Abrasives - Non-Woven - Barnes Distribution

Abrasives - Non-Woven - Barnes Distribution

Abrasives - Non-Woven - Barnes Distribution

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

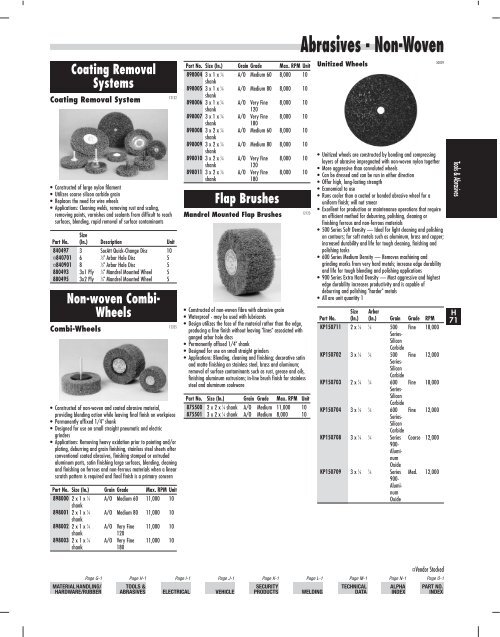

Coating Removal<br />

Systems<br />

Coating Removal System<br />

• Constructed of large nylon filament<br />

• Utilizes coarse silicon carbide grain<br />

• Replaces the need for wire wheels<br />

• Applications: Cleaning welds, removing rust and scaling,<br />

removing paints, varnishes and sealants from difficult to reach<br />

surfaces, blending, rapid removal of surface contaminants<br />

<strong>Non</strong>-woven Combi-<br />

Wheels<br />

Combi-Wheels<br />

MATERIAL HANDLING/<br />

HARDWARE/RUBBER<br />

12122<br />

Part No.<br />

Size<br />

(In.) Description Unit<br />

840497 3 SocAtt Quick-Change Disc 10<br />

e840701 6 1 ⁄2" Arbor Hole Disc 5<br />

e840901 8 1 ⁄2" Arbor Hole Disc 5<br />

880493 3x1 Ply 1 ⁄4" Mandrel Mounted Wheel 5<br />

880495 3x2 Ply 1 ⁄4" Mandrel Mounted Wheel 5<br />

12325<br />

• Constructed of non-woven and coated abrasive material,<br />

providing blending action while leaving final finish on workpiece<br />

• Permanently affixed 1/4" shank<br />

• Designed for use on small straight pneumatic and electric<br />

grinders<br />

• Applications: Removing heavy oxidation prior to painting and/or<br />

plating, deburring and grain finishing, stainless steel sheets after<br />

conventional coated abrasives, finishing stamped or extruded<br />

aluminum parts, satin finishing large surfaces, blending, cleaning<br />

and finishing on ferrous and non-ferrous materials when a linear<br />

scratch pattern is required and final finish is a primary concern<br />

Part No. Size (In.) Grain Grade Max. RPM Unit<br />

898000 2 x 1 x 1 ⁄4<br />

shank<br />

A/O Medium 60 11,000 10<br />

898001 2 x 1 x 1 ⁄4<br />

shank<br />

A/O Medium 80 11,000 10<br />

898002 2 x 1 x 1 ⁄4 A/O Very Fine 11,000 10<br />

shank<br />

120<br />

898003 2 x 1 x 1 ⁄4 A/O Very Fine 11,000 10<br />

shank<br />

180<br />

Part No. Size (In.) Grain Grade Max. RPM Unit<br />

898004 3 x 1 x 1 ⁄4<br />

shank<br />

A/O Medium 60 8,000 10<br />

898005 3 x 1 x 1 ⁄4<br />

shank<br />

A/O Medium 80 8,000 10<br />

898006 3 x 1 x 1 ⁄4 A/O Very Fine 8,000 10<br />

shank<br />

120<br />

898007 3 x 1 x 1 ⁄4 A/O Very Fine 8,000 10<br />

shank<br />

180<br />

898008 3 x 2 x 1 ⁄4<br />

shank<br />

A/O Medium 60 8,000 10<br />

898009 3 x 2 x 1 ⁄4<br />

shank<br />

A/O Medium 80 8,000 10<br />

898010 3 x 2 x 1 ⁄4 A/O Very Fine 8,000 10<br />

shank<br />

120<br />

898011 3 x 2 x 1 ⁄4 A/O Very Fine 8,000 10<br />

shank<br />

180<br />

Flap Brushes<br />

Mandrel Mounted Flap Brushes<br />

• Constructed of non-woven fibre with abrasive grain<br />

• Waterproof - may be used with lubricants<br />

• Design utilizes the face of the material rather than the edge,<br />

producing a fine finish without leaving "lines" associated with<br />

ganged arbor hole discs<br />

• Permanently affixed 1/4" shank<br />

• Designed for use on small straight grinders<br />

• Applications: Blending, cleaning and finishing; decorative satin<br />

and matte finishing on stainless steel, brass and aluminum;<br />

removal of surface contaminants such as rust, grease and oils,<br />

finishing aluminum extrusions; in-line brush finish for stainless<br />

steel and aluminum cookware<br />

FVendor Stocked<br />

Page G-1 Page H-1 Page I-1 Page J-1 Page K-1 Page L-1 Page M-1 Page N-1 Page O-1<br />

