ACO Haustechnik

ACO Haustechnik

ACO Haustechnik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Installation and operating instructions<br />

Service line<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

1<br />

<strong>ACO</strong> H a u s t e c h n i k<br />

0150.16.70<br />

Wastewater lifting plants according to DIN EN 12050-1 for the collection and automatic<br />

lifting of wastewater without faecal matter, and with faecal and fatty matter, to above<br />

the backflow level, for free-standing / above-floor installation in the building.<br />

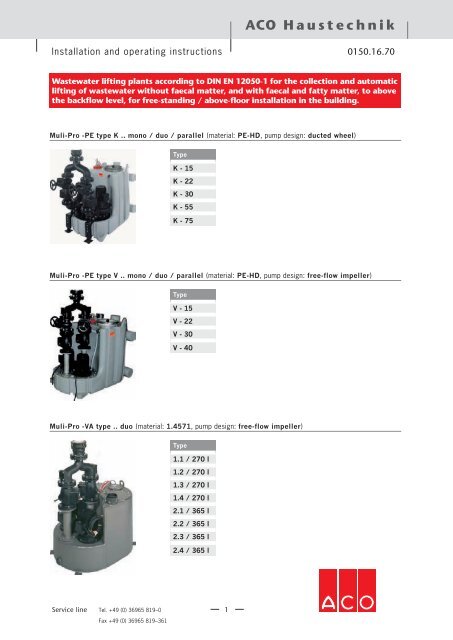

Muli-Pro -PE type K .. mono / duo / parallel (material: PE-HD, pump design: ducted wheel)<br />

Type<br />

K - 15<br />

K - 22<br />

K - 30<br />

K - 55<br />

K - 75<br />

Muli-Pro -PE type V .. mono / duo / parallel (material: PE-HD, pump design: free-flow impeller)<br />

Type<br />

V - 15<br />

V - 22<br />

V - 30<br />

V - 40<br />

Muli-Pro -VA type .. duo (material: 1.4571, pump design: free-flow impeller)<br />

Type<br />

1.1 / 270 l<br />

1.2 / 270 l<br />

1.3 / 270 l<br />

1.4 / 270 l<br />

2.1 / 365 l<br />

2.2 / 365 l<br />

2.3 / 365 l<br />

2.4 / 365 l

Data on the type plate |<br />

Muli-Pro-...<br />

Note | These operating instructions contain basic instructions which<br />

have to be observed during installation, operation and maintenance. It<br />

is therefore essential that the mechanic and responsible qualified staff/<br />

operator read these instructions prior to installation and operation, and<br />

that they are always available where the machine is installed.<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

<strong>ACO</strong> Passavant GmbH<br />

Im Gewerbepark 11c<br />

36457 Stadtlengsfeld, Germany<br />

Telephone 49-(0) 36965 819 - 0<br />

Fax 49-(0) 36965 819 - 361<br />

Wastewater lifting plant DIN EN 12050 - 1<br />

External monitoring certification LGA - Würzburg No. 0120022<br />

Year of manufacture<br />

Article number<br />

Serial number<br />

2<br />

Data<br />

0150.16.70<br />

Please copy and enter the data<br />

from the original type plate on<br />

the system.

Service line<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

3<br />

<strong>ACO</strong> H a u s t e c h n i k<br />

0150.16.70<br />

Content<br />

Chapter Page<br />

1. Product identification<br />

1.1 Manufacturer ........................................................................................................................... 5<br />

1.2 Supplier .................................................................................................................................. 5<br />

1.3 Electrician ............................................................................................................................... 5<br />

1.4 Address ... .............................................................................................................................. 5<br />

1.5 Fitter ...................................................................................................................................... 5<br />

1.6 Plant fitter ............................................................................................................................... 5<br />

1.7 Address ... .............................................................................................................................. 5<br />

1.8 EU conformity declaration ........................................................................................................ 6<br />

1.9 Installation of wastewater lifting plants, where and why .............................................................. 7<br />

1.10 Description: design / type ........................................................................................................ 9<br />

1.11 Description: mono / duo / parallel designs .............................................................................. 10<br />

1.12 Areas of application ............................................................................................................... 10<br />

1.13 Technical data, dimensions, performance diagrams, characteristic data .................................... 11<br />

2. Scope<br />

2.1 Applicability of the installation and operating instructions .......................................................... 18<br />

2.2 General information ............................................................................................................... 18<br />

3. Notes<br />

3.1 Explanation of symbols and notes ........................................................................................... 19<br />

3.2 Safety notices ....................................................................................................................... 20<br />

3.3 Directives and standards ........................................................................................................ 22<br />

4. Product description<br />

4.1 Components of Muli-Pro-PE design .......................................................................................... 27<br />

4.2 Components of Muli-Pro-VA design .......................................................................................... 28<br />

4.3 Switch box design types ........................................................................................................ 29<br />

4.4 Function (except for type K-55 and K-75) ................................................................................. 32<br />

4.5 Function Type K-55 and K-75 .................................................................................................. 33<br />

4.6 Installation recommendations ................................................................................................. 34<br />

4.7 Information on energy supply .................................................................................................. 35<br />

4.8 Information on potential-free contact – collective fault signal / operating signal .......................... 35<br />

4.9 Environmental conditions ........................................................................................................ 35<br />

4.10 Accessories .......................................................................................................................... 36<br />

5. Preparation of the product for use<br />

5.1 Transport, delivery and storage .............................................................................................. 38<br />

5.2 Fitter work for the mono and duo designs................................................................................ 39<br />

5.3 Fitter work for the parallel design ............................................................................................ 44<br />

5.4 Electrical work ...................................................................................................................... 46

6. Operating instructions<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

4<br />

0150.16.70<br />

6.1 Commissioning ...................................................................................................................... 49<br />

6.2 Explanation of the operating and indicating elements of the plug-ready switch boxes .................. 50<br />

6.3 Explanation of the operating and indicating elements of the connection-ready switch boxes ......... 52<br />

6.4 Schematic representation of the pneumatic level switching (with air bubbling) ............................. 54<br />

6.5 Test run process description (in this example: duo design with inlet from above) ......................... 56<br />

6.6 Operation .............................................................................................................................. 60<br />

6.7 Faults and their remedies ....................................................................................................... 61<br />

7. Servicing<br />

7.1 Instructions for maintenance and repair work ........................................................................... 62<br />

7.2 Regular inspections ............................................................................................................... 62<br />

7.3 Regular maintenance and repair work ...................................................................................... 63<br />

8. Repair<br />

9. Decommissioning<br />

9.1 Disassembly ......................................................................................................................... 64<br />

9.2 Disposal ............................................................................................................................... 64<br />

9.3 Decommissioning for a limited period of time .......................................................................... 64<br />

10. Stocking of spare parts and after-sales services<br />

10.1 Maintenance and wearing parts .............................................................................................. 65<br />

10.2 Order data ............................................................................................................................ 65<br />

