AL STIRT - San Diego Woodturners

AL STIRT - San Diego Woodturners

AL STIRT - San Diego Woodturners

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Greetings All…<br />

Chapter AAW<br />

SHAVINGS<br />

...from the Prez<br />

Well the rain didn’t keep many<br />

of you away from our last<br />

meeting and Roman Sheidel’s<br />

demo! We had one of our best<br />

attended sessions so far! Roman’s<br />

knack for connecting<br />

with his audience was evident<br />

by the various comments and<br />

questions generated. I always<br />

find it interesting to observe<br />

reactions of the crowd --- ie.<br />

nodding in agreement, smiling/<br />

laughing at comments, jotting<br />

down notes, and “wowing”…<br />

Thanks Roman, it’s so good to<br />

have you back with us!<br />

Many of you seriously need to<br />

think about attending the Utah<br />

Woodturning Symposium , 16-<br />

19 May, in Orem Utah and/or<br />

AAW Symposium, 8 – 10 June,<br />

in <strong>San</strong> Jose CA.<br />

(Continued on page 2)<br />

A Chapter of the AAW<br />

Volume 2012 Number 02 February 2012<br />

P.O. Box 507061 • <strong>San</strong> <strong>Diego</strong>, CA 92150-7061 www.sdwt.org<br />

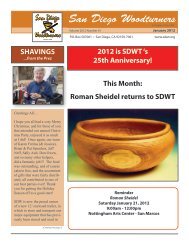

2012 is SDWT ‘s<br />

25th Anniversary!<br />

<strong>AL</strong> <strong>STIRT</strong><br />

Reminder<br />

Al Stirt<br />

Saturday February 18, 2012<br />

9:00am - 4:00pm<br />

$25 Admission (lunch provided)<br />

Nottingham Arts Center - <strong>San</strong> Marcos

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 2 February 2012<br />

(Shavings - Continued from page 1)<br />

We will continue to have a signup<br />

sheet to help folks arrange<br />

transportation, hotels, special<br />

events, etc. If you have not<br />

attended one of these fantastic<br />

events, you owe it to yourself<br />

to think about attending. Check<br />

out the web sites and note the<br />

outstanding list of presenters -<br />

-- notably among which are our<br />

own Sally Ault, Art Majerus,<br />

and Mike Jackofsky. Time to<br />

talk about one or both with your<br />

buddies!<br />

2012 is the 25th Anniversary of<br />

SDW’s founding, and we are<br />

trying to come up with a special<br />

way to celebrate. One suggestion<br />

is to get a special shirt from<br />

Art and Lu Majerus with the<br />

our logo and special 25th Anniversity<br />

embroidery, so we can<br />

wear it to Utah and/or <strong>San</strong> Jose.<br />

We’re open to suggestions, so<br />

put your thinking caps on…<br />

We are fortunate to have another<br />

great 2012 calendar. One favorite,<br />

coming back again in March,<br />

is “Tips and Techniques”. This<br />

is your opportunity to try a<br />

different technique/approach<br />

with the help of one of our “old<br />

timers”. Stay tuned in for the<br />

line-up! Coming right up on our<br />

list is the Al Stirt Demo on 18<br />

Feb --- check out his web site,<br />

he is amazing! Learn the latest,<br />

yet classic enhancing techniques<br />

for your turnings. So until next<br />

time… have fun, work hard, and<br />

stay safe!<br />

Nan<br />

HAPPENINGS<br />

Shavings 1<br />

Coming Events/Classes 3<br />

This Month: Al Stirt 4<br />

New Workshops/Updates 5<br />

January’s Program: Roman Sheidel 6<br />

Klingspor Woodworking Shop Offer 9<br />

Thickness Gauge Project 10<br />

A Woodturner’s Paradise 12<br />

Membership Message 13<br />

Mentors Available/2012 SD County Fair Timeline 14<br />

What do you do?/Bowls Wanted 15<br />

New Tablesaw Rules 16<br />

Safety in Woodturning 17<br />

Structured Cellulose Communications 18<br />

<strong>San</strong> <strong>Diego</strong> Woodturner’s Mentoring 19<br />

A. Bit Askew / Library News 20<br />

2012 Best Newsletter Contest 21<br />

Wants and Disposals 22<br />

February Raffle 25<br />

SDWT/Rockler Coupon 26<br />

Mentors/Committees/Board Members 27<br />

Resources/Wood News 28<br />

Membership Application 29<br />

Click on any title or page number to navigate to that page.......<br />

NOTTINGHAM ACCESS<br />

For access to the Nottingham Arts Center contact Terry Sullivan via<br />

e-mail (go2tms@sbcglobal.net.) Or at the number listed in the member<br />

directory. Include the day and time you intend on arriving as well as<br />

the purpose of your visit.<br />

Newsletter Blast<br />

Welcome to this month’s SDWT Turning “Magazine”.<br />

It’s your articles, pictures, and participation that make<br />

not only this newsletter, but the club as a whole what it<br />

is.... <strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> are one of the finest turning<br />

organizations anywhere! Thanks for your help!<br />

Phil Stivers<br />

woodenwonders@cox.net

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 3 February 2012<br />

February 18, 2012<br />

Al Stirt<br />

Demo and Classes<br />

All day demo with Al Stirt. $25 (bring check to SDWT) for<br />

admission. Lunch will be provided.<br />

March 17, 2012<br />

Tips and Techniques<br />

Nottingham Center<br />

Learn from the club’s “masters”. Hone your skills on different<br />

techniques. Try your hand at new ones.<br />

April 21, 2012<br />

Sally Ault<br />

Jewelry and wearable art.<br />

May 12, 2012 (Note Date Change)<br />

Richard Raffin<br />

Demo and Classes<br />

(Hands-on workshops will be BEFORE the club demo)<br />

All day demo with Richard Raffin. $30 (made out to<br />

SDWT) for admission.<br />

May17-19, 2012<br />

Utah Symposium<br />

Come to Utah for the “Super Sale”, Mike Mahoney, and the<br />

works of renowned turners from around the world.<br />

June 8-10, 2012<br />

AAW Symposium<br />

<strong>San</strong> Jose, CA. See AAW website for details.<br />

June 16, 2012<br />

Spring Fling Picnic<br />

Join us in celebrating the beginning of a beautiful <strong>San</strong><br />

<strong>Diego</strong> summer. Special raffle! Contest! Fishing!<br />

July 21, 2012<br />

Richard Spencer<br />

Segmenting<br />

WOODTURNING CLASSES/COMING EVENTS<br />

The following is a list of the woodturning classes and coming events. If you are interested in signing up for any<br />

of these classes act quickly since classes usually fill-up. Interested in being a demonstrator? Contact Sally Ault<br />

to sign-up or for more information. E-mail: sallyault@cox.net or by phone at 619-415-5308<br />

August 18, 2012<br />

Phil Stivers<br />

Hollow Globe Ornaments<br />

Download the demo notes from our website beginning<br />

in June.<br />

September 15, 2012<br />

Joe Fleming<br />

A master of color and calabash alike.<br />

October 20, 2012<br />

Take-A-Turn<br />

Nottingham Center<br />

Learn to CA finish, make a pen, core bowls, etc. Club<br />

turners and mentors will help you with these and other<br />

projects.<br />

November 17, 2012<br />

John Jordan<br />

SDWT Board Elections<br />

All day demo with John Jordan. $25 (bring check to<br />

SDWT) for admission. Lunch provided.<br />

December 8, 2012<br />

Annual Christmas Party!<br />

Do you have and idea for a demo/presentation?<br />

Contact Sally Ault (sallyault@cox.net - 619-415-5308

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 4 February 2012<br />

This Month -Al Stirt<br />

Al Stirt All day demo February 18 9am-4pm<br />

Al Stirt has been one of the pioneers in woodturnings move from strictly utilitarian to art. Al makes beautiful<br />

simple bowls as well as pieces with complex surface patterns. His attention to form and detail is legendary.<br />

As an instructor Al is able to make the process of whatever he is teaching extremely clear and easy to understand.<br />