TOOLS &<br />

SECURITY<br />

ABRASIVES ELECTRICAL VEHICLE PRODUCTS WELDING<br />

<strong>Abrasives</strong> - <strong>Non</strong>-<strong>Woven</strong><br />

12123<br />

Part No. Size (In.) Grain Grade Max. RPM Unit<br />

875500 2 x 2 x 1 ⁄4 shank A/O Medium 11,000 10<br />

875501 3 x 2 x 1 ⁄4 shank A/O Medium 8,000 10<br />

Unitized Wheels<br />

TECHNICAL<br />

DATA<br />

ALPHA<br />

INDEX<br />

30809<br />

• Unitized wheels are constructed by bonding and compressing<br />

layers of abrasive impregnated with non-woven nylon together<br />

• More aggressive than convoluted wheels<br />

• Can be dressed and can be run in either direction<br />

• Offer high, long-lasting strength<br />

• Economical to use<br />

• Runs cooler than a coated or bonded abrasive wheel for a<br />

uniform finish; will not smear<br />

• Excellent for production or maintenance operations that require<br />

an efficient method for deburring, polishing, cleaning or<br />

finishing ferrous and non-ferrous materials<br />

• 500 Series Soft Density — Ideal for light cleaning and polishing<br />

on contours; for soft metals such as aluminum, brass and copper;<br />

increased durability and life for tough cleaning, finishing and<br />

polishing tasks<br />

• 600 Series Medium Density — Removes machining and<br />

grinding marks from very hard metals; increase edge durability<br />

and life for tough blending and polishing applications<br />

• 900 Series Extra Hard Density — Most aggressive and highest<br />

edge durability increases productivity and is capable of<br />

deburring and polishing "harder" metals<br />

• All are unit quantity 1<br />

Part No.<br />

Size<br />

(In.)<br />

KP150711 2 x 1 ⁄4<br />

KP150702 3 x 1 ⁄4<br />

KP150703 2 x 1 ⁄4<br />

KP150704 3 x 1 ⁄4<br />

KP150708 3 x 1 ⁄4<br />

KP150709 3 x 1 ⁄4<br />

Arbor<br />

(In.) Grain Grade RPM<br />

Fine 18,000<br />

1 ⁄4 500<br />

Series-<br />

Silicon<br />

Carbide<br />

1 ⁄4 500<br />

Series-<br />

Silicon<br />

Carbide<br />

1 ⁄4 600<br />

Series-<br />

Silicon<br />

Carbide<br />

1 ⁄4 600<br />

Series-<br />

Silicon<br />

Carbide<br />

1 ⁄4 Series<br />

900-<br />

Aluminum<br />

Oxide<br />

1 ⁄4 Series<br />

900-<br />

Aluminum<br />

Oxide<br />

Fine 12,000<br />

Fine 18,000<br />

Fine 12,000<br />

Coarse 12,000<br />

Med. 12,000<br />

PART NO.<br />

INDEX<br />

Tools & <strong>Abrasives</strong><br />

H<br />

71

Tools & <strong>Abrasives</strong><br />

H<br />

72<br />

<strong>Abrasives</strong> - <strong>Non</strong>-<strong>Woven</strong><br />

FVendor Stocked<br />

Convolute Wheels<br />

Convolute Wheels<br />

Metal Finishing Wheels<br />

