SINTEF REPORT

SINTEF REPORT

SINTEF REPORT

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

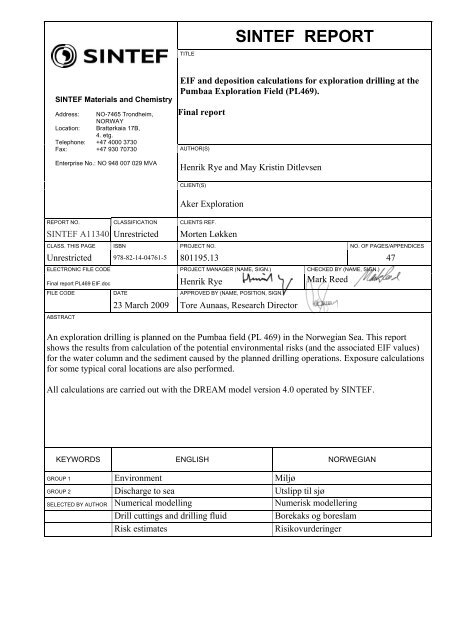

<strong>SINTEF</strong> Materials and Chemistry<br />

Address: NO-7465 Trondheim,<br />

NORWAY<br />

Location: Brattørkaia 17B,<br />

4. etg.<br />

Telephone: +47 4000 3730<br />

Fax: +47 930 70730<br />

Enterprise No.: NO 948 007 029 MVA<br />

TITLE<br />

<strong>SINTEF</strong> <strong>REPORT</strong><br />

EIF and deposition calculations for exploration drilling at the<br />

Pumbaa Exploration Field (PL469).<br />

Final report<br />

AUTHOR(S)<br />

Henrik Rye and May Kristin Ditlevsen<br />

CLIENT(S)<br />

Aker Exploration<br />

<strong>REPORT</strong> NO. CLASSIFICATION CLIENTS REF.<br />

<strong>SINTEF</strong> A11340 Unrestricted Morten Løkken<br />

CLASS. THIS PAGE ISBN PROJECT NO. NO. OF PAGES/APPENDICES<br />

Unrestricted 978-82-14-04761-5 801195.13 47<br />

ELECTRONIC FILE CODE PROJECT MANAGER (NAME, SIGN.) CHECKED BY (NAME, SIGN.)<br />

Final report PL469 EIF.doc Henrik Rye Mark Reed<br />

FILE CODE DATE APPROVED BY (NAME, POSITION, SIGN.)<br />

ABSTRACT<br />

23 March 2009 Tore Aunaas, Research Director<br />

An exploration drilling is planned on the Pumbaa field (PL 469) in the Norwegian Sea. This report<br />

shows the results from calculation of the potential environmental risks (and the associated EIF values)<br />

for the water column and the sediment caused by the planned drilling operations. Exposure calculations<br />

for some typical coral locations are also performed.<br />

All calculations are carried out with the DREAM model version 4.0 operated by <strong>SINTEF</strong>.<br />

KEYWORDS ENGLISH NORWEGIAN<br />

GROUP 1 Environment Miljø<br />

GROUP 2 Discharge to sea Utslipp til sjø<br />

SELECTED BY AUTHOR Numerical modelling Numerisk modellering<br />

Drill cuttings and drilling fluid Borekaks og boreslam<br />

Risk estimates Risikovurderinger

SUMMARY:<br />

An exploration drilling is planned on the Pumbaa field (PL 469) in the Norwegian Sea. The<br />

present report shows the results from calculation of the potential environmental risks (and the<br />

associated EIF values) for the water column and the sediment caused by the planned drilling<br />

operations. Potential impacts on corals located nearby are addressed in particular.<br />

The well comprises 6 sections, drilled with Water Based Mud (WBM). 4 sections (42”, 9 7/8”<br />

pilot hole, 36” and 26”) give discharges directly to the sea floor, while two sections (17 ½” and<br />

12 ¼”) give discharges from the drilling rig.<br />

EIF results<br />

The results from the EIF calculations are summarized in the table below:<br />

Summary of results from EIF calculations.<br />

Scenario Compartment Max. Duration for Dominant risk<br />

impacted EIF EIF > 0 contributor<br />

Base case Upper water<br />

column<br />

2255 4 days Barite part.<br />

Lower water<br />

157 6 days Bentonite and barite<br />

column<br />

part.<br />

Sediment 58 > 10 years Copper in barite<br />

The results show that for the water column, particle effects caused by discharges of particle matter<br />

(barite and bentonite) are dominating the risk for both the upper and lower water column. The<br />

particles may impact on organisms that are filtering sea water (like sea shells, scallops,<br />

zooplankton, fish). For the sediment, heavy metals in the particle matter represent the largest<br />

potential for environmental risk. The presence of heavy metals in barite and bentonite that deposit<br />

on the sea floor will partly dissolve in the sediment pore water, and thus become bioavailable. Cu<br />

in barite gives the largest risk contribution, caused by a relatively large concentration of Cu in the<br />

barite that is planned to be used. Later results indicate that the risks associated with Cu in barite<br />

are probably over-estimated.<br />

The values of the EIF’s are largest for the water column impact. However, the duration period of<br />

impact is significantly shorter than for the duration of impact for the sediment. When the EIF’s<br />

are adjusted according to duration of impact, the revised EIF (denoted EIFyear) becomes of order<br />

300 – 500 for the sediment (adjusted for a 10-year duration of impact), and of order 3 - 30 for the<br />

water column (durations about 4 - 6 days for the water column impacts). Although the impacts in<br />

the sediment and in the water column are not directly comparable, the order-of-magnitude<br />

differences of the EIFyear’s for the water column and sediment indicate that the potential sediment<br />

impact may be judged to be more severe that the potential water column impact (due to its short<br />

duration) 1 . Therefore, the heavy metal content in barite appears to represent the largest potential<br />

for environmental impact for the present EIF simulation.<br />

1<br />

One of the basis for the intercomparison between water column and sediment EIF’ s are that both EIF’s are based on<br />

a unity on the horizontal scale equal to 100m x 100m.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

2

Impact on corals<br />

Corals are present in the area where the drilling operations are planned. Two types of impacts can<br />

be envisaged:<br />

• Impacts caused by burial<br />

• Impact on on corals through filtering behavior<br />

Impacts caused by burial are described in Chapter 5.1. Criteria for damage expected on corals<br />

caused by drilling discharges are not established. In the present report, results are shown for<br />

depositions that exceed the expected natural deposition in the area on a yearly basis. In the<br />

recently published report on ”Consequences caused by regular discharges to sea, Norwegian Sea<br />

area” 2 , an estimate of the natural sedimentation rate in this area (over-all values) is presented.<br />

Based on observations of existing natural depositions in the area, of order 0.01 – 0.02 mm/year<br />

was arrived at. Therefore, results are shown for added depositions caused by the drilling<br />

discharges down to 0.01 mm in total. The simulations carried out show that this amount of burial<br />

caused by the discharges should be expected up to order 800 – 900 m from the well location in<br />

direction N – S, and up to 2 km from the well in the E – W direction. These distances include the<br />

location of some corals in the vicinity of the well.<br />

Impacts on corals through filtering are described in Chapter 5.2. The potential for impact can be<br />

illustrated by showing time series of total particle content in the water masses close to the sea<br />

floor. The corals are feeding on (or filtering) particle matter present in the water column. The<br />

corals may therefore also be impacted by particles suspended in the water masses before they<br />

settle on the sea floor. These particles comprise essentially the finer fractions of the particles<br />

originating from the top hole section discharges. Because some coral locations are relatively close<br />

to the planned well, some suspended matter may pass the coral locations when the current<br />

direction coincides with the direction of coral location from the well.<br />

The period of impact will be restricted to the period of discharge from the top hole sections,<br />

essentially (neglecting the possibility of re-suspension of the deposited matter). Time series of<br />

calculated concentration of particle matter shows that some of the coral locations closest to the<br />

drilling site may occasionally experience exceedence of potential no-effect concentrations<br />