He will show us how a slight change in the position of the grain can make all the difference between a<br />

nice bowl and a fabulous bowl.<br />

Al is well known for using surface<br />

patterns on simple shapes to create<br />

pieces that have a dynamic surface<br />

that both contrasts with and compliments<br />

the form. He will show us a<br />

number of techniques for enhancing<br />

the surface of a piece in either<br />

extremely controlled or free flowing<br />

patterns, Al uses Milk Paint to<br />

enhance his carvings and we will<br />

learn what a wonderful surface can be created with the combination of<br />

the paint, texture and wood.<br />

Al has developed a number of excellent “tools” to make carving the textures<br />

easier and we will see some of those and learn how to make them.<br />

(My favorite is the vacuum carving stand!)<br />

I know you will enjoy Al’s demo. Besides being an incredible talent he<br />

is a really nice guy!<br />

In Al’s words:<br />

“I consider myself a “bowl maker” more than a wood turner because, although the turning process fascinates<br />

me, it is the resulting bowl that commands my interest. From the earliest times bowls have had meanings for<br />

people beyond the purely utilitarian. The bowl as vessel has a resonance deep within the human psyche. I have<br />

always thought of each piece that I make as a composition<br />

utilizing elements of pattern, line, weight, texture<br />

and form. Even in the most simple pieces I try to find a<br />

harmony of grain and shape. I seek a balance in my work<br />

between the dynamic and the serene. By playing with the<br />

tension created by combining the circle’s perfection with<br />

the energy of pattern I am trying to make pieces that have<br />

life. I use patterns, whether created by grain structure or<br />

organic fluting & carving or repeated geometric shapes,<br />

to develop harmony in each of my pieces. I find myself<br />

always looking for a new means of expression within the<br />

turned form.”

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 5 February 2012<br />

New Workshops and Updates<br />

<strong>AL</strong> <strong>STIRT</strong><br />

There are a few spots in Al Stirt’s workshops Feb 61/17 or 19/20. The cost will be $225 for the workshop<br />

and will include lunch. The workshops will be held at Nottingham.<br />

Al’s club demo will be on February 18 and will be $25. Please bring your check already made out to SDWT<br />

to save time.<br />

MIKE JACKOFSKY<br />

Mike Jackofsky will teach a 3 day class on hollowing for those who have either taken his 2 day class or already<br />

have some experience with hollowing. He will also offer a two day “beginners” class before the three<br />

day add on (Can you say “I want to take all 5 days!”) The two day class will be March 21 & 22 ($200). The<br />

three day class will be March 24,25,26 and will cost $300 for the 3 days including lunch and some wood.<br />

I am forming a waiting list for Mike Jackofsky’s 3 day advanced and 2 day beginner classes. If the waiting<br />

list gets long enough I will try to talk Mike into another class.<br />

RICHARD RAFFIN<br />

Richard Raffan will do 3 two-day hands on workshops in May. The workshops will be May 5-6, 7-8, 10-11<br />

and the club demo will be on May 12.(Note that this is not our normal meeting date)<br />

The workshops will be $300 for the 2 days and will include lunch. The workshops will be at Nottingham.<br />

There is 1 spot in Raffan’s 2 day workshop on either May 7-8 or May 10-11. Richard’s demo will be on May<br />

12 and the cost will be $30. Please bring your check already made out to SDWT to save time in the check in<br />

line.<br />

TOM EDWARDS<br />

We are starting an interest list for another Tom Edward’s resin class this summer (Resin works best when it<br />

isn’t cold.)<br />

The class would be two days ad the topics would be casting and turning resin, filling voids, finishing with<br />

resin, and whatever else Tom comes up with or what you ask him to cover.<br />

Don’t miss seeing and working with these woodturning masters.<br />

Please let me know if you want to reserve a spot in one of these workshops.<br />

Thanks,<br />

Sally Ault<br />

sallyault@cox.net<br />

619-415-5308

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 6 February 2012<br />

January’s Presentation: Roman Sheidel Demo<br />

Roman Sheidel began his presentation<br />

by asking each member<br />

present to give him the exact<br />

mileage they covered to attend<br />

the presentation. He took a few<br />

minutes to calculate the total<br />

mileage covered by all members<br />

including one who came all the<br />

way from Virginia that very<br />

morning, divided by 167 paid in<br />

full members, added the mileage<br />

he’d covered in coming all the<br />

way from France, then drew a<br />

large zero on the easel to show<br />

how much of that mileage could<br />

be deducted from taxes. We<br />

found, during the presentation,<br />

that Mr. Sheidel had spent much<br />

of his time in France studiously<br />

forgetting English names for<br />

lathe accessories and turning<br />

terms in general.<br />

After that introduction, Mr.<br />

Sheidel, hereafter referred to as<br />

Roman, began getting into the<br />

meat of his presentation. He<br />

had two main points: keeping<br />

his pants from falling off and<br />

getting to the second part of his<br />

presentation where he would<br />

tell us how to obtain free plastic<br />

wrap from truckers.<br />

We began with a series of drawings,<br />

mostly circular, with dots<br />

representing the centers of trees.<br />

Early on, I noticed that some of<br />

the dots were not in the center<br />

and that this could be a PROB-<br />

LEM. Evidently, wood is not<br />

kind, shrinks differently if the<br />

dot is not at the center, thereby<br />

causing all kinds of problems<br />

such as the oval bowl or the misshapen<br />

bowl. The message here<br />

by Mike McElhney<br />

is to keep the dot in the center of<br />

the bowl, a lesson that I thought<br />

had a certain Zen quality.<br />

Then we moved to actual turning,<br />

but only after Roman had<br />

once again managed to keep his<br />

pants from falling to the floor.<br />

He had with him a piece of what<br />

he identified as “Possibly Elm”<br />

or, in the Latin, “Quam Ulmas<br />

minor var, vulgaris” or in the<br />

French, “Possible d’Orme. ”<br />

(Poss eee blay duh Or May) We<br />

found that the wood from this<br />

tree is extremely abrasive and<br />

acts much like sandpaper on the<br />

edges of what were thought to be<br />

sharp tools. Mr. Sheidel managed<br />

to shape the outside of the<br />

bowl in a way he found slightly<br />

offensive and then, after pulling<br />

up his pants again, showed us<br />

how to keep the bark from flying<br />

into the audience. The trick, he<br />

said, is to cut against the grain,<br />

even though the wood doesn’t<br />

like it, the tool doesn’t like it,<br />

you don’t like it and we assume<br />

that even the French don’t like<br />

it.<br />

An earlier point made by Ro-<br />

(Continued on page 7)