11. Appendix<br />

11.1 Connection diagram for plug-ready switch box design -mono- up to 5 kW .................... 66<br />

11.2 Connection diagram for plug-ready switch box design -duo- up to 5 kW .................... 66<br />

11.3 Connection diagram for connection-ready switch box design -mono- 5.5 kW and higher .......... 67<br />

11.4 Connection diagram for connection-ready switch box design -duo- 5.5 kW and higher ......... 67

1. Product identification<br />

1.1 Manufacturer<br />

<strong>ACO</strong> Passavant GmbH<br />

Im Gewerbepark 11c<br />

36457 Stadtlengsfeld, Germany<br />

Telephone 49-(0) 36965 819 - 0<br />

Fax 49-(0) 36965 819 - 36<br />

1.2 Supplier<br />

Telephone<br />

Fax<br />

1.4 Electrician<br />

Telephone<br />

Fax<br />

1.6 Address ...<br />

Telephone<br />

Fax<br />

Service line<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

5<br />

<strong>ACO</strong> H a u s t e c h n i k<br />

After-Sales Service Department<br />

<strong>ACO</strong> <strong>Haustechnik</strong> GmbH<br />

Im Gewerbepark 11c<br />

36457 Stadtlengsfeld, Germany<br />

0150.16.70<br />

Service - Telephone 49-(0) 36965 819 - 444<br />

Service - Fax 49-(0) 36965 819 - 367<br />

E-mail service@aco-online.de<br />

1.3 Fitter<br />

Telephone<br />

Fax<br />

1.5 Plant fitter<br />

Telephone<br />

Fax<br />

1.7 Address ...<br />

Telephone<br />

Fax

1.8 EU conformity declaration<br />

EG - Konformitätserklärung<br />

Hiermit erklärt der Hersteller<br />

<strong>ACO</strong> Passavant GmbH<br />

Ulsterstraße 3<br />

36269 Philippsthal<br />

dass die Maschinenanlagen<br />

Muli Pro - PE / VA mono, duo und parallel<br />

konform sind mit der Bestimmung der<br />

EG-RL 2006/42/EG (Maschinenrichtlinie).<br />

Maschinen der Anlage sind konform mit weiteren Richtlinien:<br />

EG-RL 2006/95/EG (Niederspannungsrichtlinie).<br />

Folgende harmonisierte Normen wurden angewandt:<br />

DIN EN 12050-1 (Ausgabe 2001-05)<br />

Folgende gemeldete Stelle wurde eingeschaltet:<br />

LGA-Würzburg, Kenn-Nr. 0120022<br />

für:<br />

Fremdüberwachung<br />

Zuständiger Dokumentenbeauftragter:<br />

Herr Marco Eulenstein<br />

<strong>ACO</strong> <strong>Haustechnik</strong> GmbH<br />

Im Gewerbepark 11c<br />

36457 Stadtlengsfeld<br />

Philippstahl, 01.11.2009<br />

Unterschrift<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

Ralf Sand<br />

(Geschäftsführung, <strong>ACO</strong> Passavant GmbH)<br />

6<br />

0150.16.70

1.9 Installation of wastewater lifting plants, where and why<br />

General aspects<br />

Building regulations | According to state building regulations, buildings<br />

and other structures may only be erected if the elimination of wastewater is<br />

properly and permanently ensured. Property grounds on which wastewater<br />

arises must be connected to the public sewer system, if they are ready<br />

for operation. It is this requirement, i.e., the direct connection of a<br />

property's drainage system to the public sewer system, that gives rise<br />

to the problem of backflow in this area. The frequency of such backflows<br />

depends on the type of sewer system used, i.e. whether it is a separate or<br />

combined system. In separate sewer systems, dirty water and rainwater<br />

are transported in separate pipe systems. This makes it less common for<br />

backflows to occur in dirty water sewers due to factors such as illegal<br />

introduction of waste, pipeline blockages and operationally necessary<br />

sewer measures; however, such backflows can never be entirely prevented.<br />

For economic reasons and to ensure the self-cleaning capability of the<br />

system, the current practice is to dimension drainage systems for a<br />

moderate level of rainfall. However, it must be expected that heavy rainfalls<br />

exceeding the amount used as the basis for calculation will occur. This<br />

means that a drainage system overload could occur at any time.<br />

Sewer backup | The physical effects of a sewer backup are based on<br />

the law of communicating tubes. If a backup occurs, the wastewater finds<br />

its way through these pipes into the property drainage system because the<br />

pipe systems of the property drainage system are directly connected to<br />

the public sewer system. The water rises to the same level as the water in<br />

the public sewer. This means that wastewater will continue to escape from<br />

all unprotected openings, such as floor drains, toilets, etc., until the water<br />

levels have reached equilibrium (Fig. 1-1).<br />

Backflow level | This results in a specific elevation or level below which<br />

special measures must be implemented as part of the property drainage<br />

system to protect against the risk of backflows on the property. This level<br />

is referred to as the backflow level. The pertinent backflow level is defined<br />

by the local authorities in the town by-laws. If no such definition exists, DIN<br />

EN 12056-4 and DIN 1986-100 defines the backflow level as the level of<br />

the top edge of the street above the location where the property drainage<br />

line connects to the public sewer system.<br />

Nevertheless, the backing up of water even above this level cannot be<br />

completely ruled out, for instance due to pipe blockages. If backed-up<br />

water penetrates within buildings into unprotected rooms, masonry walls<br />

and foundations can become saturated. This backed-up water can also<br />

cause water damage to furnishings. There may also be health risks due to<br />

infections. For these reasons, the risk and potential damage of backflowing<br />

wastewater must be kept as low as possible using preventive measures.<br />

According to town wastewater by-laws, the responsibility for these<br />

measures generally lies with the property owner. Property owners can hire<br />

suitable experts, such as qualified planners and fitters, to properly plan and<br />

execute such measures.<br />

Service line<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

7<br />

<strong>ACO</strong> H a u s t e c h n i k<br />

Figure 1-1:<br />

Sewer backflow<br />

0150.16.70

General aspects<br />

Protection against backflow | The greatest possible protection against<br />

backflow can be achieved with a wastewater lifting plant with a pressurised<br />

line that runs to above the backflow level (Fig. 1-2, 1-3).<br />

Backflow level<br />

Figure 1-2:<br />

Protection against backflow with an incline to the<br />

sewer using a wastewater lifting plant<br />

Regulations | DIN1986-100, “Drainage systems on private ground” and<br />

EN 12056 “Gravity drainage systems inside buildings” require that dirty<br />

water arising below the backflow level and precipitation water from surfaces<br />

below the backflow level be brought into the public sewer system in a<br />

manner than protects against backflows through the use of an automatic<br />

lifting plant.<br />

Drainage systems are planned according to the principle that “arising<br />

surface water must be diverted away from the building and not brought into<br />

the building.” Accordingly, surfaces exposed to rain must be drained by<br />

separate pump stations outside of the building.<br />

All drainage features situated above the backflow area must be drained<br />

with natural inclines (gravity principle); the wastewater from these drainage<br />

features may not be diverted through anti-flooding valves and may only be<br />

diverted through wastewater lifting plants in exceptional cases in which this<br />

is absolutely necessary (e.g. old building renovation).<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

8<br />

Backflow level<br />

0150.16.70<br />

Figure 1-3:<br />

Protection against backflow when the sewer is<br />

situated at a higher level than the drainage features

1.10 Description: design / type<br />

Design ...<br />

-PE | Polyethylene (PE-HD), rotated, collecting container.<br />

-VA | Stainless steel (1.4571), welded, collecting container.<br />

Type ...<br />

-K | Pump design, hydraulic component with ducted wheel (particle size<br />

70 mm or 100 mm with type K-75).<br />

The ducted wheel is suitable for pumping dirty water containing faecal<br />

matter as well as for pumping wastewater with firm, short, fibrous solids<br />

and thick matter, sludge and organic materials.<br />

Figure 1-4:<br />

3D ducted wheel<br />

-V | Pump design, hydraulic component with free-flow impeller (particle<br />

size 80 mm).<br />

A large open space in the pump housing (a sphere passage) allows the<br />

liquid to easily flow through the suction opening into the pump chamber<br />

and allows solid and long-fibred thick matter, such as long sanitary towels,<br />

textiles, etc. to pass through the pump housing without difficulty.<br />

Another advantage: Since free-flow pumps do not have a choke gap<br />

between the impeller and the pump housing, this design offers great<br />

operational reliability for applications with very long periods of inactivity.<br />

