Development of low-nickel austenitic stainless-steel wire for forming ...

Development of low-nickel austenitic stainless-steel wire for forming ...

Development of low-nickel austenitic stainless-steel wire for forming ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Development</strong> <strong>of</strong> <strong>low</strong>-<strong>nickel</strong><br />

<strong>austenitic</strong> <strong>stainless</strong>-<strong>steel</strong> <strong>wire</strong> <strong>for</strong><br />

<strong>for</strong>ming, grids, springs…<br />

JM. Hauser 1 , E. Chauveau 1 , L. Antoni 1 ,B. Héritier 1 ,<br />

A. Sage 2<br />

1 - Ugine-Savoie Imphy<br />

Avenue Paul-Girod F73400 Ugine<br />

2 - Sprint-Métal Immeuble Pacific<br />

13, Cours Valmy F-92070 La Défense Cedex<br />

A new 16.2 % Cr- 7.5% Mn – 3 %Cu- 0.2%N –<br />

1.9% Ni <strong>austenitic</strong> <strong>steel</strong> may substitute to 304. Its<br />

metallurgical , magnetic, and mechanical<br />

properties are presented here. It is oxidation<br />

resistant up to 800°C. Its corrosion resistance is<br />

equivalent to that <strong>of</strong> 304 <strong>for</strong> many applictions ,<br />

including gratings, grids, springs,….<br />

1. INTRODUCTION<br />

Standard <strong>austenitic</strong> <strong>stainless</strong> <strong>steel</strong>s, such as<br />

304,are prone to large price variations in relation with<br />

the economical cycles and with the <strong>nickel</strong> price .<br />

Steadinox, also called 204Cu, a <strong>low</strong>-<strong>nickel</strong> <strong>austenitic</strong><br />

grade containing manganese, copper and nitrogen,<br />

was designed to be able to replace 304 in most 304<br />

<strong>wire</strong> applications. Its typical composition is (mass%) :<br />

0.05 C - 0.8 Si- 7.5 Mn -1.9 Ni - 16.2 Cr- 0.3 Mo - 3<br />

Cu-0.2 N - 0.0025 B - 0.001 S - 0.025 P ; it is in<br />

accordance with UNS S20430 (204Cu) and under<br />

european EN10088 standardisation procedure<br />

(X8CrMnCuNB17-8-3 ) .<br />

Similar <strong>stainless</strong> <strong>steel</strong>s have been already studied<br />

[1][2][3][4][5] , although this one is somehow<br />

differently equilibrated, to be in ferritic solidification<br />

mode ( weldable), without too much high<br />

temperature ferrite ( hot-workable) and with<br />

sufficiently <strong>low</strong> carbon to avoid ICS after most<br />

operations. A small quantity <strong>of</strong> <strong>nickel</strong> contributes to<br />

adequate phase equilibrium as well as to sufficient<br />

resistance to crevice corrosion; the medium level <strong>of</strong><br />

silicon was designed to obtain fairly good oxidation<br />

resistance despite <strong>of</strong> the high level <strong>of</strong> manganese.<br />

Austenite stability was adapted to obtain the same<br />

level <strong>of</strong> work-hardening coefficient as that <strong>of</strong> 304, and<br />

