the coking properties of coal at elevated pressures. - Argonne ...

the coking properties of coal at elevated pressures. - Argonne ... the coking properties of coal at elevated pressures. - Argonne ...

Post Flame Cavity -(TJ 0 Temperature OF Figure 1. Effect of Temperature and Stoichiometric P,atio on Equilibrium Calcium Distribution - % Ca as CaS04 or CaS (Ca/S = 1) 4-L Air + Coal- Radiant 0 Sample Locations 0 Sorbent Injection A Internal Air Staging External Air Staging - Cooling Air II II 0 Exhaust Figure 2. Schematic of Test Furnace Showing Location of Sample Ports, Staged Air Addition and Sorbent Injection. 160

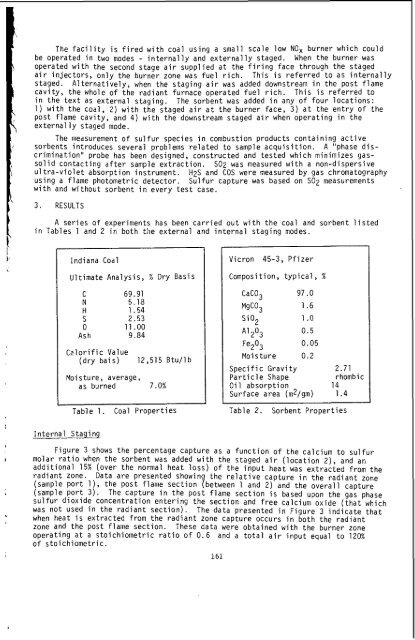

The facility is fired with coal using a small scale low NOx burner which could be operated in two modes - internally and externally staged. When the burner was operated with the second stage air supplied at the firing face through the staged air injectors, only the burner zone was fuel rich. This is referred to as internally staged. Alternatively, when the staging air was added downstream in the post flame cavity, the whole of the radiant furnace operated fuel rich. This is referred to in the text as external staging. The sorbent was added in any of four locations: 1) with the coal, 2) with the staged air at the burner face, 3) at the entry of the post flame cavity, and 4) with the dowixtream staged air when operating in the externally staged mode. The measurement of sulfur species in combustion products containing active sorbents introduces several problems related to sample acquisition. A "phase discrimination" probe has been designed, constructed and tested which minimizes gassolid contacting after sample extraction. SO2 was measured with a non-dispersive ul tra-violet absorption instrument. H2S and COS were measured by gas chromatography using a flame photometric detector. Sulfur capture was based on SO2 measurements with and without sorbent in every test case. 3. RESULTS A series of experiments has been carried out with the coal and sorbent listed in Tables 1 and 2 in both the external and internal staging modes. Indiana Coal Ultimate Analysis, % Dry Basis C 69.91 N 5.13 H 1.54 S 2.53 0 11 .OD Ash 9.84 Cslorific Value (dry bais) 12,515 Btu/lb Moisture, average, as burned 7.0% Internal Staging Table 1. Coal Properties Vicron 45-3, Pfizer Composition, typical, % CaC03 97.0 MgC03 1.6 sio2 1 .o 2'3 0.5 Fe203 Moisture 0.05 0.2 Specific Gravity Particle Shape Oil absorption Surface area (m2/gm) ~~ Table 2. Sorbent Properties 2.71 rhombic 4 1.4 Figure 3 shows the Percentage capture as a function of the calcium to sulfur molar ratio when the sorbent was added with the staged air (location 2), and an additional 15% (over the normal heat loss) of the input heat was extracted from the radiant zone. Data are presented showin the relative capture in the radiant zone (sample port 11, the post flame section ?between 1 and 2) and the overall capture (sample port 3). The capture in the post flame section is based upon the gas phase sulfur dioxide concentration entering the section and free calcium oxide (that which was not used in the radiant section). The data presented in Figure 3 indicate that when heat is extracted from the radiant zone capture occurs in both the radiant zone and the post flame section. These data were obtained with the burner zone operating at a stoichiometric ratio of 0.6 and a total air input equal to 120% of stoichiometric . 161