This prevents the impeller from rusting into place, which would result in<br />

blocking of the pump.<br />

Figure 1-6:<br />

3D free-flow wheel<br />

Service line<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

Figure 1-5:<br />

Ducted wheel cross-section<br />

Figure 1-7:<br />

3D pump cross section<br />

9<br />

<strong>ACO</strong> H a u s t e c h n i k<br />

0150.16.70

1.11 Description: mono / duo / parallel designs<br />

mono design<br />

Wastewater lifting plants with one pump = -mono- design.<br />

Used in places where the wastewater flow may be interrupted or in rooms<br />

subject to less frequent use.<br />

Figure 1-8:<br />

-mono- wastewater lifting plant<br />

duo design<br />

Wastewater lifting plants with two pumps = -duo- design.<br />

Used in places where the wastewater flow may not be interrupted.<br />

The two pumps operate in alternation or together in event of a heavy load.<br />

parallel design<br />

Wastewater lifting plants with two collecting containers and 2 pumps =<br />

-parallel- design.<br />

Used in places where the wastewater flow may not be interrupted and in<br />

buildings with large volumes of wastewater, typically for commercial and<br />

industrial applications.<br />

The two pumps operate in alternation or<br />

together in event of a heavy load.<br />

1.12 Areas of application<br />

matter<br />

faecal with<br />

<br />

water<br />

= suitable<br />

- = not suitable Dirty<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

Pumping medium<br />

Wastewater with firm and short,<br />

fibrous solids and thick matter,<br />

sludge and organic materials<br />

10<br />

Wastewater with firm and long,<br />

fibrous thick matter<br />

Figure 1-9:<br />

-duo- wastewater lifting plant<br />

Figure 1-10:<br />

-parallel- wastewater lifting plant<br />

Wastewater containing grease<br />

For large volumes of wastewater<br />

For long pressure lines and<br />

greater height differences<br />

0150.16.70<br />

Type K mono - -<br />

Type K duo - <br />

Type V mono -<br />

Type V duo <br />

Type 1.1- 2.4 duo <br />

Type K parallel - <br />

Type V parallel <br />

Wastewater flow may be<br />

interrupted<br />

Wastewater flow may not be<br />

interrupted

Service line<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

11<br />

<strong>ACO</strong> H a u s t e c h n i k<br />

1.13 Technical data, dimensions, performance diagrams, characteristic data<br />

Muli-Pro-PE K- (15, 22, 30, 55, 75) mono<br />

-Product information |<br />

Wastewater lifting plants acc. to DIN EN 12050-1<br />

For collection and automatic lifting of greasy<br />

wastewater with or without faecal matter to above<br />

the backflow level<br />

For free-standing / above-floor installation in<br />

buildings<br />

Polyethylene collecting container<br />

Length 1500 x 780 x 1035 mm / LxWxH<br />

Drain screw and connection for hand diaphragm<br />

pump R 1 1/2<br />

Fastening set for anchoring against lifting<br />

forces<br />

Total container volume: 515 litres,<br />

Useful container volume depending on inlet<br />

height<br />

1x inlet DN 150 inlet height 600 mm = 180 l<br />

2x inlet DN 150 inlet height 750 mm = 250 l<br />

1x inlet DN 150 inlet height 800 mm = 275 l<br />

-Dimensions |<br />

-Characteristic data |<br />

1x inlet DN 150 from above 1015 mm = 275 l<br />

1x inspection opening, width 320 mm<br />

Connection for ventilation line DN 100<br />

Pipe connections suitable for plastic pipes or<br />

coated, grey cast iron plain end pipes<br />

Pressure line with connection for pipe outer Ø 108<br />

- 114 mm<br />

Special check valve DN 80 (on K-75 DN 100)<br />

with air intake mechanism<br />

Shut-off valve DN 80<br />

(on K-75 DN 100)<br />

Special fastener for connection to the pressure<br />

line<br />

Pump unit<br />

Motor 400 V / 50 Hz,<br />

Connection cable 7 m long<br />

Protection type IP 68<br />

Shaft seal and floating ring seal<br />

-Performance diagram |<br />

Type Motor power in kW Rated current Weight Article<br />

number<br />

P 1 P 2 A at 400 V approx. / in kg<br />

K - 15 2.01 1.5 3.6 225 0175.13.00<br />

K - 22 2.94 2.2 5.2 250 0175.13.01<br />

K - 30 3.87 3.0 6.6 315 0175.13.02<br />

K - 55 6.71 5.5 11.6 335 0175.13.03<br />

K - 75 8.97 7.5 15.5 335 0175.13.04<br />

0150.16.70<br />

Ducted wheel with 70 mm particle size<br />

(on K-75 100 mm)<br />

Pneumatic level switch with pitot tube and<br />

pneumatic control line (7 m long)<br />

Compact compressor for bubbling air<br />

Switching and warning device<br />

Protection type IP 54<br />

Plug-ready, with 1.5 m cable and CEE plug<br />

(on K-15 up to 30),<br />

dimensions 250 x 200 x 100 mm / WxHxD<br />

Connection-ready, cable provided by customer<br />

(on K-55 and 75),<br />

dimensions 380 x 600 x 210 mm / WxHxD<br />

With potential-free collective fault and operating<br />

signal

Muli-Pro-PE K- (15, 22, 30, 55, 75) duo<br />

-Product information |<br />

Wastewater lifting plants acc. to DIN EN 12050-1<br />

For collection and automatic lifting of greasy<br />

wastewater with or without faecal matter to above<br />

the backflow level<br />

For free-standing / above-floor installation in<br />

buildings<br />

Polyethylene collecting container<br />

Length 1500 x 780 x 1035 mm / LxWxH<br />

Drain screw and connection for hand diaphragm<br />

pump R 1 1/2<br />

Fastening set for anchoring against lifting<br />

forces<br />

Total container volume: 515 litres,<br />

Useful container volume depending on inlet<br />

height<br />

1x inlet DN 150 inlet height 600 mm = 160 l<br />

2x inlet DN 150 inlet height 750 mm = 230 l<br />

1x inlet DN 150 inlet height 800 mm = 250 l<br />

-Dimensions |<br />

-Characteristic data |<br />

Type Motor power in kW Rated current Weight Article<br />

number<br />

P 1 P 2 A at 400 V approx. / in kg<br />

K - 15 2.01 1.5 3.6 315 0175.13.17<br />

K - 22 2.94 2.2 5.2 325 0175.13.18<br />

K - 30 3.87 3.0 6.6 420 0175.13.19<br />

K - 55 6.71 5.5 11.6 465 0175.13.20<br />

K - 75 8.97 7.5 15.5 510 0175.13.21<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

