TDS-243 - Lubrizol

TDS-243 - Lubrizol

TDS-243 - Lubrizol

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TECHNICAL DATA SHEET<br />

<strong>TDS</strong>-<strong>243</strong><br />

Edition: January, 2002<br />

Optimizing Performance of Carbopol ® ETD 2020 and Ultrez 10<br />

Polymers with Partial Neutralization of Polymer Dispersions<br />

Unique Dispersions from New<br />

Generation Carbopol ® Polymers<br />

Carbopol ETD and Ultrez polymers are "easy to<br />

disperse" crosslinked polyacrylic acid polymers<br />

synthesized in a toxicologically preferred cosolvent<br />

system of ethyl acetate and cyclohexane. Although<br />

Carbopol ETD 2020 and Ultrez 10 have properties<br />

similar to traditional Carbopol polymers, they are<br />

specifically designed to provide easily made<br />

dispersions that are less susceptible to lumping as<br />

well as easier to pump and handle in processing<br />

due to its low dispersion viscosity before<br />

neutralization. This unique dispersion performance<br />

is derived from their ability to wet quickly and<br />

hydrate slowly, uncoiling at a relatively slower rate.<br />

Dispersions made with Carbopol Ultrez 10 and ETD<br />

2020 may appear to be non-uniform, containing<br />

visible aggregate particles which may settle into a<br />

separate phase when not mixed. This is typical of<br />

Carbopol "easy to disperse" polymers.<br />

Creating Uniform Dispersions<br />

In order to achieve a homogeneous dispersion<br />

without phase separation, it is recommended to<br />

prepare dispersions with a minimum polymer<br />

concentration of 2% by weight. This is especially<br />

true when preparing a stock dispersion that will not<br />

be completely used. This creates a space-filled<br />

dispersion that does not phase separate.<br />

Another alternative is to partially neutralize the<br />

dispersion, achieving enough viscosity and yield<br />

value to gain homogeneity and the suspension of<br />

aggregate particles in a continuous phase.<br />

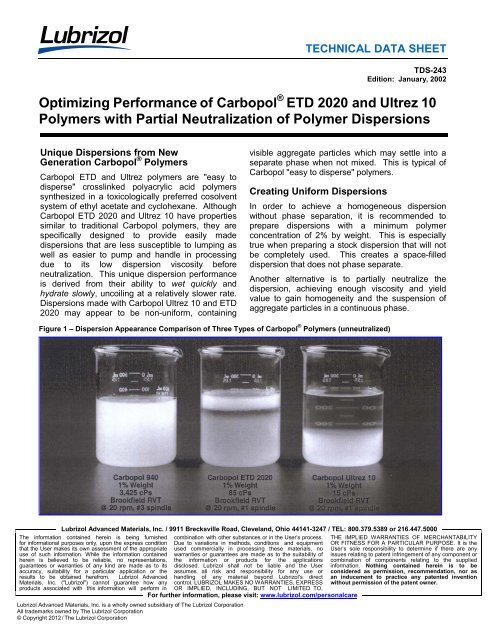

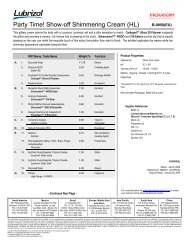

Figure 1 – Dispersion Appearance Comparison of Three Types of Carbopol ® Polymers (unneutralized)<br />

<strong>Lubrizol</strong> Advanced Materials, Inc. / 9911 Brecksville Road, Cleveland, Ohio 44141-3247 / TEL: 800.379.5389 or 216.447.5000<br />