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 7 February 2012<br />

(Roman Sheidel- continued from page 6)<br />

man, involved a wooden cutout<br />

showing which direction that<br />

wood likes to be cut. Hollowing<br />

out a bowl, turning wood on<br />

a spindle, shaping a bowl – all<br />

wood has likes and dislikes.<br />

This insight into the nature of<br />

wood was quite helpful and<br />

we were instructed to go home<br />

and cut out a cross section of a<br />

bowl on plywood and make the<br />

necessary horizontal cuts so we<br />

could study this novel concept in<br />

depth. The likes and dislikes of<br />

wood are essential to the finished<br />

product.<br />

Roman confessed that he had, on<br />

occasion, bowed to the demands<br />

of wood’s cutting preferences<br />

and blown the bark from trees<br />

or, allowed potential customers<br />

or current students to pick<br />

up pieces with bark and pull the<br />

bark away with prying fingers.<br />

But we were told to not despair,<br />

that he knew a way to make<br />

everything better. A Sharpie, a<br />

black one for all woods unless<br />

the bark is white. White bark<br />

needs another color. The Sharpie<br />

covers up the damage, but you<br />

must never tell anyone, not even<br />

your best friend or think about a<br />

hippopotamus while coloring.<br />

Roman took us up to break time,<br />

after once again managing to<br />

keep his pants from falling to<br />

his knees. He showed us that<br />

with a dull chisel and a wooden<br />

hammer, it is possible to burrow<br />

into the bark far enough to<br />

allow the insertion a lathe drive<br />

center, which is, in French called<br />

“Tour d’entraînement du center,”<br />

During the break Roman<br />

finished hollowing out the bowl,<br />

but forgot to address the ongoing<br />

problem of the falling pants,<br />

which is, in French, le problème<br />

du pantaloon tombant. We were<br />

warned to take great care when<br />

we hammered (martelaged) the<br />

drive center into the wood lest<br />

we deform the Morse Taper and<br />

eventually destroy our lathe.<br />

Roman then proceeded to use a<br />

wooden martelage to drive tour<br />

entrainment du center into his<br />

piece.<br />

After the break, le problem du<br />

pantaloon tombant fell once<br />

again from Roman’s lips, but<br />

he battled bravely on with his<br />

demonstration. The bowl, now<br />

nearly complete except for the<br />

bottom, balanced precariously<br />

on top of a block of wood situated<br />

high over the lathe and just<br />

out of camera range. Helpful<br />

suggestions from the audience<br />

were met with a lengthy explanation<br />

of how Roman’s deaf<br />

mother and his own willful exposure<br />

to loud noises in his formative<br />

years had rendered him<br />

completely deaf and that he was<br />

now forced to read lips or to take<br />

all questions in writing ahead<br />

of time, much like the current<br />

crop of Republican presidential<br />

candidates.<br />

An attentive audience held a<br />

collective breath as Roman told<br />

us how to befriend a trucker for<br />

free plastic wrap, or if all else<br />

failed, to cut an existing piece<br />

of wrap on the band saw thereby<br />

fusing the edges. We moved<br />

onto the demonstration we had<br />

all been waiting for which was<br />

to use the plastic film to keep the<br />

delicate bowl from flying away<br />

as the bottom was turned. A plywood<br />

round, some foam which<br />

could be cut with scissors if<br />

anyone had them, and a block of<br />

wood were all necessary to ini-<br />

(Continued on page 8)

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 8 February 2012<br />

(Roman Sheidel- continued from page 7)<br />

tially position the finished bowl.<br />

Then the plastic, care taken to<br />

put it on in the right direction<br />

lest it unravel, tangle, rip body<br />

parts from, and eventually kill<br />

the operator, went around the<br />

plywood several times and then<br />

began looping down to actually<br />

hold the bowl in place. Roman<br />

spent quite a bit of time adjusting<br />

the bowl thus held to get it<br />

absolutely perfect on center but<br />

eventually let it, as the French<br />

say, laissez assez bien seuls.<br />

Using a gouge a’creuser, Roman<br />

smoothed out the rough<br />

patches and then inscribed,<br />

with a pointed tool whose name<br />

in English he did not know, a<br />

series of circles in the bottom<br />

of the bowl. We were informed<br />

that this series of circles was<br />

not invented by the person who<br />

thought they invented it nor even<br />

by anyone back into the distant<br />

annals of time or maybe by Neanderthals.<br />

Now that his presentation<br />

was wrapped up, Roman<br />

returned to his plywood cutout<br />

of a bowl and once again suggested<br />

strongly that everyone go<br />

home and cut one out. He then<br />

critiqued his bowl, telling us that<br />

the shape was not pleasing even<br />

though members of the audience<br />

disagreed with him.<br />

The presentation ended with<br />

pantalons still in the upright<br />

position, a nicely turned bowl,<br />

essential information on how<br />

to befriend truckers, and some<br />

good insights on the use of<br />

plastic wrap and the possible<br />

dangers thereof. As an added<br />

note, we learned that taking a<br />

penknife on an airplane is not a<br />

good idea.

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 9 February 2012<br />

Please remind your members that club member names are not sold. Members can<br />

also order online. They just need to call 800-228-0000 and set up a user name<br />

and password with one of our customer service representatives or create one<br />

themselves online. We also have a Club Listing on our website. If you would like<br />

for your Club to be listed please let me know and there will be a link added to go<br />

to your site from ours.<br />

This program is a great way to help woodworkers across the country save money<br />

on products that are already being purchased and also to help promote our great<br />

sanding products to your club members. Listed below are some examples of what<br />

we have to offer your woodworking members:<br />

· 10% discount on all non-powered merchandise in our catalogues<br />

· **Discounts do not apply to items already discounted in catalog**<br />

· regular mailings of our most up-to-date catalogs<br />

· monthly newsletter via email<br />

· donations for raffles (twice a year) You have to request them.<br />

· expert advice on sanding and woodworking applications<br />

Please feel free to contact me anytime with questions or concerns. My number is<br />

1-800-228-0000 ext. 247, fax me at 1-800-872-2005, or email me at pbarden@<br />

woodworkingshop.com.<br />

Thank you for your time and I look forward to hearing from you soon.<br />

Sincerely,<br />

Pam Barden<br />

Operation’s Manager<br />

Klingspor’s Woodworking Shop<br />

KLINGSPOR<br />

Woodworking Shop

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 10 February 2012<br />

At Mike Jackofsky’s hollow<br />

vessel class and on his video,<br />

he uses a measuring device to<br />

determine the thickness of the<br />

walls and bottom of a hollow<br />

vessel. Apparently they are no<br />

longer available. I decided to<br />

give it a try to make my own.<br />

The device works by placing the<br />

pointy end of the rod against the<br />

end of the hook. As the point<br />

moves away from the end of the<br />

hook, the rod passes through the<br />

T connector the same amount.<br />

By noting the zero starting<br />

point where the rod just exits<br />

the T and seeing how far that<br />

point moves away from the T,<br />

you know how far the point has<br />

moved from the end of the hook,<br />

i.e., the thickness of your vessel<br />

wall.<br />

Home Depot has everything you<br />

need:<br />

From the hardware department:<br />

1/4” square steel bar 36 inches<br />

long<br />

3/16 smooth round bar 36 inches<br />

long<br />

From the plumbing department:<br />

a pop-up rod clip for bathroom<br />

faucets (the little spring thing<br />

that connects the rod you push<br />

up and down to open and close<br />

the sink drain to the stopper)<br />

Thickness Gauge<br />

A brass connector “T” 1/4” outer<br />

diameter. The three pressure<br />

nuts and inserts that are attached<br />

to it when you buy it are not<br />

used.<br />

Using my bench grinder, I first<br />

rounded off approximately 3/4<br />

of an inch of the square bar to a<br />

radius of approximately 3/16 of<br />

an inch. This is the side of the<br />

bar that will be soldered into the<br />

“base” of the T connector. Don’t<br />

try for a tight fit between the bar<br />

and the key connector since you<br />

have to leave room around the<br />

perimeter for solder to flow.<br />

I also ground off the sharp<br />

corners of the other end of the<br />

square bar.<br />

Then I bent the square steel bar<br />

into something like a half circle<br />

with a “hook” that is on the end<br />

of the bar opposite to the ground<br />

end. You have to decide what<br />

shape is going to fit around the<br />

perimeter of the type of hollow<br />

vessel you primarily make and<br />

then the bar to match. I took<br />

a short piece of pipe and put it<br />

in my workbench vise. Then,<br />

inserting the bar to its middle<br />

and proceeded to make a series<br />

of SM<strong>AL</strong>L bends while gradually<br />

lifting the bar out of the pipe<br />

by an inch or two between each<br />

bend. I then flipped the bar over<br />

and inserted the unbent half of<br />

the bar to its middle and made<br />

by Eric Freedus<br />

similar bends in the other half<br />

until I got the arc that I wanted.<br />

The last 2 inches of the hook<br />

end was bent so that it pointed to<br />

the ground end. You are going<br />

to have to tweak the arc of the<br />

bar to make things line up later<br />

so don’t spend too much time<br />

trying to make it perfect at this<br />

point.<br />

I then took the T connector and<br />

removed the screw caps and inserts.<br />

The 3/16” does not fit into<br />

the T connector. Actually, you<br />

probably can insert it but then<br />

have one heck of a time getting<br />

it out (as I found out in the<br />

store!). I first tried drilling out<br />

the channel through the “top”<br />

of the T with a 3/16 bit since<br />

my bar was 3/16. However, I<br />

found that that allowed too much<br />

“slop” and made it difficult for<br />

the end of the bar to line up<br />

with the hook and stay in place.<br />

After buying a second T, I used<br />

a small round file and gradually<br />

widened the channel through the<br />

T until the 3/16”round rod went<br />

through. Before arriving at the<br />

final filing, I ran the rod along<br />

a wire wheel which seemed to<br />

clean it up a bit. I also ground a<br />

rounded “point” where the rod<br />

will line up with the hook. By<br />

the way, make sure you don’t<br />

get a rod that has any bend in it.<br />

Roll it on the floor at the store to<br />

see if there’s any bend in it and<br />

reject it if there is. Any bend<br />

(Continued on page 11)