1x inlet DN 150 from above 1015 mm = 250 l<br />

1x inspection opening, width 320 mm<br />

Connection for ventilation line DN 100<br />

Pipe connections suitable for plastic pipes or<br />

coated, grey cast iron plain end pipes<br />

Pressure line with connection for<br />

pipe outer Ø 108 - 114 mm<br />

2x special check valve DN 80 (on K-75 DN 100)<br />

with air intake mechanism<br />

2x shutoff valve DN 80<br />

(on K-75 DN 100)<br />

Y-pipe<br />

Special fastener for<br />

connection to the pressure line<br />

2 pump units<br />

Motor 400 V / 50 Hz,<br />

Connection cable 7 m long<br />

Protection type IP 68<br />

-Performance diagram |<br />

12<br />

0150.16.70<br />

Shaft seal and floating ring seal<br />

Ducted wheel with 70 mm particle size (on K-75<br />

100 mm)<br />

Pneumatic level switch with pitot tube and<br />

pneumatic control line (7 m long)<br />

Compact compressor for bubbling air<br />

Switching and warning device<br />

Protection type IP 54<br />

Plug-ready, with 1.5 m cable and CEE plug (on<br />

K-15 up to 30),<br />

dimensions 250 x 200 x 100 mm / WxHxD<br />

Connection-ready, cable provided by customer<br />

(on K-55 and 75),<br />

dimensions 380 x 600 x 210 mm / WxHxD<br />

With potential-free collective fault and operating<br />

signal

Muli-Pro-PE V- (15, 22, 30, 40) mono<br />

-Product information |<br />

Wastewater lifting plants acc. to DIN EN 12050-1<br />

For collection and automatic lifting of greasy<br />

wastewater with or without faecal matter to above<br />

the backflow level<br />

For free-standing / above-floor installation in<br />

buildings<br />

Polyethylene collecting container<br />

Length 1500 x 780 x 1035 mm / LxWxH<br />

Drain screw and connection for hand diaphragm<br />

pump R 1 1/2<br />

Fastening set for anchoring against lifting<br />

forces<br />

Total container volume: 515 litres, useful<br />

container volume depends on inlet height<br />

1x inlet DN 150 inlet height 600 mm = 180 l<br />

2x inlet DN 150 inlet height 750 mm = 250 l<br />

1x inlet DN 150 inlet height 800 mm = 275 l<br />

1x inlet DN 150 from above 1015 mm = 275 l<br />

-Dimensions |<br />

-Characteristic data |<br />

Type Motor power in kW Rated current Weight Article<br />

number<br />

P 1 P 2 A at 400 V approx. / in kg<br />

V - 15 2.01 1.5 4.1 180 0175.12.81<br />

V - 22 2.94 2.2 5.2 185 0175.12.82<br />

V - 30 3.87 3.0 6.6 195 0175.12.83<br />

V - 40 5.1 4.0 10.3 200 0175.12.84<br />

Service line<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

1x inspection opening, width 320 mm<br />

Connection for ventilation line DN 100<br />

Pipe connections suitable for plastic pipes or<br />

coated, grey cast iron plain end pipes<br />

Pressure line with connection for<br />

pipe outer Ø 108 - 114 mm<br />

Special check valve DN 80 with air intake<br />

mechanism<br />

Shut-off valve DN 80<br />

Special fastener for connection to the pressure<br />

line<br />

Pump units<br />

Motor 400 V / 50 Hz,<br />

Connection cable 7 m long<br />

Protection type IP 68<br />

Shaft seal and floating ring seal<br />

Non-blocking free-flow impeller with 80 mm<br />

particle size<br />

13<br />

<strong>ACO</strong> H a u s t e c h n i k<br />

-Performance diagram |<br />

0150.16.70<br />

Pneumatic level switch with pitot tube and<br />

pneumatic control line (7 m long)<br />

Compact compressor for bubbling air<br />

Switching and warning device<br />

Protection type IP 54<br />

Plug-ready, with 1.5 m cable and CEE plug,<br />

dimensions 250 x 200 x 100 mm / WxHxD<br />

With potential-free collective fault and operating<br />

signal

Muli-Pro-PE V- (15, 22, 30, 40) duo<br />

-Product information |<br />

Wastewater lifting plants acc. to DIN EN 12050-1<br />

For collection and automatic lifting of greasy<br />

wastewater with or without faecal matter to above<br />

the backflow level<br />

For free-standing / above-floor installation in<br />

buildings<br />

Polyethylene collecting container<br />

Length 1500 x 780 x 1035 mm / LxWxH<br />

Drain screw and connection for hand diaphragm<br />

pump R 1 1/2<br />

Fastening set for anchoring against lifting<br />

forces<br />

Total container volume: 515 litres,<br />

Useful container volume depending on inlet<br />

height<br />

1x inlet DN 150 inlet height 600 mm = 160 l<br />

2x inlet DN 150 inlet height 750 mm = 230 l<br />

1x inlet DN 150 inlet height 800 mm = 250 l<br />

-Dimensions |<br />

-Characteristic data |<br />

Type Motor power in kW Rated current Weight Article<br />

P 1 P 2 A at 400 V approx. / in kg<br />

number<br />

V - 15 2.01 1.5 4.1 210 0175.12.89<br />

V - 22 2.94 2.2 5.2 215 0175.12.90<br />

V - 30 3.87 3.0 6.6 225 0175.12.91<br />

V - 40 5.1 4.0 10.3 230 0175.12.92<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

1x inlet DN 150 from above 1015 mm = 250 l<br />

1x inspection opening, width 320 mm<br />

Connection for ventilation line DN 100<br />

Pipe connections suitable for plastic pipes or<br />

coated, grey cast iron plain end pipes<br />

Pressure line with connection for<br />

pipe outer Ø 108 - 114 mm<br />

2x special check valve DN 80 with air intake<br />

mechanism<br />

2x shutoff valve DN 80<br />

Y-pipe<br />

Special fastener for connection to the pressure<br />

line<br />

2 pump units<br />

Motor 400 V / 50 Hz,<br />

Connection cable 7 m long<br />

Protection type IP 68<br />

Shaft seal and floating ring seal<br />

14<br />

-Performance diagram |<br />

0150.16.70<br />

Non-blocking free-flow impeller with 80 mm<br />

particle size<br />

Pneumatic level switch with pitot tube and<br />

pneumatic control line (7 m long)<br />

Compact compressor for bubbling air<br />

Switching and warning device<br />

Protection type IP 54<br />

Plug-ready, with 1.5 m cable and CEE plug,<br />

dimensions 250 x 200 x 100 mm / WxHxD<br />

With potential-free collective fault and operating<br />

signal

Muli-Pro-VA ... (1.1, 1.2, 1.3, 1.4, 2.1, 2.2, 2.3, 2.4) duo<br />

-Product information |<br />

Wastewater lifting plants acc. to DIN EN 12050-1<br />

For collection and automatic lifting of greasy<br />

wastewater with or without faecal matter to above<br />

the backflow level<br />

For free-standing / above-floor installation in<br />

buildings<br />

Stainless steel collecting container 1.4571<br />

Length 1000 x 750 x 688 mm / LxWxH<br />

Drain screw and connection for hand diaphragm<br />

pump R 1 1/2<br />

Fastening set for anchoring against lifting<br />

forces<br />

Total container volume: 270 or 355 litres,<br />

container useful volume: 98 or 185 litres<br />

Either 2x inspection opening width 285 mm or<br />

2x inlet DN 100/150 side inlet height<br />

Connection for ventilation line DN 100<br />

-Dimensions |<br />

-Characteristic data |<br />

Type Motor power in kW Rated current Weight Article No.<br />

Service line<br />

P 1 P 2 A at 400 V approx. / in kg<br />

VA - 1.1 2.01 1.5 4.1 210 0175.06.69<br />

VA - 1.2 2.94 2.2 5.2 215 0175.06.70<br />

VA - 1.3 3.87 3.0 6.6 225 0175.06.71<br />

VA - 1.4 5.1 4.0 10.3 230 0175.06.72<br />

VA - 2.1 2.01 1.5 4.1 290 0175.06.74<br />

VA - 2.2 2.94 2.2 5.2 295 0175.06.75<br />

VA - 2.3 3.87 3.0 6.6 305 0175.06.76<br />

VA - 2.4 5.1 4.0 10.3 310 0175.06.77<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

Pipe connections suitable for plastic pipes or<br />

coated, grey cast iron plain end pipes<br />

Pressure line with connection for pipe outer Ø 108<br />

- 114 mm<br />

2x special check valve DN 80 with air intake<br />

mechanism<br />

2x shutoff valve DN 80<br />

Y-pipe<br />

Special fastener for connection to the pressure<br />

line<br />

2 pump units<br />

Motor 400 V / 50 Hz,<br />

Connection cable 7 m long<br />

Protection type IP 68<br />

Shaft seal and floating ring seal<br />

Non-blocking free-flow impeller with 80 mm<br />

particle size<br />

15<br />

<strong>ACO</strong> H a u s t e c h n i k<br />

0150.16.70<br />

Pneumatic level switch with pitot tube and<br />

pneumatic control line (7 m long)<br />

Compact compressor for bubbling air<br />

Switching and warning device<br />

Protection type IP 54<br />

Plug-ready, with 1.5 m cable and CEE plug,<br />

dimensions 250 x 200 x 100 mm / WxHxD<br />

With potential-free collective fault and operating<br />

signal<br />

-Performance diagram |

Muli-Pro-PE K- (15, 22, 30, 55, 75) parallel<br />

-Product information |<br />

Wastewater lifting plants acc. to DIN EN 12050-1<br />

For collection and automatic lifting of greasy<br />

wastewater with or without faecal matter to above<br />

the backflow level<br />

For free-standing / above-floor installation in<br />

buildings<br />

2x Polyethylene collecting containers<br />

Length 1500 x 780 x 1035 mm / LxWxH<br />

Drain screw and connection for hand diaphragm<br />

pump R 1 1/2<br />

Fastening set for anchoring against lifting<br />

forces<br />

Total container volume: 1030 litres, useful<br />

container volume depends on inlet height<br />

1x inlet DN 150 inlet height 600 mm = 320 l<br />

2x inlet DN 150 inlet height 750 mm = 460 l<br />

1x inlet DN 150 inlet height 800 mm = 500 l<br />

1x inlet DN 150 from above 1015 mm = 500 l<br />

-Dimensions |<br />

-Characteristic data |<br />

Type Motor power in kW Rated current Weight Article No.<br />

P 1 P 2 A at 400 V approx. / in kg<br />

K - 15 2.01 1.5 3.6 450 0175.13.23<br />

K - 22 2.94 2.2 5.2 500 0175.13.24<br />

K - 30 3.87 3.0 6.6 530 0175.13.25<br />

K - 55 6.71 5.5 11.6 670 0175.13.26<br />

K - 75 8.97 7.5 15.5 670 0175.13.27<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

