Kalzip flat roofing systems

Kalzip flat roofing systems

Kalzip flat roofing systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Kalzip</strong> Ltd<br />

<strong>Kalzip</strong> <strong>flat</strong> <strong>roofing</strong> <strong>systems</strong><br />

product review<br />

High performance, cost effective solutions<br />

for <strong>flat</strong> / low pitched roofs<br />

<strong>Kalzip</strong> aluminium roof system is BBA approved (Agrément Certificate No 98/3481)*<br />

for use on <strong>flat</strong>/low pitched roofs down to 1.5º, making it a robust and cost effective<br />

alternative to single ply membrane.<br />

<strong>Kalzip</strong> is a proven solution offering complete versatility across every kind of <strong>roofing</strong><br />

application and its many advantages can eliminate the concerns often associated with<br />

single ply <strong>flat</strong> <strong>roofing</strong> products.<br />

Benefits<br />

• Roof sheets are secret-fixed to the substructure by means of non-penetrative<br />

clips – there are no through fixings and therefore no leaks<br />

• Mechanical design of <strong>Kalzip</strong> eliminates the need for sealants and bonding as a<br />

method of weathering making the system reliably weathertight<br />

• Buildings can be made watertight far sooner than would be possible using<br />

alternative single ply <strong>roofing</strong> methods<br />

• High standing seam eliminates potential for ingress at joints<br />

• Unlimited sheet lengths with on-site production means no end laps<br />

• Aluminium is more resistant to damage (e.g. punctures, tears) than other single<br />

ply materials and its properties are not compromised by temperature cycling<br />

• No hot processes on-site<br />

*Certificate number may change pending the issue of a new BBA certificate.

Proven benefits, new opportunities<br />

Architects, designers and specifiers<br />

have long recognised the creative<br />

possibilities afforded by the <strong>Kalzip</strong><br />

standing seam <strong>roofing</strong> system, with<br />

millions of square metres now installed<br />

on roofs of every shape and size.<br />

The success of any roof is measured<br />

by its long term performance and this<br />

is just one area in which <strong>Kalzip</strong> offers<br />

substantially improved performance –<br />

and whole life cost – compared with<br />

traditional <strong>flat</strong> roof materials.<br />

Inherently strong and watertight<br />

With its ease of installation, inherent<br />

water-tightness, durability and 40 year<br />

guarantee, <strong>Kalzip</strong> makes sense from a<br />

financial as well as aesthetic point of<br />

view.<br />

<strong>Kalzip</strong> is renowned for its visual<br />

impact and performance on numerous<br />

landmark and prestigious buildings<br />

around the world, and for its ability to<br />

accommodate the most complex of<br />

geometries, both angular and organic<br />

in form.<br />

As an aluminium product, <strong>Kalzip</strong> combines strength with lightness. It is durable,<br />

corrosion-resistant and essentially maintenance-free. In short, it offers the best of<br />

both worlds: aesthetic appeal and ultimate practicality.<br />

The design of the <strong>Kalzip</strong> system builds on these qualities, enabling quick and easy<br />

installation with techniques that maintain the robustness of the material.<br />

<strong>Kalzip</strong>’s weather-tightness is based on its mechanical properties as opposed to<br />

manual finishing or the application of sealants. As an aluminium product it is also<br />

far more resistant to damage (e.g. punctures, tears) than other materials and its<br />

properties will not be compromised by temperature cycling.<br />

It is also a system as well suited to<br />

<strong>flat</strong>/low pitch roofs as it is to the more<br />

elaborate curved and/or tapered roofs<br />

for which it has earned its outstanding<br />

reputation.<br />

<strong>Kalzip</strong> is a proven solution offering<br />

complete versatility across every kind<br />

of <strong>roofing</strong> application and is available<br />

in a multitude of standard <strong>Kalzip</strong><br />

configurations to cater for all designs<br />

and the most exacting performance<br />

requirements.<br />

Examples of standard <strong>Kalzip</strong> configurations for <strong>flat</strong> roof applications<br />

<strong>Kalzip</strong> liner system <strong>Kalzip</strong> liner deck system <strong>Kalzip</strong> acoustic build<br />

Profile Filler<br />

sealed top and<br />

bottom<br />

Butyl seal<br />

Butyl seal<br />

Boundary wall composite gutter<br />

THE MAIN AREAS OF POTENTIAL LEAKAGE ARE<br />

AT JUNCTION DETAILS. CONSIDERATION SHOULD BE GIVEN<br />

TO COMPONENT JUNCTIONS TO ACHIEVE AIRTIGHTNESS<br />

6<br />

Composite insulated gutter<br />

Above Gutter - Patent Pending<br />

5 3<br />

2<br />

Profile fillers sealed top<br />

and bottom to liner<br />

4<br />

1<br />

KALZIP SHEET<br />

THERMAL INSULATION<br />

VAPOUR CONTROL LAYER<br />

STRUCTURAL DECKING<br />

ROOF BEAM<br />

FLASHING SUPPORT<br />

Clip Size<br />

E-120<br />

VERGE FLASHING<br />

GABLE END CLIP<br />

GABLE END<br />

CHANNEL<br />

KALZIP CLIP INTERNAL<br />

FLASHING<br />

RIDGE FLASHING<br />

Z-SECTION RIDGE SUPPORT<br />

U-TYPE RIDGE FILLER<br />

U-TYPE RIDGE CLOSURE<br />

E-CLIP<br />

Typical double skin parapet detail<br />

E Clip<br />

Spacer<br />

E-100<br />

Clip Size<br />

Spacer<br />

APRON FLASHING SEALED UNDER PARAPET<br />

INSULATION<br />

KALZIP SHEET<br />

LINER SHEET<br />

VAPOUR CONTROL LAYER<br />

Double skin abutment verge detail to parapet<br />

STRAP<br />

FLASHING<br />

TREATED TIMBER

Cost-effective solution for <strong>flat</strong>/low pitched roofs<br />

The durability, ease of installation and maintenance-free<br />

nature of <strong>Kalzip</strong> also means it offers a cost-effective alternative<br />