• Features open-web construction; uniform final finish; eliminates<br />

loading and glazing<br />

• <strong>Non</strong>-metallic; no contamination of workpiece<br />

• Smooth running; quiet and smoother than wire brushes<br />

• Most conformable convolute wheel; prevents undercutting or<br />

gouging<br />

Part No. Size (In.) Grain Grade Max RPMs Unit<br />

e851122 6 x 1 x 1 S/C Medium 3000 3<br />

e851222 6 x 2 x 1 S/C Medium 3000 2<br />

e851422 8 x 2 x 3 S/C Medium 2500 2<br />

General-Purpose Wheels<br />

• Features dense, non-woven construction; long-lasting, durable,<br />

and non-dusting<br />

• <strong>Non</strong>-metallic; no contamination of workpiece<br />

• Smooth running; less operator fatigue<br />

• Smear-resistant formula; possibility of smearing is greatly<br />

reduced<br />

• Soft; greatly reduces gouging and unnecessary metal removal<br />

• Part No. e851112 is a soft density wheel; all others are of<br />

medium density<br />

Part No. Size (In.) Grain Grade Max RPMs Unit<br />

e852122 6 x 1 x 1 S/C Medium 4500 3<br />

e852123 6 x 1 x 1 S/C Fine 4500 3<br />

Deburring Wheels<br />

• Features dense, non-woven silicon carbide grain construction;<br />

long-lasting, high edge durability; non-dusting<br />

• <strong>Non</strong>-metallic; no contamination of workpiece<br />

• Smooth running; less operator fatigue<br />

• Smear-resistant formula; possibility of smearing is greatly<br />

reduced<br />

• Conforms to workpiece; prevents undercutting and gouging the<br />

workpiece<br />

• Provides best durability, stock removal and finest finish; increase<br />

productivity; two steps in one<br />

Part No. Size (In.) Density Grade Unit<br />

e853023 6 x 1 ⁄2 x 1 Medium Fine 4<br />

e854023 6 x 1 ⁄2 x 1 Hard Fine 4<br />

e853122 6 x 1 x 1 Medium Medium 3<br />

e853123 6 x 1 x 1 Medium Fine 3<br />

e854123 6 x 1 x 1 Hard Fine 3<br />

e853723 8 x 1 ⁄2 x 3 Medium Fine 4<br />

e853323 8 x 1 x 3 Medium Fine 3<br />

e854323 8 x 1 x 3 Hard Fine 3<br />

e853422 8 x 2 x 3 Medium Medium 2<br />

e853923 12 x 1 x 5 Medium Fine 2<br />

Page A-1 Page B-1 Page C-1 Page D-1<br />

ASSORTMENTS<br />

& CABINETRY<br />

6731<br />

6732<br />

6733<br />

Disc Holder Pads<br />

Holder Pads<br />

• Top quality construction with a molded phenolic face<br />

• Improved grinding; cool running; snap-free<br />

• Medium grade — general-purpose work<br />

• One holder per unit<br />

Holder Pad for Small<br />

Diameter (TS) Quick Change<br />

Discs<br />

• Can be used with Norton Speed-Lok TS, 3M Roloc TS, Merit<br />

Power-Lock Type II and Standard SocAtt style Discs<br />

Part No.<br />

w/TA4 Mandrel Size Density Max RPMs Unit<br />

541052 1" Medium 40,000 1<br />

541054 1 1 ⁄2" Medium 25,000 1<br />