2x inspection opening, width 320 mm<br />

Connection for ventilation line DN 100<br />

Pipe connections suitable for plastic pipes or<br />

coated, grey cast iron plain end pipes<br />

Pressure line with connection for pipe outer Ø 108<br />

- 114 mm<br />

2x special check valve DN 80 (on K-75 DN 100)<br />

with air intake mechanism<br />

2x shutoff valve DN 80<br />

(on K-75 DN 100)<br />

Y-pipe<br />

Special fastener for connection to the pressure<br />

line<br />

2 pump units<br />

Motor 400 V / 50 Hz,<br />

Connection cable 7 m long<br />

Protection type IP 68<br />

Shaft seal and floating ring seal<br />

16<br />

-Performance diagram |<br />

0150.16.70<br />

Ducted wheel with 70 mm particle size<br />

(on K-75 100 mm)<br />

Pneumatic level switch with pitot tube and<br />

pneumatic control line (7 m long)<br />

Compact compressor for bubbling air<br />

Switching and warning device<br />

Protection type IP 54<br />

Plug-ready, with 1.5 m cable and CEE plug (on<br />

K-15 up to 30),<br />

dimensions 250 x 200 x 100 mm / WxHxD<br />

Connection-ready, cable provided by customer<br />

(on K-55 and 75),<br />

dimensions 380 x 600 x 210 mm / WxHxD<br />

With potential-free collective fault and operating<br />

signal

Muli-Pro-PE V- (15, 22, 30, 40) parallel<br />

-Product information |<br />

Wastewater lifting plants acc. to DIN EN 12050-1<br />

For collection and automatic lifting of greasy<br />

wastewater with or without faecal matter to above<br />

the backflow level<br />

For free-standing / above-floor installation in<br />

buildings<br />

2x Polyethylene collecting containers<br />

Length 1500 x 780 x 1035 mm / LxWxH<br />

Drain screw and connection for hand diaphragm<br />

pump R 1 1/2<br />

Fastening set for anchoring against lifting<br />

forces<br />

Total container volume: 1030 litres,<br />

Useful container volume depending on inlet<br />

height<br />

1x inlet DN 150 inlet height 600 mm = 320 l<br />

2x inlet DN 150 inlet height 750 mm = 460 l<br />

1x inlet DN 150 inlet height 800 mm = 500 l<br />

-Dimensions |<br />

-Characteristic data |<br />

Type Motor power in kW Rated current Weight Article No.<br />

Service line<br />

P 1 P 2 A at 400 V approx. / in kg<br />

V - 15 2.01 1.5 4.1 180 0175.12.81<br />

V - 22 2.94 2.2 5.2 185 0175.12.82<br />

V - 30 3.87 3.0 6.6 195 0175.12.83<br />

V - 40 5.1 4.0 10.3 200 0175.12.84<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

1x inlet DN 150 from above 1015 mm = 500 l<br />

2x inspection opening, width 320 mm<br />

Connection for ventilation line DN 100<br />

Pipe connections suitable for plastic pipes or<br />

coated, grey cast iron plain end pipes<br />

Pressure line with connection for pipe outer Ø 108<br />

- 114 mm<br />

2x special check valve DN 80 with air intake<br />

mechanism<br />

2x shutoff valve DN 80<br />

Y-pipe<br />

Special fastener for connection to the pressure<br />

line<br />

2 pump units<br />

Motor 400 V / 50 Hz,<br />

Connection cable 7 m long<br />

Protection type IP 68<br />

Shaft seal and floating ring seal<br />

17<br />

<strong>ACO</strong> H a u s t e c h n i k<br />

-Performance diagram |<br />

0150.16.70<br />

Non-blocking free-flow impeller with 80 mm<br />

particle size<br />

Pneumatic level switch with pitot tube and<br />

pneumatic control line (7 m long)<br />

Compact compressor for bubbling air<br />

Switching and warning device<br />

Protection type IP 54<br />

Plug-ready, with 1.5 m cable and CEE plug,<br />

dimensions 250 x 200 x 100 mm / WxHxD<br />

With potential-free collective fault and operating<br />

signal

2. Scope<br />

2.1 Applicability of the installation and operating instructions<br />

These instructions are applicable for <strong>ACO</strong> Passavant wastewater lifting<br />

plants<br />

• Muli -Pro-PE Type K mono / duo / parallel<br />

• Muli -Pro-PE Type V mono / duo / parallel<br />

• Muli -Pro-VA duo.<br />

These instructions are used for installing, commissioning, operating,<br />

maintaining, repairing and decommissioning.<br />

Data on any standards, certification marks, quality marks and trademarks<br />

correspond to those valid at the time of going to print. Illustrations, as well<br />

as size and weight measurements, may vary. We reserve the right to make<br />

changes and improvements without notification in the interest of technical<br />

progress.<br />

2.2 General information<br />

Safekeeping of the instructions | The installation and operating<br />

instructions have to be available permanently at the location of use of the<br />

wastewater lifting plant.<br />

Supplements | The operator of the system has to supplement the<br />

installation and operating instructions with the instructions prescribed by<br />

the existing national regulations on accident prevention and environmental<br />

protection.<br />

Apart from the installation and operating instructions as well as the binding<br />

regulations on accident prevention applicable in the country of use and at<br />

the location of use, the recognised technical rules for safe and expert work<br />

also have to be observed.<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

18<br />

CAUTION<br />

0150.16.70<br />

The operator must keep the instructions<br />

in a safe place.<br />

If additional instructions for individual<br />

parts of the entire plant have been<br />

enclosed, these must be observed as<br />

well!<br />

CAUTION<br />

<strong>ACO</strong> Passavant GmbH owns the<br />

copyright in these instructions.<br />

These instructions are intended for the<br />

installation, operating, maintenance<br />

and supervising staff. They contain<br />

instructions and technical drawings<br />

which may not be duplicated in whole or<br />

in part, may not be distributed or used<br />

by unauthorised persons for competitive<br />

purposes and may not be disclosed to<br />

other parties.

3. Notes<br />

General aspects | These operating instructions contain basic<br />

instructions which have to be observed during installation, operation and<br />

maintenance. It is therefore essential that the mechanic and responsible<br />

qualified staff/operator read these instructions prior to installation and<br />

operation, and that they are always available where the machine is installed.<br />

In addition to the general safety notices listed in this section, the special<br />

safety notices in other sections must also be observed, e.g., those for<br />

private use.<br />

The special operating instructions of the equipment supplied by other<br />

manufacturers and installed in the lifting plant are also important and have<br />

to be observed (see appendix and/or complete documents on delivery)!<br />

3.1 Explanation of symbols and notes<br />

This symbol is shown next to all of the work safety instructions in these<br />

operating instructions concerning work that potentially poses a threat to life<br />

and limb. These instructions must be observed and such cases in particular<br />

require that personnel exercise caution. All work safety instructions have<br />

to be communicated to other plant operators. Apart from the instructions<br />

in these installation and operating instructions, general safety and accident<br />

prevention regulations also have to be taken into consideration.<br />

This symbol is shown next to all installation and operating instructions that<br />

have to be observed especially for compliance with the relevant directives,<br />

standards, regulations and notes, and in order to ensure that the correct<br />

work sequences are observed to ensure that the plant, its parts and their<br />

surroundings are not damaged, and so as to ensure perfect function.<br />

This symbol indicates environmental protection measures.<br />

This symbol indicates listings.<br />

Instructions attached directly to the plant have to be observed as well.<br />

Service line<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

19<br />

<strong>ACO</strong> H a u s t e c h n i k<br />

CAUTION<br />

0150.16.70

3.2 Safety notices<br />

Dangers of failure to comply with safety notices<br />

Failure to observe the safety notices can put people at risk as well as cause<br />

damage to the environment and the machine.<br />

Failure to observe individual safety notices could result in the following<br />

hazards, for example:<br />

• Failure of important machine functions<br />

• Failure of prescribed maintenance and servicing methods<br />

• Risk to people from detrimental electrical, mechanical and chemical<br />

effects<br />

• Risk to the environment from leakage of hazardous substances<br />

Safety-conscious operation<br />

Observe the safety notices listed in these instructions and current national<br />

accident-prevention regulations as well as any internal work, operation and<br />

safety regulations of the operator.<br />

Safety notices for maintenance, inspection and installation<br />

Staff | Operating, maintenance, inspection and installation staff have<br />

to be appropriately qualified to carry out this work. The operator has to<br />

exactly specify the accountability, responsibility and supervision of staff.<br />