to single ply membrane. In fact, a whole life comparison (WLC)<br />

report published by the Building Research Establishment (BRE)<br />

concluded that:<br />

“… in the longer term, the predicted<br />

cumulative life cycle costs show that the<br />

<strong>Kalzip</strong> liner roof actually provides the<br />

most economical option …”<br />

The low operational cost associated with <strong>Kalzip</strong> is one of its<br />

key advantages. Where other roof types tend to require regular<br />

cleaning, maintenance and overhaul of failed areas, a <strong>Kalzip</strong><br />

roof is essentially maintenance-free, Agrément Certificate No<br />

98/3481 states that, depending on the environment, <strong>Kalzip</strong> “will<br />

have a minimum service life of 40 years” and this is reflected in<br />

the <strong>Kalzip</strong> XL Guarantee, a forty year performance guarantee<br />

that covers the full system build from the outer sheet through<br />

to the internal liner.<br />

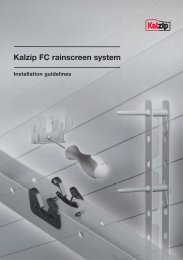

Fast, quality-assured installation<br />

Installation of <strong>Kalzip</strong> <strong>roofing</strong> is carried out to a high level of<br />

predetermined standard details by fully trained and approved<br />

members of the Teamkal installer network. Indeed, the<br />

Agrément Certificate specifically links site working practices<br />

with system details, providing further assurances of the highest<br />

standard of installation.<br />

The mechanical nature of the fix, combined with a system<br />

of integrated, prefabricated components and accessories,<br />

minimises installation time and ensures that the building is<br />

watertight far sooner than would be possible using alternative<br />

<strong>roofing</strong> methods. Another important benefit is <strong>Kalzip</strong>’s ability to<br />

be installed in virtually all conditions, substantially reducing the<br />

risk of delays due to adverse weather.<br />

Excellent thermal and acoustic<br />

insulation<br />

Once installed, a <strong>Kalzip</strong> roof provides excellent performance in<br />

terms of minimising heat transfer and sound levels.<br />

The use of aluminium helps to reduce heat transfer and this<br />

property can be enhanced with surface treatments, enabling<br />

energy flow through the roof to be cut from 340 to 50 W/m 2 .<br />

The qualities of heat reflection in summer and heat retention in<br />

winter enable energy saving and associated cost reduction.<br />

<strong>Kalzip</strong> also offers good acoustic performance, with tests<br />

demonstrating the ability to reduce noise levels by as much<br />

as 53dB (typically 38-40dB). Insulants or acoustic mat can be<br />

incorporated to further enhance this performance if required.

www.kalzip.com<br />

Care has been taken to ensure that this<br />

information is accurate, but Tata Steel Europe<br />

Limited – including its subsidiaries – does not<br />

accept responsibility for information which is<br />

found to be misleading.<br />

Copyright 2010<br />

Corus<br />

<strong>Kalzip</strong> Ltd<br />

Haydock Lane<br />

Haydock<br />

St Helens<br />

Merseyside WA11 9TY<br />

England<br />

T: +44 (0) 1942 295500<br />

F: +44 (0) 1942 295508<br />

Email: enquiries.uk@kalzip.com<br />

English<br />

Outstanding sustainability<br />

Aluminium is inherently sustainable. The raw material that contains aluminium, bauxite,<br />

is the third must abundant element in the earth’s crust with at least 300 years of<br />

reserves left at the current rate of usage. Furthermore, the power used in its production<br />

is predominantly hydroelectric, which is clean, CO 2 free and renewable.<br />

Once it has been produced, it then offers extraordinary recyclability: it can be reused<br />

again and again – with no loss of performance – and up to 95% of the energy used in<br />

initial manufacture is saved through recycling.<br />

<strong>Kalzip</strong> takes this recyclability a stage further with a system that provides decades of<br />

total building protection, and can then be unzipped and reused or recycled when a<br />

building reaches the end of its working life.<br />

If reuse is not possible, then <strong>Kalzip</strong>, as an aluminium product, offers an extremely high<br />

residual value compared with other <strong>roofing</strong> products, eliminating the cost and adverse<br />

environmental impact associated with disposal by landfill.<br />

This level of recyclability, together with its long term performance, means a <strong>Kalzip</strong><br />

system can provide A+ ‘Green Rating’ for BREEAM accreditation.<br />

Another green benefit of using a <strong>Kalzip</strong> roof is the opportunity to incorporate either of<br />

<strong>Kalzip</strong>’s two photovoltaic solar solutions – AluPlusSolar and Solarclad – or the advanced<br />

<strong>Kalzip</strong> Nature Roof system with its low growing, self-regenerating, drought-resistant<br />

plant cover.<br />

<strong>Kalzip</strong> AluPlusSolar <strong>Kalzip</strong> Nature Roof<br />

A fully tested and certified system<br />

<strong>Kalzip</strong> benefits from extensive 3rd party certification including:<br />

• ASTM (USA)<br />

• Avis Technique (France)<br />

• BBA (UK)<br />

• Factory Mutual (France)<br />

• Zulassung (Germany)