>in</strong>g result.<br />

Reactivity (Cure Speed)<br />

■ Def<strong>in</strong>ition:<br />

Reactivity is the speed or rate <strong>of</strong><br />

polymerization <strong>of</strong> an energy curable <strong>in</strong>k.<br />

Technically, reactivity is the energy density<br />

required to dry, cur<strong>in</strong>g or polymerize the <strong>in</strong>k<br />

film. Reactivity is reported as energy density<br />

and expressed as J/cm 2 or mJ/cm 2 .<br />

■ Equipment:<br />

• Aetek UV Cur<strong>in</strong>g System<br />

– 1-400 watts/<strong>in</strong>. UV lamp<br />

• Radiometer (light bug)<br />

• “Little Joe” Pro<strong>of</strong><strong>in</strong>g System with<br />

wedge plate<br />

■ Materials:<br />

• Coated white paper<br />

• Ink<br />

5

6 Introduction to <strong>Energy</strong> <strong>Curable</strong> <strong>Offset</strong><br />

Lithographic <strong>Inks</strong> <strong>Evaluation</strong> Capabilities at Cytec Specialty Chemicals, Americas<br />

■ Test<strong>in</strong>g Method:<br />

• Ink is applied to coated paper at<br />

appropriate film thickness us<strong>in</strong>g “Little<br />

Joe” pro<strong>of</strong>er and exposed to cur<strong>in</strong>g source<br />

• After exposure, the <strong>in</strong>k surface is<br />

vigorously rubbed with the <strong>in</strong>dex f<strong>in</strong>ger<br />

– If no <strong>in</strong>k removed, the <strong>in</strong>k is cured<br />

at this exposure. Us<strong>in</strong>g a radiometer,<br />

the energy density is measured<br />

and recorded. Also recorded is the<br />

conveyor/belt speed<br />

– The conveyor/belt speed is <strong>in</strong>creased the<br />

test is repeated until <strong>in</strong>k is removed<br />

– If <strong>in</strong> the <strong>in</strong>itial test<strong>in</strong>g, <strong>in</strong>k is rubbed<br />

<strong>of</strong>f, the conveyor/belt speed is decreased<br />

and the test repeated until <strong>in</strong>k is not<br />

removed by rubb<strong>in</strong>g the surface<br />

– The shortest exposure (lowest energy<br />

density) needed to achieve no <strong>in</strong>k<br />

removal is reported as the <strong>in</strong>k reactivity<br />

Adhesion to Non Porous Substrates<br />

■ Def<strong>in</strong>ition:<br />

Adhesion is ability <strong>of</strong> an <strong>in</strong>k to bond<br />

completely with the substrate. When there<br />

is full adhesion the <strong>in</strong>k is not removed<br />

<strong>in</strong> standard tape test<strong>in</strong>g. There are two<br />

methods used for tape test adhesion test<strong>in</strong>g –<br />

tape pull on filmic substrates and cross hatch<br />

on rigid substrates. Adhesion is typically<br />

expressed as percent <strong>of</strong> <strong>in</strong>k adher<strong>in</strong>g or<br />

rema<strong>in</strong><strong>in</strong>g on the substrate.<br />

■ Equipment:<br />

• Aetek UV Cur<strong>in</strong>g System<br />

– 1-400 watts/<strong>in</strong>. UV lamp<br />

• “Little Joe” Pro<strong>of</strong><strong>in</strong>g System with<br />

wedge plate<br />

• Specified test tape (usually 3M’s 600 or<br />

610 tape)<br />

• Cross hatch tool<br />

■ Materials:<br />

• Specified non-porous substrate<br />

– Coated<br />

– Uncoated<br />

• Ink<br />

■ Test<strong>in</strong>g Method:<br />

• Ink is applied to substrate at appropriate<br />

film thickness us<strong>in</strong>g “Little Joe” pro<strong>of</strong>er<br />