(PNEC’s) for barite and bentonite particle concentrations in the water column. This exposure will<br />

be very occasionally, restricted to the periods when the direction of the currents coincides with the<br />

direction of the location of the corals. When the directions coincide, the particle concentrations in<br />

the plume generated tend to exceed the PNEC levels of the particle matter for the coral locations<br />

closest to the drilling site (order 200 - 300 m from the well). Therefore, it may be a potential for<br />

environmental impact on the corals, but it should be noted that the time duration of the impact is<br />

rather small (order some hours, at maximum, for each time the plume hits the corals during<br />

discharge). For the 800 m location, the concentrations during the hit are expected to be smaller<br />

(below 0.3 ppm). This value is close to the PNEC values for the particle matter. The reduction in<br />

the concentration level is partly due to dilution of the discharge “cloud” at the sea floor and also<br />

partly due to that some of the content in the “cloud” is depositing on the sea floor while the<br />

“cloud” moves with the currents along the sea floor.<br />

2 <strong>SINTEF</strong>: Konsekvenser av regulære utslipp til sjø. Helhetlig forvaltningsplan for Norskehavet (HFNH). Program<br />

for utredning av konsekvenser. Sektor Petroleum og Energi. Report made for DNV/OED dated 26 February 2008.<br />

<strong>SINTEF</strong> report <strong>SINTEF</strong> F5543. <strong>SINTEF</strong> project No. 800923.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

3

ABBREVIATIONS<br />

BOP Blow-Out Preventer<br />

CB Background concentration of metal in sediment<br />

DREAM Dose related Risk and Effect Assessment Model<br />

EC50 The concentration where a specific effect is observed for 50% of the test<br />

specimen<br />

EIF Environmental Impact Factor<br />

ERMS Environment Risk Management System<br />

HOCNF Harmonized Offshore Chemical Notification Format<br />

KOC Partition coefficient organic carbon - water<br />

LC50 The concentration which causes lethality for 50% of the test specimen<br />

LOEC Lowest Observed Effect Concentration<br />

MEMW Marine Environmental Modelling Workbench<br />

MPA Maximum Permissible Addition<br />

MPC Maximum Permissible Concentration<br />

NCS Norwegian Continental Shelf<br />

NOEC No Observed Effect Concentration<br />

OBM Oil Based Mud<br />

OLF The Norwegian Oil Industry Association<br />

PAH Poly-Aromatic Hydrocarbons<br />

PEC Predicted Environmental Concentration/Change<br />

PNEC Predicted No Effect Concentration/Change<br />

PLONOR Pose Little or No Risk to the environment<br />

POW Partition coefficient used in the HOCNF testing of offshore chemicals<br />

SBM Synthetic Based Mud<br />

SFT Norwegian State Pollution Control Authority<br />

SPM Suspended Particle Matter<br />

SSD Species Sensitive Distributions<br />

TGD Technical Guideline Document (EC 1996)<br />

THC Total HydroCarbons in sediment<br />

WBM Water Based Mud<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

4

Table of Contents Page<br />

1 Introduction............................................................................................................................6<br />

2 The DREAM model and the EIF concept............................................................................7<br />

2.1 The DREAM model ..........................................................................................................7<br />

2.2 The EIF concept in general .............................................................................................12<br />

2.3 Special features for the EIF drill cuttings and mud discharges.......................................16<br />

3 Input data .............................................................................................................................19<br />

3.1 General ............................................................................................................................19<br />

3.2 Location...........................................................................................................................20<br />

3.3 Particle size of the natural sediment................................................................................21<br />

3.4 Grain size distributions in the discharge .........................................................................21<br />

3.5 PNEC’s for particles and components in the mud packages used. .................................23<br />

3.6 PNEC’s for heavy metals in sediment.............................................................................23<br />

3.7 Time duration of the discharges......................................................................................24<br />

3.8 Discharge configurations................................................. Error! Bookmark not defined.<br />

3.9 Summer heating stratification .........................................................................................25<br />

3.10 Ambient winds and currents conditions .........................................................................25<br />

3.11 Discharge setup for the various drilling sections ...........................................................26<br />

3.12 Presence of corals...........................................................................................................28<br />

4 EIF Results ...........................................................................................................................30<br />

4.1 General ............................................................................................................................30<br />

4.2 EIF Results for the upper water column..........................................................................31<br />

4.3 EIF Results for the lower water column..........................................................................33<br />

4.4 EIF Results for the sediment. ..........................................................................................35<br />

4.5 Summary of EIF results and discussion. .........................................................................37<br />

5 Impact on corals...................................................................................................................39<br />

5.1 Results from calculation of potential coral impact caused by deposition.......................39<br />

5.2 Results from calculation of potential coral impact caused by particle content in the water<br />

column.............................................................................................................................44<br />

References ....................................................................................................................................46<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

5

1 Introduction<br />

An exploration drilling is planned on the Pumbaa field (PL469) in the Norwegian Sea. The<br />

present report shows the results from calculation of the potential environmental risks (and the<br />

associated EIF values) for the water column and the sediment caused by the planned drilling<br />

operations. The well comprises 6 sections, drilled with Water Based Mud (WBM). 4 sections<br />

(42”, 9 7/8” pilot hole, 36” and 26”) give discharges directly to the sea floor, while two sections<br />

(17 ½” and 12 ¼”) give discharges from the drilling rig.<br />

The present report contains the results from the discharge fates and corresponding risk<br />

calculations. The calculations are carried out with the revised DREAM model, version 4.0.<br />

The present report comprises the following chapters:<br />

• Description of the DREAM model and the EIF concept (Chapter 2)<br />

• Details of model input data. Drilling location and drilling sections. Size distributions of<br />

particle matter. Heavy metal content. The mud package composition for each section.<br />

Also, ambient conditions (currents and ambient stratification) are described. Presence of<br />

corals (Chapter 3).<br />

• Modelling with the DREAM model discharges and fates, incuding EIF results for both the<br />

water column and sediment. Presentation and discussion of results (Chapter 4).<br />

• Results of the DREAM calculations with respect to potential impacts on corals. Results for<br />

the water column close to sea floor (lower water column). Depositions on the sea floor.<br />

Interaction with corals present in the area. Presentation and discussion of results (Chapter<br />

5).<br />

• References are included after Chapter 5.<br />

The model versions used in the present study are denoted MEMW 4.0.5 dated 21. August 2008<br />

(Fates.exe) and 03. October 2008 (MEMW.exe). The module for presentation graphics<br />

(MEMW.xls) is dated 27 September 2007.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

6

2 The DREAM model and the EIF concept<br />

2.1 The DREAM model<br />

The following description of the DREAM model is taken from Rye et. al (2008):<br />

The numerical model approach is based on the DREAM model, as it has been applied to produced<br />

water risk assessments (Johnsen et al. 2000). In addition, some modules of the numerical model<br />

ParTrack for calculation of dispersion and deposition of drill cuttings and mud (Rye et al. 1998,<br />

2004; 2006) have been implemented. The model concept applied is a “particle”, or Lagrangian<br />

approach. The model generates particles at the discharge point, which are transported with the<br />

currents and turbulence in the sea. Different properties, such as the mass of various compounds,<br />

densities and sinking velocities, are associated with each particle. Model particles can also<br />

represent different states or phases, such as bubbles, droplets, dissolved matter and solid matter.<br />

For discharges of drill cuttings and mud, solid particles, organic matter, metals attached to solid<br />

particles and dissolved matter will be of particular interest. The formulas applied for spreading in<br />

the water column are given in Reed and Hetland (2002).<br />

The ocean current field applied in the DREAM model is usually imported from outputs generated<br />

from 3-dimensional and time-variable hydrodynamic models. It is also possible to apply observed<br />

ocean current profiles generated from measurements at a specific location.<br />

Generic features for the calculation of deposition. A more reliable description of the behavior of<br />

drilling discharges has been undertaken by incorporation of additional modules into the model<br />

system. These include a near field plume, sinking velocities of particles depositing on the sea<br />

floor and particle size distributions specified for each particle group (cuttings, barite).<br />

Near-field plume. Discharges of drill cuttings and mud have densities that are significantly higher<br />

than the ambient water. A near field plume is therefore included in order to account for the<br />

descent of the plume. This descent will cease when the density of the descending plume equals the<br />

density of the ambient water. The plume path is governed by the ocean current velocities (and<br />

directions) and also by the vertical variation of the ambient salinity and temperature<br />