If staff do not have the necessary knowledge, they have to be trained and<br />

instructed accordingly. The operator also has to ensure that the staff have<br />

fully understood the contents of these operating instructions.<br />

The operator has to ensure that corresponding measures are taken to<br />

protect the staff.<br />

Safety instructions for maintenance, inspection and mounting<br />

work | The operator has to ensure that all maintenance, inspection and<br />

installation work be carried out by authorised and qualified professionals<br />

who have sufficiently informed themselves by thoroughly studying the<br />

operating instructions.<br />

The plant and its components must generally be shut down when<br />

performing work on it.<br />

The procedure for shutting down the plant described in the instructions has<br />

to be observed. Pumps and pumping sets carrying hazardous material must<br />

be decontaminated.<br />

Legal regulations have to be observed.<br />

When the work has been completed, all safety and protection devices have<br />

to be immediately reattached and put into operation.<br />

Before the machine is put into operation again, the points listed in the<br />

section on first commissioning have to be observed.<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

20<br />

CAUTION<br />

0150.16.70<br />

If hot or cold machine parts are<br />

hazardous, the customer has to protect<br />

these parts from being touched.<br />

Protection devices of moving parts (e.g.<br />

impeller) may not be removed from the<br />

plant while operating.<br />

Leaks (e.g. at the shaft seal) of hazardous<br />

pumping material (e.g. explosive,<br />

toxic, hot) must be discharged in such a<br />

way that it represents no risk to people<br />

or the environment.; legal regulations<br />

have to be observed.<br />

Dangers posed by electrical energy<br />

have to be eliminated (for more detailed<br />

information, refer to the National<br />

Electric Code and local energy supply<br />

company regulations for example).

Designated use<br />

This type of wastewater lifting plant is designed for the pumping of<br />

wastewater with or without faecal matter or grease.<br />

Any other uses shall not be considered designated. The manufacturer shall<br />

not be held liable for any resulting damage; the risk shall be borne by the<br />

operator alone.<br />

The following must not be introduced: See page 60, section 6.6.<br />

Unauthorised alteration and spare-parts manufacture<br />

Alterations or changes to the machine are only permitted following<br />

consultation with the manufacturer.<br />

Delay of installation<br />

If it is known or if it must be expected at the time of installation that a<br />

longer period of time will pass until the plant will be commissioned for the<br />

first time, the following measures have to be taken to protect the plant:<br />

• Protect the plant (and parts) against moisture and soiling (applicable for<br />

electric parts in particular).<br />

• Occasionally move functional parts in order to prevent seizure.<br />

• If the pump cables are not connected, protect the cable ends from<br />

moisture.<br />

Shutdown and restart<br />

As a matter of principle, work on the plant may be carried out only when<br />

the moving parts are at a standstill.<br />

The procedure for shutting down the parts of the machine described in the<br />

instructions has to be observed.<br />

When the work has been completed, all safety and protection devices have<br />

to be immediately reattached and put into operation.<br />

Service line<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

21<br />

<strong>ACO</strong> H a u s t e c h n i k<br />

CAUTION<br />

0150.16.70<br />

CAUTION<br />

Designated use includes also:<br />

Observation of all national laws and<br />

regulations.<br />

Observation of the inspection and<br />

maintenance instructions.<br />

Observation of the installation,<br />

commissioning, operating and<br />

maintenance instructions prescribed<br />

by the manufacturer.<br />

Original spare parts and accessories<br />

authorised by the manufacturer should<br />

be used for safety purposes.<br />

The manufacturer may refuse liability<br />

for resulting damages if other parts<br />

are used.<br />

The use of <strong>ACO</strong> Passavant's original<br />

parts ensures a safe and reliable<br />

operation of the separator.<br />

NOTE<br />

In case of a period of more than one<br />

year passes before the initial operation,<br />

an inspection has to be carried out by<br />

<strong>ACO</strong> <strong>Haustechnik</strong> - Services Department<br />

(against invoice).<br />

NOTE<br />

Before the plant is put into operation<br />

again, the points listed in the section<br />

on first commissioning have to be<br />

observed.

Electrical safety<br />

The electrical installation of a plant component has to be in conformity with<br />

the stipulations of European standards EN 1012, Part 1 and EN 60 204,<br />

Part 1; if and when necessary, the local regulations of the power supply<br />

companies have to be taken into consideration.<br />

The local potential adaptations have to be included.<br />

Work on the electric equipment of the wastewater lifting plant may only be<br />

carried out by an electrician or by trained persons under the management<br />

or supervision of a qualified electrician in keeping with the rules governing<br />

the use of electricity.<br />

Environmental protection<br />

The waste disposal regulations have to be observed when disposing of<br />

matter that was removed from the plant.<br />

Safety and health protection measures<br />

With respect to the fundamental safety and health protection measures<br />

to be observed, reference is made to the pertinent regulations of the<br />

professional associations and the German Federal Work Group of Accident<br />

Insurance Companies, such as the BGR (rules), BGV (regulations) and BGI<br />

(information).<br />

3.3 Directives and standards<br />

(Note: the summaries provided below do not claim to be complete)<br />

Legal regulations<br />

The requirements on operation of property drainage systems are defined by<br />

the construction, water and waste management laws of Germany and the<br />

German states as well as local by-laws. The ordinances and laws may differ<br />

between German states.<br />

All legal regulations have in common that they refer to the generally<br />

accepted rules and conditions of engineering with regard to specific<br />

requirements.<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

22<br />

0150.16.70<br />

CAUTION<br />

Prior to any work on electrical systems, the<br />

following measures have to be carried out in the<br />

order listed here:<br />

Disconnect all power connections<br />

(switch off main switch or pull power<br />

plug).<br />

Protect against switching on and check<br />

for absence of voltage.

Overview of key standards and directives<br />

Service line<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

23<br />

<strong>ACO</strong> H a u s t e c h n i k<br />

0150.16.70<br />

Standard / directive Version Title<br />

DIN EN 12050-1/2 05-2001 Wastewater lifting plants for buildings and properties<br />

Principles of construction and testing<br />

(product standard)<br />

Part 1: Lifting plants for wastewater containing faecal matter /<br />

Part 2: Lifting plants for faecal-free wastewater<br />

DIN EN 12056-1 01-2001 Gravity drainage systems inside of buildings<br />

Part 1: General and performance requirements<br />

DIN EN 12056-4 01-2001 Gravity drainage systems inside of buildings<br />

Part 4: Wastewater lifting plants - layout and calculation<br />

DIN 1986-100 01-2001 Drainage systems for buildings and properties<br />

Part 100: Additional specifications regarding DIN EN 752 and DIN EN 12056<br />

DWA-M 167-4 12-2007 Backflow prevention with wastewater lifting plants or anti-flooding valves<br />

Planning standards and directives<br />

Key word Symbol Title Standard / directive;<br />

-section- (excerpt)<br />

Drainage<br />

system<br />

Natural<br />

incline<br />

Backflow<br />

protection<br />

Backflow<br />

level<br />

- Plants consisting of drainage fixtures, pipes and other components<br />

that collect wastewater and drain it via gravity. A wastewater lifting<br />

plant can be part of a gravity drainage system.<br />

- All drainage objects above the backflow level are to be drained by<br />

means of natural incline and may therefore not be connected to the<br />

wastewater lifting plant.<br />

- Drainage points beneath the backflow level must be secured<br />

against backflow. The protection against backflow is provided by<br />

wastewater lifting plants with backflow loop. Only designs with a<br />

backflow loop offer a high level of protection against backflow.<br />

- If the backflow level has not been determined by the responsible<br />

authority, the height of the road at the point of connection shall<br />

apply.<br />

Selection - The planning and selection of wastewater lifting plants must take<br />

place according to DIN EN 12056-4 and DIN 1986-100.<br />

Planning<br />

documents<br />

Accessibility<br />

Installation<br />

site<br />

Connection<br />

heights<br />

Surface<br />

water<br />

Useful<br />

volume<br />

- Before installation of the lifting plant or anti-flood valve, it is<br />

necessary to evaluate whether the plant being installed conforms to<br />

the approved planning documents and applicable standards.<br />

- Accessibility to installation, maintenance, inspection and disposal<br />

must be ensured including during operation.<br />

- The installation site must have sufficient load-bearing capacity and<br />

satisfy the regulations for noise prevention in structures.<br />

- The existing drainage pipes have to be checked for suitable<br />

connection height.<br />

- Surface water arising outside of the building and below the<br />

backflow level must be transported separately from the building<br />

wastewater and outside of the building via a wastewater lifting<br />

plant.<br />

- The useful volume of the lifting plant must be greater than the<br />

pressure line volume extending through the check valve up to the<br />

backflow loop, but no less than 20 l. This ensures that the volume<br />

in the pressure line will be exchanged during pump operation.<br />

DIN EN 12056-1;<br />

-3.1.3-<br />

DIN EN 12056-1;<br />

-4.1-<br />

DIN EN 12056-4;<br />

-4-<br />

DIN EN 12056-4;<br />

-4-<br />

DWA-M 167;<br />

-3.1-<br />

DWA-M 167;<br />

-3.1-<br />

DWA-M 167;<br />

-3.1-<br />

DWA-M 167;<br />

-3.1-<br />

DWA-M 167;<br />

-3.1-<br />

DIN EN 12056-4;<br />

-5.1-<br />

DIN EN 12056-4;<br />

-6.3-

Standards and directives regarding installation<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

