OpenPDM brochure - Prostep AG

OpenPDM brochure - Prostep AG

OpenPDM brochure - Prostep AG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

OPENPDM - OPENPDM - OPENPDM - OPENPDM<br />

OpenPD <strong>OpenPDM</strong><br />

OpenPD<br />

Product data management<br />

without limits

I n t e g r a t i o n r e p r e s e n t s a k i n d o f<br />

0.1<br />

1.<br />

1.<br />

Numerous Numerous Communica<br />

Communication<br />

Communica<br />

Communica tion<br />

Breakdowns.<br />

Breakdowns.<br />

Product development is a collaborative task<br />

that demands a high level of communication.<br />

Therefore the systems being used must speak<br />

one language.<br />

Global Collaboration<br />

Speaking one language<br />

Companies in the automotive and<br />

aerospace industries develop<br />

highly complex products with a wide<br />

variety of different versions because<br />

today’s customers demand individual<br />

solutions. The number of model<br />

variants is increasing steadily and the<br />

ability to use carry-over parts is<br />

becoming increasingly important.<br />

Suppliers take over a major part of<br />

development work. They no longer<br />

supply just individual parts but rather<br />

complete modules or systems. In order<br />

to reduce the development time for<br />

the number of moduls and variants,<br />

OEMs, system vendors and suppliers<br />

must be able to access up-to-date<br />

development data at any time.<br />

Within individual companies, however,<br />

the data and information used in the<br />

developed process is distributed over<br />

a large number of different systems<br />

that are unable to communicate with<br />

one another.<br />

This makes it difficult to ensure<br />

company-wide access to up-to-date<br />

development data.<br />

the communication of product data<br />

across companies.<br />

the coordination of critical business<br />

processes such as release or change<br />

management.<br />

The cross-system integration of<br />

product data is therefore an<br />

important requirement for improving<br />

the coordination of distributed<br />

development processes and an<br />

efficient management of the entire<br />

product lifecycle (PLM). Without<br />

integration, communication remains<br />

fragmented.

If all participants worked with the<br />

same system, communication would<br />

obviously be much easier. Each<br />

company, however, wants to use the<br />

best system for each task. Therefore,<br />

these systems must speak the same<br />

language.<br />

The requirements for system<br />

integration have increased in direct<br />

proportion to the extent to which<br />

manufacturers have outsourced a<br />

growing number of development tasks<br />

to their suppliers. In order to<br />

coordinate distributed development,<br />

2.<br />

2.<br />

A A c ccommon<br />

c ommon pla platf pla pla tf tform. tf orm.<br />

Companies want to use the best system for<br />

each task while providing their product data<br />

with a common platform.<br />

the suppliers need not only the<br />

geometric data but also the structural<br />

information stored in the management<br />

systems.<br />

The communication of master data,<br />

structures, configurations,<br />

effectivities, change histories and<br />

releases within a single company and<br />

between different companies requires<br />

very powerful integration components.<br />

At the same time, the solution must be<br />

scalable to meet the complex<br />

requirements of the OEMs and<br />

suppliers.<br />

The most important requirements for a<br />

product data integration solution are:<br />

Functional connections to the<br />

systems being used, including legacy<br />

applications.<br />

Workflow components to support the<br />

distributed processes.<br />

Online and offline access options for<br />

partners.<br />

Easy-to-use tools that can be used<br />

to coordinate the processes of<br />

partners and customers.<br />

Cross-system integration therefore<br />

requires detailed knowledge of the<br />

systems in use, the processes to be<br />

supported and the data structures<br />

used.