541057 2" Medium 25,000 1<br />

541060 3" Medium 20,000 1<br />

Holder Pad for Small Diameter<br />

(TR) Quick Change Discs (3M<br />

Roloc Style)<br />

• Can be used with Norton Speed-Lok TR, 3M Roloc, Merit Power-<br />

Lock Type III and Standard Lockit style Discs<br />

• Match mfg. of disc to mandrel for best fit<br />

Part No. Mfg. Size Density RPMs Unit<br />

C21539 3M 1" Medium 30,000 1<br />

546054 Norton 1 1 ⁄2" Medium 25,000 1<br />

05539 3M 2" Hard 20,000 1<br />

546057 Norton 2" Medium 25,000 1<br />

546060 Norton 3" Medium 20,000 1<br />

05540 3M 3" Hard 20,000 1<br />

05541 3M 4" Hard 20,000 1<br />

Hook & Loop Style Holder Pad<br />

• Can be used with Norton Hook and Loop, and Merit Velcro ® -Style<br />

Discs<br />

Part No. Size (In.) Mtg. Type Max RPMs Unit<br />

840020 2 1<br />

⁄4 stem 22,000 1<br />

840030 3 1<br />

⁄4 stem 18,000 1<br />

840042 4 1 ⁄2<br />

5 ⁄8-11 10,000 1<br />

840050 5 5 ⁄8-11 10,000 1<br />

840070 7 5 ⁄8-11 6,000 1<br />

FASTENERS FITTINGS & HOSE<br />

CHEMICALS<br />

6726<br />

6727<br />

6728<br />

6729<br />

Scotchbrite ® Disc Holder<br />

(Hook & Loop)<br />

• For 4" Scotchbrite ® surface conditioning discs<br />

Part No. Size (In.) Unit<br />

07492 4 5<br />

Adapter for Large<br />

Diameter Holder Pads<br />

Part No. Size (In.) Unit<br />

547017 5 ⁄8-11M x 1 ⁄4 shank 1<br />

Assortment Kits<br />

Abrasive Disc Assortment Kits<br />

• All metal attachment on the holder pad and disc ensures safe,<br />

secure, durable fit<br />

• Quickly change discs by simply twisting to unlock the disc from<br />

the holder pad<br />

• Speed-Lok TS system is the most popular attachment system in<br />

the world<br />

Page E-1<br />

MAINTENANCE &<br />

SHOP SUPPLIES<br />

12328<br />

12329<br />

Part No. Description Unit<br />

510006 Laminated Disc Kit (39 pcs.) contains:<br />

(3) 2" x 36 grit A/Oxide disc (#522402)<br />

(3) 2" x 80 grit A/Oxide disc (#522406)<br />

(3) 2" x 36 grit B/Carbide disc (#522414)<br />

(3) 2" x 80 grit B/Carbide disc (#522418)<br />

(3) 2" x 36 grit A/O Extra (#522452)<br />

(3) 2" x 80 grit A/O Extra (#522456)<br />

(3) 2" x 36 grit Norzon (#522426)<br />

(3) 2" x 60 grit Norzon (#522429)<br />

(3) 2" x 36 grit Pinnacle (#525412)<br />

(3) 2" x 60 grit Pinnacle (#525415)<br />

(3) 2" x 36 grit Power Zinc (#528422)<br />

(3) 2" x 60 grit Power Zinc (#528425)<br />

(1) 2" Back-up Pad (#541007)<br />

(1) TA4 Mandrel (#540013)<br />

(1) 6" x 9" G.P. A/O Hand Pad (#22063)<br />

1<br />

6923<br />

Page F-1<br />

SAFETY SUPPLIES

Stem Mounted Brushes<br />

Crimped Wire End Brushes<br />

• Heat treated high carbon steel wire provides greater tensile<br />