- Page 109 and 110: I. INTRODUCTION DIRECT METHANATION

- Page 111 and 112: The catalyst development program fo

- Page 113 and 114: Preparing process flow diagrams and

- Page 115 and 116: \ \ i 1. 2,000 4,000 6,000 8,000 10

- Page 117 and 118: (JMS-OlBM-2). The mass spectra were

- Page 119 and 120: I I Fairbridge, R.W. (ed.) 1972, En

- Page 121 and 122: v- W V z d 3 z m 4 ? P m W c3 W m N

- Page 123 and 124: e. \ I , W 2 m 4 t- CI 99-79 noooo

- Page 125 and 126: L Table I: Compositions of High Tem

- Page 127 and 128: \ " \ I For all three coals, the pr

- Page 129 and 130: 4 , 1024 1024 3a 3b J Mineral Parti

- Page 131 and 132: The Determination of Mineral Distri

- Page 133 and 134: pyrite crystals in framboids locate

- Page 135 and 136: FIG. 1. TEM MICROGRAPH OF A HIGH VO

- Page 137 and 138: \ \ FIG. 5. SEM MICROGRAPH SHOWING

- Page 139 and 140: \ , species. In fact, combustion ex

- Page 141 and 142: 1, It is possible to make a reasona

- Page 143 and 144: \ i SURFACE AND BULK ENRICHMENT OF

- Page 145 and 146: I Coal Ash Sintering Model and the

- Page 147 and 148: 5 carried out such sintering measur

- Page 149 and 150: I this ash and other bituminous coa

- Page 151 and 152: forming propensity. However, none o

- Page 153 and 154: t I 153

- Page 155 and 156: CENTRAL ELECTRICIN RESEARCH LABORAT

- Page 157 and 158: 157 18 I I a I

- Page 159: temperature, sulfur species concent

- Page 163 and 164: Tests have been carried out to dete

- Page 165 and 166: under which conditions sulfur speci

- Page 167 and 168: I TITANIUM L Corn AS A TRACER FOR D

- Page 169 and 170: E 6 i i h \ 1 1 \ on the XRF is cau

- Page 171 and 172: \ ? CONCLUSIONS Titanium can accura

- Page 173 and 174: NY) m * oa

- Page 175 and 176: GFETC constructed a 0.2 square mete

- Page 177 and 178: \: Stage 3. Sulfated ash-cemented a

- Page 179 and 180: I FIG. 1. Initial ash coating on qu

- Page 181 and 182: FIG 9. Limestone bed material alter

- Page 183 and 184: (4) Since the operating temperature

- Page 185 and 186: I I maximum particle diameter leavi

- Page 187 and 188: ! suspension chambers and cyclone f

- Page 189 and 190: Pilot Plant of a Coal Fired Fluidiz

- Page 191 and 192: After the fiscal year 1982, the fol

- Page 193 and 194: MBC CBC Fig. 1 Boiler Structure 193

- Page 195 and 196: \ i Table 2. Coal Properties Planne

- Page 197 and 198: -2- more than 3 years, since 1977.

- Page 199 and 200: , I B. 2 which temporarily raised t

- Page 201 and 202: -6- abrasion rate at the bottom of

- Page 203 and 204: \if F3.3 - Particulate Circulation

- Page 205 and 206: \' I/O. analog 1/13. industrial I/O

- Page 207 and 208: ACQUISITION DATA UNIT < I L- J (T)

- Page 209 and 210: SAMPLING SYSTEM FOR FLUIDIZED BED A

The facility is fired with <strong>coal</strong> using a small scale low NOx burner which could<br />

be oper<strong>at</strong>ed in two modes - internally and externally staged. When <strong>the</strong> burner was<br />

oper<strong>at</strong>ed with <strong>the</strong> second stage air supplied <strong>at</strong> <strong>the</strong> firing face through <strong>the</strong> staged<br />

air injectors, only <strong>the</strong> burner zone was fuel rich. This is referred to as internally<br />

staged. Altern<strong>at</strong>ively, when <strong>the</strong> staging air was added downstream in <strong>the</strong> post flame<br />

cavity, <strong>the</strong> whole <strong>of</strong> <strong>the</strong> radiant furnace oper<strong>at</strong>ed fuel rich. This is referred to<br />

in <strong>the</strong> text as external staging. The sorbent was added in any <strong>of</strong> four loc<strong>at</strong>ions:<br />