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 11 February 2012<br />

(Project- continued from page 10)<br />

will make it almost impossible<br />

to pass through the brass T and<br />

line up with the hook end of<br />

your curved piece.<br />

I drilled out the base of the T<br />

to allow the ground part of the<br />

square bar to go in a little deeper.<br />

I then did some dry fitting<br />

and adjustment of the arc so that<br />

when the T is placed onto the<br />

arc and the rod is passed through<br />

the top of the T, the pointy end<br />

of the rod lines up with the end<br />

of the hook closing the “capital<br />

D” shape. The round rod is<br />

much longer than necessary. I<br />

left about 4 inches protruding<br />

through the T (outside the “capital<br />

D”) and cut off the remainder.<br />

I then gently taped the pointy<br />

end of the ride to the end of<br />

the hook to keep it in place and<br />

clamping the whole thing in the<br />

vice with the arc up (so that the<br />

base of the brass T is facing up<br />

to accept solder) and supported<br />

the arc with something on the<br />

bench so it doesn’t just fall to<br />

the side, I soldered the arc into<br />

the brass T together making<br />

sure that the T was lined up and<br />

“square”. I said “gently taped”,<br />

because solder will run down<br />

inside the base of the T and you<br />

will end up soldering the rod inside<br />

the top of the T unless you<br />

move the rod to keep the solder<br />

from adhering. If you’ve used<br />

too much tape, you won’t be<br />

able to move the rod before the<br />

solder cools. (As I found out!)<br />

I’m sure someone could tell me<br />

what I could’ve put on the rod<br />

to prevent that, but I just kept<br />

rotating the rod until the solder<br />

cooled. Any excess solder that<br />

might have interfered with the<br />

rod sliding back and forth was<br />

easily filed out.<br />

Having something on the rod to<br />

mark the zero point, i.e. flush up<br />

against the end of the T, makes<br />

it easy to measure the distance<br />

between the end of the T and<br />

that “something”. Since there<br />

is a certain amount of flexibility<br />

in the square rod, the distance<br />

across the arc changes from time<br />

to time. Therefore, having a permanent<br />

“zero” marker wouldn’t<br />

work. I first used one of those<br />

drill bit depth stoppers that slide<br />

onto the outside of the drill bit<br />

and is fixed in place by an Allen<br />

screw. However, I found that<br />

to make adjustments to that I<br />

needed three hands: one to hold<br />

the pointer zeroed against the<br />

hook end, a second to hold the<br />

depth stop place and a third to<br />

tighten it with an Allen wrench.<br />

I also found that merely putting<br />

pressure on the Allen wrench<br />

would sometimes cause the arc<br />

to flex making zero point move.<br />

What I came up with and which<br />

seems to work pretty well is a<br />

nylon spacer that slides over<br />

the 3/16” rod and a pop-up rod<br />

clip described above. With one<br />

hand, I can zero the pointer<br />

against the hook end in with the<br />

second and I can squeeze the rod<br />

clip and slide it in and out so that<br />

the nylon spacer is held flush<br />

against the outside of the brass<br />

T. Using just the rod clip alone<br />

didn’t work because it does not<br />

create a surface perpendicular to<br />

the rod and made measurement<br />

of the space created when the<br />

rod slides difficult. The spacer<br />

gives a nice clean line against<br />

which to measure. I put a dab<br />

of lube inside the brass to help<br />

reduce friction.<br />

Two notes: if the channel<br />

through the brass T is too loose,<br />

you get “slop”. If too tight, it’s<br />

tough to hold your vessel and<br />

manipulate the rod and bar with<br />

the other hand. I’m going to try<br />

to add some length of brass to<br />

the fitting to increase the length<br />

of the channel through which the<br />

rod passes. By having another<br />

reference point through which<br />

the rod passes further from the<br />

T might make it easier to widen<br />

the channel slightly but still<br />

avoid excessive “slop”.<br />

I considering making another<br />

arc out of thicker square steel<br />

to avoid the flexing. The end<br />

would have to be ground more<br />

to fit into the same size T to take<br />

the round rod, but that shouldn’t<br />

be a problem. However, bending<br />

and adjusting it would be<br />

more difficult.<br />

(Continued on page 12)

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 12 February 2012<br />

(Project- continued from page 11)<br />

Wood Wandering:<br />

A Woodturner’s Paradise<br />

by Mike Lorch<br />

More than a tropical paradise, Hawaii for me is a magical place where Koa and Mango and Milo grow. Years<br />

ago when I first went to Hawaii I e-mailed thirteen turners and asked if I could visit them. I explained that I<br />

was not a collector and that I was just another bowl turner. Twelve of them invited me to come to their shops.<br />

I managed that year to visit about eight of them and we sat and talked about finishes, and woods, and chisels,<br />

about galleries and design. We talked about traditions of the Hawaiian people and how the oldest bowls have<br />

influenced Hawaiian turning.<br />

In all of my trips the same openness and willingness to share and help each other that our club enjoys was<br />

imbedded in the Hawaiian turners that I met. One of the kindest people I met was Dan Deluze. Considered<br />

the patriarch of turners in Hawaii every turner I met there knew Dan and had a story about how he had helped<br />

them in one way or another.<br />

On this trip I spent two mornings with Dan talking. We talked about Koa and Milo, two of his favorite woods.<br />

We talked about why he only used mineral oil to finnish his work and how he loved to sand. I asked how in<br />

the hell anyone could like to sand and he said “With that attitude you probably don’t do a very good job finnishing.”<br />

I laughed and I’m still thinking about what he said.<br />

About a week after our visits Dan DeLuze died of a massive stroke. Chris Allen wrote to tell me about his<br />

passing. Chris cuts and sells wood and used to work for Dan. I will miss Dan and will forever remember our<br />

talks. Everyone who knew Dan DeLuze is a better turner if they listened carefully.

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 13 February 2012<br />

SDWT Members,<br />

Once in a while, I need to mention renewal fees.<br />

It’s a new year and the AAW/SDWT membership renewal<br />

process should now be complete for most of us. The few<br />

people who have not yet renewed will be affected by last<br />

year’s 2011 AAW policy of “resetting the membership<br />

clock” to the day AAW processes your renewal fee, which is<br />

the same as the people who joined in 2011.<br />

- If you joined AAW/SDWT before 2011, your membership has always expired December 31<br />

- If you joined AAW/SDWT in 2011, your membership expires the following year on the day AAW processed<br />

your application<br />

- If your renewal process is not completed prior to your renewal date, your membership renewal period will<br />

be reset to the day AAW processes your renewal fee and any missed AAW Journals will not be mailed<br />

For the SDWT Membership Chairperson (me), this is a tracking challenge. If you know your renewal date<br />

and tell me, I will record it, and help remind you. Also, watch for the renewal notices attached to your last<br />

two AAW Journals.<br />

Thanks!<br />

Leonard Badour<br />

SDWT Secretary and Membership Chairperson<br />

Details On Membership and Renewal<br />

In order to be a member of the SAN DIEGO WOODTURNERS, it is necessary for you to also be a current<br />

member of AAW (SDWT synchronizes renewal to AAW)<br />

To sign up or renew online with AAW<br />

Go to the AAW website, www.woodturner.org, click on Member Area (top menu), then Renew-Extend Your<br />

Membership (left margin) and follow the instructions to renew with a credit card.<br />

- To renew AAW and SDWT memberships TOGETHER<br />

For your convenience, SDWT can handle AAW membership and renewal for you (but please allow enough<br />

time for SDWT and AAW to process the paperwork). For a membership application, visit our website www.<br />

sdwt.org and on the left side, select Membership, then Membership Application within the text. Print the application,<br />

fill it out, and either bring it with cash or check for $73 (AAW $48 + SDWT $25) to the next meeting<br />

at Nottingham Center for the Arts, 240 S. Bent Ave., <strong>San</strong> Marcos, CA 92078 (same street as Fry’s in <strong>San</strong><br />

Marcos) or send the application with a check to:<br />

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong><br />

P.O. Box 507061<br />

<strong>San</strong> <strong>Diego</strong>, CA 92150-7061<br />

To renew your SDWT membership ONLY<br />

Bring a check or cash for $25 to the next meeting and give it to Leonard Badour to renew your membership.<br />

Or you can mail your check made out to <strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> with an application to the address above.<br />

See you at the next meeting!