strength, more fatigue resistance, longer brush life.<br />

• Permanently mounted on 1/4" steel stem for quick installation<br />

in a chuck or collet.<br />

• Perfectly balanced for vibration-free running provides less stress<br />

on the machine tool bearings and reduced operator fatigue.<br />

• High RPM rating permits safer use in high speed, portable tools;<br />

faster finishing.<br />

• Applications include: carbon cleaning, die, mold and tool cleaning<br />

and polishing, weld cleaning, rust and paint removal, seal and<br />

slag removal, rubber and plastic flash removal, deburring ID<br />

pipe cleaning, spot facing, cleaning and finishing recessed areas<br />

on ID's.<br />

• Unit is 1 for all part numbers.<br />

CAUTION: Improper speeds and/or feeds may cause cutting tools to<br />

shatter. Always wear safety glasses when using cutting tools.<br />

Solid-Fill Type, Stem Mounted<br />

Brushes<br />

• Unit is 1 for all part numbers<br />

Part No. Dia. (In.)<br />

MATERIAL HANDLING/<br />

HARDWARE/RUBBER<br />

Wire Type<br />

(In.)<br />

Wire Size<br />

(In.)<br />

Stem Mounted Crimped<br />

Wire Brush<br />

Trim Lgth.<br />

(In.)<br />

876<br />

7286<br />

Max. Safe<br />

Free<br />

Speed<br />

-21589-1 1 ⁄2 STL .006 7 ⁄8 25,000<br />

KP36310 1 ⁄2 STL .0104 7 ⁄8 25,000<br />

KP73452 1 ⁄2 STL .020 7 ⁄8 25,000<br />

21589 3 ⁄4 STL .006 1 20,000<br />

KP36311 3 ⁄4 STL .0104 7 ⁄8 22,000<br />

21587 3 ⁄4 STL .020 1 20,000<br />

KP36312 1 STL .0104 7 ⁄8 22,000<br />

KP36313 1 SS .0104 7 ⁄8 22,000<br />

-21587-1 1 STL .020 7 ⁄8 20,000<br />

998238 1 .SS .020" 1 1 ⁄8" 20,000<br />

16266<br />

• Highest quality oil tempered steel wire<br />

• Densely filled<br />

• Long life<br />

• Applications: weld cleaning, deburring, removing rust and paint,<br />

polishing tools, dies and molds<br />

Part No. Dia. (In.)<br />

Wire Size<br />

(In.)<br />

Trim Lgth.<br />

(In.) Max. (rpm) Unit<br />

KP68424 1 3 ⁄4 Coarse 3 ⁄4 4500 1<br />

KP78801 1 3 ⁄4 .0118 3 ⁄4 4500 1<br />

C125312 2 3 ⁄4 .0118 7 ⁄8 4500 1<br />

Narrow Face Crimped<br />

Wire Brush<br />

• Single section<br />

• Highest quality oil tempered steel wire<br />

• Densely filled<br />

• Long life<br />

• Applications: cleaning tools, dies and molds, removing scale,<br />

slag, rust, paint, rubber and plastic flash; deburring<br />

• KP36314 is Stainless Steel wire<br />

Part No. Dia. (In.)<br />

Circular Flared Type, Stem-<br />

Mounted Brushes<br />

• 3/8" face width<br />

Wire Size<br />

(In.)<br />

Knot Wire End Brush<br />

• Unit is 1 for all part numbers<br />

FVendor Stocked<br />

Page G-1 Page H-1 Page I-1 Page J-1 Page K-1 Page L-1 Page M-1 Page N-1 Page O-1<br />