24<br />

0150.16.70<br />

Key word Symbol Title Standard / directive;<br />

-section- (excerpt)<br />

Collecting<br />

container<br />

Collecting container for wastewater containing faecal matter may not be<br />

structurally connected to the building.<br />

Pump sump A pump sump must be installed to lift plants for draining rooms of<br />

wastewater containing faecal matter.<br />

Rotation<br />

prevention<br />

Protection<br />

against<br />

lifting forces<br />

Clearance<br />

600<br />

600<br />

Wastewater lifting plants must be installed with measures to prevent rotation<br />

of the plant.<br />

Plants exposed to lifting forces must be anchored securely against such<br />

forces.<br />

Spaces for the wastewater lifting plant must be large enough that a<br />

clearance of at least 600 mm exists next to and above all parts used in<br />

operation and maintenance.<br />

DIN EN 12056-4;<br />

-5.1-<br />

DIN EN 12056-4;<br />

-5.1-w<br />

DIN EN 12056-4;<br />

-5.1-<br />

DIN EN 12056-4;<br />

-5.1-<br />

DIN EN 12056-4;<br />

-5.1-<br />

Illumination The installation room must be sufficiently illuminated. DIN EN 12056-4;<br />

-5.1-<br />

Room<br />

ventilation<br />

The installation room must have sufficient ventilation. DIN EN 12056-4;<br />

-5.1-<br />

Double plant A double plant must be installed in situations where the flow of wastewater<br />

must not be interrupted.<br />

Line<br />

drainage<br />

All pipelines must be installed such that they can drain themselves (except<br />

for the pressure line).<br />

Stress-free The connections of the drainage lines to the wastewater lifting plant must be<br />

free of stress.<br />

Nominal<br />

width<br />

reduction<br />

DIN EN 12056-4;<br />

-5.1-<br />

DIN EN 12056-4;<br />

-5.2-<br />

DIN EN 12056-4;<br />

-5.2-<br />

The lines may not narrow in the direction of flow. DIN EN 12056-4;<br />

-5.2-<br />

Inlet pipe A shutoff valve must be situated on the inflow side. DIN EN 12056-4;<br />

-5.2-

Standards and directives regarding installation<br />

Service line<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

25<br />

<strong>ACO</strong> H a u s t e c h n i k<br />

0150.16.70<br />

Key word Symbol Title Standard / directive;<br />

-section- (excerpt)<br />

Sound<br />

insulation<br />

All line connections to the wastewater lifting plant must have sound<br />

insulation and be implemented flexibly.<br />

DIN EN 12056-4;<br />

-5.1-<br />

Weight relief The lines must be appropriately relieved of their own weight. DIN EN 12056-4;<br />

-5.1-<br />

Ventilation Ventilation lines (primarily for lifting plants carrying faecal matter) must rise<br />

constantly to above the roof without decreasing in nominal width. The line<br />

may therefore be run to the main or secondary exhaust ventilation line.<br />

Ventilation The ventilation of the plant may not be connected to the intake ventilation<br />

line of a grease separator.<br />

Pressure<br />

line<br />

Pressure<br />

line<br />

Pressure<br />

line<br />

Pressure<br />

line<br />

Pressure<br />

line<br />

Pressure<br />

line min<br />

Pressure<br />

line<br />

Pressure<br />

line<br />

The pressure line of the wastewater lifting plant must be run such that the<br />

base of the backflow loop will be above the backflow level.<br />

DIN EN 12056-4;<br />

-5.3-<br />

DIN EN 12056-4;<br />

-5.3-<br />

DIN EN 12056-4;<br />

-5.2-<br />

The pressure line must be appropriately relieved of its own weight. DIN EN 12056-4;<br />

-5.1-<br />

A check valve must be installed in the pressure line. If no shutoff mechanism<br />

is situated after this point in the plant, the check valve must have an air<br />

intake mechanism or some other option must exist for draining.<br />

A shutoff mechanism must be installed in the pressure line after the check<br />

valve. This is not necessary if the nominal width of the line < DN 80.<br />

The line must be secured against coming unattached at connections that<br />

are not designed to elastically accept longitudinal forces.<br />

The minimum nominal width of the pressure line must comply with Table 5 of<br />

DIN EN 12056-4.<br />

Pressure lines must always be connected to ventilated ground lines or<br />

mains. The connections must be designed as connections for pressure-free<br />

lines.<br />

The pressure line must accept at least 1.5 times the maximum pump<br />

pressure of the plant. Appropriate pressure pipes must be used.<br />

DIN EN 12056-4;<br />

-5.2-<br />

DIN EN 12056-4;<br />

-5.2-<br />

DIN EN 12056-4;<br />

-5.2-<br />

DIN EN 12056-4;<br />

-5.2-<br />

DIN EN 12056-4;<br />

-5.2-<br />

DIN EN 12056-4;<br />

-5.2-

Standards and directives regarding installation<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

26<br />

0150.16.70<br />

Key word Symbol Title Standard / directive;<br />

-section- (excerpt)<br />

Pressure<br />

line<br />

Pressure<br />

line<br />

Pressure<br />

line<br />

Pressure<br />

line<br />

Key word Symbol Title Standard / directive;<br />

-section- (excerpt)<br />

Commissioning<br />

Commissioning must be performed by appropriate experts, and the<br />

immediate supplier of the wastewater lifting plant will be responsible<br />

for ensuring that such experts be available. During commissioning,<br />

a test run with water must be performed for at least two switching<br />

operations. Dry running must be avoided during the test run. Checks to<br />

be performed before, during and after this test run: see standard.<br />

Inspection Wastewater lifting plants should be inspected once a month by the<br />