there<strong>for</strong>e equivalent tensile ductility.<br />

1- METALLURGICAL, MECHANICAL AND<br />

PHYSICAL PROPERTIES<br />

2.1 Phases<br />

As-cast or as-welded structures exhibit a few %<br />

remaining ferrite, mainly on dendritic axis; thus, it<br />

solidifies in a ferritic mode, which is prefered to avoid<br />

hot-cracking . After hot-rolling and quench-annealing<br />

at 1050°C, a fully <strong>austenitic</strong> structure is obtained<br />

(ferrite < 0.5% ).<br />

2.2 Mechanical properties and cold-working ;<br />

amagnetism<br />

Tensile properties <strong>of</strong> the annealed material are<br />

slightly higher than those <strong>of</strong> 304, due mainly to the<br />

hardening effect <strong>of</strong> nitrogen ( table 1 ).<br />

Table 1 -Tensile properties<br />

( φ 5.5 mm rod-<strong>wire</strong>, annealed, typical)<br />

Y.S. T.S. Elongation<br />

Mpa MPa %(5d)<br />

Steadinox 340 675 60<br />

304 235 600 62<br />

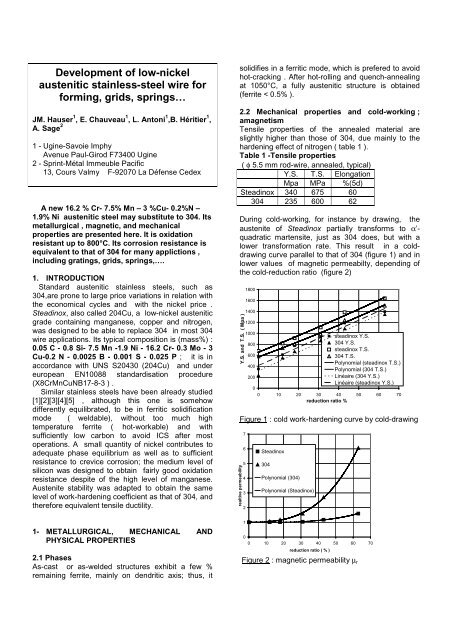

During cold-working, <strong>for</strong> instance by drawing, the<br />

austenite <strong>of</strong> Steadinox partially trans<strong>for</strong>ms to α’quadratic<br />

martensite, just as 304 does, but with a<br />

<strong>low</strong>er trans<strong>for</strong>mation rate. This result in a colddrawing<br />

curve parallel to that <strong>of</strong> 304 (figure 1) and in<br />

<strong>low</strong>er values <strong>of</strong> magnetic permeabilty, depending <strong>of</strong><br />

the cold-reduction ratio (figure 2)<br />

Y.S. and T.S. ( Mpa )<br />

realtive permeability<br />

1800<br />

1600<br />

1400<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

0<br />

0 10 20 30 40 50 60 70<br />

reduction ratio %<br />

Figure 1 : cold work-hardening curve by cold-drawing<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

Steadinox<br />

304<br />

Polynomial (304)<br />

Polynomial (Steadinox)<br />

Figure 2 : magnetic permeability µr<br />

steadinox Y.S.<br />

304 Y.S.<br />

steadinox T.S.<br />

304 T.S.<br />

Polynomial (steadinox T.S.)<br />

Polynomial (304 T.S.)<br />

Linéaire (304 Y.S.)<br />

Linéaire (steadinox Y.S.)<br />

0<br />

0 10 20 30 40 50 60 70<br />

reduction ratio ( % )

3. HIGH TEMPERATURE BEHAVIOUR<br />

3.1 Mechanical behaviour<br />

Annealed 204Cu <strong>wire</strong>s exhibit high tensile strength,<br />

at the same level as AISI 347 [6], up to 800°C<br />

(figures 3 ), with secondary hardening in the range<br />

500-800°C, due probably to chromium nitride<br />

precipitation ( no sigma phase was observed in that<br />

range ) .<br />

Y.S., U.T.S. ( Mpa)<br />

Y.S. ( Mpa )<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

400<br />

300<br />

200<br />

100<br />

STEADINOX<br />

EL %<br />

U.T.S.<br />

Y.S.<br />

EL%<br />

0<br />

0<br />

0 200 400 600 800 1000<br />

Temperature °C<br />

316L<br />

steadinox<br />

347<br />

304<br />

321<br />

0<br />

0 200 400 600 800<br />

Temperature °C<br />

1000<br />

Figures 3 : high temperature tensile properties<br />

100<br />

3.2 Scaling<br />

High temperature oxidation properties <strong>of</strong> Steadinox<br />

has been compared with that <strong>of</strong> a classical AISI 304<br />

(18.0 Cr 11.1Ni 1.3 Mn 0.5 Si 0.05 C 0.04 N bal.<br />

Fe),using cylindrical samples (φ4x30 mm) from<br />

industrial <strong>wire</strong>s. Metal losses were measured after<br />

descaling the samples by a chemical procedure [7].<br />

The maximum operation temperature Tmax <strong>of</strong> these<br />

grades has been determined fol<strong>low</strong>ing the definition<br />

incorporated in the draft <strong>of</strong> EN 10295 [8], known as<br />

the 5 x 24 h test. The results are presented in figure<br />

4. It can be deduced that Tmax is almost the same<br />

<strong>for</strong> both grades and equals 870°C.<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