TOOLS &<br />

SECURITY<br />

ABRASIVES ELECTRICAL VEHICLE PRODUCTS WELDING<br />

Power & Hand Tube Brushes<br />

16269<br />

Trim Lgth.<br />

(In.) Max. (rpm) Unit<br />

KP73456 3 .008 1 ⁄2 20,000 1<br />

C125013 3 .0118 1 ⁄2 20,000 1<br />

KP36314 3 .014 1 ⁄2 20,000 1<br />

Part No. Dia. (In.)<br />

Part No. Dia. (In.)<br />

Wire Size<br />

(In.)<br />

Wire<br />

Type<br />

(In.)<br />

Wire Size<br />

(In.)<br />

Trim Lgth.<br />

(In.)<br />

Trim Lgth.<br />

(In.)<br />

878<br />

Max. Safe<br />

Free Speed Unit<br />

21588 1 1 ⁄2 .020 7 ⁄16 20,000 1<br />

-21588-1 1 1 ⁄2 .008 7 ⁄16 20,000 1<br />

KP36338 3 .008 1 16,000 1<br />

-21588-2 3 .020 1 16,000 1<br />

CAUTION: Improper speeds and/or feeds may cause cutting tools to<br />

shatter. Always wear safety glasses when using cutting tools.<br />

881<br />

Max. Safe<br />

Free Speed<br />

998239 3 ⁄4" STL .020 7 ⁄8" 20,000<br />

21600 1 1 ⁄8 STL .014 7 ⁄8 22,000<br />

KP75691 1 1 ⁄8 STL .020 7 ⁄8 22,000<br />

KP36309 1 1 ⁄8 S.S. .020 7 ⁄8 22,000<br />

CAUTION: Improper speeds and/or feeds may cause cutting tools to<br />

shatter. Always wear safety glasses when using cutting tools.<br />

Knot Wire Wheel<br />

Standard Twist<br />

Part No. Dia.<br />

Heavy-Duty Stem<br />

Mounted Wire Brushes<br />

Wheel Brushes<br />

• All steel brushes (STL.) are manufactured using heat treated,<br />

high tensile wire providing superior fatigue resistance and<br />

cutting action<br />

• Stainless steel brushes (S.S.) are made using Type-302 wire,<br />

which provides longer life and corrosion resistance<br />

• Power brushes are used in five general applications; deburring,<br />

surface preparation, edge blending, roughening and clearing<br />

• Knot style brushes are more aggresive than a crimped wire<br />

brush<br />

• Made in the U.S.A.<br />

TECHNICAL<br />

DATA<br />

Wire<br />

Size<br />

Trim<br />

Length<br />

ALPHA<br />

INDEX<br />

20238<br />

Max<br />

Safe Unit<br />

KP82932 3 .014 5 ⁄8 25,000 1<br />

C125023 3 .020 5 ⁄8 25,000 1<br />

Part<br />

No.<br />

Brush<br />

Dia.<br />

Stem<br />

Dia.<br />

Wire<br />

Size<br />

Wire<br />

Type<br />

Knot Style (Drill & Die Grinders)<br />

KP82932 3 1 ⁄4 .014 STL. 3 ⁄8<br />

KP82455 4 1 ⁄4 .014 STL. 1 ⁄2<br />

ALL UNIT QTY: 1<br />

Part<br />

No.<br />

Trim<br />

Length<br />

Max.<br />

R.P.M.<br />

Brush<br />

Type<br />

Knot Style (Drill & Die Grinders)<br />

KP82932 5 ⁄8 25,000 Standard<br />

KP82455 7 ⁄8 20,000 Standard<br />

ALL UNIT QTY: 1<br />

Crimped Style/Narrow Face<br />

(Drill & Die Grinders)<br />

Part<br />

No.<br />

Brush<br />

Dia.<br />

Stem<br />

Dia.<br />

Wire<br />

Size<br />

Wire<br />

Type<br />

KP73456 3 1 ⁄4 .008 STL. 3 ⁄8<br />

KP67347 3 1 ⁄4 .0118 STL. 3 ⁄8<br />

KP36314 3 1 ⁄4 .014 S.S. 3 ⁄8<br />

ALL UNIT QTY: 1<br />

30469<br />

Face<br />

Width<br />

Face<br />

Width<br />

Continued on next page<br />

PART NO.<br />

INDEX<br />

Tools & <strong>Abrasives</strong><br />

H<br />

73

Tools & <strong>Abrasives</strong><br />

H<br />

74<br />

Power & Hand Tube Brushes<br />