and then cured with appropriate energy<br />

density<br />

• After cur<strong>in</strong>g, a strip <strong>of</strong> test tape is applied<br />

to the <strong>in</strong>k surface<br />

– If test<strong>in</strong>g adhesion to a rigid substrate, a<br />

cross hatch tool is used to score the <strong>in</strong>k<br />

film prior to apply<strong>in</strong>g the tape<br />

• At a 60° angle, the tape is quickly ripped<br />

from the <strong>in</strong>k surface<br />

• The percent <strong>in</strong>k rema<strong>in</strong><strong>in</strong>g on the<br />

substrate is determ<strong>in</strong>ed and reported

Pr<strong>in</strong>tability<br />

■ Def<strong>in</strong>ition:<br />

Pr<strong>in</strong>tability is the <strong>in</strong>k’s behavior <strong>in</strong> a<br />

lithographic pr<strong>in</strong>t<strong>in</strong>g environment.<br />

This test<strong>in</strong>g simulates the handl<strong>in</strong>g and<br />

application <strong>of</strong> an <strong>in</strong>k at a pr<strong>in</strong>ter’s facility.<br />

The test<strong>in</strong>g evaluates <strong>in</strong>k transfer, <strong>in</strong>k-water<br />

balance, image quality and productivity.<br />

■ Equipment:<br />

• Ryobi CD 2800 Duplicator outfitted<br />

with <strong>in</strong>tegrated dampen<strong>in</strong>g system and<br />

UV cur<strong>in</strong>g system (See Fig. 7)<br />

■ Materials:<br />

• 70# coated paper<br />

• Founta<strong>in</strong> solution<br />

• Ink<br />

■ Test<strong>in</strong>g Method:<br />

• Ink is pr<strong>in</strong>ted <strong>in</strong> accordance with <strong>in</strong>dustry<br />

procedures<br />

• Dur<strong>in</strong>g pr<strong>in</strong>t<strong>in</strong>g, <strong>in</strong>k is evaluated for ease<br />

<strong>of</strong> establish<strong>in</strong>g and ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g color<br />

density and pr<strong>in</strong>t contrast<br />

• Also evaluated are press make ready and<br />

clean up<br />

Fig. 7: Ryobi CD 2800 Duplicator.<br />

7

8<br />

Products for <strong>Energy</strong> <strong>Curable</strong><br />

Lithographic <strong>Inks</strong><br />

This section describes products recommended<br />

for energy curable <strong>of</strong>fset <strong>in</strong>ks. General<br />

recommendations are given on the use <strong>of</strong> the<br />

different types <strong>of</strong> acrylates <strong>in</strong> energy curable<br />

<strong>of</strong>fset <strong>in</strong>ks. Features and benefits <strong>of</strong> each<br />