Metal Loss (g/m²/h)<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

T max : Metal loss < 1 g/m²/h at T max<br />

and Metal loss < 2 g/m²/h at T max+50°C<br />

steadinox<br />

304<br />

0<br />

650 750 850<br />

Temperature (°C)<br />

950 1050<br />

Figure 4 : Metal loss vs. temperature plots <strong>for</strong><br />

the isothermal oxidation in still air <strong>of</strong> alloys<br />

Steadinox and 304 after 5 x 24 h testing time.<br />

The resistance to thermal cycling <strong>of</strong> these materials,<br />

which can strongly influence their lifetime in service<br />

conditions [9] has been characterized at 800°C up to<br />

1200 cycles (or 400 h total dwell time) using a severe<br />

thermal cycle described elsewhere [7]. Figure 5<br />

indicates that both grades behave analogously.<br />

Metal Loss (g/m²)<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

number <strong>of</strong> cycles<br />

0 300 600 900 1200<br />

steadinox<br />

304<br />

0 100 200 300 400<br />

Total Dwell Time (h)<br />

Figure 5 : Metal loss vs. total dwell time plots<br />

<strong>for</strong> the cyclic oxidation in still air <strong>of</strong> alloys<br />

Steadinox and 304 at 800°C (thermal cycle :<br />

20 min dwell time, 5 min air <strong>for</strong>ced cooling)

4 . CORROSION RESISTANCE : GENERAL<br />

BEHAVIOUR<br />

This part includes a comparison <strong>of</strong> Steadinox, 430<br />

(1.4016) and 304 (1.4301) <strong>for</strong> different types <strong>of</strong><br />

corrosion in several chemical solutions.<br />

4.1 CORROSION RESISTANCE IN A HIGHLY<br />

CHLORINATED MEDIUM : CREVICE CORROSION<br />

In some complicated confined areas, an acid solution<br />

may exist, by the crevice corrosion mechanism,<br />

which is studied by several electrochemical tests.<br />

Electrochemical test <strong>for</strong> crevice corrosion :<br />

measurement <strong>of</strong> depassivation pH : the <strong>low</strong>er this<br />

pHd, the higher the corrosion resistance ; pHd is<br />

evaluated using the dissolution current on a<br />

polarisation curve at different pH values (1,5 à 3) in a<br />

highly chlorinated ( 2M ) solution at 23°C : pHd is<br />

obtained at 10 µA/cm².<br />

Figure 6 shows the variation <strong>of</strong> the dissolution<br />

current at several pH values <strong>for</strong> 304 , Steadinox and<br />

430. .<br />

i critical (µA/cm²)<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

CREVICE CORROSION TEST in NaCl 2M, 23°C<br />

430<br />

Steadinox<br />

304<br />

0<br />

1,5 1,7 1,9 2,1 2,3 2,5 2,7 2,9 3,1<br />

Figure 6 : electrochemical dissolution current<br />

Steadinox appears to be equivalent to 304 :same<br />

depassivation pH and same speed <strong>of</strong> crevice’s<br />

growth ( represented by the slope <strong>of</strong> the curve ) .<br />

4.2 STRESS CORROSION RESISTANCE<br />

Stress corrosion resistance is studied by tensile<br />

testing in a solution <strong>of</strong> MgCl2 boiling at 155°C : it is<br />

defined as the critical de<strong>for</strong>mation speed, under<br />

which the tensile strength and the rupture elongation,<br />

measured in corrosive solution, are <strong>low</strong>er than those<br />

in an inert silicon oil ( or <strong>low</strong>er than at very high<br />

speed <strong>of</strong> de<strong>for</strong>mation in corrosive solution ) .<br />