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 14 February 2012<br />

Mentors Available<br />

Our Mentors are here to assist woodturners who need help with the fundamentals of turning. safety, wood<br />

acquisition and handling, recommended tools, elementary tool sharpening, the basics of rough-turning of<br />

green wood, bowl turning tips, chucking methods, use of “super glues”, and. The goal of this mentoring is to<br />

bring the new turner up to speed on some of the basics, build confidence, and establish skills that they could<br />

improve through advanced instruction. Even our more experienced turners can learn a new skill from other<br />

members. The program is also very beneficial to members who are new to woodturning by providing one-onone<br />

instruction in the basics of woodturning. Some of the subjects that can be covered are;<br />

• Lathe safety / setup<br />

• Where to find wood and how to prepare it for the lathe<br />

• Dry vs. green wood turning<br />

• Tool selection / sharpening and proper use of various tools<br />

• The cuts<br />

• Mounting techniques / chuck types<br />

• Basic design elements<br />

• Natural edge bowls<br />

• Turned boxes<br />

• Grain and feature orientation to achieve best results<br />

• Basic multi-axis turning<br />

• Basic texturing and coloring techniques basic finishing procedures<br />

• Basic finishing procedures<br />

• Workshop design and dust control<br />

TIME LINE: 2012 SAN DIEGO COUNTY FAIR<br />

Entry Deadline: drop off- April 27, 2012, 5:00 pm drop off<br />

Fair set up, May 21, 2012, Monday: Staff & Volunteers & Marines -- Install lights; Setup demonstration<br />

booths; Place Platforms; Display cases; install blue walls.<br />

DELIVERY OF ENTRIES: May 31, 2012, Thursday 12:00 (noon) to 8:00 pm<br />

Fair Opens: June 8, 2012, Friday<br />

Award ceremony: June 10, 2012, Sunday 7:00 pm<br />

Fair closes: July 4, 2012, Wednesday 12:00 midnight<br />

Exhibits closed: Mondays, June 11, 18, and 25<br />

Take down Exhibits & Pick up Entries:<br />

Pick up entries: July 5, 2012, Thursday – Noon – 8:00pm, Start take down (Marines)

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 15 February 2012<br />

Turning and Burning: One<br />

Week Class With Molly Winton<br />

Molly will be teaching a one-week class at Anderson<br />

Ranch Arts Center, (AndersonRanch.org) in<br />

beautiful Snowmass Village, Colorado this coming<br />

summer, July 9-13, 2012. Did you see her during<br />

our club meeting, or participate in the workshop,<br />

but want more? Get a chance to spend a whole<br />

week learning to make homemade brands and<br />

burning tips, as well as use commercially made<br />

pyrography pens to enhance your work. You will<br />

design and make turned pieces with enhancement<br />

in mind, and have ample opportunity to burn to<br />

your heart’s content.<br />

For more information: http://www.andersonranch.org/workshops/courses/index.<br />

php?page=woodturning<br />

What do YOU do?<br />

Do business with a fellow<br />

SDWT member<br />

SDWT is made up of members with a vast variety<br />

of talents.<br />

Rather than flail around looking for someone to do<br />

business with that you don’t already know, I suggest<br />

you contact a member to see if they can be of<br />

help. I personally have had excellent work done<br />

at my home by Jim Meeks and Billy Howse and I<br />

know there are other members I may need sometime<br />

(except Karen…I don’t plan to go to jail)<br />

We would like to compile a list of the available<br />

skills of our members. If you would like other<br />

SDWT members know what you do and how they<br />

can contact you please send me (Sally Ault - sallyault@cox.net)<br />

your contact information and a brief<br />

description of the services or products you hvae to<br />

offer.<br />

Members who have retired often work as consultants<br />

or on a part time basis and have skills available<br />

for hire. They too are a valuable resource.<br />

Clubs can make the world a better place. If you’re wondering how to donate one or more of your creations to<br />

a worthwhile cause, here’s some suggestions:<br />

Bowls for Service Wives<br />

Our servicemen are protecting us overseas but their wives and families are holding down the fort at home<br />

and also deserve some recognition and our gratitude. Ray Brooks is collecting small bowls and boxes to be<br />

presented to the service wives at the holidays. Please contact Ray if you are able to help.<br />

If you would like to contribute, please bring some of your artwork to one of our club meetings and give them<br />

to any board member, or give the listed person a call and we’ll make arrangements for a pick up.<br />

Thanks in advance,<br />

The <strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong><br />

Bowls For Benefactors

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 16 February 2012<br />

Tools & Power Equipment<br />

CPSC moves to toughen safety<br />

standards for table saws<br />

After nearly a decade of discussion,<br />

the Consumer Product<br />

Safety Commission is taking<br />

steps to regulate table saws in<br />

an effort to prevent the tens of<br />

thousands of injuries, including<br />

finger amputations, that occur<br />

each year. “The injuries resulting<br />

from the use of table saws<br />

are, in many cases, particularly<br />

gruesome,” said Chairman Inez<br />

Tenenbaum in a Washington<br />

Post report.<br />

On Wednesday, the commission<br />

voted 5-0 to begin looking<br />

at ways to reduce injuries from<br />

saws, which they say cost an<br />

average of $35,000 per injury—more<br />

than $2 billion each<br />

year—including medical expenses<br />

and lost time from work.<br />

In their quest, they will look at<br />

new safety devices including the<br />

SawStop flesh-sensing technology<br />

developed by an amateur<br />

New Tablesaw Rules on Horizon<br />

woodworker.<br />

“Since 2003, the federal government<br />

has known that SawStop’s<br />

flesh-sensing technology<br />

seems to virtually<br />

eliminate the amputations<br />

and severe<br />

lacerations that<br />

result from contact<br />

with a blade saw,”<br />

said Commissioner<br />

Robert Adler in a<br />

statement. “Over the<br />

years, no one has<br />

stepped forward to challenge the<br />

efficacy of this technology.”<br />

Adler added that he hopes the<br />

industry looks at SawStop as<br />

well as competing technologies,<br />

noting that the “CPSC writes<br />

product safety standards, we do<br />

not mandate a particular technology.<br />

We write performance<br />

standards and leave it to manufacturers<br />

to decide how to meet<br />

them.”<br />

In the past the Power Tool Institute,<br />

an industry organization<br />

that represents manufacturers,<br />

has argued that the SawStop<br />

technology is too expensive—<br />

especially for lower-priced saws<br />

used by millions of home woodworkers<br />

and do-it-yourselfers.<br />

The industry has also argued that<br />

the technology is not foolproof<br />

and is difficult to include in<br />

table saws because of extensive<br />

patents.<br />

Still, Tenenbaum is intent on<br />

preventing the 10 finger amputations<br />

that occur each day. The<br />

CPSC will take comments from<br />

industry and consumers over<br />

the next 60 days and then begin<br />

to develop and propose safety<br />

regulations. “Comments from<br />

the public inform and enlighten<br />

us as to whether moving forward<br />

with this mandatory rulemaking<br />

is necessary and, if so, exactly<br />

what direction it should take,”<br />

said Adler.<br />

Editor’s Note:<br />

These discussions and subsequent<br />

regulations will have a<br />

profound impact on the woodworking<br />

industry and woodworker’s<br />

everywhere.<br />

This is a topic sure to follow in<br />

the coming months.<br />

-Phil

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 17 February 2012<br />

Safety in Woodturning<br />

Safety in the shop is something we often talk about but too often do not really make a priority.<br />

This year the woodturning community had a wake up call with the tragic death of woodturner Joan Kelly.<br />

Joan was killed when an unstable piece of wood she was turning at too high a speed came apart and hit her in<br />

the head. There isn’t a piece of wood or a project in the world that is worth your life.<br />

Here are a few of the basics that you really need to keep in mind every time you are in your shop.<br />

