Metaullics Zinkoff Recovery System (MZR) - Pyrotek

Metaullics Zinkoff Recovery System (MZR) - Pyrotek

Metaullics Zinkoff Recovery System (MZR) - Pyrotek

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

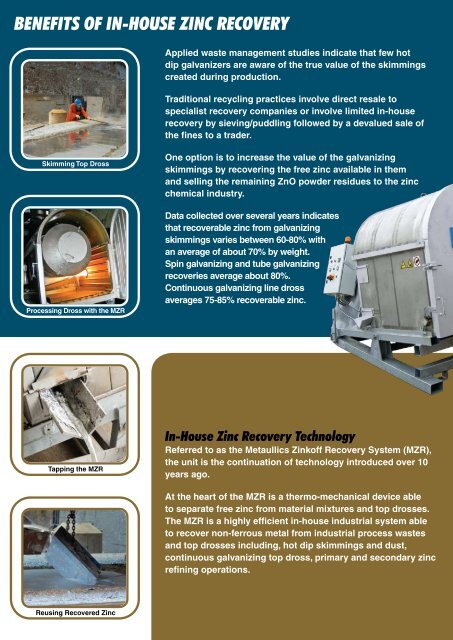

BEnEfIts Of In-hOusE ZInc REcOvERy<br />

Skimming Top Dross<br />

Processing Dross with the <strong>MZR</strong><br />

Tapping the <strong>MZR</strong><br />

Reusing Recovered Zinc<br />

Applied waste management studies indicate that few hot<br />

dip galvanizers are aware of the true value of the skimmings<br />

created during production.<br />

Traditional recycling practices involve direct resale to<br />

specialist recovery companies or involve limited in-house<br />

recovery by sieving/puddling followed by a devalued sale of<br />

the fines to a trader.<br />

One option is to increase the value of the galvanizing<br />

skimmings by recovering the free zinc available in them<br />

and selling the remaining ZnO powder residues to the zinc<br />

chemical industry.<br />

Data collected over several years indicates<br />

that recoverable zinc from galvanizing<br />

skimmings varies between 60-80% with<br />

an average of about 70% by weight.<br />

Spin galvanizing and tube galvanizing<br />

recoveries average about 80%.<br />

Continuous galvanizing line dross<br />

averages 75-85% recoverable zinc.<br />

In-house Zinc <strong>Recovery</strong> technology<br />

Referred to as the <strong>Metaullics</strong> <strong>Zinkoff</strong> <strong>Recovery</strong> <strong>System</strong> (<strong>MZR</strong>),<br />

the unit is the continuation of technology introduced over 10<br />

years ago.<br />

At the heart of the <strong>MZR</strong> is a thermo-mechanical device able<br />

to separate free zinc from material mixtures and top drosses.<br />

The <strong>MZR</strong> is a highly efficient in-house industrial system able<br />

to recover non-ferrous metal from industrial process wastes<br />

and top drosses including, hot dip skimmings and dust,<br />

continuous galvanizing top dross, primary and secondary zinc<br />

refining operations.