the coking properties of coal at elevated pressures. - Argonne ...

the coking properties of coal at elevated pressures. - Argonne ... the coking properties of coal at elevated pressures. - Argonne ...

Turkgodan et al. (18) studied the pore characteristics of several carbons, graphite, coke and charcoal. They concluded thdt about 1/2 of the volume is located in micropores and therefore not avdilable for reaction, Most of the internal surface area was located in pores in the micropore range. The pore vol unie, pore surface area, and effective di ffusi vi ty increased with conversion during internal oxidation, Dutta and Wen (16, 17) studied the reactivities of several raw coals and chars. They noted a change in the actual pore structures of a few samples at di Fferent conversions from scanning electron micrographs. A rate equation was proposed that incorporated the change of the relative available surface area during reaction. No measurements of this change were made. A rate expression, which includes the influence of a chemical and diffusion reaction controlling niechanisnis, is expressed where: c= dX dt rl s k c c02 (l-xc) Xc is the conversion of the solid S is the surface area available for reaction k is the reaction rate constant rl is the effectiveness factor is the concentration of C02 in gas phase cco2 t is time The effectiveness factor n is equal to the ratio of the reaction rate under diffusion-controlled conditions to that which would occur if the concentration of reactants were equal to the surface concentration. For a first order diffu- sion-controlled reaction the influence of pore-diffusion is given by equation 2) where : S is the specific surface k is the reaction rate constant rc is the radius of the particle De is the effective diffusivity The effectiveness factor n is a function of the effective modulus, $, which is dependent upon the effective diffusivity, D . The effective diffusivity and the surface area available for reaction chgnge during the reaction, 32 1)

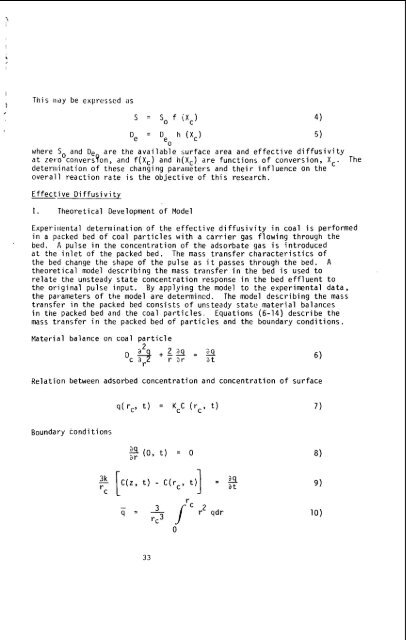

I 1 This itidy be expressed as s = so f iXC) De = D h (X,) en 5) where So and De are the available surface area and effective diffusivity at zero convers?on, and f(Xc) and h(Xc) are functions of conversion, Xc. deterillination of these changing parameters and their influence on the overall reaction rate is the objective of this research. Effective Diffusi vi ty I. Theoretical Development of Model Experiinental determination of the effective diffusivity in coal is performed in a packed bed of coal particles with a carrier gas flowing through the bed. A pulse in the concentration of the adsorbate gas is introduced at the inlet of the packed bed. The mass transfer characteristics of the bed change the shape of the pulse as it passes through the bed. theoretical model describing the mass transfer in the bed is used to relate the unsteady state concentration response in the bed effluent to the original pulse input. By applying the model to the experimental data, the parameters of the model are determined. The model describing the mass transfer in the packed bed consists of unsteady state material balances in the packed bed and the coal particles. Equations (6-14) describe the mass transfer in the packed bed of particles and the boundary conditions. Material balance on coal particle Relati.on between adsorbed concentration and concentration of surface Boundary condi t ons q(rc, t) = KcC (rc. t) 3 (0, t) = 0 33 4) A The

- Page 1 and 2: I / The Coking Properties of Coal a

- Page 3 and 4: Procedure : Hand picked lunips of c

- Page 5 and 6: Apparatus: The equipment for this t

- Page 7 and 8: the total pressure on the swelling

- Page 9 and 10: A comparison of the results obtaine

- Page 11 and 12: was used, however, general trends a

- Page 13 and 14: 1 D 13 3 G

- Page 16 and 17: Table 8 L_ Effect os FaeO Compo.lrl

- Page 18 and 19: i-l SPARE SAblPLE Plortlc 209 Figur

- Page 20 and 21: - z c 100,000 50,000 10,000 0 n 5,0

- Page 22 and 23: Flnure 9 SWELLltlG PROPERTIES OF PI

- Page 24 and 25: Fi ure 13 EFFECT OF TOTAL PRESSQRE,

- Page 26 and 27: TABLE 1. OPERATING CONDITIONS Opera

- Page 28 and 29: 1. . 2. 3. 4. 5. 6. 7. 8. 9. REFERE

- Page 30 and 31: Figure 4. SCANNING ELECTRON MICROGR

- Page 34 and 35: Materidl balance on packed bed Boun

- Page 36 and 37: These phenomena iiiay be described

- Page 38 and 39: Walker, P. L., Rusinko, F., and Aus

- Page 40 and 41: -""I- *I,".. I Dlrf".,on Co.1flcl.n

- Page 42 and 43: After a variable residence time, th

- Page 44 and 45: Changes in Char Chemistry The infra

- Page 46 and 47: 20. 21. 22. 23. 24. 25. 26. 27. 28.