product are also mentioned.<br />

General Recommendations<br />

Product Type Benefits<br />

Polyester acrylates Pigment wett<strong>in</strong>g<br />

Ink water balance<br />

Diluted polyesters Adhesion to plastics<br />

and metals<br />

Epoxy acrylates Reactivity<br />

Hardness; scratch resistance<br />

Solvent resistancy<br />

Modified epoxy<br />

acrylates<br />

Improved <strong>in</strong>k water balance<br />

Urethane acrylates Reactivity (dark colors)<br />

Hardness; scratch resistance<br />

Solvent resistancy<br />

Dilut<strong>in</strong>g acrylates Viscosity/tack adjustment

Polyester Acrylates<br />

Products<br />

Functionality,<br />

Theoretical<br />

EBECRYL ® 657 Tetrafunctional 103500<br />

EBECRYL 811 Trifunctional 90000<br />

EBECRYL 838 Hexafunctional 49298<br />

EBECRYL 846 Tetrafunctional 45000<br />

EBECRYL 870 Hexafunctional 43070<br />

EBECRYL 871 Hexafunctional 47450<br />

EBECRYL 889 Tetrafunctional 32300<br />

EBECRYL 1657 Tetrafunctional 124800<br />

Diluted Polyesters<br />

Products Description<br />

EBECRYL 436<br />

EBECRYL 438<br />

EBECRYL 586<br />

Chlor<strong>in</strong>ated polyester<br />

<strong>in</strong> 40% TMPTA<br />

Chlor<strong>in</strong>ated polyester<br />

<strong>in</strong> 40% OTA 480<br />

Chlor<strong>in</strong>ated polyester<br />

<strong>in</strong> 40% TMPTA<br />

Oligomers and Monomers for<br />

Lithographic <strong>Inks</strong><br />

Viscosity,<br />

cP @ 25°C Key Features and Benefits<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Good pigment wett<strong>in</strong>g, especially yellow pigments<br />

Provides <strong>in</strong>k with higher <strong>in</strong>k tacks<br />

Very low <strong>in</strong>k mist<strong>in</strong>g<br />

Provides very good <strong>in</strong>k-water balance<br />

Good surface hardness<br />

Good chemical resistance<br />

Good reactivity<br />

Suitable for paper and board on web presses<br />

Excellent pigment wett<strong>in</strong>g<br />

Good overall lithographic properties<br />

Excellent pigment wett<strong>in</strong>g<br />

Provides <strong>in</strong>k with lower <strong>in</strong>k tacks<br />

Good adhesion to super-calendared paper<br />

Good pr<strong>in</strong>tability to super-calendared paper<br />

Purified version <strong>of</strong> EBECRYL 657<br />

Low residual odor<br />

Viscosity,<br />

cP @ 25°C Key Features and Benefits<br />

100000<br />

85600<br />

45029<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Good adhesion to non–porous substrates<br />

Good adhesion to metals<br />

Good adhesion to non–porous substrates<br />

Good adhesion to metals<br />

Good adhesion to non–porous substrates<br />

Good flexibility<br />

9

10<br />

Products for <strong>Energy</strong> <strong>Curable</strong><br />

Lithographic <strong>Inks</strong> (cont<strong>in</strong>ued)<br />

Epoxy Acrylates<br />

Products Description<br />

EBECRYL 860<br />

EBECRYL 3411<br />

EBECRYL 3701<br />

EBECRYL 3702<br />

EBECRYL 3708<br />

Epoxidized Soya Oil<br />

Tetra-Acrylate<br />

Fatty Acid Modified<br />

Epoxy Diacrylate<br />

Modified Bisphenol A<br />

Epoxy Diacrylate<br />

Fatty Acid Modified<br />

Epoxy Diacrylate<br />

Modified Bisphenol A<br />

Epoxy Acrylate<br />

Viscosity,<br />

cP @ 25°C Key Features and Benefits<br />

26518<br />

40100<br />

1600000<br />

495000<br />

190000<br />

EBECRYL 3720 Bisphenol A Epoxy Diacrylate 750000<br />

Urethane Acrylates (used as additives)<br />

Products Description<br />

EBECRYL 220 Aromatic Urethane Hexacrylate 28268<br />

EBECRYL 230 Aliphatic Urethane Diacrylate 44014<br />

EBECRYL 1290 Aliphatic Urethane Hexacrylate 85000<br />

EBECRYL 4827 Aromatic Urethane Diacrylate 238000<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Good flow and level<strong>in</strong>g<br />

Good compatibility with hybrids <strong>in</strong>ks<br />

Good pigment wett<strong>in</strong>g<br />

Good flow and level<strong>in</strong>g<br />

High reactivity<br />

Increases <strong>in</strong>k tack<br />

Increased flexibility<br />

Increases <strong>in</strong>k tack<br />

Provides flexibility<br />

Recommended for metal deco<br />

Good solvent resistance<br />

Increases <strong>in</strong>k tack<br />

Viscosity,<br />

cP @ 25°C Key Features and Benefits<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Enhances reactivity <strong>in</strong> dark colored <strong>in</strong>ks<br />