(stratification). The combination of these factors causes the plume to level out at some depth (the<br />

“depth of trapping”) or sink down to the sea floor and level out there. Mineral particles (cuttings,<br />

weight material) are allowed to fall out of the plume, dependent on the sinking velocity and the<br />

rate of entrainment of water into the plume. The principal features of the near field plume model<br />

are given in Johansen (2000, 2006).<br />

Descent of particles to the sea floor. Figure 2.1 shows a vertical cross section of an underwater<br />

plume on the downstream side of the release site calculated with the DREAM model. The “depth<br />

of trapping” in the case shown indicates that this appears at about 20 m depth (discharge depth is<br />

about 5 m). At this depth, the underwater plume separates into 2 parts: 1) To spread horizontally<br />

at the depth of trapping. This part consists of dissolved compounds (not sinking) and of solid<br />

particles that are so small in diameter that sinking velocities are negligible. 2) The other part of<br />

the discharge appears to sink down to the sea floor. This part may consist of coarser particles (like<br />

cuttings particles with relatively large diameters) with some chemicals attached to them.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

7

Figure 2.1 An example illustrating the vertical cross section of the near field plume and the<br />

deposition of particles on the sea floor. Discharge point to the upper left corner of<br />

the figure. Sea floor at about 400 m depth.<br />

The sinking velocities of the particles can be divided into 2 regimes, the Stokes regime and the<br />

Constant drag regime. The sinking velocities within the Stokes regime for smaller particles are<br />

given by Equation 1:<br />

2<br />

d g'<br />

W 1 =<br />

18υ<br />

(1)<br />

where W1 is laminar Stokes sinking velocity of a particle, d is the particle diameter, g’ is the<br />

reduced gravity = g ( ρ particle − ρ water ) / ρ water , g is the standard gravity, ρ is the density of particle<br />

or sea water and υ = kinematic viscosity = 1.358 x 10 -6 m 2 /s at 10 o C for sea water.<br />

The second contribution to the sinking of the particles is the friction dominated Constant drag<br />

regime for larger particles. A general expression for this sinking velocity can be derived from the<br />

balance between buoyancy forces and drag forces acting on the particle (Hu and Kintner, 1955)<br />

calculated by Equation 2:<br />

W<br />

4 d g'<br />

3<br />

2 = (2)<br />

CD<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

8

The drag coefficient CD in this equation is a function of the Reynolds number ( Re 2 / ν d W = ). On<br />

this basis, two asymptotic regimes are identified, the Stokes regime and the Constant drag regime<br />

(Equation 3):<br />

1) Stokes regime (Re<br />

< 1) :<br />

2) Constant drag regime (Re<br />

2<br />

d g'<br />

W1<br />

=<br />

18ν<br />

(3)<br />

> 1000) : W = K d g'<br />

2<br />

where K is an empirical dimensionless constant. For intermediate values of the Reynolds number<br />

(1 < Re < 1000), an interpolation equation for the total sinking velocity W of the particle may be<br />

used, expressed by the Equation 4:<br />

W =<br />

⎛ 1<br />

⎜<br />

⎝W<br />

1<br />

1<br />

1 ⎞<br />

+ ⎟<br />

W2<br />

⎠<br />

The empirical constant K is chosen so that correspondence is reached between the friction<br />

dominated sinking velocity as given in US Army Coastal Engineering Manual (2007) and the<br />

Equation 3 above. This equation takes into account that grains are usually non-spherical and have<br />

therefore generally lower sinking velocities than grains with spherical shapes.<br />

A graphical presentation of the curve shape given by Equation 4 is shown in Figure 2.2. For low<br />

diameter particles (diameters lower than 2 x 10 -4 m), the equation corresponds well with the<br />

Stokes sinking velocity (Equation 1). For larger particle diameters (diameters larger than 2 x 10 -3<br />

m), the equation corresponds well with the friction dominated velocity (Equation 2). In the<br />

diameter range in between, the sinking velocities are influenced by contributions from both<br />

regimes.<br />

Deposition of chemicals on the sea floor--In WBM (Water based Mud), most of the added<br />

chemicals are mainly assumed to dissolve in the water column. For other types of mud (e.g. OBM<br />

and SBM, Oil Based Mud and Synthetic Based Mud), dissolution of the chemicals in the water<br />

column may be slow. These chemicals (typically exhibiting large octanol – water partition<br />

coefficient Kow) may also have a high capacity for adsorption to organic matter present in the<br />

sediment or water column.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

(4)<br />

9

Rise velocity, m/s<br />

Sinking velocity, m/s<br />

1.0E+00<br />

1.0E-01<br />

1.0E-02<br />

1.0E-03<br />

1.0E-04<br />

Stokes law<br />

Constant drag<br />

1.0E-05<br />

1.0E-05 1.0E-04 1.0E-03 1.0E-02<br />

Particle diameter, m<br />

Figure 2.2 Particle size dependent variation in fall velocity of mineral particles in seawater.<br />

Solid density 2500 kg/m 3 , resembling cuttings particles. Thin lines: Stokes law and<br />

constant drag law. Thick line: Interpolation formula.<br />

According to the EC (2003), substances with Koc < 500 – 1000 L/kg are not likely to adsorb to<br />

sediment. The EC (2003) states that “To avoid extensive testing of chemicals, a logKoc or logKow<br />

of ≥ 3 (or ≥ 1000 L/kg) can be used as a trigger value for sediment effects assessment”.<br />

In accordance to the TGD the chemicals with low Kow or Koc values (< 1,000 L/kg) are assumed<br />

to dissolve (completely) in the water column. For large Kow or Koc values ( ≥ 1,000 L/kg), the<br />

chemicals are assumed to adsorb (or “attach”) to particles and eventually deposit on the sea floor.<br />

This process may take place either through “agglomeration” (in which new particles are formed),<br />

or by “attachment”, where chemicals are thought to “attach” to individual mineral particles in the<br />

discharge. The Kow and Koc are partition coefficients, the Kow is the octanol-water partition<br />

coefficient, and the Koc is the particle organic carbon partition coefficient. The relationship<br />

between Koc and Kow has been studied by Di Toro et al. (1991). It was found that Koc and Kow are<br />

closely related. The TGD (EC 2003) does not differentiate between use of Kow or Koc. Therefore,<br />

it is recommended to use Kow if no Koc value is available for organic substances. The octanolwater<br />

partition coefficient denoted Pow is assumed equal to Kow.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

10

Figure 2.3 shows the basic features of the developed model for calculating the fate of drilling<br />

discharges. Concentrations in the water column and depositions on the sea floor are illustrated.<br />

The particles in the model have been spread in the recipient due to ocean currents and turbulence<br />

(after the termination of the near field plume phase).<br />

Ecological risks in<br />

water column<br />

and sediments<br />

Vertical cross section<br />

Water column<br />

concentrations Sediment<br />

concentrations<br />

and stressors<br />

Complete<br />

mass<br />

balance<br />

Time (days:hrs:min)<br />

Figure 2.3 Visualization of the fate of drilling discharges. The figure demonstrates the<br />

following:<br />

1). Concentrations of dissolved compounds (and/or particle matter) calculated for the<br />

water column, concentrations shown in ppm (mg/L).<br />

2). Deposition of the particle matter on the sea floor (along with chemicals attached<br />

to the particles), deposition in kg/m 2 sediment surface.<br />

3). A mass balance histogram that shows the amounts that are depositing on the sea<br />

floor, and the amounts that remain in the water column.<br />

4). A vertical cross section that shows the plume in the water column (close to sea<br />

surface) and the deposition of particles falling out below the plume. The actual cross<br />

section chosen is shown by an arrow on the main figure.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

11

2.2 The EIF concept in general<br />

General. The operators on the Norwegian Continental Shelf (NCS) have agreed with the<br />