Continued from previous page<br />

Part<br />

No.<br />

Wire Cup Brushes — Crimped<br />

Dense Filled<br />

FVendor Stocked<br />

Wire Cup Brushes<br />

Wire Cup Brushes<br />

• Heat-treated, high-carbon steel wire provides greater tensile<br />

strength, more fatigue resistance, longer brush life<br />

• 302 stainless steel wire provides long life with added corrosion<br />

resistance<br />

• Constructed for perfect balance; no vibration during use, longer<br />

brush life<br />

• High impact action (knot cups) for fast aggressive cutting and<br />

maximum cleaning action in severe applications<br />

• 5/8"-11 mounting nut<br />

• Applications include: heavy-duty cleaning of large metal<br />

surfaces, roughening, deburring, weld scale and corrosion<br />

removal, cleaning prior to welding, rust and paint removal,<br />

cleaning ships, steel tanks, etc.<br />

• Unit is 1 for all part numbers<br />

Part No. Dia. (In.)<br />

Trim<br />

Length<br />

Wire<br />

Type<br />

Page A-1 Page B-1 Page C-1 Page D-1<br />

ASSORTMENTS<br />

& CABINETRY<br />

Max.<br />

R.P.M.<br />

Wire Ga.<br />

(In.)<br />

Trim Lgth.<br />

(In.)<br />

Brush<br />

Type<br />

KP73456 1 ⁄2 20,000 Conflex<br />

KP67347 1 20,000 Conflex<br />

KP36314 1 ⁄2 20,000 Conflex<br />

ALL UNIT QTY: 1<br />

End Brushes<br />

Part<br />

No.<br />

Brush<br />

Dia.<br />

Stem<br />

Dia.<br />

Knot Style (Drill & Die Grinders)<br />

KP75691 11 ⁄8<br />

KP36309 11 ⁄8<br />

ALL UNIT QTY: 1<br />

Part<br />

No.<br />

Trim<br />

Length<br />

Wire<br />

Size<br />

Wire<br />

Type<br />

1 ⁄4" .020 STL. -<br />

1 ⁄4" .020 S.S. -<br />

Max.<br />

R.P.M.<br />

Brush<br />

Type<br />

Knot Style (Drill & Die Grinders)<br />

KP75691 7 ⁄8 22,000 Hollow<br />

KP36309 7 ⁄8 22,000 Hollow<br />

ALL UNIT QTY: 1<br />

Face<br />

Width<br />

885<br />

7287<br />

Max. Safe<br />

Free Speed<br />

C125302 2 3 ⁄4 STL .014 1 14,000<br />

19094 3 STL .014 1 12,500<br />

KP75788 3 1 ⁄2 STL .014 7 ⁄8 12,000<br />

KP78825 3 1 ⁄2 S.S. .014 7 ⁄8 12,000<br />

19096 4 STL .014 1 3 ⁄8 9,000<br />

-19094-1 4 STL .020 1 3 ⁄8 9,000<br />

998240 5" STL .014 1 1 ⁄4" 10,200<br />

-19094-2 6 STL .014 1 1 ⁄2 6,600<br />

CAUTION: Improper speeds and/or feeds may cause cutting tools to<br />

shatter. Always wear safety glasses when using cutting tools.<br />

Wire Cup Brush — Full Cable<br />

Twisted<br />

• High-impact action (knot cups) results in fast, aggressive cutting<br />

and maximum cleaning action for severe applications<br />

• Unit is 1 for all part numbers<br />

• Steel wire except where noted<br />

Part No. Dia. (In.)<br />

Wire Wheels &<br />

Accessories<br />

Crimped Wire Wheels, Medium<br />

& Wide Face — 2" Center<br />

• .014 wire size<br />

• Heat-treated, high-carbon steel wire provides greater tensile<br />

strength, more fatigue resistance, longer brush life<br />

• Constructed for perfect balance; no vibration<br />

• Applications include: flash removal, edge blending, deburring,<br />

surface prep prior to plating or painting, cleaning dirt, rust,<br />

scale, roughening for adhesion, and finishing for appearance.<br />