Enhances scratch resistance<br />

Increases flexibility<br />

Low Tg<br />

Enhances hardness<br />

Increases scratch resistance<br />

Enhances flexibility<br />

Enhances adhesion to plastics

Dilut<strong>in</strong>g Acrylates<br />

Products<br />

EBECRYL 1039<br />

EBECRYL 113<br />

TRPGDA<br />

NPG(PO) 2 DA<br />

EBECRYL 150<br />

TMPEOTA<br />

OTA 480<br />

TMPTA<br />

Description<br />

Theoretical<br />

Urethane Mon<strong>of</strong>unctional<br />

Acrylate<br />

Aliphatic Mon<strong>of</strong>unctional<br />

acrylate<br />

Tripropylene Glycol<br />

Diacrylate<br />

Neopentyl Glycol Propoxylate<br />

Diacrylate<br />

Bisphenol A Ethoxylate<br />

Diacrylate<br />

Trimethylolpropane Ethoxy<br />

Triacrylate<br />

Propoxylated Glycerol<br />

Triacrylate<br />

Trimethylolpropane<br />

Triacrylate<br />

Viscosity,<br />

cP @ 25°C Key Features and Benefits<br />

40<br />

120<br />

12 .9<br />

15 .9<br />

1347<br />

21<br />

88<br />

108<br />

EBECRYL 40 Polyether Tetra-acrylate 147<br />

EBECRYL 140<br />

Di-trimethylolpropane<br />

Tetra-acrylate<br />

979<br />

DPHA Acrylated Dipentaerythriol 17093<br />

Specialty: Bioligomers – Renewable<br />

Products Description<br />

EBECRYL 5500 Glycerol Derivative Triacrylate 110<br />

EBECRYL 5610 Modified Epoxy Acrylate 2200<br />

EBECRYL 5820 Polyester Tetra-Acrylate 66100<br />

EBECRYL 5821 Polyester Pentaacrylate 27500<br />

EBECRYL 5822 Polyester Pentaacrylate 29200<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Enhances adhesion to non-porous substrates<br />

Good reactivity (for mon<strong>of</strong>unctional monomer)<br />

Enhances adhesion to non-porous substrates<br />

Good pigment wett<strong>in</strong>g<br />

Good reactivity (for mon<strong>of</strong>unctional monomer)<br />

Good diluent<br />

Good reactivity without brittleness<br />

Increases flexibility<br />

Lower surface tension<br />

High reactivity<br />

Enhances scratch resistance<br />

Good reactivity<br />

Increased flexibility (vs . TMPTA)<br />

Good pigment wett<strong>in</strong>g<br />

Good reactivity<br />

Increases crossl<strong>in</strong>k<strong>in</strong>g and hardness<br />

Good chemical resistance<br />

Good reactivity<br />

Good hardness without brittleness<br />

High crossl<strong>in</strong>k<strong>in</strong>g<br />

Increased hardness<br />

High reactivity<br />

Increased hardness<br />

Viscosity,<br />

cP @ 25°C Key Features and Benefits<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Partially based on renewable resources<br />

Good cure response<br />

Hardness<br />

Partially based on renewable resources<br />

Developed for OPV’s<br />

Good flow and level<strong>in</strong>g<br />

Partially based on renewable resources<br />

Good pigment wett<strong>in</strong>g<br />

Partially based on renewable resources<br />

Good reactivity<br />

• Partially based on renewable resources<br />

•<br />

Good color development with carbon blacks<br />

11

12<br />

Products for <strong>Energy</strong> <strong>Curable</strong><br />

Lithographic <strong>Inks</strong> (cont<strong>in</strong>ued)<br />

Specialty: Low Odor and Low Extractables<br />

Products Description<br />

EBECRYL LEO ® 10501 Trifunctional Dilut<strong>in</strong>g Acrylate 80<br />

EBECRYL LEO 10601 Modified Epoxy Acrylate 200000<br />

EBECRYL LEO 10801 Hexafunctional Polyester Acrylate 48000<br />

Additives<br />

Photo<strong>in</strong>itiators<br />

Miscellaneous<br />

Viscosity,<br />

cP @ 25°C Key Features and Benefits<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

