- Page 1 and 2:

ENVIRONMENTAL ERGONOMICS XII Procee

- Page 3 and 4:

ENVIRONMENTAL ERGONOMICS XII Procee

- Page 5 and 6:

International Conferences on Enviro

- Page 7 and 8:

TABLE OF CONTENTS Table of contents

- Page 9 and 10:

Table of contents ALTITUDE ATTENUAT

- Page 11 and 12:

Table of contents TOWARDS PREVENTIO

- Page 13 and 14:

Table of contents RATE AFFECT EXERC

- Page 15 and 16:

Table of contents Uroš Dobnikar, S

- Page 17 and 18:

Table of contents TO A HOT ENVIRONM

- Page 19 and 20:

Table of contents Andreas D. Flouri

- Page 21 and 22:

Table of contents PHYSICAL FITNESS

- Page 23 and 24:

Table of contents ESTIMATION OF THE

- Page 25 and 26:

Herman Potocnic Lecture the advanta

- Page 27 and 28:

Invited presentation Gravitational

- Page 29 and 30:

Gravitational Physiology SKELETAL M

- Page 31 and 32:

Lf (mm) 50.0 40.0 30.0 20.0 10.0 Fa

- Page 33 and 34:

Gravitational Physiology maximum is

- Page 35 and 36:

Gravitational Physiology THERMOREGU

- Page 37 and 38:

Gravitational Physiology THE EXERCI

- Page 39 and 40:

Gravitational Physiology Since exer

- Page 41 and 42:

Gravitational Physiology During the

- Page 43 and 44:

Gravitational Physiology CARDIOVASC

- Page 45 and 46:

as observed at rest after LBNP was

- Page 47 and 48:

Gravitational Physiology THERMOREGU

- Page 49 and 50:

Gravitational Physiology THE EFFECT

- Page 51 and 52:

Gravitational Physiology Fortney SM

- Page 53 and 54:

Gravitational Physiology Contractil

- Page 55 and 56:

Gravitational Physiology Edgerton V

- Page 57 and 58:

Diving Physiology A library of imag

- Page 59 and 60:

Diving Physiology Information recal

- Page 61 and 62:

Diving Physiology RESULTS Figure 1

- Page 63 and 64:

Diving Physiology sensitivity is no

- Page 65 and 66:

Diving Physiology Physiological Mea

- Page 67 and 68:

Diving Physiology same sequence. Th

- Page 69 and 70:

Diving Physiology HYPERVENTILATION

- Page 71 and 72:

Diving Physiology software. Individ

- Page 73 and 74:

Diving Physiology REFERENCES IMCA.

- Page 75 and 76:

Diving Physiology recorded (MIE Med

- Page 77 and 78:

Diving Physiology DISCUSSION The ma

- Page 79 and 80:

Altitude Physiology vastus laterali

- Page 81 and 82:

Altitude Physiology IS INTERMITTENT

- Page 83 and 84:

Altitude Physiology Table 2: Lactat

- Page 85 and 86:

Altitude Physiology CARBOHYDRATE IN

- Page 87 and 88:

Altitude Physiology Figure 1: Mean

- Page 89 and 90: Altitude Physiology HYPOXIA INDUCED

- Page 91 and 92: Altitude Physiology Figure 1. Mean

- Page 93 and 94: Altitude Physiology ANALYSIS OF MUS

- Page 95 and 96: SOL MG TA BF VM Altitude Physiology

- Page 97 and 98: Altitude Physiology LOAD CARRIAGE I

- Page 99 and 100: Table 2: Differential ratings of pe

- Page 101 and 102: Altitude Physiology EFFECTS OF INTE

- Page 103 and 104: Cerebral deoxy-Hb (delta, µM) Cere

- Page 105 and 106: Altitude Physiology ENDURANCE RESPI

- Page 107 and 108: Altitude Physiology Wylegala JA, Pe

- Page 109 and 110: Invited presentation Cognitive and

- Page 111 and 112: Cognitive and Psycophysiological Fu

- Page 113 and 114: Cognitive and Psycophysiological Fu

- Page 115 and 116: Cognitive and Psycophysiological Fu

- Page 117 and 118: Cognitive and Psycophysiological Fu

- Page 119 and 120: Cognitive and Psycophysiological Fu

- Page 121 and 122: Cognitive and Psycophysiological Fu

- Page 123 and 124: Cognitive and Psycophysiological Fu

- Page 125 and 126: Cognitive and Psycophysiological Fu

- Page 127 and 128: Cognitive and Psycophysiological Fu

- Page 129 and 130: Cognitive and psychophysiological f

- Page 131 and 132: CLOTHING AND TEXTILE SCIENCE 131

- Page 133 and 134: Clothing SPACER FABRICS IN OUTDOOR

- Page 135 and 136: F i / g m -2 4,0 3,5 3,0 2,5 2,0 1,

- Page 137 and 138: Clothing TOTAL EVAPORATIVE RESISTAN

- Page 139: 9,0 8,0 7,0 6,0 5,0 4,0 3,0 2,0 1,0

- Page 143 and 144: Clothing parallel It values ranged

- Page 145 and 146: Clothing CORRELATION BETWEEN SUBJEC

- Page 147 and 148: Clothing and left side chest, scapu

- Page 149 and 150: Clothing studies using an ice vest

- Page 151 and 152: Insulation (Clo) (Clo) Clo / kg 6 5

- Page 153 and 154: Clothing EFFECTS OF MOISTURE TRANSP

- Page 155 and 156: Clothing the P plots above 60%RH (p

- Page 157 and 158: Clothing EFFECT OF CLOTHING INSULAT

- Page 159 and 160: Clothing EFFECTS OF QUILT AND MATTR

- Page 161 and 162: 38 33 28 23 18 0 30 60 90 120 150 m

- Page 163 and 164: Clothing German) were measured, and

- Page 165 and 166: Clothing Metabolism decreased and w

- Page 167 and 168: Clothing Table 1. Comparison of ski

- Page 169 and 170: Clothing PHYSIOLOGICAL RESPONSES AT

- Page 171 and 172: Clothing underwear at 25 °C in per

- Page 173 and 174: Clothing REDUCTION OF HEAT STRESS I

- Page 175 and 176: Clothing THE INTERACTION BETWEEN PH

- Page 177 and 178: Relative humidity (%) Clothing Figu

- Page 179 and 180: Clothing DEVELOPMENT OF THE “WEAR

- Page 181 and 182: Clothing EFFECTS OF AIR GAPS UNDER

- Page 183 and 184: Temper at ur e( ˇ ć) 28.5 27.5 26

- Page 185 and 186: Personal protective equipment Invit

- Page 187 and 188: Personal protective equipment fabri

- Page 189 and 190: Personal protective equipment PHYSI

- Page 191 and 192:

Mean skin temperature (ºC) 38.0 37

- Page 193 and 194:

Personal protective equipment the S

- Page 195 and 196:

Personal protective equipment DISCU

- Page 197 and 198:

Personal protective equipment Final

- Page 199 and 200:

Personal protective equipment REFER

- Page 201 and 202:

Personal protective equipment Tc wa

- Page 203 and 204:

Personal protective equipment level

- Page 205 and 206:

F i / g m -2 300 250 200 150 100 50

- Page 207 and 208:

h M / % 90 80 70 60 50 40 activity

- Page 209 and 210:

Personal protective equipment 0.05

- Page 211 and 212:

Personal protective equipment was u

- Page 213 and 214:

Personal protective equipment THERM

- Page 215 and 216:

Personal protective equipment the s

- Page 217 and 218:

Personal protective equipment the c

- Page 219 and 220:

Personal protective equipment wette

- Page 221 and 222:

Table 1 1. Properties of the tested

- Page 223 and 224:

Personal protective equipment HEAT

- Page 225 and 226:

Personal protective equipment Profi

- Page 227 and 228:

Personal protective equipment PHYSI

- Page 229 and 230:

Personal protective equipment REDUC

- Page 231 and 232:

39.0 38.5 38.0 37.5 37.0 36.5 40.0

- Page 233 and 234:

Personal protective equipment EXERC

- Page 235 and 236:

Personal protective equipment appro

- Page 237 and 238:

Personal protective equipment Table

- Page 239 and 240:

Personal protective equipment reduc

- Page 241 and 242:

Invited presentation Non-thermal fa

- Page 243 and 244:

Non-thermal factors heat loss by al

- Page 245 and 246:

Non-thermal factors DOES A FATIGUE-

- Page 247 and 248:

Non-thermal factors cycling, despit

- Page 249 and 250:

Non-thermal factors INDIVIDUAL VARI

- Page 251 and 252:

Non-thermal factors to some categor

- Page 253 and 254:

Non-thermal factors RATES OF TOTAL

- Page 255 and 256:

Non-thermal factors CHANGES IN BLOO

- Page 257 and 258:

Non-thermal factors Table 1. Thresh

- Page 259 and 260:

Non-thermal factors THE DIFFERENCE

- Page 261 and 262:

Water intake(g) 2000 1800 1600 1400

- Page 263 and 264:

Non-thermal factors IMPROVED FLUID

- Page 265 and 266:

Non-thermal factors A tendency for

- Page 267 and 268:

Sweating Table 1: Sweat gland count

- Page 269 and 270:

Sweating Taylor, N.A.S. (2000). Reg

- Page 271 and 272:

Sweating back/waist area and finall

- Page 273 and 274:

Figure 1: A chrome dome following p

- Page 275 and 276:

Sweating Such differences could be

- Page 277 and 278:

Sweating the forearm and thigh skin

- Page 279 and 280:

Sweating dramatically after puberty

- Page 281 and 282:

Sweating In addition local sweating

- Page 283 and 284:

Sweating REGIONAL FOOT SWEAT RATES

- Page 285 and 286:

Sweating REGIONAL SWEAT RATES OF TH

- Page 287 and 288:

Sweating Figure 2 shows the skin te

- Page 289 and 290:

Sweating SWEATY HANDS: DIFFERENCES

- Page 291 and 292:

Sweating Figure 2: Inter-site sweat

- Page 293 and 294:

Sweating REGIONAL DIFFERENCES IN TO

- Page 295 and 296:

Sweating Figure 2: Inter-site sweat

- Page 297 and 298:

Sweating MENSTRUAL CYCLE DOES NOT A

- Page 299 and 300:

Sweating RESULTS On average, the ma

- Page 301 and 302:

Sweating THE SWEAT SECRETION AND SO

- Page 303 and 304:

Sweating Figure 1: A quadrant diagr

- Page 305 and 306:

Invited presentation FINGER COLD IN

- Page 307 and 308:

Cold physiology INTRA-INDIVIDUAL DI

- Page 309 and 310:

Cold physiology number was estimate

- Page 311 and 312:

Cold physiology cold receptors decr

- Page 313 and 314:

Cold physiology EFFECT OF URAPIDIL

- Page 315 and 316:

Cold physiology THE EFFECT OF EXERC

- Page 317 and 318:

TRAINABILITY OF COLD INDUCED VASODI

- Page 319 and 320:

Cold physiology REFERENCES Adams, T

- Page 321 and 322:

Cold physiology THE EFFECT OF REPEA

- Page 323 and 324:

Cold physiology THE EFFECT OF ALTIT

- Page 325 and 326:

Cold physiology SKIN SURFACE MENTHO

- Page 327 and 328:

Cold physiology COGNITIVE PERFORMAN

- Page 329 and 330:

Seconds 6.5 6.0 5.5 5.0 4.5 4.0 3.5

- Page 331 and 332:

Cold water immersion REFERENCES Mek

- Page 333 and 334:

Cold water immersion the formula: M

- Page 335 and 336:

Cold water immersion REFERENCES Cho

- Page 337 and 338:

Cold water immersion were: 1 metre

- Page 339 and 340:

Cold water immersion surf beaches.

- Page 341 and 342:

Cold water immersion Table 1. Break

- Page 343 and 344:

Cold water immersion ARM INSULATION

- Page 345 and 346:

Cold water immersion RESULTS Experi

- Page 347 and 348:

Cold water immersion thermogenesis

- Page 349 and 350:

Cold water immersion The other comp

- Page 351 and 352:

Cold water immersion REFERENCES And

- Page 353 and 354:

Thermal comfort THERMAL SENSATIONS

- Page 355 and 356:

Exer - cise PC Wind (m·s -1 ) 0 ne

- Page 357 and 358:

Thermal comfort and heart rate usin

- Page 359 and 360:

Thermal comfort A NEW METHOD FOR EV

- Page 361 and 362:

Thermal comfort DEVELOPMENT OF AN I

- Page 363 and 364:

Thermal comfort DISCUSSION This new

- Page 365 and 366:

Thermal comfort limit of exposure d

- Page 367 and 368:

Table 2: Statistical summary. Gende

- Page 369 and 370:

Thermal comfort comfortable”), wh

- Page 371 and 372:

Thermal comfort RELATION BETWEEN TH

- Page 373 and 374:

Thermal comfort Figure 2. Skin wett

- Page 375 and 376:

Thermal comfort THE EVALUATION OF T

- Page 377 and 378:

Temp.ˇ ]˘ Jˇ ^ 42 40 38 36 34 32

- Page 379 and 380:

time(min) Thermal comfort WHY DO JA

- Page 381 and 382:

Thermal comfort TCT : THERMAL COMFO

- Page 383 and 384:

Thermal comfort INTERNATIONAL STAND

- Page 385 and 386:

Acute and chronic heat exposure PHY

- Page 387 and 388:

Acute and chronic heat exposure Fig

- Page 389 and 390:

Acute and chronic heat exposure EFF

- Page 391 and 392:

Acute and chronic heat exposure 2.2

- Page 393 and 394:

Acute and chronic heat exposure EFF

- Page 395 and 396:

Acute and chronic heat exposure A N

- Page 397 and 398:

Acute and chronic heat exposure of

- Page 399 and 400:

Acute and chronic heat exposure PHY

- Page 401 and 402:

Acute and chronic heat exposure Tab

- Page 403 and 404:

Acute and chronic heat exposure INT

- Page 405 and 406:

probability plot 99 95 80 60 40 20

- Page 407 and 408:

Acute and chronic heat exposure HAN

- Page 409 and 410:

Acute and chronic heat exposure ALL

- Page 411 and 412:

Acute and chronic heat exposure Tab

- Page 413 and 414:

Acute and chronic heat exposure UNC

- Page 415 and 416:

Thermal Sensation Scale 10 9 8 7 6

- Page 417 and 418:

Acute and chronic heat exposure RES

- Page 419 and 420:

Acute and chronic heat exposure eve

- Page 421 and 422:

Acute and chronic heat exposure 30%

- Page 423 and 424:

Acute and chronic heat exposure REF

- Page 425 and 426:

RADIANT FLOW THROUGH BICYCLE HELMET

- Page 427 and 428:

Figure 2. Difference in heat transf

- Page 429 and 430:

Manikins DEVELOPMENT OF A LYING DOW

- Page 431 and 432:

IT = 6.45( _ ,Tsk - _ ,Tair)/(Q/A)

- Page 433 and 434:

Manikins cases. If the body is even

- Page 435 and 436:

Heat balance components 100% 80% 60

- Page 437 and 438:

Manikins clothing system. This effe

- Page 439 and 440:

Manikins The coupled system was val

- Page 441 and 442:

Manikins A NOVEL APPROACH TO MODEL-

- Page 443 and 444:

Manikins THERMAL MANIKIN EVALUATION

- Page 445 and 446:

SR (g/min) Figure 2. Predictive mod

- Page 447 and 448:

ESTIMATION OF COOLING EFFECT OF ICE

- Page 449 and 450:

Manikins Figure 3: Comparison among

- Page 451 and 452:

Manikins EVALUATION OF THE ARMY BOO

- Page 453 and 454:

Ty [Nm] 60 50 40 30 20 10 0 0 5 10

- Page 455 and 456:

Manikins different black 100% cotto

- Page 457 and 458:

Manikins REFERENCES Bogerd, C.P., H

- Page 459 and 460:

Modelling RESULTS From this kind of

- Page 461 and 462:

Modelling (T , T , V& , ) = 1. 0 +

- Page 463 and 464:

NORMALIZED CVCL 8 7 6 5 4 3 2 1 0 M

- Page 465 and 466:

Modelling illustrated in Figure 1.

- Page 467 and 468:

Modelling MODELLING PATIENT TEMPERA

- Page 469 and 470:

Modelling Figure 1: Blood and mean

- Page 471 and 472:

Modelling simulations the additiona

- Page 473 and 474:

Modelling Table 1. Descriptive summ

- Page 475 and 476:

Modelling concomitant increase in b

- Page 477 and 478:

Modelling REFERENCES 1. U.S. Depart

- Page 479 and 480:

Modelling from the 1988 population.

- Page 481 and 482:

Modelling somatotypes in multivaria

- Page 483 and 484:

Modelling Each scan data was first

- Page 485 and 486:

Modelling The line through the data

- Page 487 and 488:

Hip( width) −Waist ( width ) HW

- Page 489 and 490:

Modelling measurements are extracte

- Page 491 and 492:

Measurement methods not included in

- Page 493 and 494:

Measurement methods humidity. The o

- Page 495 and 496:

Measurement methods DISCUSSION Base

- Page 497 and 498:

Air film Skin surface Skin layer δ

- Page 499 and 500:

Measurement methods and calculated

- Page 501 and 502:

Rectal temperature ( o C) 39.5 39.0

- Page 503 and 504:

Measurement methods work rates, and

- Page 505 and 506:

Measurement methods HUMIDEX: CAN TH

- Page 507 and 508:

Measurement methods highlighted. In

- Page 509 and 510:

Invited presentation Universal Ther

- Page 511 and 512:

Universal Thermal Climate Index dat

- Page 513 and 514:

Universal Thermal Climate Index DYN

- Page 515 and 516:

Universal Thermal Climate Index DIS

- Page 517 and 518:

Universal Thermal Climate Index COM

- Page 519 and 520:

Skin temperature (°C) Universal Th

- Page 521 and 522:

Universal Thermal Climate Index PRO

- Page 523 and 524:

Universal Thermal Climate Index The

- Page 525 and 526:

Universal Thermal Climate Index ASS

- Page 527 and 528:

Universal Thermal Climate Index ima

- Page 529 and 530:

Universal Thermal Climate Index min

- Page 531 and 532:

Working environment EFFECTS OF LIGH

- Page 533 and 534:

Working environment It is interesti

- Page 535 and 536:

30 25 20 15 10 5 0 25 12 Working en

- Page 537 and 538:

Working environment ERGONOMICS OPTI

- Page 539 and 540:

Working environment astigmatism, an

- Page 541 and 542:

Working environment RESULTS The hig

- Page 543 and 544:

Working environment hearing protect

- Page 545 and 546:

Working environment Redistribution

- Page 547 and 548:

Working environment DISCUSSION Thes

- Page 549 and 550:

Working Environment over the phone

- Page 551 and 552:

Working Environment DISCUSSION Diff

- Page 553 and 554:

Working Environment results, conclu

- Page 555 and 556:

Working Environment BP as the refer

- Page 557 and 558:

Working Environment significantly a

- Page 559 and 560:

Working Environment responses betwe

- Page 561 and 562:

Working Environment Casualty handli

- Page 563 and 564:

Working Environment REFERENCES Davi

- Page 565 and 566:

Working Environment RESULTS The sub

- Page 567 and 568:

Temperature (C) 35 33 31 29 27 25 2

- Page 569 and 570:

Working Environment METHODS Student

- Page 571 and 572:

Working Environment ANTHROPOGENIC I

- Page 573 and 574:

Working Environment RESULTS The res

- Page 575 and 576:

Employment Standards VISUAL ACUITY

- Page 577 and 578:

Employment Standards Results are pr

- Page 579 and 580:

Employment Standards to spend free

- Page 581 and 582:

Occupational Thermal Problems and d

- Page 583 and 584:

Occupational Thermal Problems HEAT

- Page 585 and 586:

Occupational Thermal Problems some

- Page 587 and 588:

Occupational Thermal Problems HORSE

- Page 589 and 590:

Occupational Thermal Problems range

- Page 591 and 592:

Occupational Thermal Problems PHYSI

- Page 593 and 594:

Occupational Thermal Problems DISCU

- Page 595 and 596:

Occupational Thermal Problems recom

- Page 597 and 598:

DLEmin [hours] 7,0 6,0 5,0 4,0 3,0

- Page 599 and 600:

Occupational Thermal Problems EFFEC

- Page 601 and 602:

Occupational Thermal Problems PERIP

- Page 603 and 604:

Occupational Thermal Problems durin

- Page 605 and 606:

Occupational Thermal Problems PRODU

- Page 607 and 608:

Time (hours) 4 3,5 3 2,5 2 1,5 1 0,

- Page 609 and 610:

Occupational Thermal Problems (Suun

- Page 611 and 612:

Occupational Thermal Problems highl

- Page 613 and 614:

Occupational Thermal Problems and o

- Page 615 and 616:

1) estimated (208 - 0.7 x age) *P

- Page 617 and 618:

Occupational Thermal Problems of a

- Page 619 and 620:

Occupational Thermal Problems tempe

- Page 621 and 622:

Table 1: Environmental conditions o

- Page 623 and 624:

Occupational Thermal Problems The h

- Page 625 and 626:

Occupational Thermal Problems RESUL

- Page 627 and 628:

Occupational Thermal Problems PHYSI

- Page 629 and 630:

Occupational Thermal Problems corre

- Page 631 and 632:

Occupational Thermal Problems DEVEL

- Page 633 and 634:

Occupational Thermal Problems All i

- Page 635 and 636:

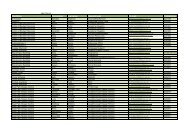

A Adolfsson Niklas 540 Ainslie Phil

- Page 637 and 638:

Kim Myung-Ju 409 Kim Taegyou 189 Kl

- Page 639 and 640:

Sormunen Erja 599 Spindler Uli 145

- Page 641:

SPONSOR 641