Metaullics Zinkoff Recovery System (MZR) - Pyrotek

Metaullics Zinkoff Recovery System (MZR) - Pyrotek

Metaullics Zinkoff Recovery System (MZR) - Pyrotek

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

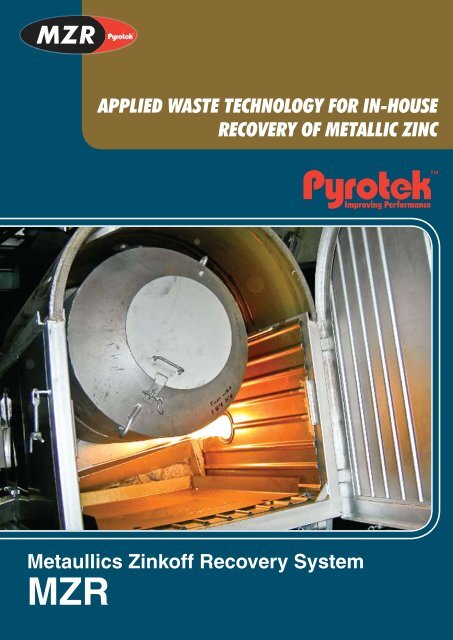

<strong>MZR</strong><br />

<br />

APPlIEd WAstE tEchnOlOgy fOR In-hOusE<br />

REcOvERy Of MEtAllIc ZInc<br />

<strong>Metaullics</strong> <strong>Zinkoff</strong> <strong>Recovery</strong> <strong>System</strong><br />

<strong>MZR</strong>

BEnEfIts Of In-hOusE ZInc REcOvERy<br />

Skimming Top Dross<br />

Processing Dross with the <strong>MZR</strong><br />

Tapping the <strong>MZR</strong><br />

Reusing Recovered Zinc<br />

Applied waste management studies indicate that few hot<br />

dip galvanizers are aware of the true value of the skimmings<br />

created during production.<br />

Traditional recycling practices involve direct resale to<br />

specialist recovery companies or involve limited in-house<br />

recovery by sieving/puddling followed by a devalued sale of<br />

the fines to a trader.<br />

One option is to increase the value of the galvanizing<br />

skimmings by recovering the free zinc available in them<br />

and selling the remaining ZnO powder residues to the zinc<br />

chemical industry.<br />

Data collected over several years indicates<br />

that recoverable zinc from galvanizing<br />

skimmings varies between 60-80% with<br />

an average of about 70% by weight.<br />

Spin galvanizing and tube galvanizing<br />

recoveries average about 80%.<br />

Continuous galvanizing line dross<br />

averages 75-85% recoverable zinc.<br />

In-house Zinc <strong>Recovery</strong> technology<br />

Referred to as the <strong>Metaullics</strong> <strong>Zinkoff</strong> <strong>Recovery</strong> <strong>System</strong> (<strong>MZR</strong>),<br />

the unit is the continuation of technology introduced over 10<br />

years ago.<br />

At the heart of the <strong>MZR</strong> is a thermo-mechanical device able<br />

to separate free zinc from material mixtures and top drosses.<br />

The <strong>MZR</strong> is a highly efficient in-house industrial system able<br />

to recover non-ferrous metal from industrial process wastes<br />

and top drosses including, hot dip skimmings and dust,<br />

continuous galvanizing top dross, primary and secondary zinc<br />

refining operations.

MEtAullIcs ZInkOff REcOvERy systEM<br />

<strong>MZR</strong>-750<br />

Representing proven technology for in-house zinc recovery, the <strong>MZR</strong>-750 has a waste<br />

processing capacity of 750 kg (1650 lbs.) for each batch process to yield about 400-<br />

500 kg of technically re-usable metal or alloy. The unit is simple to operate and does<br />

not need special, dedicated staff recruitment to man it.<br />

Operating costs are dependent on the costs applicable to the country of operation<br />

but the main cost factors involved are:<br />

Gas: Approximately 25 m³ (800 ft3 max) per burn<br />

(optional oil with approximately 25 litres [6.6 gallons] per burn)<br />

Labor: About 60 minutes per burn<br />

Barrel: Life depends on conditions and usage<br />

<strong>MZR</strong> Recovered Metal Analyses<br />

The analyses of reclaimed metal from the <strong>MZR</strong><br />

reflects the analyses of the process metal the type of<br />

galvanizing being carried out (batch, continuous, wire,<br />

tube, etc).<br />

Experience built over many years of <strong>MZR</strong> use and operation<br />

in partnership with a wide range of customers indicates that<br />

reclaimed metal is both technically and commercially acceptable<br />

for re-use and re-introduction into the process kettles and baths<br />

from which it originally came.<br />

<strong>MZR</strong>-1500<br />

The <strong>MZR</strong>-1500 is the latest development with in-house zinc recovery.<br />