1) with <strong>the</strong> <strong>coal</strong>, 2) with <strong>the</strong> staged air <strong>at</strong> <strong>the</strong> burner face, 3) <strong>at</strong> <strong>the</strong> entry <strong>of</strong> <strong>the</strong><br />

post flame cavity, and 4) with <strong>the</strong> dowixtream staged air when oper<strong>at</strong>ing in <strong>the</strong><br />

externally staged mode.<br />

The measurement <strong>of</strong> sulfur species in combustion products containing active<br />

sorbents introduces several problems rel<strong>at</strong>ed to sample acquisition. A "phase discrimin<strong>at</strong>ion"<br />

probe has been designed, constructed and tested which minimizes gassolid<br />

contacting after sample extraction. SO2 was measured with a non-dispersive<br />

ul tra-violet absorption instrument. H2S and COS were measured by gas chrom<strong>at</strong>ography<br />

using a flame photometric detector. Sulfur capture was based on SO2 measurements<br />

with and without sorbent in every test case.<br />

3. RESULTS<br />

A series <strong>of</strong> experiments has been carried out with <strong>the</strong> <strong>coal</strong> and sorbent listed<br />

in Tables 1 and 2 in both <strong>the</strong> external and internal staging modes.<br />

Indiana Coal<br />

Ultim<strong>at</strong>e Analysis, % Dry Basis<br />

C 69.91<br />

N 5.13<br />

H 1.54<br />

S 2.53<br />

0 11 .OD<br />

Ash 9.84<br />

Cslorific Value<br />

(dry bais) 12,515 Btu/lb<br />

Moisture, average,<br />

as burned 7.0%<br />

Internal Staging<br />

Table 1. Coal Properties<br />

Vicron 45-3, Pfizer<br />

Composition, typical, %<br />

CaC03 97.0<br />

MgC03 1.6<br />

sio2 1 .o<br />

2'3 0.5<br />

Fe203<br />

Moisture<br />

0.05<br />

0.2<br />

Specific Gravity<br />

Particle Shape<br />

Oil absorption<br />

Surface area (m2/gm)<br />

~~<br />

Table 2. Sorbent Properties<br />

2.71<br />

rhombic<br />

4<br />

1.4<br />

Figure 3 shows <strong>the</strong> Percentage capture as a function <strong>of</strong> <strong>the</strong> calcium to sulfur<br />

molar r<strong>at</strong>io when <strong>the</strong> sorbent was added with <strong>the</strong> staged air (loc<strong>at</strong>ion 2), and an<br />

additional 15% (over <strong>the</strong> normal he<strong>at</strong> loss) <strong>of</strong> <strong>the</strong> input he<strong>at</strong> was extracted from <strong>the</strong><br />

radiant zone.<br />

D<strong>at</strong>a are presented showin <strong>the</strong> rel<strong>at</strong>ive capture in <strong>the</strong> radiant zone<br />

(sample port 11, <strong>the</strong> post flame section ?between 1 and 2) and <strong>the</strong> overall capture<br />

(sample port 3). The capture in <strong>the</strong> post flame section is based upon <strong>the</strong> gas phase<br />

sulfur dioxide concentr<strong>at</strong>ion entering <strong>the</strong> section and free calcium oxide (th<strong>at</strong> which<br />

was not used in <strong>the</strong> radiant section). The d<strong>at</strong>a presented in Figure 3 indic<strong>at</strong>e th<strong>at</strong><br />

when he<strong>at</strong> is extracted from <strong>the</strong> radiant zone capture occurs in both <strong>the</strong> radiant<br />

zone and <strong>the</strong> post flame section. These d<strong>at</strong>a were obtained with <strong>the</strong> burner zone<br />

oper<strong>at</strong>ing <strong>at</strong> a stoichiometric r<strong>at</strong>io <strong>of</strong> 0.6 and a total air input equal to 120%<br />

<strong>of</strong> stoichiometric .<br />

161