Norwegian Authorities to work towards a reduction of the environmental impacts from produced<br />

water releases (and from drill cuttings and mud releases as well) down to a level of “zero harmful<br />

effects”. To more clearly define this goal, the EIF (Environmental Impact Factor) has been<br />

developed as an indicator of the environmental risk caused by regular releases to sea. The EIF is<br />

used as a measure of the environmental benefit achieved when alternate measures are considered<br />

for reducing environmental impacts.<br />

The method has the advantage that it gives a quantitative measure of the environmental risks<br />

involved when effluents are discharged to sea, and is thus able to form a basis for reduction of<br />

impacts in a systematic and a quantitative manner.<br />

This method is based on the calculation of the EIF using the numerical model DREAM (Dose<br />

related Risk and Effect Assessment Model) developed by <strong>SINTEF</strong>, with financial support from<br />

StatoilHydro, ENI, Total, ExxonMobil, Petrobras, ConocoPhillips, and Shell.<br />

General description of the method. The EIF method is based on a PEC/PNEC approach, in which<br />

the concentration for each compound discharged into the recipient is compared to a concentration<br />

threshold for that compound. When the predicted (modeled) environmental concentration (PEC) is<br />

larger than the predicted no-effect concentration (PNEC), an “unacceptable” environmental risk<br />

for damage is encountered. When the PEC is lower than the PNEC threshold, the environmental<br />

risk is considered to be “acceptable”.<br />

An outline of the EIF method applied to produced water discharges is given in Johnsen et. al.,<br />

2000.<br />

The PEC. The PEC (Predicted Environmental Concentration) is the three-dimensional and time<br />

variable concentration in the recipient caused by the discharge to sea. The PEC is calculated for<br />

all compounds in the discharge that are assumed to represent a potential for harmful impact on the<br />

biota. The calculations are carried out by using the numerical DREAM model. This model is fully<br />

three-dimensional and time variable. It calculates the fate in the recipient of each compound<br />

considered under the influence of<br />

• currents (tidal, residual, meteorological forcing)<br />

• turbulent mixing (horizontal and vertical)<br />

• evaporation at the sea surface<br />

• reduction of concentration due to biodegradation<br />

The PNEC. The PNEC (Predicted No Effect Concentration) is the estimated lower limit for<br />

effects on the biota in the recipient for a single chemical component or component group. A<br />

PNEC level is given for each component present in the discharge. It is derived from laboratory<br />

testing of toxicity for each component (or chemical product) in question. The PNEC value is<br />

derived from EC50, LC50 or NOEC values from laboratory testing, where the EC50, LC50 or the<br />

NOEC value determined is divided by some assessment factor in order to arrive at the expected<br />

PNEC.<br />

A major data collection work has been performed in order to obtain data of sufficient reliability to<br />

be selected for determination of PNEC values. Different procedures have been selected for<br />

determination of the PNEC values for added chemicals in drilling mud (and produced water as<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

12

well). The PNEC values for added chemicals can be derived from information found in the<br />

HOCNF (Harmonized Offshore Chemical Notification Format) scheme. Further details can be<br />

found in Johnsen et. al., 2000 (produced water case).<br />

Environmental risk and the EIF. The EIF for a single component or component group is related to<br />

the recipient water volume where the ratio PEC/PNEC exceeds unity. The ratio PEC/PNEC is<br />

related to the probability of exceedence of the PNEC level according to a method developed by<br />

Karman et. al., 1994 (and also published in Karman and Reerink, 1997). When PEC/PNEC = 1,<br />

this corresponds to a level at which there exists a risk for impact to the 5% most sensitive species.<br />

Figure 2.4 shows the relation between the PEC/PNEC ratio and the probability of environmental<br />

impact.<br />

The EIF method has the advantage over other risk assessment methods in that it can calculate risk<br />

contributions from a sum of chemicals and/or natural compounds in the recipient. For the total<br />

risk from a sum of compounds, the total risk is calculated formulas for the sum of independent<br />

probabilities:<br />

P( A + B)<br />

= P(<br />

A)<br />

+ P(<br />

B)<br />

− P(<br />

A)<br />

* P(<br />

B)<br />

(5)<br />

where P(A) is the probability of environmental risk for compound A and P(B) is the probability of<br />

risk for compound B. For small risks (that is, P(A) and P(B) are both small), or risks from<br />

chemicals which are toxicologically similar in their activity, the risks can be considered to be<br />

linearly additive, approximately. The method does not account for interactions among chemicals.<br />

Probability of<br />

environmental injury (%)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

PEC/PNEC ratio versus environmental risk<br />

5% ~ PEC/PNEC = 1<br />

0.01 0.1 1 10 100 1000 10000<br />

Ratio PEC/PNEC<br />

Figure 2.4 Relation between the PEC/PNEC level and the risk level (in %) for impact to biota.<br />

Based on Karman et. al., 1994. PEC/PNEC = 1 corresponds to a level at which<br />

there exists a possibility of impact to the 5% most sensitive species.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

13

The total risk resulting from all components in a release is calculated by the DREAM model in<br />

space and time within the model domain. The sum of risks (for every point in space and for each<br />

time) is then summarized and converted back to a nominal PEC/PNEC value with the aid of the<br />

function in Figure 2.4. The results are then presented as shown in Figure 2.5 (snapshot in time).<br />

Results can also be presented as risk in percent. The water volume indicated by red then indicates<br />

the water volume where the nominal PEC/PNEC is larger than one. Note that the PEC/PNEC<br />

ratios for all individual components in the release may be less than unity, but the cumulative risk<br />

from all components may exceed 5%, such that the nominal PEC/PNEC ratio produced by the<br />

procedure described above, and representing a conglomerate value for the release, exceeds unity.<br />

56°34'N<br />

56°32'N<br />

56°30'N<br />

2 km<br />

3°10'E<br />

3°10'E<br />

3°15'E<br />

3°15'E<br />

Risk Map Time Series<br />

Figure 2.5 Calculation of PEC/PNEC for the sum of various compounds in a discharge.<br />

Snapshot in time. Horizontal extent (upper figure) and vertical extent (lower figure)<br />

are both shown.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

8:12:00<br />

56°34'N<br />

56°32'N<br />

56°30'N<br />

14

An EIF of unity is defined as a water volume 100m x 100m x 10m (10 5 m 3 ) in which there is a<br />

risk of impact to the 5% most sensitive species. For a single component, this corresponds to a<br />

PEC/PNEC ratio exceeding unity. In addition, the EIF water volume is adjusted upwards by a<br />

factor of two for those compounds that have a small biodegradation factor combined with a large<br />

bioaccumulation factor (sometimes called “red” chemicals). Details are given in Johnsen et al.,<br />

2000.<br />

An attractive feature of the EIF approach is that the method is able to discriminate among the<br />

various contributors to environmental risk. An example of the distribution of contribution to risk<br />

among components in a release is shown in Figure 2.6. This capability provides useful<br />

information when comparing alternative proposed methodologies for reducing environmental<br />

risks associated with a discharge.<br />

Thus it is possible to separate a chemical product into its constituents and calculate the EIF<br />

contribution from each of them. The results of the calculations can then be used to improve the<br />

product in terms of replacing the constituents in the product with the largest contribution to the<br />

EIF.<br />

Total risk, EIF = 0.2678<br />

Corrosioninhibitor<br />

0 %<br />

Corrosioninhibitor<br />

0 %<br />

Zi<br />

0 %<br />

Ni<br />

0 %<br />

BTEX<br />

1 %<br />

Naphthalenes<br />

0 %<br />

De-emulgation<br />

chemical<br />

2-3 ring PAH<br />

1 %<br />

0 %<br />

4-ring+ PAH<br />

18 %<br />

Scale inhibitor<br />

47 %<br />

Aliphatics<br />

9 %<br />

C4+ phenol<br />

12 %<br />

Phenol C0-C3<br />

12 %<br />

Figure 2.6 Distribution of contribution to risk for an EIF calculation. Here the scale inhibitor<br />

contributes 47 % of the total risk.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

15

2.3 Special features for the EIF drill cuttings and mud discharges<br />

EIF for drilling discharges for the water column is defined similarly as for produced water<br />

discharges. EIF for toxic compounds in the drilling mud is therefore calculated is the same way as<br />

outlined above for the water column. In addition, risks caused by particle stress on filtering<br />

organisms in the water column (typically caused by barite and bentonite particles) are included as<br />

well.<br />

The risks for discharges of drill cuttings and mud include more stressors than for produced water<br />