High reactivity<br />

Lower viscosity<br />

Good solvent resistance<br />

Good reactivity<br />

Good pigment wett<strong>in</strong>g<br />

High reactivity<br />

Products Type Key Features and Benefits<br />

ADDITOL ® BCPK Mixture<br />

ADDITOL DX Mixture<br />

ADDITOL LX Mixture<br />

ADDITOL BP H-Abstraction<br />

ADDITOL BDK α-cleavage<br />

ADDITOL CPK α-cleavage<br />

ADDITOL HDMAP α-cleavage<br />

ADDITOL ITX H-Abstraction<br />

ADDITOL TPO α-cleavage<br />

EBECRYL P39 H-Abstraction<br />

EBECRYL 350 Silicone Diacrylate<br />

EBECRYL 1360 Silicone Hexaacrylate<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Easily <strong>in</strong>corporated<br />

Good comb<strong>in</strong>ation <strong>of</strong> surface and through cure<br />

Liquid photo<strong>in</strong>itiator<br />

Effective <strong>in</strong> pigmented <strong>in</strong>ks at 5-10% levels<br />

Liquid photo<strong>in</strong>itiator<br />

Effective <strong>in</strong> white and yellow <strong>in</strong>ks at 5-10% levels<br />

Good solubility<br />

Excellent surface cure<br />

Good solubility<br />

Multipurpose photo<strong>in</strong>itiator – use alone or comb<strong>in</strong>ed<br />

with other photo<strong>in</strong>itiators<br />

Good solubility<br />

Good surface an through cure<br />

Liquid photo<strong>in</strong>itiator<br />

Good solvency <strong>of</strong> solid photo<strong>in</strong>itiators<br />

Good solubility<br />

Good through cure<br />

Low yellow<strong>in</strong>g <strong>in</strong> white pigmented <strong>in</strong>ks<br />

Good through cure<br />

Low residual odor<br />

Pourable liquid<br />

COF reduction<br />

Non-migratory<br />

• COF reduction<br />

• Non-migratory<br />

•<br />

Especially effective <strong>in</strong> EB

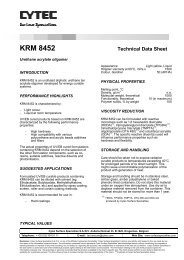

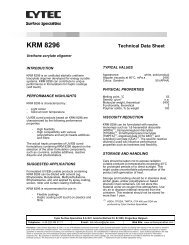

General Properties <strong>of</strong> Products for <strong>Energy</strong> <strong>Curable</strong> Lithographic <strong>Inks</strong> (Relative rank<strong>in</strong>g)<br />