The information contained herein is being furnished combination with other substances or in the User’s process. THE IMPLIED WARRANTIES OF MERCHANTABILITY<br />

for informational purposes only, upon the express condition Due to variations in methods, conditions and equipment OR FITNESS FOR A PARTICULAR PURPOSE. It is the<br />

that the User makes its own assessment of the appropriate used commercially in processing these materials, no User’s sole responsibility to determine if there are any<br />

use of such information. While the information contained warranties or guarantees are made as to the suitability of issues relating to patent infringement of any component or<br />

herein is believed to be reliable, no representations, the information or products for the applications combination of components relating to the supplied<br />

guarantees or warranties of any kind are made as to its disclosed. <strong>Lubrizol</strong> shall not be liable and the User information. Nothing contained herein is to be<br />

accuracy, suitability for a particular application or the assumes all risk and responsibility for any use or considered as permission, recommendation, nor as<br />

results to be obtained herefrom. <strong>Lubrizol</strong> Advanced handling of any material beyond <strong>Lubrizol</strong>'s direct an inducement to practice any patented invention<br />

Materials, Inc. ("<strong>Lubrizol</strong>") cannot guarantee how any control. LUBRIZOL MAKES NO WARRANTIES, EXPRESS without permission of the patent owner.<br />

products associated with this information will perform in OR IMPLIED, INCLUDING, BUT NOT LIMITED TO,<br />

For further information, please visit: www.lubrizol.com/personalcare<br />

<strong>Lubrizol</strong> Advanced Materials, Inc. is a wholly owned subsidiary of The <strong>Lubrizol</strong> Corporation<br />

All trademarks owned by The <strong>Lubrizol</strong> Corporation<br />

© Copyright 2012 / The <strong>Lubrizol</strong> Corporation

Dispersions of three different Carbopol polymer<br />

types in Figure 1 illustrate the distinct appearance of<br />

dispersions made with these polymers:<br />

• Carbopol 940 - Homogeneous dispersion<br />

• Carbopol ETD 2020 - Layered phases<br />

• Carbopol Ultrez 10 - Softly settled polymer<br />

particles<br />

The varying appearances are unique to each<br />

Carbopol polymer type. Formulators and processors<br />

working with the various Carbopol polymers need to<br />

keep in mind that it is typical for dispersions with<br />

Carbopol ETD 2020 and Carbopol Ultrez 10 to form<br />

separate layers. These dispersions can be made<br />

uniform with gentle mixing.<br />

Optimizing Performance in<br />

Surfactant Systems<br />

Besides uniform dispersion preparation, this concept<br />

is also helpful when formulating Carbopol ETD<br />

polymers in high-active surfactant systems such as<br />

shampoos, bath gels, hand soaps and facial and<br />

body scrubs. In these systems, high concentrations<br />

of surfactants prevent uncoiling of Carbopol polymer<br />

chains if the polymer neutralization is carried out<br />

after the addition of surfactants. This results in either<br />

low viscosity or yield value of the end product,<br />

graininess, insoluble "jelly particles" (or "fish eyes")<br />

and insoluble precipitates. This is particularly true<br />

when cationics or secondary surfactants, such as<br />

amphoterics or alkyl polyglycosides, are present at<br />

higher levels. Clarity of the final product can also be<br />

adversely affected in such cases.<br />

Normally, for partial neutralization, approximately<br />

10% of total neutralizing agent necessary for the<br />

whole batch should be sufficient. Partial neutralization<br />

will result in an increase in the pH of the<br />

dispersion (approximately 3.8 - 4.0) and viscosity<br />

due to the partial uncoiling or swelling of the<br />

polymer.<br />

The following graph (Figure 2) represents typical<br />

viscosity increases during this procedure.<br />

<strong>TDS</strong>-<strong>243</strong><br />

Optimizing Performance of Carbopol ® ETD 2020 and Ultrez 10<br />

Polymers with Partial Neutralization of Polymer Dispersions<br />

Page 2 of 2<br />

Figure 2<br />

Typical Viscosity Response of Carbopol ® Ultrez 10 and<br />

ETD 2020 During Partial Neutralization Procedure<br />

Neutralized with NaOH (18%)<br />

Any conventional neutralizing agent can be used<br />

in this method but the use of a weaker<br />

neutralizing agent such as a TEA is<br />

recommended for better control of the pH.<br />

Figure 3<br />

Dispersion Viscosities of Various Carbopol ® Polymers