It has been designed and built to specifications requested by large<br />

top dross volume producers such as primary and secondary metal<br />

refiners and alloy producers, continuous galvanizers and large<br />

general hot dip galvanizing groups.<br />

The <strong>MZR</strong>-1500 has an increased waste processing<br />

capacity of 1500 kg (3300 lbs.). Heating chamber<br />

efficiency is upgraded with a 100 mm thickness<br />

of low thermal mass insulation in the walls and<br />

the heating source is a system of high efficiency<br />

burners. The <strong>MZR</strong>-1500 is more user friendly, with<br />

greater ease in loading the drum.

<strong>MZR</strong> BEnEfIts<br />

Operational & Economic Benefits<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Reduction in the volume of virgin zinc<br />

bought at LME rates<br />

No LME premium on recovered zinc<br />

Low operational cost<br />

Reduced volume of residual skimmings for<br />

disposal<br />

Value in residual skimmings after zinc<br />

removal<br />

Improving Performance<br />

The <strong>MZR</strong> provides a simple, cost effective<br />

engineered solution for in-house zinc recovery,<br />

enabling dross producers to lower their overall<br />

operational costs and logistics while protecting the<br />

environment.<br />

Our <strong>Pyrotek</strong> representatives are available globally to<br />

support your business. For more information, email<br />

info@pyrotek.info or visit our website:<br />

www. .inf / mzr<br />

REGIONAL OFFICES<br />

NETHERLANDS<br />

(31) (0)180-590890<br />

barendrecht@pyrotek-inc.com<br />

ITALY<br />

(39) 02-96458222<br />

caronnopertusella@pyrotek-inc.com<br />

SWEDEN<br />

(46) (0)534-62000<br />

ed@pyrotek-inc.com<br />

AUSTRALIA<br />

(61) (0)2 9631-1333<br />

unanderra@pyrotek-inc.com<br />

JAPAN<br />

(81) (0)78-265-5590<br />

kobe@pyrotek-inc.com<br />

SOUTH KOREA<br />

(82) (0)53-523-5202<br />

daegu@pyrotek-inc.com<br />

INDIA<br />

(91) 22-2809-2561<br />

mumbai@pyrotek-inc.com<br />

TAIWAN<br />

(886) 7-224-8222<br />

taiwan@pyrotek-inc.com<br />

BRAZIL<br />

(55) 11-4786-5233<br />

saopaulo@pyrotek-inc.com<br />

CANADA<br />

(1) 519-787-1421<br />

fergus@pyrotek-inc.com<br />

MEXICO<br />

(52) 81-8336-9117<br />

santacatarina@pyrotek-inc.com<br />

USA<br />

(1) 724-318-8290<br />

ambridge@pyrotek-inc.com<br />

Environmental Benefits<br />

Additionally, in-house recovery procedures<br />

are rapidly gaining favor with authorities<br />

dealing with European Commission<br />

Integrated Pollution Prevention and Control<br />

(IPPC) rules and regulations applicable to<br />

waste management. The IPPC recognized<br />

<strong>MZR</strong> technology as the best available<br />

technique for dross waste management.<br />

In-house recovery reduces<br />

total volumes of waste for<br />

disposal, as well as reduces<br />

the amount transportation<br />

required for virgin zinc and<br />

waste products up to 90%.<br />

<strong>Pyrotek</strong>’s mission is to provide innovative solutions to customer<br />

needs utilizing our global resources.<br />

<strong>Pyrotek</strong> Inc. • corPorate offIce • 9503 e. MontgoMery avenue • SPokane valley, Wa 99206, uSa • P: 509-926-6212 • f: 509-927-2408<br />

www.pyrotek.info/mzr • email: info@pyrotek.info May-09-el-866