Tanco Autowrap Technical information

Tanco Autowrap Technical information

Tanco Autowrap Technical information

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Subject Cut and Start<br />

Description Testing and adjusting the pressure<br />

Modified 13-8-04<br />

Location found on turntable type machines<br />

Model 404 M/EH 280 580 1080<br />

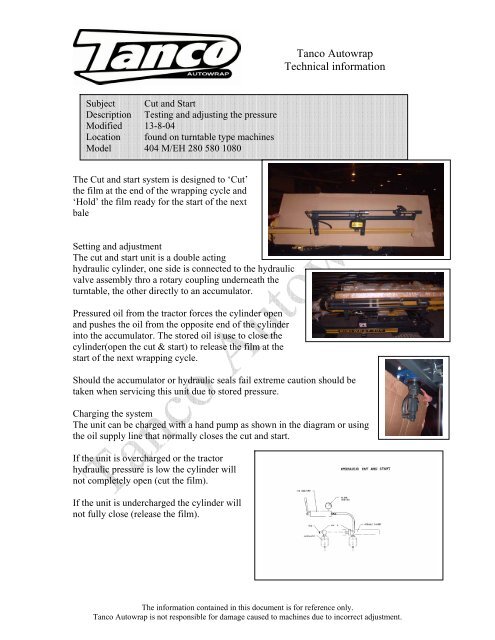

The Cut and start system is designed to ‘Cut’<br />

the film at the end of the wrapping cycle and<br />

‘Hold’ the film ready for the start of the next<br />

bale<br />

Setting and adjustment<br />

The cut and start unit is a double acting<br />

hydraulic cylinder, one side is connected to the hydraulic<br />

valve assembly thro a rotary coupling underneath the<br />

turntable, the other directly to an accumulator.<br />

Pressured oil from the tractor forces the cylinder open<br />

and pushes the oil from the opposite end of the cylinder<br />

into the accumulator. The stored oil is use to close the<br />

cylinder(open the cut & start) to release the film at the<br />

start of the next wrapping cycle.<br />

<strong>Tanco</strong> <strong>Autowrap</strong><br />

<strong>Technical</strong> <strong>information</strong><br />

Should the accumulator or hydraulic seals fail extreme caution should be<br />

taken when servicing this unit due to stored pressure.<br />

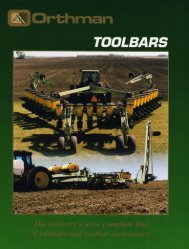

Charging the system<br />

The unit can be charged with a hand pump as shown in the diagram or using<br />

the oil supply line that normally closes the cut and start.<br />

If the unit is overcharged or the tractor<br />

hydraulic pressure is low the cylinder will<br />

not completely open (cut the film).<br />

If the unit is undercharged the cylinder will<br />

not fully close (release the film).<br />

The <strong>information</strong> contained in this document is for reference only.<br />

<strong>Tanco</strong> <strong>Autowrap</strong> is not responsible for damage caused to machines due to incorrect adjustment.

<strong>Tanco</strong><br />

Cut and start<br />

The purpose of the C & S(Cut & Start)is to enable an automatic<br />

application of the film to the bale at the start of the wrapping cycle.<br />

Then at the end of the cycle, the cutting of the film.<br />

The C & S cycle is the same for all of the models, the only difference<br />

being weather it happens automatically or manually as on the 580S.<br />

The C & S on the turntable models use a stored pressure system which<br />

uses an accumulator to open the unit. The 1300 & 1500 models use a<br />

double acting cylinder.<br />

On the 280/580/1080 models<br />

After 2 revelations of the turntable, the oil pressure is diverted from<br />

the C & S and returned to the tractor automatically, this releases the<br />

held tail of the film. The cutter cylinder remains retracted for the<br />

rest of the wrapping cycle.<br />

After the preset number of turns has been reached the turntable slows<br />

to half speed(on the automatic machines. On the manual models the<br />

turntable will stop at the position as set by the operator on the<br />

controller) normally with the cutter to the rear of the machine.<br />

The automatic machine will position the turntable with the cutter<br />

directly under the film. The manual model may require a small movement<br />

of the control leaver.<br />

Automatic model.<br />

The 'tip button' on the controller is then pressed to unload the bale.<br />

The turntable frame tips upward, and the film gathering arm lowers to<br />

gather the film to a smaller area.<br />

A sensor on the rear of the turntable sets the correct angle for<br />

cutting the film. (some small adjustment is normally required for new<br />

machines) Once the film is lying flat across the cutter bars the<br />

cylinder is powered out to cut the film. The turntable continues<br />

tipping to unload the bale. The Film is held ready for the start of the<br />

next bale.<br />

Manual model.<br />

The control leaver is operated to tip the turntable, once the film is<br />

lying flat across the cutter bars the button on the top of the control<br />

leaver is pressed. This diverts the oil flow from the tipping cylinder<br />

to the cutter. Once the film has been cut the button can be released<br />

and the turntable continues tipping to unload the bale. The Film is<br />

held ready for the start of the next bale.<br />

On the 1300/1500 models<br />

After 2 revelations of the rotating arm the cutters open for a preset<br />

time set by the controller, this releases the tail of the film. The<br />

cutter then closes to avoid damaging the film as the rotating arm will<br />

soon return for the next pass of the bale.<br />

After the number of rotations have been reached, the wrapping arm will<br />

slow to half speed on the opposite side of the bale from the cutter.<br />

The wrapping arm will continue to rotate slowly and the cutter will<br />

open. The wrapping arm will stop when it reaches the sensor(depending<br />

on any time settings in the controller), the cutter will then close to<br />

complete the cycle. The Film is held ready for the start of the next<br />

bale.