(6 stressors instead of 1, two for the water column and 4 for the sediment). Figure 2.7 illustrates<br />

how the various compounds in a drilling discharge impacts on the various stressors in the water<br />

column and in the sediment:<br />

Impact on water column:<br />

Discharge compound: Impact:<br />

Chemicals with Pow < 1000<br />

Chemicals with Pow ≥ 1000<br />

Heavy metals in barite<br />

Particles in mud<br />

Cuttings<br />

Impact on sediment:<br />

Discharge compound: Impact:<br />

Chemicals with Pow < 1000<br />

Chemicals with Pow ≥ 1000<br />

Heavy metals in barite<br />

Particles in mud<br />

Cuttings<br />

Chemical stress<br />

Particle stress<br />

Water column<br />

Sediment<br />

Water column<br />

Sediment<br />

Chemical stress<br />

Oxygen depletion<br />

Grain size change<br />

and burial<br />

Figure 2.7 Illustration of the impact calculated for the water column (upper figure) and for the<br />

sediment (lower figure) caused by the various ingredients in the drilling discharges.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

16

Another feature that is different from the produced water is the time variability of the discharges.<br />

The discharges from a drilling rig to the sea are rather intermittent and time variable, with various<br />

composition and amounts of the mud discharged from each drilling section. This causes<br />

corresponding time variability in the EIF. This is expressed in terms of presenting the EIF as a<br />

time function, with the corresponding risk contributions shown as a function of time as well. An<br />

example of presenting the EIF for such a case for the water column is shown in Figure 2.8.<br />

g<br />

EIF<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

0.0<br />

0.4<br />

0.9<br />

1.3<br />

1.8<br />

2.2<br />

2.6<br />

3.1<br />

3.5<br />

3.9<br />

4.4<br />

4.8<br />

Time development chart<br />

5.3<br />

5.7<br />

Time (days)<br />

Figure 2.8 Time series development of the EIF for the water column caused by drilling<br />

discharges. Impacts are intermittent according to the discharges from the different<br />

drilling sections. The main contribution comes from barite and a chemical for the<br />

case shown. The duration of the impact is limited to between day 3 and 7, basically,<br />

for the case shown. Unit for the EIF in the water column is a water volume equal to<br />

100m x 100m x 10m.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

6.1<br />

6.6<br />

DAYS<br />

7.0<br />

7.4<br />

7.9<br />

24.0<br />

586.4<br />

1216.4<br />

1846.4<br />

2476.4<br />

3106.4<br />

EIF_Ilmenite<br />

EIF_Bentonite<br />

EIF_Barite<br />

EIF_Cuttings<br />

Defoam-AL-comp4<br />

Defoam-AL-comp3<br />

Defoam-AL-comp2<br />

Defoam-AL-comp1<br />

Ultrafree NS<br />

Safe-Scav HS<br />

Safe-cide<br />

EIF_MEG<br />

Ultracap<br />

EMI-939<br />

EIF_Lead_Bentonite<br />

EIF_Mercury_Bentonite<br />

EIF_Cadmium_Bentonite<br />

EIF_Mercury_Ilmenite<br />

EIF_Chromium_Ilmenite<br />

EIF_Lead_Barite<br />

EIF_Mercury_Barite<br />

EIF_Copper_Barite<br />

EIF_Cadmium_Barite<br />

Defoam-NS<br />

OCR 325 AG<br />

Bestolife 3010 NM<br />

17

Likewise, for the impact on the sediment, the impact may be intermittent and time variable as<br />

well. A special feature here is that the time of the impact may extend far beyond the duration of<br />

the discharge. As an example, if biodegradable chemicals (with large Pow partition coefficients)<br />

attached to cuttings are depositing on the sea floor along with the cuttings particles, the<br />

biodegradation of the chemicals may consume oxygen from the sediment layers and thus cause<br />

anoxic conditions in the sediment. Such a case is shown by an example in Figure 2.9.<br />

A separate “sediment module” that calculates the fate of the particles deposited and chemicals in<br />

the sediment is also developed. This module calculates the effects from bioturbation (mixing in<br />

the sediment layer due to the presence of biota), oxygen consumption and partition of chemicals<br />

between sediment and pore water compartments. Equilibrium partition principle is used. The<br />

matter dissolved in the pore water is assumed to be bioavailable. Both chemicals and heavy metals<br />

attached to particle matter are assumed to dissolve in the pore water. Restitution of the sediment<br />

layer due to biodegradation of chemicals and mixing caused by bioturbation are included as well.<br />

EIF<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0.0<br />

0.2<br />

Grain size<br />

Oxygen<br />

Thickness<br />

Drill-chem-4<br />

Drill-chem-1<br />

LUBR-1<br />

EIF_Zinc_Barite<br />

EIF_Lead_Barite<br />

EIF_Mercury_Barite<br />

EIF_Copper_Barite<br />

EIF_Chromium_Barite<br />

EIF_Cadmium_Barite<br />

0.4<br />

0.6<br />

0.8<br />

0.9<br />

1.1<br />

1.3<br />

1.5<br />

1.7<br />

1.9<br />

2.1<br />

Time development chart<br />

2.3<br />

2.4<br />

2.6<br />

2.8<br />

3.0<br />

3.2<br />

Time (days)<br />

DAYS<br />

Figure 2.9 The time development of the EIF for the sediment caused by drilling discharges.<br />

Note that although the discharge is lasting for some days only, the impact on the<br />

sediment layer is extending over a time period of more than 10 years. The oxygen<br />

depletion (yellow contribution) is lasting of order one year before the<br />

biodegradable chemicals have been biodegraded. Other significant contributions to<br />

the sediment stress are change of grain size (introduction of “exotic” sediment) and<br />

burial (denoted “thickness” in the legend). In addition, heavy metals present in<br />

barite (Cu in particular) contribute to toxicity in the sediment. Unit of the EIF for<br />

the sediment is 100m x 100m sediment surface.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

3.4<br />

3.6<br />

3.8<br />

3.9<br />

4.1<br />

4.3<br />

4.5<br />

4.7<br />

4.9<br />

5.9<br />

572.8<br />

1382.8<br />

2192.8<br />

3002.8<br />

18

3 Input data<br />

3.1 General<br />

As illustrated in Figure 2.7, the risks associated with discharges of drill cuttings and mud to sea<br />

are related to impacts both in the water column and the sediment. The calculation of<br />

environmental risks for the water column includes two types of “stressors”:<br />

• Dissolved non-PLONOR compounds or chemicals. These are calculated as dissolved<br />

chemicals in the water column. Only compounds with a logPow < 3 are included, because<br />

these are assumed to dissolve in the water column and thus appear in a bioavailable form.<br />

Compounds with a log Pow ≥ 3 are assumed to “attach” to particles, sink down with the<br />

particles and thus enter the sediment layer on the sea floor. Here they may contribute to<br />

environmental risks in the sediment (see below).<br />

• Particle stress from barite or other types of particles present in the water column.<br />

For the sediment layer, four stresses are calculated:<br />

• Toxicity caused by chemicals in the sediment layer. Only compounds with a logPow ≥ 3<br />

are included. These are assumed not to dissolve in the water column, but attach to particles<br />

and enter the sediment layer. Here they will biodegrade and therefore contribute to oxygen<br />

depletion in the sediment layer. Stresses in the sediment caused by heavy metals in particle<br />

matter are included as well. These may cause toxicity in the sediment but does not<br />

contribute to oxygen consumption.<br />

• Excessive oxygen consumption in the sediment layer due to biodegradation of organic<br />

chemicals.<br />

• Thickness of deposited matter due to deposition of particle matter on the sea floor.<br />

• Stresses originating from change of grain size in the sediment layer caused by the particle<br />

depositions.<br />

In order to calculate these stressors, a variety of input information must be made available. This<br />

chapter describes the information that has been applied as input to the DREAM calculations in the<br />

Pumbaa exploration drilling case (PL469).<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