t o p u t t o g e t h e r p a r t s t o c r e a t e a w h o l e .<br />

0.2<br />

Intelligent Solutions<br />

We understand you<br />

PROSTEP provides the optimal solution<br />

to meet your needs:<br />

The scalable <strong>OpenPDM</strong> ® family of<br />

products allows you to create<br />

integration solutions with different<br />

degrees of complexity – from the<br />

simple linking of two systems<br />

in the Intranet to engineering portals<br />

for suppliers and customers around<br />

the globe or the integration of PLM<br />

over a number of systems.<br />

3.<br />

3.<br />

KNO KNOW-HO KNO -HO -HOW -HO W is is the the K KKey.<br />

K ey.<br />

We provide solutions that meet any<br />

integration requirement. Because<br />

we understand your processes.<br />

What you need is not only a powerful<br />

product but also a solution provider<br />

who understands your processes<br />

and is capable to support you with<br />

implementing your requirements.<br />

The specialists from PROSTEP<br />

are familiar with the requirements<br />

of the automotive and aerospace<br />

industries.<br />

can help you optimize your<br />

distributed engineering processes.<br />

implement integration solutions for<br />

your IT systems.<br />

guarantee that your project runs<br />

efficiently and cost-effectly.

I f s o m e t h i n g h a s b e e n “ i n t e g r a t e d ” ,<br />

4. 4.<br />

4.<br />

Building Building bridges.<br />

bridges.<br />

You decide how you want to communicate –<br />

<strong>OpenPDM</strong> ® supports your forms of communication<br />

and your communication processes.<br />

You decide<br />

The <strong>OpenPDM</strong> ® product family from<br />

PROSTEP is an integration solution for<br />

product data from different PDM, ERP<br />

or legacy systems that have connectors<br />

to PDM systems like Teamcenter, UG<br />

Manager, mySAP/PLM, ENOVIAVPM,<br />

Windchill, Pro/INTRALINK or eMatrix.<br />

Integration packages also exist for<br />

OEMs’ proprietary solutions.<br />

The connectors allow all relevant PDM<br />

information such as part and<br />

document master data, product and<br />

model structures, configuration<br />

information and release statuses to be<br />

exchanged or made accessible while at<br />

the same time ensuring consistent and<br />

conflict-free access to the systems.<br />

<strong>OpenPDM</strong> ® does not dictate the way<br />

you communicate your product data<br />

within your company or with your<br />

partners. <strong>OpenPDM</strong> ® supports both<br />

file-based data exchange between<br />

different systems and online access to<br />

data in other systems.<br />

<strong>OpenPDM</strong> ® supports the release and<br />

change processes normally found in<br />

the automotive and aerospace<br />

industries. Using graphical tools, the<br />

objects and structures from the source<br />

system can be linked with those in the<br />

target system.<br />

The consistent use of standards allows<br />

the implementation of complex<br />

integration concepts. <strong>OpenPDM</strong> ®<br />

combines the strengths of the STEP<br />

product data standard and of the<br />

Internet standard XML for engineering<br />

data transmission.<br />

The architecture of <strong>OpenPDM</strong> ® is<br />

based on a single application server<br />

(e.g. IBM WebSphere, JBoss, BEA<br />

WebLogic, among others) with a<br />

powerful Web interface which ensures<br />

access to your partners’ data with no<br />

need to know their systems and data<br />

models.

