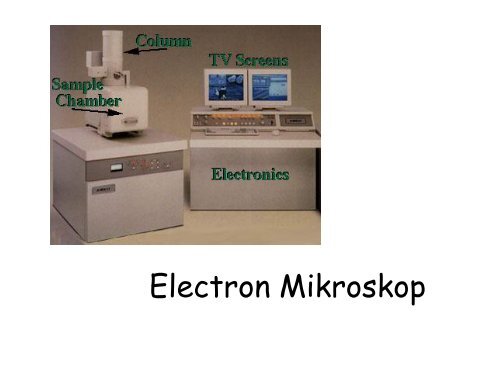

Electron Mikroskop

Electron Mikroskop

Electron Mikroskop

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Electron</strong> <strong>Mikroskop</strong>

Scanning <strong>Electron</strong> Microscopy (SEM)<br />

•Apa itu SEM?<br />

•Prinsip Kerja SEM<br />

•Komponen utama dan fungsinya<br />

•<strong>Electron</strong> beam - spesimen interaksi<br />

•Inteaksi volume dan escape volume<br />

•Perbesaran, resolusi, depth of field dan<br />

kontras bayangan<br />

•Energy Dispersive X-ray Spectroscopy (EDS)<br />

•Wavelength Dispersive X-ray Spectroscopy<br />

(WDS)<br />

•Orientation Imaging Microscopy (OIM)<br />

•X-ray Fluorescence (XRF)

Comparison of OM,TEM and SEM<br />

Light source<br />

Condenser<br />

Specimen<br />

Objective<br />

Eyepiece Projector<br />

Source of<br />

electrons<br />

Magnetic<br />

lenses<br />

Specimen<br />

OM TEM SEM<br />

detector<br />

CRT<br />

Cathode<br />

Ray Tube<br />

Principal features of an optical microscope, a transmission<br />

electron microscope and a scanning electron microscope,<br />

drawn to emphasize the similarities of overall design.

Glass Magnetic<br />

coils<br />

Anode<br />

Under vacuum

PERBEDAAN MO DAN SEM<br />

MO : resolusi/daya pisah<br />

lebih rendah<br />

SEM: resolusi/daya<br />

pisah lebih tinggi<br />

Kombinasi perbesaran dan daya pisah yang lebih besar dan kemampuan deteksi unsur pada<br />

permukaan material SEM lebih teliti untuk riset dan industri

I. Basics of <strong>Electron</strong> Microscopy<br />

• Electro-magnetic lenses<br />

• Scanning Transmission EM (STEM)<br />

– Mass determination<br />

– Elemental mapping<br />

• Scanning EM (SEM)<br />

– Surface relief<br />

• Transmission EM (TEM)<br />

– Structures<br />

– Imaging or Diffraction<br />

– 0.03 Å theoretical resolution<br />

1.0 Å practical resolution

II. <strong>Electron</strong> Source<br />

• Tungsten filament (thermionic)<br />

• Tungsten crystal (field emission) 100x brighter<br />

• <strong>Electron</strong>s Accelerated to defined energy<br />

behave as a wave.<br />

• kV (100 – 1000 kV with 200kV-> 0.025 Å)

<strong>Electron</strong> beam Source<br />

W or LaB6 Filament<br />

Thermionic or Field Emission Gun

ELEKTRON YANG BERHAMBUR DAN<br />

DITANGKAP SEM SAAT SAMPEL<br />

DITEMBAK ELEKTRON

HAMBURAN ELEKTRON DIDETEKSI DAN<br />

ENERGINYA DITAMPILKAN DALAM BENTUK<br />

GAMBAR DAN GRAFIK<br />

Tiap Jenis hamburan elektron<br />

ditangkap detektor yang<br />

berbeda<br />

Tempat Sampel

TEMPAT SAMPEL DI SCANNING<br />

ELECTRON MICROSCOPE

PENGAMATAN DENGAN SCANNING<br />

ELECTRON MICROSCOPE<br />

Perbesaran<br />

OM 4x – 1000x<br />

SEM 10x – 3000000x<br />

Aplikasi :<br />

•Mengamati struktur maupun<br />

bentuk permukaan yang<br />

berskala lebih halus<br />

•Dilengkapi Dengan EDS<br />

(<strong>Electron</strong> Dispersive X ray<br />

Spectroscopy)<br />

•Dapat mendeteksi unsur2<br />

dalam material.<br />

•Permukaan yang diamati<br />

harus penghantar elektron

Keuntungan SEM terhadap OM<br />

Perbesaran Depth of Field Resolusi<br />

OM 4x – 1000x 15.5mm – 0.19mm ~ 0.2mm<br />

SEM 10x – 3000000x 4mm – 0.4mm 1-10nm<br />

SEM mempunyai depth of field yang besar, yang dapat<br />

memfokus jumlah sampel yang lebih banyak pada satu<br />

waktu dan menghasilkan bayangan yang baik dari<br />

sampel tiga dimensi. SEM juga menghasilkan bayangan<br />

dengan resolusi tinggi, yang berarti mendekati bayangan<br />

yang dapat diuji dengan perbesaran tinggi.<br />

Kombinasi perbesaran yang lebih tinggi, dark field,<br />

resolusi yang lebih besar, dan komposisi serta informasi<br />

kristallografi membuat SEM merupakan satu dari<br />

peralatan yang paling banyak digunakan dalam<br />

penelitian, R&D industri khususnya industri<br />

semikonductor.