1. Always use a face shield when roughing out a piece of wood.<br />

2. Start your lathe on slow speed and do not turn it up until you are sure that the wood is stable, then turn it up<br />

slowly.<br />

3. Always stand to the side when you turn on your lathe until you are sure everything is stable.<br />

4. Don’t switch from your face shield to safety glasses until the wood has been rounded.<br />

5. Sharpen your tools. A sharp tool will make turning safer.<br />

6. When you are turning dry wood or sanding you must protect your lungs. At the very least, use a dust<br />

mask…better still use a respirator. The fine dust can permanently damage your lungs.<br />

7. After Russ Duff’s tragic fire (thank God both Duff’s are OK), we should all paty attention to making sure it<br />

doesn’t happen to anyone else.<br />

a. Keep all oily rags in a fire-safe lidded container or let them dry flat…outside and away from anything<br />

flammable.<br />

b. Keep shavings out of your lights…blow them out daily.<br />

c. If a fire starts and you put it out…never assume it is really out. Sweep the entire shop and wet down<br />

all the shavings you remove.<br />

A few additional safety requirements when you are in a turning class::<br />

by Sally Ault<br />

1. Always angle your lathe so that if a piece flies off it will not be aimed at another student.<br />

2. When walking behind someone who is turning, wait until they have finished their cut so you don’t startle<br />

them and cause a catch.<br />

3. Don’t use unstable wood…especially when others are in the same room..<br />

4. LISTEN to the instructor. If you are told to stop doing something…STOP! Ask why later.<br />

5. Do not use home made tools without permission from the instructor.<br />

6. Do not use the band saw without permission from the instructor.<br />

Please stay safe in your shop. If you follow basic safely procedures and don’t take unnecessary risks your<br />

turning hobby will be one that will continue for a long time.

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 18 February 2012<br />

successful this day thanks to the hard work of everyone.<br />

Barry Rockwell and I picked up some choice<br />

pieces of wood from Russ Duff’s place on<br />

January 5th. This wood will be available for<br />

donations at our January 21st and February<br />

18th meetings. As you are probably aware by<br />

now Russ lost his shop and much of his home<br />

to a fire in December.<br />

On January 6th Barry Rockwell, Tom Edwards,<br />

Allen Driver, Jim Kelly, Mark Jones,<br />

Jamie Little, Mike Ross, Roy Ulrich, and I<br />

descended on Bent Street in an effort to take<br />

down a small olive tree and clean up the wood<br />

trailer and surrounding grounds. We were very<br />

I look forward to seeing you come bye and look at the wood we have available for you at the trailer. There<br />

is carob, black acacia, olive, Victoria box, Norfolk Island Pine, fruit wood, burl, and much more to wet your<br />

turning appetite. Remember, for just $.25/lb you can be turning some of this choice wood in your shop. Tom<br />

Edwards shared a turned piece of Norfolk Island Pine he turned at the meeting in January and it was gorgeous!!!<br />

We have a supply (by-the-gallon) of anchorseal available for purchase. It comes all the way from New York.<br />

If you buy it elsewhere the cost is $25+/gallon. We have it for $12/gallon (such a deal)! Come by the trailer<br />

and pick up a gallon to seal you wood “ends”. You are welcome to e-mail me to insure a gallon or two are<br />

saved for you.<br />

We are still looking for a few more good men and good women to join the ranks of those willing to gather<br />

wood on behalf of the club. Those who help often end up with a choice piece to two for their efforts. The<br />

time together is great and spending time with other wood turners can’t be beat! You can always call or e-mail<br />

to be added to the team.<br />

Dan White: 619-403-0377<br />

bldewhite@gmail.com<br />

Structured Cellulose Communications<br />

(aka - Wood News)

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 19 February 2012<br />

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Mentoring<br />

Woodturning requires technical skills to excel at the craft. Often times you just need to see something done<br />

once to be able to do it yourself or you just need a little help to finish something.<br />

Our mentoring programs is designed to give hands on training to individuals. Our mentors can help with basic<br />

safety, complex turning and everything in between. This is a great way jump start your turning skills. Our<br />

mentors are dedicated to sharing information concerning all facets of woodturning. Contact a mentor directly<br />

to discuss your needs and desires.<br />

This is an offer you need to take advantage of. All you need to do is ask. Phone numbers are provided below.<br />

You can also talk to them at our club meeting.<br />

Allen Brooks Pete Campbell Tom Cummings<br />

(619) 445-4769 Alpine (951) 767-0455 Temecula (760) 745-2769 Escondido<br />

Ed Ducharme Joe Fleming<br />

(619) 448-0389 <strong>San</strong>tee (858) 586-0562 Scripps Ranch<br />

Mike Jackofsky Oskar Kirsten Chuck Luebbers<br />

(760) 741-7112 Escondido (858) 274-3472 Pacific Beach (619) 262-8522 <strong>San</strong> <strong>Diego</strong><br />

Jim Meeks Don Owens<br />

(858) 775-7740 Rancho Bernardo (619) 426-1457 Chula Vista<br />

Horst Remmling Ken Roth Paul Terlouw<br />

(760) 436-6758 Encinitas (858) 842-1236 Poway (760) 753-2693 Encinitas

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 20 February 2012<br />

A. Bit Askew<br />

NEWS FROM THE DVD LIBRARY<br />

Thanks to all our members who have returned many of the delinquent DVD’s. Coming soon to the DVD<br />

library will be a DVD by Alan Batty on Thread Chasing.<br />

Return your DVD’s at the meeting or mail to:<br />

Tom Edwards<br />

2782 Dahlia Ave<br />

<strong>San</strong> <strong>Diego</strong> 92154.<br />

Remember there is a $5.00 per month per DVD late fee.<br />

How to clean your DVD<br />

Use a soft cloth ~ lint free ~(an old clean T-shirt works great)<br />

Put a little water on the cloth<br />

Wipe the disc from the center to the outside edge ~<br />

DO NOT WIPE IN A CIRCULAR MOTION!<br />

by Mike Lorch<br />

If the water does not solve the problem put some Isopropyl (rubbing) Alcohol on the cloth and wipe from the<br />

center to the outside edge. Again, do not wipe in a circular motion.

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 21 February 2012<br />

Please send contest questions to the AAW webmaster. Put “2012 Newsletter Contest question” in the subject<br />

line of your email.<br />

A) Contest submissions:<br />

Local Chapters newsletter editors or a Chapter officer must submit their newsletters for the competition.<br />

Chapters who wish to enter their newsletter in this year’s competition must do so by email. Postal Service<br />

(snail-mail) entries will not be accepted.<br />

To enter, send email to the AAW webmaster.<br />

Please put “Entry for 2012 Newsletter Contest” in the subject line of your email.<br />

Include the following information with your email submission: Send a link to your four best newsletters from<br />

the past year. Linked newsletters must be in pdf file format. Do not send any of the four newsletters themselves<br />

- the file sizes would overwhelm the judges’ in-boxes! Please include the issue dates, Local Chapter<br />

Name as well as the name and contact information for your newsletter editor in the email.<br />

You will receive an email verification that the submission was received. If you do not receive the email verification,<br />

please re-send your initial email or send a query to the AAW office.<br />

B) Evaluation Process<br />

Three Chapters will be chosen as winners (first, second, third) based on ranking from the judging criteria<br />

listed below. The judges for the newsletter contest will be five independent AAW members. Past Best Chapter<br />

Newsletter winners are shown here. Read their newsletters to get a general idea of what it takes to put together<br />

an excellent newsletter.<br />

Judges will be looking for:<br />

Visually appealing layout<br />

Content that is current<br />

Best Local Chapter Newsletter Contest<br />

Content that pertains to woodturning<br />

Content that contributes to AAW’s mission statement<br />

Useful woodturning and news-related information<br />

Sound writing skills Above all, newsletters should be fun to read and provide useful information to<br />

members of the chapter they serve.