19

3.2 Location<br />

The co-ordinates of the Pumbaa exploration drilling case (PL469) are 64° 09’ 40.44” N 7° 48’<br />

27.87” E. The water depth is 307 meter. A map of the location is shown in Figure 3.1.<br />

Figure 3.1 Location of the Pumbaa exploration drilling well (PL469).<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

20

3.3 Particle size of the natural sediment<br />

The model calculates the stresses caused by the deposition of grains that have sizes that are<br />

different from the natural grain sizes on the actual location. Therefore, the actual natural grain size<br />

on the location should be known.<br />

However, no surveillance has (so far) been carried out at the actual location. The natural grain size<br />

at the location is therefore not known. Therefore, the natural grain size has been judged to be<br />

about 0.1 mm based on information found in ERMS project report No 12 (available at:<br />

http://www.sintef.no/Projectweb/ERMS/ ). This report shows median particle sizes of natural<br />

sediment as a function of water depth on the Norwegian Continental Shelf. But the results related<br />

to natural grain size changes should be considered as rather uncertain due to lack of field data<br />

from the actual location.<br />

3.4 Grain size distributions in the discharge<br />

The discharges consist to a large extent of particles (cuttings, barite and bentonite). Cementing<br />

discharges are neglected. The grain size of cuttings particles have been investigated by Saga<br />

(1994). A typical distribution found by them is given in Table 3.1.<br />

Table 3.1 Grain size distributions of cuttings particles measured during an exploration<br />

drilling in the Barents Sea. From Saga (1994). Density of cuttings 2500 kg/m 3 .<br />

DRILL CUTTINGS<br />

Diameter Weight Density Velocity Velocity<br />

mm % SG m/s m/day<br />

0.007 10 2.5 1.9E-05 1.7<br />

0.015 10 2.5 8.8E-05 7.6<br />

0.025 10 2.5 2.5E-04 21.2<br />

0.035 10 2.5 4.8E-04 41.6<br />

0.05 10 2.5 9.8E-04 84.9<br />

0.075 10 2.5 2.2E-03 191.0<br />

0.2 10 2.5 1.6E-02 1356.5<br />

0.6 10 2.5 5.7E-02 4898.9<br />

3 10 2.5 2.1E-01 17988.5<br />

7 10 2.5 3.2E-01 27483.8<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

21

Other particle ingredients in the discharge include barite as the weight material. A particle size<br />

distribution found by Saga (1994) for barite particles is shown in Table 3.2.<br />

Table 3.2 Grain size distributions of barite particles measured during an exploration drilling<br />

in the Barents Sea (Saga 1994). The sampling of the barite is taken at the shaker,<br />

after the particles have been through the drill pit.<br />

BARITE PARTICLES<br />

Diameter Weight, Density, Velocity, Velocity,<br />

mm % Tones/m3 m/s m/day<br />

0.0007 10 4.2 4.4E-07 0.04<br />

0.001 10 4.2 9.1E-07 0.08<br />

0.002 10 4.2 3.6E-06 0.31<br />

0.003 10 4.2 8.2E-06 0.71<br />

0.005 10 4.2 2.3E-05 1.96<br />

0.009 10 4.2 7.4E-05 6.35<br />

0.014 10 4.2 1.8E-04 15.37<br />

0.018 10 4.2 2.9E-04 25.41<br />

0.028 10 4.2 7.1E-04 61.49<br />

0.05 10 4.2 2.3E-03 196.08<br />

Bentonite is also planned to be used for the upper (top hole) drilling sections. The particle size<br />

distribution assumed for bentonite is shown in Table 3.3. Since the particle size distribution for<br />

the bentonite is not known, it is assumed to be similar to barite (Table 3.2).<br />

Generally, bentonite is a clay-like material with individual particle sizes of order ≤ 1 – 2 μm.<br />

However, experience has shown that this material flocculates to a large extent when discharged to<br />

the sea. The flocculation process causes the formation of larger particles. This process therefore<br />

justifies the use of larger particles sizes for bentonite in the discharge calculations.<br />

Table 3.3 Grain size distribution of the bentonite particles. Density of bentonite is 2500 kg/m 3 .<br />

BENTONITE PARTICLES<br />

Diameter Weight Density Velocity Velocity<br />

mm % tonn/m3 m/s m/day<br />

0.0007 10 2.5 5.78E-07 0.05<br />

0.001 10 2.5 2.31E-06 0.20<br />

0.002 10 2.5 5.2E-06 0.45<br />

0.003 10 2.5 9.24E-06 0.80<br />

0.005 10 2.5 1.44E-05 1.25<br />

0.009 10 2.5 5.78E-05 4.99<br />

0.014 10 2.5 0.00013 11.23<br />

0.018 10 2.5 0.000231 19.96<br />

0.028 10 2.5 0.000924 79.85<br />

0.05 10 2.5 0.00283 244.53<br />

SUM 100<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

22

“Particles” related to cementing discharges are neglected. These discharges deposit normally<br />

rather close to the wellhead, of order 5 – 10 m from the wellhead for the top hole sections.<br />

Cementing discharges from the drilling rig are usually small, compared to the drilling discharges.<br />

3.5 PNEC’s for particles and components in the mud packages used.<br />

Particle groups. The PNEC levels for particles in the water column have been considered for<br />

barite and bentonite as a part of the ERMS project (ERMS, 2008). For other particle groups, no<br />

PNEC values are available.<br />

Added chemicals. Various chemical mud packages are planned to be used for the various drilling<br />

sections. For EIF calculations, only non-PLONOR chemicals are included. For the present case, a<br />

chemical Glydrill is included for the discharges from the drilling rig. The PNEC for Glydrill<br />

(water soluble) is given in Table 3.4, along with the PNEC’s assumed for the various particle<br />

groups.<br />

Table 3.4 PNEC’s for various particle groups and non-PLONOR chemicals.<br />

Particle/component PNEC, ppm Reference<br />

Bentonite 0.088 From ERMS project (2008)<br />

Barite 0.200 From ERMS project (2008)<br />

Grydrill 0.310 HOCNF scheme<br />

3.6 PNEC’s for heavy metals in sediment<br />

Some of the particle groups contain heavy metals. These may dissolve into the pore water when<br />

the particles enter the sediment compartment. The heavy metals may thus contribute to toxicity in<br />

the pore water.<br />

In the present project, heavy metals in barite and bentonite are included. The actual concentrations<br />

are derived from HOCNF info.<br />

The EIF method for sediment includes subtraction of background concentration levels of heavy<br />

metals before the partition of the metals into the pore water is calculated. Cuttings in the discharge<br />

are assumed to contain background heavy metal concentrations for the sediment. Therefore, heavy<br />

metals in cuttings are assumed not to contribute to toxicity in the sediment. However, the barite<br />

and bentonite may contribute to toxicity of heavy metals in the pore water in the case that the<br />

content of heavy metals in these particle groups exceeds the background heavy metal<br />

concentration levels.<br />

The background metal levels in the sediment on the drilling location are not known. Therefore,<br />

the Table 3.5 shows the background concentrations of heavy metals in the sediment as average<br />

values for the whole Norwegian Continental Shelf (NCS). These are therefore used as a substitute<br />

for the background heavy metal concentration at Pumbaa drilling location. The HOCNF info for<br />

the metal contents in barite and bentonite shows that the metal contents exceed the average heavy<br />

metal levels (NCS averages) in the sediment in the area for some of the metals. Therefore,<br />

environmental risks caused by heavy metals in barite and bentonite are included in the DREAM<br />

risk calculations. But the results for the heavy metal impacts in the sediment may be uncertain due<br />

to lack of measurements at the actual field location.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

23

Table 3.5 Background average values for the heavy metal content in the sediment on the<br />