• Topography<br />

Aplikasi Utama SEM<br />

The surface features of an object and its texture<br />

(hardness, reflectivity… etc.)<br />

• Morphology<br />

The shape and size of the particles making up the<br />

object (strength, defects in IC and chips...etc.)<br />

• Composition<br />

The elements and compounds that the object is<br />

composed of and the relative amounts of them<br />

(melting point, reactivity, hardness...etc.)<br />

• Crystallographic Information<br />

How the grains are arranged in the object<br />

(conductivity, electrical properties, strength...etc.)

<strong>Electron</strong> Gun<br />

A More<br />

Detaile<br />

d Look<br />

Inside<br />

Source: L. Reimer,<br />

“Scanning <strong>Electron</strong><br />

Microscope”, 2 nd Ed.,<br />

Springer-Verlag, 1998, p.2<br />

e - beam

Preparasi Sampel<br />

• Hindari semua air, larutan atau<br />

material-material lain yang mudah<br />

menguap dalam vakum.<br />

• Permukaan harus rata untuk BSE dan<br />

OIM<br />

• Tentukan jumlah sample.<br />

• Samples Non-logam, seperti building<br />

materials, insulating ceramics, harus di<br />

caoting agar konduktivitas listriknya<br />

baik. Logam dan samples konduktivitas<br />

dapat diletakan langsung kedalam SEM.

Image Magnification<br />

Example of a series of increasing magnification (spherical lead<br />

particles imaged in SE mode)

Bagaimana Elektron Beam<br />

dihasilkan ?<br />

• Elektron guns digunakan untuk<br />

menghasilkan kontrol beam yang halus<br />

dari elektron yang kemudian difokuskan<br />

pada permukaan spesimen.<br />

• Eelektron guns bisa dalam bentuk<br />

thermionik gun atau field-emission gun

Thermionic Emission Gun<br />

• A tungsten filament<br />

heated by DC to<br />

approximately 2700K or<br />

LaB 6 rod heated to around<br />

2000K<br />

• A vacuum of 10 -3 Pa (10 -4<br />

Pa for LaB 6) is needed to<br />

prevent oxidation of the<br />

filament<br />

• <strong>Electron</strong>s “boil off” from<br />

the tip of the filament<br />

• <strong>Electron</strong>s are accelerated<br />

by an acceleration voltage<br />

of 1-50kV

Field Emission Gun<br />

• The tip of a tungsten needle is<br />

made very sharp (radius < 0.1<br />

mm)<br />

• The electric field at the tip is<br />

very strong (> 10 7 V/cm) due<br />

to the sharp point effect<br />

• <strong>Electron</strong>s are pulled out from<br />

the tip by the strong electric<br />

field<br />

• Ultra-high vacuum (better than<br />

10 -6 Pa) is needed to avoid ion<br />

bombardment to the tip from<br />

the residual gas.<br />

• <strong>Electron</strong> probe diameter < 1<br />

nm is possible

Filament<br />

Source of <strong>Electron</strong>s<br />

T: ~1500o Thermionic Gun<br />

C<br />

W and LaB 6<br />

(5-50mm)<br />

E: >10MV/cm<br />

(5nm)<br />

Cold- and thermal FEG<br />

<strong>Electron</strong> Gun Properties<br />

Source Brightness Stability(%) Size Energy spread Vacuum<br />

W 3X10 5 ~1 50mm 3.0(eV) 10 -5 (t )<br />

LaB 6 3x10 6 ~2 5mm 1.5 10 -6<br />

C-FEG 10 9 ~5 5nm 0.3 10 -10<br />

T-FEG 10 9

Lensa Magnetik<br />

• Lensa Condenser – focusing<br />

determines the beam current<br />

which impinges on the sample.<br />

• Lensa Objective – final probe<br />

forming<br />

determines the final spot size of<br />

the electron beam, i.e., the<br />

resolution of a SEM.

Kenapa perlu Vakum?<br />

Bila SEM digunakan, kolum elektron-optik<br />

dan sampel chamber harus selalu pada<br />

kondisi vakum.<br />

1. Bila kolum ada gas didalamnya maka elektron akan<br />

diskaterd oleh molekul gas yang menyebabkan<br />

intensitas dan stability beam akan berkurang<br />

2. Molekul-molekul gas lain, yang datang dari sampel<br />

atau dari microskop itu sendiri, dapat membentuk<br />

persenyawaan dan kondens pada sampel. Ini akan<br />

membuatan kontras menjadi lebih rendah dan<br />

bayangan menjadi kabur.

<strong>Electron</strong> Detectors and Sample Stage<br />

Objective<br />

lens<br />

Sample stage

Coating Techniques<br />

Sputter coater is used to coat insulating samples<br />

Au and Al – good for SE yield<br />

AuPd alloy – good for high resolution<br />

C – used if X-ray microanalysis is required<br />

Coating should have low granularity in order not to<br />

mask the underlying structure (

OIM-Grain Boundary Maps<br />

Grain Boundary Map Orientation Map<br />

A Grain boundary Map can be generated by comparing the orientation<br />

between each pair of neighboring points in an OIM scan. A line is<br />

drawn separating a pair of points if the difference in orientation<br />

between the points exceeds a given tolerance angle. An Orientation<br />

Map is generated by shading each point in the OIM scan according to<br />

some parameter reflecting the orientation at each point. Both of these<br />

maps are shown overlaid on the digital micrograph from the SEM.