Products Viscosity Reactivity<br />

Pigment<br />

Wett<strong>in</strong>g<br />

Ink<br />

Tack<br />

Ink<br />

Mist<strong>in</strong>g Pr<strong>in</strong>tability<br />

Adhesion to<br />

Non-porous<br />

Substrates<br />

EBECRYL 113 N/A ●●● ●●● N/A N/A N/A ●●●●<br />

EBECRYL 1039 N/A ●●● ●●● N/A N/A N/A ●●●●<br />

EBECRYL 150 N/A ●●● ●● N/A N/A N/A ●<br />

OTA 480 N/A ●●● ●●●●● N/A N/A N/A ●<br />

EBECRYL 40 N/A ●●●● ●●● N/A N/A N/A ●<br />

EBECRYL 140 N/A ●●●● ●●● N/A N/A N/A ●<br />

DPHA N/A ●●●●● N/A N/A N/A N/A ●<br />

EBECRYL 436 ●● ●● ● ●●● ●●● N/A ●●●●●<br />

EBECRYL 438 ●● ●● ● ●●● ●●● N/A ●●●●●<br />

EBECRYL 586 ●● ●● ● ●●● ●●● N/A ●●●●●<br />

EBECRYL 657 ●● ●●●●● ●●●●● ●●● ●●●● ●●●●● ●●<br />

EBECRYL 811 ●● ●●● ●●● ●●●● ●●●●● ●●●●● ●●●<br />

EBECRYL 838 ●●●●● ●●●●● ●●●● ●●● ●●● ●●●● ●<br />

EBECRYL 846 ●●●●● ●●●●● ●●●● ●●●● ●●●● ●●●● ●<br />

EBECRYL 860 ●●● ●●● ●● ●●● ●● ●● ●●<br />

EBECRYL 870 ●●●●● ●●●●● ●●●●● ●●●● ●●●● ●●●●● ●●<br />

EBECRYL 871 ●●●●● ●●●●● ●●●●● ●●●● ●●●● ●●●●● ●<br />

EBECRYL 889 ●●●● ●●●● ●●●● ●●●● ●●●● ●●●● ●<br />

EBECRYL 1657 ●● ●●●●● ●●●●● ●●●● ●●●● ●●●● ●<br />

EBECRYL 3411 ●●●● ●●● ●●●●● ●●● ●●● ●●● ●<br />

EBECRYL 3701 ● ●●● ●● ● ●●● ●● ●<br />

EBECRYL 3702 ● ●●● ●●● ● ●●● ●● ●<br />

EBECRYL 3720 ● ●●● ●● ● ●●● ●● ●<br />

EBECRYL 220 N/A ●●●●● N/A N/A N/A N/A ●<br />

EBECRYL 230 N/A ●●● N/A N/A N/A N/A ●●●<br />

EBECRYL 1290 N/A ●●●●● N/A N/A N/A N/A ●<br />

EBECRYL 4827 N/A ●●● N/A N/A N/A N/A ●●●<br />

N/A = Not Applicable<br />

Key<br />

Adhesion to Non-Porous Substrates Poor Excellent<br />

Ink Mist<strong>in</strong>g High Low<br />

Ink Tack High Low<br />

Pigment Wett<strong>in</strong>g Poor Excellent<br />

Pr<strong>in</strong>tability Poor Excellent<br />

Reactivity Low High<br />

Viscosity Higher Lower<br />

13

14<br />

Standard Ink Formulations for <strong>Evaluation</strong> <strong>of</strong><br />

Oligomers for <strong>Energy</strong> <strong>Curable</strong> Lithographic <strong>Inks</strong><br />

The formulations <strong>in</strong>dicated below have only<br />

been designed to provide us with a test method<br />

to evaluate our new development products.<br />

They are representative enough to give an<br />

<strong>in</strong>dication <strong>of</strong> the way our products perform <strong>in</strong><br />

Paper and Board Stock:<br />

Pigment Dispersion<br />

Acrylated oligomer 50-60%<br />

Polyester acrylate and/or epoxy acrylate<br />

Pigment 30-40%<br />

OTA 480 5-10%<br />

Ink<br />

Pigment dispersion 55-60%<br />

Acrylated oligomer 20-30%<br />

Polyester acrylate and/or epoxy acrylate<br />

Inert Filler 2-5%<br />

Wax 0-2%<br />

Dilut<strong>in</strong>g acrylate 2-5%<br />

TRPGDA, TMPTA or TMPEOTA<br />

Additol DX liquid photo<strong>in</strong>itiator blend 8-10%<br />

<strong>Energy</strong> <strong>Curable</strong> <strong>Offset</strong> <strong>Inks</strong>. However, they can<br />