Norwegian Continental Shelf, based on the MOD data base.<br />

Metal<br />

Average heavy metal content in sediment, average values<br />

for the Norwegian Continental Shelf<br />

(mg/kg sediment)<br />

Cadmium (Cd) 0.037<br />

Chromium (Cr) 40<br />

Copper (Cu) 4.1<br />

Mercury (Hg) 0.021<br />

Lead (Pb) 10.7<br />

Zinc (Zn) 20.7<br />

3.7 Time duration of the discharges<br />

When drilling an exploration well, the duration is expected to last for two to three months. In<br />

practice, there are long periods with no drilling (and discharges) at all due to other activities. In<br />

the DREAM simulations, only “effective” drilling time is therefore considered. This allows the<br />

duration of all the simulation periods to be reduced considerably. The duration per drilled section<br />

is estimated from a penetration rate during drilling to be within the interval 10 – 25 m/hour, the<br />

lowest penetration rates for the top hole sections. This allows all discharges to be simulated within<br />

a considerable shorter time span (saves computer time).<br />

3.8 Discharge configurations<br />

The fate of a discharge to the sea is in part dependent on the discharge configuration. For the top<br />

hole sections (36” and 26”), the discharges take place directly to the sea floor. The discharges for<br />

the top hole sections are therefore assumed to have a diameter equal to the diameter of the section<br />

drilled, directed upwards. The discharge is denser than the ambient water, and will therefore sink<br />

down on the sea floor rather immediately.<br />

For the deeper drilling sections (17 ½” sections and smaller), the discharges will take place from<br />

the drilling rig at 18 m depth. For such a case, an underwater plume will form, bringing the<br />

discharge downwards. If the ambient water is stratified (like temperature stratification caused by<br />

the summer heating of the water masses), the plume is expected to level out at some depth. The<br />

discharge is after the entrapment of the plume assumed to be transported away with the ambient<br />

currents. The particle matter (cuttings and barite discharged from the drilling rig) will partly be<br />

transported away with the currents (smaller particles) and partly sink down on the sea floor<br />

according to its size and density (larger particles).<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

24

3.9 Summer heating stratification<br />

The summer heating in the Norwegian Sea causes the surface water masses to undergo an increase<br />

in temperature in the summer and early autumn. The rise in temperature causes a density decrease<br />

of the water masses. The temperature (and salinity) stratification applied in the discharge<br />

simulations are based on field data from the Norne field. Table 3.6 shows the actual stratification<br />

in the ambient that has been applied (late summer/autumn).<br />

Table 3.6 Ambient summer stratification assumed for the Pumbaa exploration drilling<br />

location. Data from the Norne field.<br />

Depth m Temperature °C Salinity<br />

0 10.76 34.738<br />

35 10.75 34.745<br />

45 10.62 34.778<br />

55 9.17 35.012<br />

105 7.99 35.182<br />

285 6.78 35.129<br />

400 6.78 35.129<br />

3.10 Ambient winds and currents conditions<br />

The DREAM model uses simulated three-dimensional and time variable ocean currents for the<br />

actual area. This type of data secures that the behavior (actual time and space variability) of the<br />

discharges in the ambient sea is included in the simulations. For the actual case, simulated current<br />

data based on output from the ECOM 3D model operated by Met.no (Det Norske Meteorologiske<br />

Institutt, Oslo) has been used. The year simulated is 2000 with a horizontal resolution of 4 km.<br />

Figure 3.2 shows a snapshot of the current direction and velocity for the surface layers together<br />

with the discharge locations shown.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

25

Figure 3.2. Snapshot showing an example of the currents taken from the month of June in the<br />

Pumbaa area. Drilling location is shown as well.<br />

3.11 Discharge setup for the various drilling sections<br />

Table 3.7 shows details of the discharge setup for the Pumbaa exploration (PL469) case.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

26

Table 3.7 Input data for exploration drilling at the Pumbaa location (PL 469) in the Norwegian Sea.<br />

Drilling section: Base case: 42” drilling 36” drilling 9.875 “ pilot 26” drilling 17.5” drilling 12.25” drilling<br />

Start of discharge, h 1) 0 24 24 24 24 24<br />

Section length, m: 22 50 478 386 190 571<br />

Drilling rate m/h 10 10 25 20 25 25<br />

Discharge depth, m 1 m above sea floor 1 m above sea floor 1 m above sea floor 1 m above sea floor 18 m below sea surface 18 m below sea surface<br />

Diameter of outlet opening (m) 1.0668 0.9144 0.254 0.66 0.4 0.4<br />

Orientation of outlet opening Vertically upwards Vertically upwards Vertically upwards Vertically downwards Vertically downwards Vertically downwards<br />

Duration 2) : 2.2 hours 5 hours 19.12 hours 19.3 hours 7.6 hours 22.84 hours<br />

Compound Amounts Amounts Amounts Amounts Amounts Amounts<br />

Components in discharge Tonnes tonnes tonnes tonnes tonnes tonnes<br />

Particles Cuttings 49.16 82.086 58.6594 330.545 73.71 108.439<br />

Particles Bentonite 6.43 10.84 16.38 47.81 0 0<br />

Particles Barite 31.62 53.29 28.58 123.88 36.76 143.27<br />

Chemical Glydrill 0 0 0 0 4.91 9.13<br />

Sum MUD 3) 78.05 137.13 293.96 762.69 147.67 269.4<br />

1) Start of discharge is time elapsed before starting discharge for this section (i.e. time passed after the previous discharge ends). Unit in hours.<br />

2) Automatically calculated by the model.<br />

3) Includes water and PLONOR chemicals in addition<br />

Table 3.7 continue Metals attached to barite and bentonite in Pumbaa drilling case,<br />

Weight ratio – ppm 5)<br />

Attached/ Attached/<br />

Barite Bentonite<br />

Cadmium Cd 0.123 0.523<br />

Chromium Cr 4.1 0<br />

Copper Cu 71.9 19.5<br />

Mercury Hg 0.0104 0.3994<br />

Lead Pb 61.7 19.7<br />

Zinc Zn 0 36.3<br />

5)<br />

The weight ratio only includes the heavy metal content in the grain size group (barite and bentonite) in excess of the natural metal content in the sediment.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc

3.12 Presence of corals<br />

The presence of corals in the area has been surveyed by Fugro (2008). Local site information is<br />

shown in Figure 3.3. Double-lines with arrows indicate plough marks caused by the motion of<br />

icebergs. Lines with squares indicate ridges. Blue areas indicate the presence of corals. The<br />

associated numbers to the blue areas indicate maximum height of the corals, and yellow<br />

background indicates the bottom of silty sand. The distance from the proposed drilling location to<br />

the nearest coral is 280 (direction S – SW).<br />

The figure shows that the main presence of corals is found in direction to the south and east of the<br />

proposed well location. Also note the large coral structure of 12.5 m height to the SW of the<br />

proposed drilling location (distance about 860 m and beyond).<br />

Figure 3.3 Location of exploration well Pumbaa and the presence of corals in the area.<br />

Double-lines with arrows indicate plough marks caused by ice bergs. Lines with<br />

squares indicate ridges, magenta areas indicate the presence of corals. The<br />

numbers associated with the magenta areas indicate maximum height of the corals.<br />

Yellow background indicates the bottom of silty sand. The distance from the<br />

proposed drilling location to the nearest coral is 280m (direction S – SW). Copied<br />

from Fugro (2008). The Draugen field name is identical with the Pumbaa<br />

exploration field.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

28

280 m<br />

Figure 3.4 Close-up picture of the presence of the corals closest to the planned well location.<br />

Distance and direction to the nearest coral is indicated. For explanation of<br />

symbols, see figure text in Figure 3.3. Copied from Fugro (2008). The Draugen<br />

field name is identical with the Pumbaa exploration field.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

29

4 EIF Results<br />

4.1 General<br />

The EIF value expresses the potential risk for damage to the recipient. It is aimed at guiding the<br />

operator on the expected environmental benefits from the options available to reduce<br />

environmental risk. The parameter that expresses the environmental benefit is the reduction of the<br />

EIF, expressing the reduced size of the water volume or sediment area that may have a potential<br />

for environmental damage. The reduced size of the area or volume expressed through the EIF<br />

parameter, and the duration of the potential impact, thus serve as guidance on the environmental<br />

benefits from various options.<br />

It should be stressed that the size of the area or water volume calculated does not mean that an<br />

environmental damage is to be expected within the area/volume indicated by the EIF value. There<br />

is some degree of conservatism built into the PNEC values used when the size of the area/volume<br />

for potential impact is calculated. This is true in particular for toxicity of added chemicals and<br />

heavy metals in sediment.<br />

Chapters 4.1 – 4.5 show the EIF results from the planned exploration drilling operation. The<br />

results are presented in a set of figures. The following figures are shown:<br />

