Integrated Melting System (IMS) - Pyrotek

Integrated Melting System (IMS) - Pyrotek

Integrated Melting System (IMS) - Pyrotek

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

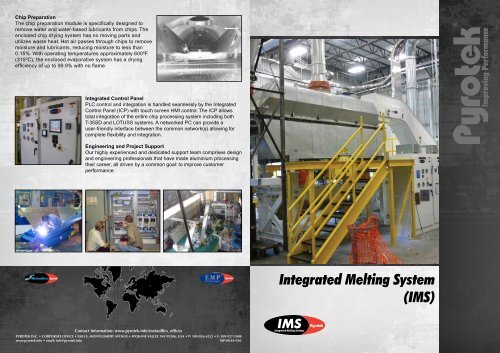

Chip Preparation<br />

The chip preparation module is specifically designed to<br />

remove water and water-based lubricants from chips. The<br />

enclosed chip drying system has no moving parts and<br />

utilizes waste heat. Hot air passes through chips to remove<br />

moisture and lubricants, reducing moisture to less than<br />

0.15%. With operating temperatures approximately 600ºF<br />

(315ºC), the enclosed evaporative system has a drying<br />

efficiency of up to 99.9% with no flame.<br />

<strong>Integrated</strong> Control Panel<br />

PLC control and integration is handled seamlessly by the <strong>Integrated</strong><br />

Control Panel (ICP) with touch screen HMI control. The ICP allows<br />

total integration of the entire chip processing system including both<br />

T-35SD and LOTUSS systems. A networked PC can provide a<br />

user-friendly interface between the common network(s) allowing for<br />

complete flexibility and integration.<br />

Engineering and Project Support<br />

Our highly experienced and dedicated support team comprises design<br />

and engineering professionals that have made aluminium processing<br />

their career, all driven by a common goal: to improve customer<br />

performance.<br />

contact Information: www.pyrotek.info/metaullics_offices<br />

<strong>Pyrotek</strong> Inc. • corPorate offIce • 9503 e. MontgoMery avenue • SPokane valley, Wa 99206, uSa • P: 509-926-6212 • f: 509-927-2408<br />

www.pyrotek.info • email: info@pyrotek.info SeP-08-e4-930<br />

<strong>Integrated</strong> <strong>Melting</strong> <strong>System</strong><br />

<strong>IMS</strong><br />

<strong>Integrated</strong> <strong>Melting</strong> <strong>System</strong>s<br />

(<strong>IMS</strong>)<br />

®

The <strong>Integrated</strong> <strong>Melting</strong> <strong>System</strong> (<strong>IMS</strong>)<br />

is a system engineered to process<br />

machining chips and convert them<br />

back into usable metal. Designed<br />

specifically for foundries, the <strong>IMS</strong> can<br />

be used by any facility generating chips<br />

from machining operations. <strong>System</strong>s<br />

are custom designed to customer<br />

needs, considering the material to be<br />

processed, the desired end product<br />

and any existing equipment.<br />

A unique feature of the <strong>IMS</strong> is its<br />

energy efficiency: it uses waste heat<br />

from other thermal processes, such<br />

as the melting furnace, to significantly<br />

increase the thermal efficiency of the<br />

complete process.<br />

LOTUSS benefits include the following:<br />

• High metal recovery rates<br />

• Maximize metal production<br />

• Designed for continuous, automated operation<br />

• Low operating cost<br />

• Low capital investment<br />

• Low maintenance<br />

• Easy installation<br />

• Can be retrofit to existing furnaces<br />

At the heart of the <strong>IMS</strong> is the LOTUSS system, one of<br />

the best technologies available for melting light gauge<br />

scrap. The LOTUSS system operates in conjunction<br />

with a Metaullics Tensor Series circulation pump or an<br />

electromagnetic pump. Metal is pumped from the main<br />

furnace chamber into a circular refractory well. The well<br />

design incorporates a unique and patented shape to<br />

generate a downward vortexing action for the metal flow.<br />

While a conveyor continuously introduces scrap into the<br />

LOTUSS, the metal flow pattern quickly submerges the<br />

scrap charge materials. The metal is then directed into<br />

the dross well located downstream of the LOTUSS, where<br />

proper dross treatment and fluxing is completed. Because<br />

the charge well is separate from the dross well, charging<br />

can be continuous even during fluxing and dross working /<br />

removal operations.<br />

<strong>System</strong>s are available for processes up to 2<br />

metric tons per hour. Available modules include<br />

the following:<br />

• Hot Air Drier<br />

• Receiving and Storage Hoppers<br />

• Conveyors<br />

• Shredders<br />

• Centrifuge<br />

• Magnetic Separator<br />

• Weigh Belt<br />

• Control Panel<br />

• LOTUSS<br />

• Metaullics Circulation Pump / EMP Pump<br />

• Emission Control Equipment<br />

• Transfer Pumps<br />

• Molten Metal Filters<br />

• STAR Degassing <strong>System</strong><br />

• Other equipment can be supplied as needed<br />

The type of light gauge scrap fed into the melting furnace by<br />

means of the LOTUSS will have an impact on the yield. By<br />

pulling dry material subsurface through the vortex, oxidation<br />

is minimized regardless of scrap type. Recovery rate increases<br />

are typically 1–5%, depending on the existing method.<br />

If the system is operated properly, consistent metal recoveries<br />

of 96-98% can be expected. For maximum recovery, salt flux<br />

may be required.