operator to ensure correct functioning by monitoring a minimum of<br />

two switching operations.<br />

Maintenance<br />

Maintenance<br />

contract<br />

No other connections may be made to the pressure line. DIN EN 12056-4;<br />

-5.2-<br />

Pressure lines of wastewater lifting plants may not be connected to<br />

wastewater downpipes.<br />

The flow rate in the pressure line must not fall below 0.7 m/s or<br />

exceed 2.3 m/s.<br />

The plant must be maintained by an expert. The maintenance<br />

intervals should not exceed:<br />

- 3 months in commercial operations.<br />

- 6 months in multifamily dwellings.<br />

- 1 year in single-family dwellings.<br />

Work to be carried out during maintenance: See standard.<br />

- It is recommended that plant operators conclude a maintenance<br />

contract for regular performance of maintenance and service work.<br />

DIN EN 12056-4;<br />

-5.2-<br />

DIN EN 12056-4;<br />

-6.1-<br />

Ventilation valves are not permitted in the pressure line. DIN EN 12056-4;<br />

-5.2-<br />

Pipeline The line routes must be protected against frost. DIN EN 12056-4;<br />

-5.2-<br />

Electrical<br />

equipment<br />

Electrical<br />

connections<br />

Standards and directives regarding operation<br />

Electrical systems that are not flood-safe must be installed in dry<br />

and well-ventilated rooms such that they are safe from flooding.<br />

The electrical connection work may only be performed by a<br />

qualified electrician. The applicable state-specific regulations must<br />

be observed.<br />

DIN EN 12056-4;<br />

-5.5-<br />

DIN EN 12056-4;<br />

-5.5-<br />

DIN EN 12056-4;<br />

-8.1-<br />

DIN EN 12056-4;<br />

-8.1-<br />

DIN EN 12056-4;<br />

-8.2-<br />

DIN EN 12056-4;<br />

-8.3-

4. Product description<br />

4.1 Components of Muli-Pro-PE design<br />

16<br />

15<br />

12<br />

2<br />

17<br />

14<br />

13<br />

Service line<br />

19<br />

10<br />

9<br />

1<br />

3 11 8 6 5<br />

Figure 1-11:<br />

Example Muli-Pro-PE V duo<br />

18<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

4<br />

7<br />

27<br />

<strong>ACO</strong> H a u s t e c h n i k<br />

0150.16.70<br />

1 PE-HD collecting container<br />

2 Drain screw cap<br />

3 Brackets for securing against<br />

lifting forces<br />

4 Inlet connection DN 150<br />

(sealed)<br />

5 Inspection cover, width 320 mm<br />

6 Connection DN 100 for exhaust<br />

ventilation<br />

7 Connection DN 150 (closed) only<br />

for overflow in parallel plant<br />

8 Screw lid with connection for<br />

control lines / pneumatic level<br />

measurement<br />

9 Pump housing rotary pump with<br />

free-flow impeller or ducted wheel<br />

10 Three-phase motor<br />

11 Pump housing ventilation<br />

12 Rising pipe (on type V) or bend<br />

(on type K)<br />

13 Check valve with drain screw<br />

and testing connection<br />

14 Shutoff valve (accessories)<br />

15 Y-pipe (on duo design)<br />

16 Special fastening element DN 100<br />

17 Hand diaphragm pump<br />

connection<br />

R 1 1/2<br />

18 Switch box<br />

19 Compact compressor<br />

Description | A polyethylene casing 1 functions as collecting container. The hydraulic parts (ducted wheel / type<br />

K or free-flow impeller / type V) of the rotary pumps and the two pitot tubes (short / long) for the pneumatic level<br />

switching are housed in the collecting container. The pump housing 9 (with ducted wheel for type K) and the threephase<br />

motors 10 sit outside. A check valve 13 with drain cock is attached on the pump discharge side after a<br />

flanged bend 12 (on type K) or a rising pipe 12 (for type V). A Y-pipe 15 merges the flows, and a special fastening<br />

element 16 is connected as termination, forming the transition point to the customer connection. A shutoff valve<br />

14 (accessory) is installed between the check valve and Y-pipe. The inlet connections 4 (4 on side at various<br />

heights and 1 from above) and ventilation 6 are located on the container. The one inlet connection, which should be<br />

used as inlet, must first be opened by sawing off the sealed end piece. The drain screw 2 (base drain) is located<br />

near the bottom on the side of the container. A screw connection 17 for connecting a hand diaphragm pump is<br />

located to the side of the pump on the base plate.<br />

The lifting plant is connected to the switch box 18 and the compact compressor 19 via sufficiently long pump<br />

cables and the pneumatic control lines.

4.2 Components of Muli-Pro-VA design<br />

16<br />

15<br />

14<br />

13<br />

12<br />

1<br />

2<br />

Figure 1-12:<br />

Example Muli-Pro-VA duo<br />

17<br />

10<br />

9<br />

7 3<br />

8 6 11<br />

5<br />

18<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

19<br />

4<br />

28<br />

0150.16.70<br />

1 Collecting container of 1.4571<br />

2 Drain screw and connection for<br />

hand diaphragm pump R 1 1/2<br />

3 Brackets for securing against<br />

lifting forces<br />

4 Inlet clamping flange (closed)<br />

Connection flange (accessory)<br />

5 Inspection lid flange<br />

usable as inlet with connection<br />

flange (accessory)<br />

6 Connection DN 100 for exhaust<br />

ventilation<br />

7 Rubber underlays<br />

8 Lid with connection for<br />

control lines / pneumatic level<br />

measurement<br />

9 Pump housing rotary pump with<br />

free-flow impeller<br />

10 Three-phase motor<br />

11 Pump housing ventilation<br />

12 Rising pipe<br />

13 Check valve with drain screw<br />

and testing connection<br />

14 Shutoff valve (accessories)<br />

15 Y-pipe<br />

16 Special fastening element DN<br />

100<br />

17 Switch box<br />

18 Compact compressor<br />

19 Pitot tube (short and long)<br />

Description | A stainless steel 1.4571 casing 1 functions as collecting container. The free-flow impellers of the<br />

rotary pumps and the two pitot tubes 19 for the pneumatic level switching are housed in the collecting container.<br />

The three-phase motors 10 and the two pump housing 9 sit outside. In each case, a check valve 13 with drain<br />

cock is attached after the rising pipe 12 on the pump discharge side. A Y-pipe 15 merges the flows, and a special<br />

fastening element 16 is connected as termination, forming the transition point to the customer connection. A<br />

shutoff valve 14 (accessory) is installed between the check valve and Y-pipe. Dummy connection flanges 4 for<br />

inlet DN 100 or 150 (3x above/on type 1.1-1.4, plus additional 2x on side/on type 2.1-2.4) are provided on the<br />

container. The corresponding connection parts are available as accessories. A pipe connection 6 DN 100 serves<br />

for connection of the ventilation pipe. The drain screw 2 (base drain) is located at a low point on the side of the<br />

container, where a hand diaphragm pump can also be connected.<br />

The lifting plant is connected to the switch box 17 and the compact compressor 18 via sufficiently long pump<br />

cables and the pneumatic control lines.

4.3 Switch box design types<br />

Switch box for mono type lifting plant (all types except K 55 and K 75)<br />

Technical data, standard design |<br />

Dimensions: 250 x 200, 100 mm (WxH, D)<br />

Protection type: IP 54<br />

Material: Plastic, white<br />

Operating voltage: 400 V / 50 Hz, max. back-up fuse 16 A<br />

Connection: Plug-ready, 1.5 m cable with CEE plug 16 A<br />

Indicators: 1 x digital level height indicator<br />

1 x rotation direction check / red<br />

1 x operation / green<br />

1 x fault / red<br />

Operation: 1 x control dial level 1 / pump<br />

1 x control dial level 2 / alarm<br />

1 x control dial follow-up time<br />

1 x control dial cutoff current<br />

1 x flip switch off/auto/manual<br />

1 x reset button<br />

Messages: 1 x potential-free collective fault signal<br />

1 x potential-free pump operating signal<br />

Switch box for mono type lifting plant (for types K 55 and K 75)<br />

Technical data, standard design |<br />

Dimensions: 380 x 600, 210 mm (WxH, D)<br />

Protection type IP 66<br />

Material: Coated steel, RAL 7032<br />

Operating voltage: 400 V / 50 Hz, max. back-up fuse 32 A<br />

Connection: Connection-ready, cable not included<br />

Indicators: 1 x rotation direction check / red<br />

1 x high alarm / red<br />

1 x fault / red<br />

1 x plant ready / green<br />

Operation: 1 x illuminated locking toggle switch<br />

1 x main switch<br />

Messages: 1 x potential-free collective fault signal<br />

1 x potential-free pump operating signal<br />

Service line<br />

Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

29<br />

<strong>ACO</strong> H a u s t e c h n i k<br />

Niveauhöhe in cm<br />

Figure 1-13:<br />

Single plant PCSP pump control<br />

Figure 1-14:<br />

Single plant PCSP pump control<br />

0150.16.70<br />

Pumpensteuerung Einzelanlage PSE<br />

Drehrichtung<br />

falsch<br />

40<br />

40<br />

30 50<br />

30 50<br />

20<br />

60<br />

20<br />

60<br />

0<br />

80<br />

0<br />

80<br />

cm (WS) cm (WS)<br />

Niveau 2 (Alarm)<br />

Niveau 1 (Pumpe ein)<br />

Pumpe<br />

Betrieb Störung Temperatur<br />

Nachlaufzeit<br />

Aus Auto Hand<br />

15<br />

1<br />

30<br />

Abschaltstrom S<br />

Strom in A<br />

Strom in A<br />

2 10<br />

A Reset<br />

Reset-Funktion bei „Störung“:<br />

1x drücken, Signalton aus<br />

2x drücken, Alarm quittiert<br />

<strong>ACO</strong> <strong>Haustechnik</strong><br />

Im Gewerbepark 11c<br />

36457 Stadtlengsfeld<br />

Tel. 036965 - 819 0<br />

Fax 036965 - 819 361

Switch box for duo type lifting plant (all types except K 55 and K 75)<br />

Technical data, standard design |<br />

Dimensions: 250 x 200, 100 mm (WxH, D)<br />

Protection type: IP 54<br />

Material: Plastic, white<br />

Operating voltage: 400 V / 50 Hz, max. back-up fuse 16 A<br />