Steadinox and 304 both have a critical speed <strong>of</strong><br />

about 2.10 -3 s -1 , and are thus equivalent .<br />

pH<br />

4.3 PITTING CORROSION RESISTANCE IN A<br />

WEAKLY CHLORINATED SOLUTION<br />

4.3.1 Methods<br />

Pitting corrosion was studied <strong>for</strong> NaCl 0,02M to 2M ;<br />

pH 2 to 6,6 ; temperature 23°C to 50°C ; with or<br />

without an oxidizing agent in the solution.<br />

Using the OCP (Open Circuit Potential)<br />

electrochemical test, the potential <strong>of</strong> the sample in a<br />

corrosive solution was measured along 5 days<br />

,leading to different kinds <strong>of</strong> behaviour :<br />

*behaviour A : stable potential, no corrosion on the<br />

sample,<br />

*behaviour B : some variations <strong>of</strong> the potential; the<br />

depth and the length <strong>of</strong> the variations are small :<br />

unstable repassivating pits ; corrosion is not<br />

dangerous in these conditions ;<br />

*behaviour C : deep variations <strong>of</strong> potential (very<br />

cathodic potential’s value <strong>for</strong> example) : pits are<br />

growing ; there is pitting corrosion on the sample.<br />

4.3.2 Corrosion resistance in a neutral solution<br />

Hooks out <strong>of</strong> Steadinox, 430 and 304 were tested in<br />

NaCl 5% ( 0.86 M ), pH 6,6 at 35°C ( figure 7 ) . This<br />

medium is equivalent to that <strong>of</strong> the salt spray test<br />

(French standard NFX41002 )<br />

On Steadinox, the number <strong>of</strong> variations <strong>of</strong> potential<br />

were small ( behaviour B , close to behaviour A ) ;<br />

there was no corrosion neither on Steadinox nor on<br />

304 (430 exhibits stable pits with corrosion ,<br />

behaviour C).<br />

304 behaviour A<br />

Steadinox<br />

behaviour A<br />

430 behaviour C<br />

Figure 7 : Hooks in a neutral solution : OCP test

4.3.3 Corrosion resistance in a highly chlorinated<br />

warm solution NaCl 2M , pH 6,6 , 50°C, with oxygen<br />

bubbling<br />

430 exhibits stable pits ( behaviour C), whereas <strong>for</strong><br />

Steadinox, the <strong>for</strong>mation <strong>of</strong> pits is limited and they<br />

are not growing ( behaviour B ) : Steadinox<br />

behaviour is better than 430 , in these pitting<br />

corrosion conditions .<br />

4.3.4 Corrosion resistance in a weakly chlorinated<br />

solution with oxidizing agent<br />

After a first 24 h step in NaCl 0,02M, pH 6,6 ,<br />

23°C ,the solution is changed to : NaCl 0,02M or<br />

0,5M , pH 6,6 , 23°C , together with an oxidizer<br />

(FeCl3 , 2.10-4 M or 5.10-3M ), which is added to<br />

obtain a very anodic potential.<br />

Such an oxidizer produces, on Steadinox, unstable<br />

pits which don’t grow ( repassivation mechanism ); on<br />

430, numerous unstable pits, with deep potential<br />

variations : the pitting corrosion is more sever on 430.<br />

So, it is possible to use Steadinox in solutions with<br />

an oxidizer, but the use in warm highly-chlorinated<br />

solutions containing an oxidizing agent will need a<br />

more complete study .<br />

4.4 UNIFORM CORROSION RESISTANCE IN ACID<br />

SOLUTIONS<br />

Using an electrochemical test in H2SO4 2M at 23°C ,<br />

dissolution current in microamp/cm2<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

204 Cu very similar to 304<br />

UNIFORM CORROSION H2SO4 2M 23°C<br />

13.7 mA/cm2<br />

304 (1.4301) UGI 204 Cu 430 (1.4016)<br />

Figure 8 : activity current <strong>for</strong> uni<strong>for</strong>m corrosion<br />