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 22 February 2012<br />

Wants And Disposals<br />

Wants & Disposals is open only to current members that want to Buy, Sell, or Trade equipment or supplies. It is not intended as a commercial<br />

marketplace. These listings are presented as a service to our members. It is not an invitation to solicit nor permission to contact the member<br />

on matters not relating to this listing.<br />

Items for wants and disposals may be e-mailed to Phil Stivers (woodenwonders@cox.net). Up to three pictures may be included and will be<br />

placed on this page as space permits.<br />

Nova DVR3000 lathe and stand (new version $2199 at Craft supplies plus<br />

$389 for the stand) $1500.<br />

16” swing<br />

34” bed<br />

1 1/4” x 8”tpi spindle<br />

Pivoting Head Stock<br />

Variable Digital speed control<br />

Direct drive motor<br />

I have loved this lathe and wouldn’t be parting with it except I am buying<br />

a BIGGER lathe.<br />

Knobs<br />

Phil Stivers will be offering<br />

for sale knobs to<br />

fit Oneway, D-Way and<br />

Hosaluk Handles. $14ea.<br />

Klingspor <strong>San</strong>ding Pads/Disks<br />

See Ken Roth at the meeting or call (858) 842-1236<br />

FLEX ARBORS Disks (hook & loop)<br />

2” - $ 8.75 each 2” - $4.00 per 25 disks<br />

3” - $ 9.50 each 3” - $5.50 per 25 disks<br />

COMING SOON ......<br />

A new Tool From OSK-Co.<br />

(Oskar Kirsten)<br />

I also have an outrigger tool available for $150 ($269 in<br />

catalogue). It is used when turning a larger piece with the<br />

headstock rotated.<br />

The lathe will be available in early March.<br />

Oskar is working on a hollowing<br />

tool rest to allow you to<br />

pivot while making the cuts in<br />

a contolled and gentle manner.<br />

Watch here for updates.<br />

Please contact Sally Ault at sallyault@cox.net or 619-415-<br />

5308.<br />

(Continued on page 23))

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 23 February 2012<br />

(Wants - continued from page 22)<br />

Roy’s Wooden Wonders<br />

858.603.2277<br />

roy.ulrich@cox.net<br />

All tools come with a 14 day satisfaction guarantee. Full refund if not completely satisfied and tool is returned<br />

in resalable condition.<br />

Tool Description/Prices<br />

Straight Hollowing Tool*<br />

8mm carbide cutter and screw mounted on 3/8”round rod and handle<br />

$ 50.00<br />

Straight Hollowing Tool (unhandled)*<br />

8mm carbide cutter and screw mounted on 3/8” round rod with handle instructions<br />

$ 40.00<br />

Curved Hollowing Tool*<br />

8mm carbide cutter and screw mounted on 3/8” curved round rod and<br />

handle<br />

$ 55.00<br />

Curved Hollowing Tool (unhandled)*<br />

8mm carbide cutter and screw mounted on 3/8” curved round rod with<br />

handle instructions<br />

$ 45.00<br />

Square Hollowing Tool*<br />

10mm carbide cutter and screw mounted on 5/8” square rod and handle<br />

$ 65.00<br />

Square Hollowing Tool (unhandled)*<br />

10mm carbide cutter and screw mounted on 5/8” square rod and handle<br />

instructions<br />

$ 55.00<br />

Square Hollowing Tool*<br />

6mm carbide cutter and screw mounted on 3/8” square rod and handle<br />

$ 55.00<br />

Square Hollowing Tool (unhandled)*<br />

6mm carbide cutter and screw mounted on 3/8” square rod and handle<br />

instructions<br />

$ 50.00<br />

Guarantee* 14 day money back guarantee if not completely satisfied.<br />

Tool must be returned in resalable condition<br />

Jet 1100 single side<br />

dust collector $225<br />

Billy Howse<br />

b.howse@att.net

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 24 February 2012<br />

Kirsten<br />

Kone<br />

Now available<br />

from<br />

Oskar Kirsten<br />

www.<br />

oskarkirsten<br />

.com<br />

Kirsten Kone -<br />

complete<br />

$64.00<br />

+<br />

$15.00<br />

Shipping and<br />

Handling<br />

All components were designed using state of the art<br />

CAD and will be precision cut with accurate CNC<br />

machines so building the cart will be relatively<br />

straight forward.<br />

Our long term goal is to offer the cart in separate<br />

kits of chassis, turret and swing table.<br />

If your interested in this project please contact<br />

Judd@montana-designs.com

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 25 February 2012<br />

FEBRURY 2012 RAFFLE<br />

January’s Raffle was another success. February Raffle will offer great more great items up for grabs. Don’t<br />

forget to put your latest turnings in the Instant Gallery for a chance to win for raffle tickets. <strong>AL</strong>L of the proceeds<br />

from the raffle are reinvested in future raffles and never used for any other purpose, so come, enjoy, and<br />

if possible, par¬ticipate in the raffle. Please feel free to tell me what items you would like to see in the raffle,<br />

and I will see if I can work them in.<br />

Below is a list of items that will be on the table for the February raffle<br />

3 Gallon 100 psi pancake air compressor 1/2” Thompson Detail gouge<br />

3/8”V Thompson finishing bowl gouge<br />

Roy Ulrich’s Hercules #1 Mini tool Roy Ulrich’s Hercules #3 tool<br />

Miscellaneous Gifts Dave Sweitzer 8” Handle w/Phil’s Knob<br />

<strong>San</strong>ding Multi-Roll Pack Craft Gift Certificates<br />

Vicmarc Chuck 1 3/4” Vicmarc Shark Jaws<br />

<strong>AL</strong>L of the proceeds from the raffle are reinvested in future raffles and never used<br />

for any other purpose. Come and enjoy the meeting. Get your raffle tickets for a<br />

chance to take home some goodies.<br />

Thanks to Mike Durlak at Rockler for Club Discounts on Raffle items!<br />

Jeff Neff (619) 384-3183 bball5457@yahoo.com

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 26 February 2012<br />

Rockler sets up a discount for SDWT<br />

Mike Durlak, manager of the <strong>San</strong> <strong>Diego</strong> Rockler Store,<br />

is offering the <strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> this exclusive discount coupon.<br />

Valid only at the <strong>San</strong> <strong>Diego</strong> location on Claremont Mesa Blvd, this coupon gives<br />

each SDWT member 20% off one item (with exclusions as noted).<br />

The coupon (shown below) is valid for one use only per members HOUSEHOLD and<br />

the member must show their current SDWT membership card.<br />

Mike is very supportive of our club and willing to continue the discount program as<br />

long as it is not abused.<br />

Be sure and give Mike a big smile and hearty thanks when you redeem your coupon.<br />

**20%<br />

********COUPON REQUIRED FOR DISCOUNT<br />

OFF**<br />

NO EXCEPTIONS**********<br />

This offer is made to current members of the <strong>San</strong> <strong>Diego</strong> Fine Woodworker’s Association.<br />

Coupon required for redemption. Each coupon can be used once. Does not apply to previous purchases. Does not apply to Leigh Dovetail<br />

Jigs.No discounts apply to power tools. No rainchecks will be offered. Offer good only on non-sale items. Discounts may not be<br />

combined. One item is defined as a single unit of an item, not multiples of a single product. Members must have their card present at time<br />

of purchase.<br />

ONE ITEM!<br />

***MEMBERS MAY USE EACH COUPON ONCE***<br />

SAN DIEGO WOODTURNERS<br />

COUPON REQUIRED FOR DISCOUNT, NO EXCEPTIONS,<br />

EXPIRES 2/19/2012<br />

Coupon may be used ONCE! Does not apply to previous purchases. Power Tools excluded.<br />

Sale items excluded. Discounts may not be combined. Discount Restricted Items Excluded. Sale prices can not<br />

be adjusted to use coupon. When in doubt, ask Mike. Coupon copies will not be accepted.<br />