not be considered as recommanded formulations<br />

and are not meant to deliver optimal<br />

performance <strong>in</strong> all applications.<br />

Non-Porous Stock:<br />

Pigment Dispersion<br />

Acrylated oligomer 50-60%<br />

Diluted polyester<br />

Pigment 30-40%<br />

OTA 480 5-10%<br />

Ink<br />

Pigment dispersion 55-60%<br />

Acrylated oligomer 20-30%<br />

Diluted polyester acrylate<br />

Inert Filler 2-5%<br />

Wax 0-2%<br />

Dilut<strong>in</strong>g acrylate 2-5%<br />

TRPGDA, NPG(PO)2DA, EBECRYL 1039 or EBECRYL 113<br />

Additol DX liquid photo<strong>in</strong>itiator blend 8-10%

Cytec <strong>Industries</strong> Inc.<br />

Americas<br />

Contact Us<br />

1950 Lake Park Drive<br />

Smyrna, GA 30080 USA<br />

Tel: 1 800 433 2873 (USA)<br />

Fax: 1 678 255 4746 (Outside USA)<br />

customerservicena@cytec .com<br />

Global Product Referral<br />

Tel: 1 800 652 6013 (USA)<br />

Tel: 1 973 357 3193 (Outside USA)<br />

cust<strong>in</strong>fo@cytec .com<br />

Trademark Notice: The ® <strong>in</strong>dicates a Registered Trademark <strong>in</strong> the United States and the or * <strong>in</strong>dicates a Trademark <strong>in</strong> the United States. The mark may also<br />

be registered, the subject <strong>of</strong> an application for registration, or a trademark <strong>in</strong> other countries.<br />

Notice: Cytec <strong>Industries</strong> Inc. <strong>in</strong> its own name and on behalf <strong>of</strong> its affiliated companies (collectively, “Cytec”) decl<strong>in</strong>e any liability with respect to the use made by<br />

anyone <strong>of</strong> the <strong>in</strong>formation conta<strong>in</strong>ed here<strong>in</strong>. The <strong>in</strong>formation conta<strong>in</strong>ed here<strong>in</strong> represents Cytec’s best knowledge thereon without constitut<strong>in</strong>g any express or<br />

implied guarantee or warranty <strong>of</strong> any k<strong>in</strong>d (<strong>in</strong>clud<strong>in</strong>g, but not limited to, regard<strong>in</strong>g the accuracy, the completeness or relevance <strong>of</strong> the data set out here<strong>in</strong>). Cytec<br />

is the sole owner or authorized user <strong>of</strong> the <strong>in</strong>tellectual property rights relat<strong>in</strong>g to the <strong>in</strong>formation communicated. The <strong>in</strong>formation relat<strong>in</strong>g to the use <strong>of</strong> the products<br />

is given for <strong>in</strong>formation purposes only. No guarantee or warranty is provided that the product is adapted for any specific use. The user or purchaser should perform<br />

its own tests to determ<strong>in</strong>e the suitability for a particular purpose. The f<strong>in</strong>al choice <strong>of</strong> use <strong>of</strong> a product rema<strong>in</strong>s the sole responsibility <strong>of</strong> the user.<br />

RAD-0004-A-EN-NA-12A<br />

©2010 Cytec <strong>Industries</strong> Inc . All rights reserved .<br />

Europe<br />

Erasmus Office Park<br />

Square Marie Curie 11<br />

B-1070 Brussels<br />

Belgium<br />

Tel: +32 2 560 45 11<br />

Fax: +32 2 560 45 21<br />

surfsspec@cytec .com<br />

www.cytec.com<br />

Asia Pacific/Ch<strong>in</strong>a<br />

11D Junyao International Plaza<br />

No . 789, Zhao Jia Bang Road<br />

Xuhui District, Shanghai 200032<br />

Tel: +86 21 64228920<br />

Fax: +86 21 64228980<br />

ch<strong>in</strong>a@cytec .com