a current <strong>of</strong> dissolution (or activity, in opposition to<br />

the passivity current), representing the speed <strong>of</strong><br />

corrosion, was measured on a polarization curve .<br />

In this mechanism, Steadinox behaves as 304 ;<br />

their corrosion speed ( 80 to 90 µA/cm² ) are far<br />

s<strong>low</strong>er than that <strong>of</strong> 430 (13.7 mA/cm² ).<br />

4.5 USE FOR FOOD STORAGE : dissolution in<br />

drinking water and in acetic acid :<br />

The elemental quantities <strong>of</strong> Cu , Ni , Fe, Cr et Mn<br />

dissolving from Steadinox in drinking water (distilled<br />

water with 506 mg/l MgSO4 , 95 mg/l K2SO4 , and<br />

330 mg/l NaCl ; pH = 6.6. ) at 23°C or 70°C are<br />

entirely consistent with the recommanded values <strong>of</strong><br />

World Health Organisation .<br />

In µg/l Cu Ni Mn Fe Cr<br />

Drinking water 23°C<br />

Steadinox<br />

7 2,6 23 90 2,6<br />

Drinking water 70°C<br />

Steadinox<br />

1,7 1,7 100 235 4,4<br />

WHO values<br />

( max )<br />

2000 20 100 300 50<br />

In acetic acid (3 %, 70°C), dissolved elemental<br />

quantities are equivalent <strong>for</strong> Steadinox and 304 (in<br />

µg/dm² ) :<br />

period Cu Ni Mn Fe Cr<br />

Steadinox 0 - 30 mn 2,8 0,4 7,1 106 15,8<br />

30 - 60 mn 0,1 0,1 1,2 5 2<br />

60 - 90 mn 0 0,3 1 1,3 1,2<br />

304 0 – 30 mn -

T2 : 650°C / 10 mn / WQ T1 : 700°C / 30 mn/ WQ<br />

Mas Crack Test Mass Crack Test<br />

loss depth Validatio loss Depth Validation<br />

In mg In µm n in mg in µm<br />

Steadinox 3,7 0 Yes 5 30 Yes<br />

304 nr1 0,5 0 Yes 0,9 0 Yes<br />

304 nr2 2,5 0 Yes 3,4 0 Yes<br />

5 . STUDY OF SOME APPLICATIONS<br />

5.1 PIGSTY GRATINGS<br />

The Steadinox resistance in the synthetic solutions<br />

(50°C ; pH 6,5 ; 0,1M NaCl ; 10ml/l NH4OH ; 25 mg/l<br />

KOH ; 5 mg/l H3PO4) <strong>of</strong> pigsty medium is equivalent<br />

to that <strong>of</strong> 304 ;potential variations in OCP test remain<br />

very limited (figure 9 ).<br />

E (mV/ECS)<br />

Figure 9 : OCP on Steadinox in pigsty medium<br />

5.2 GRIDS FOR FOOD STORAGE<br />

U (en mV/ECS)<br />

100<br />

0<br />

-100<br />

-200<br />

-300<br />

-400<br />

0<br />

-50<br />

-100<br />

-150<br />

-200<br />

-250<br />

-300<br />

-350<br />

0 24 48 72 96 120<br />

exposure( h)<br />

Steadinox<br />

Steadinox: behaviour B<br />

0 10 20 30 40 50 60 70<br />

Temps (en h)<br />

.<br />

Figure 10 : OCP on a Steadinox grid sample<br />

Figure10 represents the OCP result <strong>of</strong> a Steadinox<br />

grid sample in NaCl 5% 35°C pH 6.6, exhibiting a B<br />

behaviour , with some metastable pits ; no corrosion<br />

is visible at the end <strong>of</strong> the test.<br />

5.3 TILE HOOKS FOR ROOFS<br />

Steadinox tile hooks show a good corrosion<br />

resistance in salt environment (salt spray test , 1000<br />

hours, french standard NFX41002 NaCl 5% 35°C pH<br />

6.6 ) and in an industrial environment (test with<br />

sulphur dioxide and dampness condensation over<br />

500 hours) , in spite a very small pitting corrosion .<br />

6 . APPLICATION TO SPRING WIRES<br />

6.1 Mechanical behaviour<br />

Compression springs were made using Steadinox<br />

and 302 cold-drawn <strong>wire</strong>s,at eqivalent U.T.S. levels :<br />

T.S. Y.S. Martensite<br />

MPa Mpa %<br />

Steadinox As-drawn 2090 1750 10<br />

304<br />

180°C<br />

3 mn<br />

2140 10<br />

300°C<br />

3 mn<br />

2290 1920 11<br />

As-drawn 2080 1830 52<br />

180°C<br />

3 mn<br />

2130 1890 52<br />

A short stabilizing treatment ( 3 mn at 180°C or<br />

300°C ) was made on springs. Resistance to sagging<br />

was evaluated by successive limited compressions or<br />

by one full compression .<br />

The sagging resistance (measured by shortening)<br />

<strong>of</strong> Steadinox springs was equivalent to that <strong>of</strong> 304<br />