- Page 48 and 49: 0s-a 00-a OS'S 00-E os-2 00-2 02.1

- Page 50 and 51: COAL PYROLYSIS AT HIGH TEMPERATURES

- Page 52 and 53: actions, decreasing the secondary c

- Page 54 and 55: 01 40 60 TI MEISeC) 80 100 120 140

- Page 56 and 57: Reaction Temperature OC In-situ Ini

- Page 58 and 59: and the gas velocity is often repre

- Page 60 and 61: The mathematical model developed he

- Page 62 and 63: si sio Fraction of solid species i

- Page 64 and 65: Table 2. Differential Equations Mod

- Page 66 and 67: 1 60 I I RUN KE-5 50 T.1121K(1557'F

- Page 68 and 69: to condense excess steam, the press

- Page 70 and 71: conversion-time data.* The integrat

- Page 72 and 73: catalyzed and uncatalyzed runs were

- Page 74 and 75: CATALYTIC EFFECTS OF ALKALI METAL S

- Page 76 and 77: %me thermogravimetric measurements

- Page 78 and 79: than in steam. Figure 9 shows data

- Page 80 and 81: C - C02 REACTION C - H20 REACTION L

I<br />

1<br />

This itidy be expressed as<br />

s = so f iXC)<br />

De = D h (X,)<br />

en<br />

5)<br />

where So and De are <strong>the</strong> available surface area and effective diffusivity<br />

<strong>at</strong> zero convers?on, and f(Xc) and h(Xc) are functions <strong>of</strong> conversion, Xc.<br />

deterillin<strong>at</strong>ion <strong>of</strong> <strong>the</strong>se changing parameters and <strong>the</strong>ir influence on <strong>the</strong><br />

overall reaction r<strong>at</strong>e is <strong>the</strong> objective <strong>of</strong> this research.<br />

Effective Diffusi vi ty<br />

I. Theoretical Development <strong>of</strong> Model<br />

Experiinental determin<strong>at</strong>ion <strong>of</strong> <strong>the</strong> effective diffusivity in <strong>coal</strong> is performed<br />

in a packed bed <strong>of</strong> <strong>coal</strong> particles with a carrier gas flowing through <strong>the</strong><br />

bed. A pulse in <strong>the</strong> concentr<strong>at</strong>ion <strong>of</strong> <strong>the</strong> adsorb<strong>at</strong>e gas is introduced<br />

<strong>at</strong> <strong>the</strong> inlet <strong>of</strong> <strong>the</strong> packed bed. The mass transfer characteristics <strong>of</strong><br />

<strong>the</strong> bed change <strong>the</strong> shape <strong>of</strong> <strong>the</strong> pulse as it passes through <strong>the</strong> bed.<br />

<strong>the</strong>oretical model describing <strong>the</strong> mass transfer in <strong>the</strong> bed is used to<br />

rel<strong>at</strong>e <strong>the</strong> unsteady st<strong>at</strong>e concentr<strong>at</strong>ion response in <strong>the</strong> bed effluent to<br />

<strong>the</strong> original pulse input. By applying <strong>the</strong> model to <strong>the</strong> experimental d<strong>at</strong>a,<br />

<strong>the</strong> parameters <strong>of</strong> <strong>the</strong> model are determined. The model describing <strong>the</strong> mass<br />

transfer in <strong>the</strong> packed bed consists <strong>of</strong> unsteady st<strong>at</strong>e m<strong>at</strong>erial balances<br />

in <strong>the</strong> packed bed and <strong>the</strong> <strong>coal</strong> particles. Equ<strong>at</strong>ions (6-14) describe <strong>the</strong><br />

mass transfer in <strong>the</strong> packed bed <strong>of</strong> particles and <strong>the</strong> boundary conditions.<br />

M<strong>at</strong>erial balance on <strong>coal</strong> particle<br />

Rel<strong>at</strong>i.on between adsorbed concentr<strong>at</strong>ion and concentr<strong>at</strong>ion <strong>of</strong> surface<br />

Boundary condi t<br />

ons<br />

q(rc, t) = KcC (rc. t)<br />

3 (0, t) = 0<br />

33<br />

4)<br />

A<br />

The