****COUPON WILL NOT BE HONORED PAST THE EXPIRATION DATE****<br />

*****ONE COUPON PER MEMBER HOUSEHOLD ONLY*****

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 27 February 2012<br />

MENTORS<br />

Jeff Neff (Chairman)<br />

(619) 384-3183<br />

Pete Campbell<br />

Temecula / (951) 767-0455<br />

Tom Cummings<br />

Escondido / (760) 745-2769<br />

Ed Ducharme<br />

<strong>San</strong>tee / (619) 448-9389<br />

Joe Fleming<br />

<strong>San</strong> <strong>Diego</strong> (Scripps Ranch)<br />

(858) 586-0562<br />

Mike Jackofsky<br />

Escondido / (760) 741-7112<br />

Oskar Kirsten<br />

<strong>San</strong> <strong>Diego</strong> (Pacific Beach)<br />

(858) 274-3472<br />

Chuck Luebbers<br />

<strong>San</strong> <strong>Diego</strong> / (619) 262-8522<br />

Don Owen<br />

Chula Vista / (619) 426-1457<br />

Ken Roth<br />

Poway / (858) 842-1236<br />

Paul Terlouw<br />

Encinitas / (760) 753-2693<br />

Horst Remmling<br />

Encinitas / (760) 436-6758<br />

Jim Meeks<br />

<strong>San</strong> <strong>Diego</strong> (Rancho Bernardo)<br />

(858) 485-6544<br />

Allen Brooks<br />

Alpine / (619) 4454769<br />

Board Members<br />

President<br />

Nan Bushley (760) 728-0591<br />

Vice President<br />

Karen Freitas (760) 727-3950<br />

Secretary<br />

Leonard Badour (858) 658-2591<br />

Treasurer<br />

Ken Roth (858) 842-1236<br />

Members at Large<br />

Al Buffington (858) 571-0381<br />

Jim Berger (760) 788-7636<br />

Allen Driver (760) 518-0507<br />

Mike Foreman (760) 822-7873<br />

Ken Haines (760) 432-0563<br />

Ron Kaplan (858) 775-0906<br />

Jeff Neff (619) 384-3183<br />

Brian Saunders (858) 571-5384<br />

Pat Saunders (858) 571-5384<br />

Tom Stahl (858) 748-0068<br />

Phil Stivers (760) 480-9477<br />

Lost and Found<br />

Everything lost has been found.<br />

Everything found has found a<br />

home....<br />

If you find something at a<br />

SDWT event or think you left<br />

something there, contact Becki<br />

Edwards in the Library area or<br />

(619) 423-2778.<br />

COMMITTEES<br />

Newsletter Editor<br />

Phil Stivers (760) 480-9477<br />

Audio/Visual<br />

Mike Foreman (760) 822-7875<br />

Cam Baher (760) 310-9710<br />

Librarian<br />

Tom Edwards (619) 423-2778<br />

Raffle<br />

Jeff Neff (619) 384-3183<br />

Al Buffington (858) 571-0381<br />

Del Mar Fair<br />

Chuck Luebbers (619) 262-8522<br />

Tom Edwards (619) 423-2778<br />

Gallery 21<br />

Scott van Hoften (858) 453-8504<br />

Programs/Classes<br />

Karen Freitas (760) 727-3950<br />

Sally Ault (619) 415-5308<br />

Membership<br />

Leonard Badour (858) 658-2591<br />

Resources<br />

Dan White (619) 403-0377<br />

Sunshine<br />

Tom Cummings (760) 745-2769<br />

Refreshments<br />

Brian &<br />

Pat Saunders (858) 571-5384<br />

Tops-for-Tots<br />

Tom Cummings (760) 745-2769<br />

Instant Gallery<br />

Allen Shiro (858) 486-389<br />

Mentors<br />

Jeff Neff (619) 384-3183<br />

Meeting Set-up/Clean-up<br />

Mike Forman (760) 822-7873<br />

Christmas Party<br />

Nan Bushley (760) 728-0591<br />

Picnic<br />

Ken Roth (858) 842-1236<br />

Communications/Media<br />

AAW Liasion<br />

Scott van Hoften (858) 453-8504

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> Page 28 February 2012<br />

Tropical Exotic Hardwoods<br />

2270 Camino Vida Roble Ste “B”<br />

Carlsbad, CA. 92008<br />

(760)434-3030<br />

North County Tools<br />

955-A Rancheros Drive<br />

<strong>San</strong> Marcos, CA 92069<br />

(760) 743-2004<br />

Enviro-Safety Products<br />

516 E. Modoc Ave.<br />

Visalia, Ca 93292-7630<br />

(800) 637-6606<br />

Rockler’s<br />

8199 Clairemont Mesa Blvd.<br />

<strong>San</strong> <strong>Diego</strong>, CA 92111<br />

(858) 268-1005<br />

RESOURCES<br />

The Hardwood & Hardware Co.<br />

8849 Complex DR<br />

<strong>San</strong> <strong>Diego</strong> CA 92126<br />

(858) 536-1800<br />

Woodworker West<br />

Woodworker West<br />

PO Box 452058<br />

Los Angeles, CA 90045<br />

310-216-9265<br />

Tool Depot (two locations)<br />

3799 Gaines Street<br />

<strong>San</strong> <strong>Diego</strong>, CA<br />

(619) 220-7111<br />

1655 Broadway #13<br />

Chula Vista, CA<br />

(619) 585-1800<br />

GOT WOOD?<br />

American Furniture Design<br />

Ben Matte Tung Oil can be purchased<br />

here<br />

2243 Mountain View Dr<br />

Escondido, CA<br />

760-743-6923<br />

www.americanwfurnituredsgn.com<br />

Klingspor <strong>San</strong>ding Pads/Disks<br />

See Ken Roth at the meeting or<br />

call (858) 842-1236<br />

FLEX ARBORS<br />

2” - $ 8.75 each<br />

3” - $ 9.50 each<br />

Disks (hook & loop)<br />

2” - $4.00 per 25 disks<br />

3” - $5.50 per 25 disks<br />

If you have an interest in participating with this part of the club’s operation please give me a call. I would<br />

like to have someone help me at the trailer before and after club meetings to help members pick out that<br />

special piece of wood. This is a great time to meet and talk with other club members. I would also like to<br />

have a number of people willing to cut and or load wood that becomes available in the county. Those with<br />

chain saws and pickup trucks or trailers are encouraged to sign up. Sometimes there is advanced notice of<br />

wood to be cut or picked up. Other times we will be like the “storm chasers” in that we will be given little<br />

notice of a fallen tree, etc. Please call me if you have an interest in helping out. We want to keep a good<br />

selection of wood for club members. I would like to develop a list of a dozen or so knowing most of the<br />

time we might only need 3-6 persons for a particular effort. Please call Dan White: 619-403-0377 if you<br />

can help.

<strong>San</strong> <strong>Diego</strong><br />

<strong>Woodturners</strong><br />

A Chapter of the AAW<br />

http://www.sdwt.org<br />

P.O. Box 507061<br />

<strong>San</strong> <strong>Diego</strong>, CA 92150-7061<br />

The <strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong> is a nonprofit organization dedicated to providing education, information<br />

and organization for those interested in woodturning. Our meetings are held once a month, generally<br />

on the 3rd Saturday of the month. Meeting location and meeting topics are announced in the Club’s<br />

newsletter and are posted on the Club’s website.<br />

Monthly meetings<br />

Monthly newsletters<br />

Mentoring by experienced members<br />

Annual woodturning symposium<br />

Exhibits and shows<br />

Activities include:<br />

Discounts from local suppliers<br />

Demonstrations by national and international<br />

experts<br />

Instruction for all levels<br />

Video library<br />

To become a member, complete the form below along with your dues payment and mail it to the address<br />

above, or bring it to any meeting. The membership fee is $73 which includes membership in AAW. A new<br />

name tag is available for $5.<br />

Name:____________________________________________________________________<br />

Address:__________________________________________________________________<br />

City:_________________________________________State:_________Zip:___________<br />

Telephone:_____________________E:mail______________________________________<br />

Spouse’s name:______________________________________<br />

Annual Dues & Newsletter ($73 - includes AAW membership) ___ New name tag($5) ___<br />

For further information, contact any club officer or:<br />

Leonard Badour at: lbadour@qualcomm.com or call him at: 858-658-2591

<strong>San</strong> <strong>Diego</strong> <strong>Woodturners</strong>, Inc.<br />

A Nonprofit Corporation<br />

A Chapter of the AAW<br />

P.O. Box 507061<br />

<strong>San</strong> <strong>Diego</strong>, CA 92150-7061<br />

Chapter AAW<br />

NEXT MEETING - February 18th<br />

Al Stirt (All Day Demo)<br />

Saturday February 18, 2012<br />

9:00am until 4:00pm<br />

$25 admission<br />

Nottingham Center, <strong>San</strong> Marcos