a l l t h e p a r t s f u n c t i o n a s o n e .<br />

0.3<br />

Integrating Experience<br />

Experience counts<br />

<strong>OpenPDM</strong> ® is a product based on<br />

experience: PROSTEP implemented a<br />

large number of integration projects –<br />

both at leading OEMs such as Airbus,<br />

BMW, DaimlerChrysler, Opel and<br />

Volkswagen and industry suppliers<br />

such as Benteler, Bosch, Delphi Automotive,<br />

Webasto and ZF.<br />

In addition: Engineering service<br />

providers in the automotive and<br />

aerospace industries also rely on our<br />

solutions. The <strong>OpenPDM</strong> ® product<br />

family was developed on the basis of<br />

the experience gained in these<br />

projects. A few examples illustrate just<br />

how versatile the solution is.<br />

With Delphi CPI (Customer PDM<br />

Integration), PROSTEP has<br />

implemented a uniform system for<br />

the integration of PDM data between<br />

Delphi and its customers.<br />

<strong>OpenPDM</strong> ® ensures access to the<br />

company’s numerous Teamcenter<br />

instances as well as online (XML) and<br />

asynchronous communication (STEP)<br />

of the product data to the OEM.<br />

Ford is integrating the PDM and CAD<br />

data of its subsidiaries Volvo and<br />

Landrover with that of Ford of<br />

Europe within the framework of its<br />

European platform strategy.<br />

Using <strong>OpenPDM</strong> ® , VPM structure<br />

information and the CATIA data are<br />

exported, converted and transferred<br />

to the I-deas / TDM / Metaphase<br />

environment at Ford. This automated<br />

procedure significantly reduces the<br />

volume of manual intervention effort<br />

required to integrate the PDM<br />

worlds.<br />

Within the framework of introducing<br />

mySAP/PLM at Nothelfer GmbH,<br />

PROSTEP has integrated the CAD<br />

system CATIA directly into the PLM<br />

solution using <strong>OpenPDM</strong> ® . This link<br />

allows the automated processing of<br />

STEP structure information from the<br />

OEMs and simplifies the mass import<br />

of document master data and<br />

structures into mySAP/PLM.<br />

Webasto <strong>AG</strong> has integrated the CAD<br />

data management system<br />

ENOVIAVPM into the PLM backbone<br />

Windchill and created an OEM<br />

bridge based on <strong>OpenPDM</strong> ® . This<br />

allows the company to use a single<br />

uniform process to provide all its<br />

customers with master data from<br />

both systems thus reducing the<br />

work-load.<br />

5.<br />

5.<br />

Experience Experience shows. shows.<br />

shows.<br />

J e a n A y r e s<br />

<strong>OpenPDM</strong> ® was not created in a<br />

vacuum: This family of products<br />

incorporates the experience gained in<br />

numerous integration projects.<br />

The experience from various projects<br />

shows that the use of <strong>OpenPDM</strong> ®<br />

The experience from various projects<br />

shows that the use of <strong>OpenPDM</strong> ®<br />

significantly reduces the time and<br />

effort required to collect and<br />

distribute product data within the<br />

company.<br />

reduces development times by<br />

making the latest development and<br />

change data available in a transparent<br />

manner.<br />

prevents time-intensive and costly<br />

changes caused by working with<br />

obsolete information.<br />

accelerates the collaborative<br />

development process by<br />

incorporating the relevant partner<br />

information.<br />

The comprehensive functionality<br />

offered by <strong>OpenPDM</strong> ® The comprehensive functionality<br />

offered by <strong>OpenPDM</strong> and the project<br />

know-how provided by PROSTEP<br />

guarantees the simple and fast<br />

integration of your distributed product<br />

data using available standards.<br />

Thanks to its scalability and modular<br />

structure, the solution can be tailored<br />

to your current communication processes<br />

and, at the same time, keep up<br />

with your future requirements for<br />

product lifecycle-management.<br />

® and the project<br />

know-how provided by PROSTEP<br />

guarantees the simple and fast<br />

integration of your distributed product<br />

data using available standards.<br />

Thanks to its scalability and modular<br />

structure, the solution can be tailored<br />

to your current communication processes<br />

and, at the same time, keep up<br />

with your future requirements for<br />

product lifecycle-management.

P R O S T E P S o l u t i o n s<br />

CAD-Integration made easy<br />

Solutions for the engineering<br />

data workflow<br />

Product data management<br />

without limits<br />

Integra Integrate, Integra Integra te, Convert, Convert,<br />

Convert,<br />

Automa Automa Automate<br />

Automa te<br />

Communication is the pacemaker for<br />

global collaboration<br />

For further information<br />

www.prostep.com<br />

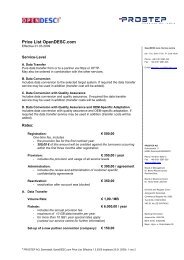

OpenDESC<br />

OpenDESC<br />

OpenDXM<br />

OpenDXM<br />

<strong>OpenPDM</strong><br />

<strong>OpenPDM</strong>

PROSTEP <strong>AG</strong><br />

Dolivostraße 11<br />

64293 Darmstadt<br />

Phone +49-61 51-92 87-0<br />

Fax +49-61 51-92 87-3 26<br />

www.prostep.com<br />

OPENPDM - OPENPDM<br />

www.prostep.com