springs :<br />

SAGGING %<br />

0,12<br />

0,10<br />

0,08<br />

0,06<br />

0,04<br />

0,02<br />

0,00<br />

Steadinox springs,HT300°C<br />

Steadinox springs, HT 180°C<br />

302 springs, HT 180°C<br />

1 full compression<br />

0 2 4 6<br />

Number <strong>of</strong> limited compressions

6.2 Corrosion resistance<br />

The Steadinox and AISI302 spring samples were<br />

tested by Open Circuit Potential in NaCl 5% , 35°C<br />

pH 6.6 after the fol<strong>low</strong>ing treatments :<br />

- stabilizing treatment<br />

- pickling, and passivation , in HNO3 solution.<br />

Both kinds <strong>of</strong> springs behave correctly the OCP test<br />

(A-behaviour).<br />

7. CONCLUSION<br />

Steadinox is similar to 304 in respect to workhardening<br />

and tensile ductility, although being less<br />

magnetic after cold-working. It may be used up to<br />

800°C without excessive oxidation. Steadinox springs<br />

exhibit as <strong>low</strong> sagging as 304 springs<br />

Its corrosion resistance is equivalent to that <strong>of</strong> 304 in<br />

weakly chlorinated mediums ; it was proved by OCP<br />

or exposure tests that it may be used as <strong>for</strong>med<br />

<strong>wire</strong>s or welded assemblies, grids,… in lot <strong>of</strong> usual<br />

mediums, and in body-, food- or water-contact.<br />

Finally, Steadinox may replace 304 in most <strong>wire</strong><br />

applications .<br />

REFERENCES<br />

[1] J.H.MAGEE <strong>Development</strong> <strong>of</strong> type 204 CU<br />

<strong>stainless</strong>, a <strong>low</strong> cost alternate to type 304<br />

Inter<strong>wire</strong> Conf., 2001-05-14,Atlanta, ed .Wire Ass.Int.<br />

[2) M.G.MECOZZI et al. Un acciao inossidable<br />

<strong>austenitic</strong>o con nichel inferiore al 2 %<br />

La Metallurgia Italiana 10/99 pp 49-55<br />

[3] R.SANCHEZ et al. Properties <strong>of</strong> an <strong>austenitic</strong><br />

<strong>stainless</strong> with less than 2% <strong>nickel</strong><br />

Innovation in Stainless Steel Conf, Florence,It.,<br />

11-14/10/1993 pp 2-231-2.236,<br />

ed.Ass.Ital.Metallurgia 1993<br />

[4] M.B.CORTIE et al.<br />

Experimental <strong>austenitic</strong> <strong>stainless</strong> <strong>steel</strong>s containing<br />

7% Mn, 2%Ni and up to 4% Cu ,<br />

High manganese high Nitrogen Austenitic Steels<br />

Conf.Proc. ed R.A.LULA / ASM (1992) pp177-185<br />

[5] K.. HOSHINO et al. The various characteristics <strong>of</strong><br />

Ni-free <strong>austenitic</strong> Stainless Steels, type NHS104<br />

Tool & Alloy Steels vol 8 (1974 ) n°1 pp 84-94<br />

Steel Furnace Monthly,1974 (9), 5, pp325-340<br />

[6] J.H.HOKE Mechanical properties <strong>of</strong> Stainless<br />

Steels at elevated temperatures,<br />

in D.PECKNER et al. Handbook <strong>of</strong> Stainless <strong>steel</strong>s<br />

ed McGraw Hill 1977, pp 21-121-2<br />

[7] ANTONI L. Comparison <strong>of</strong> the cyclic<br />

oxidation behaviour between AISI 304 and <strong>low</strong><strong>nickel</strong><br />

<strong>austenitic</strong> <strong>stainless</strong> <strong>steel</strong>s,<br />

Mater. Sci. Forum 369-372 (2001) 345-352<br />

[8] “Heating resistant <strong>steel</strong> castings” pr EN<br />

10295, draft <strong>for</strong> European Standard, issued May<br />

1998, chapter 7.2.3.1<br />

[9]. Cyclic oxidation <strong>of</strong> high temperature<br />

materials, EFC n°27, M. Schütze , W.J.<br />

Quaddakkers Eds., (The Institute <strong>of</strong> Materials,<br />

London 1999) 496pp.