For the water column:<br />

• Time series of the EIF value<br />

• Pie chart for the risk contributors<br />

• Instantaneous risk calculated for the instant with maximum risk in the water<br />

column, including vertical cross section<br />

For the water column, two sets of figures are presented. These are one set of figures from the<br />

water column impact caused by the discharges from the rig (upper water column impact), and one<br />

set of figures from the water column impact caused by the discharges at the sea floor (lower water<br />

column impact).<br />

For the sediment:<br />

• Time series of the EIF value<br />

• Pie chart for the risk contributors<br />

• Accumulated risk calculated for the simulation period<br />

• Total deposition in mm (burial)<br />

• Cross section of the extent of burial on the sea floor through the selected coral<br />

locations (mm)<br />

• Time series of particle (barite and bentonite) concentrations in the water column<br />

for selected coral locations<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

30

4.2 EIF Results for the upper water column<br />

EIF results for the upper water column are shown in Figures 4.1 – 4.3. Results from the<br />

calculations are discussed in chapter 4.5.<br />

Simulated instantaneous EIF: 2255<br />

Components Product PNEC ppb Contribution to risk Contribution EIF<br />

Total<br />

EIF_Cadmium_Bentonite 0.34 0 0<br />

EIF_Copper_Bentonite 1.1 0 0<br />

EIF_Mercury_Bentonite 0.01 0 0<br />

EIF_Lead_Bentonite 11 0 0<br />

EIF_Zinc_Bentonite 6.6 0 0<br />

EIF_Cadmium_Barite 0.34 0 0<br />

EIF_Chromium_Barite 8.5 0 0<br />

EIF_Copper_Barite 1.1 0.28 6.3139<br />

EIF_Mercury_Barite 0.01 0 0<br />

EIF_Lead_Barite 11 0.01 0.2255<br />

Glydril MC 310 3.34 75.3158<br />

EIF_Cuttings_25 100000 0.08 1.8040<br />

EIF_Bentonite 88 0 0<br />

EIF_Barite 200 96.29 2171.3063<br />

Weighted contribution to risk, EIF = 2255<br />

EIF_Barite<br />

97%<br />

Glydril MC<br />

3%<br />

Figure 4.1 Table and pie-chart with EIF results for the upper water column.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

31

Weighted EIF<br />

2500<br />

2000<br />

1500<br />

1000<br />

500<br />

0<br />

Time development chart<br />

0.0<br />

0.5<br />

1.0<br />

1.5<br />

2.0<br />

2.5<br />

3.0<br />

3.5<br />

4.0<br />

4.5<br />

5.0<br />

5.5<br />

6.0<br />

6.5<br />

7.0<br />

7.5<br />

8.0<br />

8.5<br />

9.0<br />

Time (days)<br />

Figure 4.2 Time development of the EIF for the upper water column.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

9.5<br />

10.0<br />

EIF_Barite<br />

EIF_Bentonite<br />

EIF_Cuttings_25<br />

Glydril MC<br />

EIF_Lead_Barite<br />

EIF_Mercury_Barite<br />

EIF_Copper_Barite<br />

EIF_Chromium_Barite<br />

EIF_Cadmium_Barite<br />

EIF_Zinc_Bentonite<br />

EIF_Lead_Bentonite<br />

EIF_Mercury_Bentonite<br />

EIF_Copper_Bentonite<br />

EIF_Cadmium_Bentonite<br />

Figure 4.3 Snapshot showing the time instant with maximum risk for the upper water<br />

column.<br />

32

4.3 EIF Results for the lower water column.<br />

EIF results for the lower water column are shown in Figures 4.4 – 4.6. Results from the<br />

calculations are discussed in chapter 4.5.<br />

Simulated instantaneous EIF: 157<br />

Components Product PNEC ppb Contribution to risk Contribution EIF<br />

Total<br />

EIF_Cadmium_Bentonite 0.34 0 0<br />

EIF_Copper_Bentonite 1.1 0.01 0.01567<br />

EIF_Mercury_Bentonite 0.01 0.02 0.03134<br />

EIF_Lead_Bentonite 11 0 0<br />

EIF_Zinc_Bentonite 6.6 0 0<br />

EIF_Cadmium_Barite 0.34 0 0<br />

EIF_Chromium_Barite 8.5 0 0<br />

EIF_Copper_Barite 1.1 0.22 0.34469<br />

EIF_Mercury_Barite 0.01 0 0<br />

EIF_Lead_Barite 11 0.01 0.01567<br />

Glydril MC 310 0 0<br />

EIF_Cuttings_25 100000 0.12 0.18801<br />

EIF_Bentonite 88 52.07 81.58218<br />

EIF_Barite 200 47.55 74.50034<br />

EIF_Barite<br />

48%<br />

Weighted contribution to risk, EIF = 157<br />

EIF_Bentonite<br />

52%<br />

Figure 4.4 Table and pie-chart with EIF results for the lower water column.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

33

Weighted EIF<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

0<br />

1<br />

2<br />

3<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

18<br />

104<br />

375<br />

Time development chart<br />

Time (days)<br />

645<br />

915<br />

1185<br />

1455<br />

1725<br />

1995<br />

2265<br />

2535<br />

2805<br />

3075<br />

3345<br />

3615<br />

Figure 4.5 Time development of the EIF for the lower water column.<br />

EIF_Barite<br />

EIF_Bentonite<br />

EIF_Cuttings_25<br />

Glydril MC<br />

EIF_Lead_Barite<br />

EIF_Mercury_Barite<br />

EIF_Copper_Barite<br />

EIF_Chromium_Barite<br />

EIF_Cadmium_Barite<br />

EIF_Zinc_Bentonite<br />

EIF_Lead_Bentonite<br />

EIF_Mercury_Bentonite<br />

EIF_Copper_Bentonite<br />

EIF_Cadmium_Bentonite<br />

Figure 4.6 Snapshot showing the time instant with maximum risk for the lower water column.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

34

4.4 EIF Results for the sediment.<br />

EIF results for the sediment are shown in Figures 4.7 – 4.9. Results from the calculations are<br />

discussed in chapter 4.5.<br />

Simulated instantaneous EIF: 58<br />

Components Product PNEC ppb Contribution to risk Contribution EIF<br />

Total<br />

EIF_Cadmium_Bentonite 0.34 0 0<br />

EIF_Copper_Bentonite 1.1 0.03 0.0175<br />

EIF_Mercury_Bentonite 0.01 0.09 0.0526<br />

EIF_Lead_Bentonite 11 0 0<br />

EIF_Zinc_Bentonite 6.6 3.18 1.8588<br />

EIF_Cadmium_Barite 0.34 1.64 0.9586<br />

EIF_Chromium_Barite 8.5 0.02 0.0117<br />

EIF_Copper_Barite 1.1 76.23 44.5577<br />

EIF_Mercury_Barite 0.01 0 0<br />

EIF_Lead_Barite 11 7.47 4.3663<br />

Glydril MC 310 0 0<br />

Thickness 0 2.13 1.2450<br />

Oxygen 0 0 0<br />

Grain size 0 9.2 5.3775<br />

Thickness<br />

2%<br />

EIF_Lead_Barite<br />

7%<br />

Grain size<br />

9%<br />

Weighted contribution to risk, EIF = 58<br />

EIF_Zinc_Bentonite<br />

3%<br />

EIF_Cadmium_Barite<br />

2%<br />

EIF_Copper_Barite<br />

77%<br />

Figure 4.7 Table and pie-chart with EIF results for the sediment.<br />

I:\prosjekt\8016-Marin_miljoteknologi\MK801195_Geitefjellet_eksploration_drilling_HR\Adm\Notater_Rapporter\Final_Report PL469 EIF.doc<br />

35

Weighted EIF<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

0<br />

1<br />

2<br />

3<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

18<br />

104<br />

375<br />

Time development chart<br />

Time (days)<br />