• Unit is 1 for all part numbers<br />

Part No.<br />

Brush<br />

Dia. (In.)<br />

Face<br />

Width<br />

(In.)<br />

Arbor<br />

Hole<br />

(In.)<br />

Trim<br />

Lgth.<br />

(In.)<br />

Max. Safe<br />

Free Speed<br />

21601 41 ⁄2<br />

7<br />

⁄8<br />

1 3 ⁄2, ⁄8<br />

5<br />

⁄8 6,000<br />

21590 6 11 ⁄8<br />

5 1 ⁄8, ⁄2<br />

1 1 ⁄8 6,000<br />

-21590-2 7 11 ⁄4<br />

5<br />

⁄8<br />

5 1 ⁄8 6,000<br />

-21601-1 8 1 5<br />

⁄8<br />

3 1 ⁄8 4,500<br />

998251 8" 1" 2" 1 3 ⁄8" 4,500<br />

-21590-3 10 1 1 ⁄8<br />

Wire Ga.<br />

(In.) Rows<br />

Trim Lgth.<br />

(In.)<br />

3 ⁄4 1 7 ⁄8 3,600<br />

CAUTION: Improper speeds and/or feeds may cause cutting tools<br />

to shatter. Always wear safety glasses when using cutting tools.<br />

FASTENERS FITTINGS & HOSE<br />

CHEMICALS<br />

886<br />

Max. Safe<br />

Free Speed<br />

C125322 2 3 ⁄4 .020 Single 3 ⁄4 14,000<br />

998241 2 3 ⁄4" .020 SS Single 1" 12,500<br />

KP75787 3 1 ⁄2 .023 Single 7 ⁄8 13,000<br />

19090 4 .023 Single 1 1 ⁄4 9,000<br />

19091 6 .023 Single 1 3 ⁄8 6,500<br />

19092 6 .035 Double 1 3 ⁄8 6,600<br />

-19092-1 6 .023 Double 1 3 ⁄8 6,600<br />

CAUTION: Improper speeds and/or feeds may cause cutting tools to<br />

shatter. Always wear safety glasses when using cutting tools.<br />

877<br />

Crimped Wire Wheels Narrow<br />

& Medium Face<br />

(Bench Grinder)<br />

• Heat-treated, high-carbon steel wire provides greater tensile<br />

strength, more fatigue resistance, longer brush life<br />

• Constructed for perfect balance; no vibration<br />

• Applications include: cleaning of rust, scale and dirt, light<br />

deburring, edgeblending, roughening for adhesion, finishing for<br />

appearance, and finish prep prior to plating or painting<br />

• Unit is 1 for all part numbers<br />

Part<br />

No.<br />

Dia.<br />

(In.)<br />

Wire<br />

Size<br />

(In.)<br />

Twisted Knot Wire Wheels<br />

• Heat-treated, high-carbon steel wire provides greater tensile<br />

strength, more fatigue resistance, longer brush life<br />

• Exact wire strand count in each individual tuft assures perfect<br />

balance; no vibration<br />

• High-impact action results in a fast, aggressive cutting action for<br />

severe applications<br />

• Applications include: removal of rust, scale and weld spatter,<br />

roughening surface, removal of rubber or plastic flash, heavy<br />

burr removal, heavy-duty cleaning, weld cleaning, and surface<br />

conditioning<br />

• Unit is 1 for all part numbers<br />

• KP36304 and 998242 are Stainless Steel wire<br />

Page E-1<br />

MAINTENANCE &<br />

SHOP SUPPLIES<br />

Face<br />

Width<br />

(In.)<br />

Arbor<br />

Hole<br />

(In.)<br />

Trim<br />

Lgth.<br />

(In.)<br />

883<br />

Max.<br />

(rpm)<br />

KP78797 3 .014 7<br />

⁄16<br />

1 3 ⁄2, ⁄8<br />

1<br />

⁄2 6,000<br />

21604 4 .014 1<br />

⁄2<br />

1 3 ⁄2, ⁄8<br />

13<br />

⁄16 6,000<br />

21602 6 .014 3<br />

⁄4<br />

5 1 ⁄8, ⁄2<br />

7 1 ⁄16 6,000<br />

-21604-1 6 .006 3<br />

⁄4<br />

5 1 ⁄8, ⁄2<br />

7 1 ⁄16 6,000<br />

KP78798 6 .008 1 5 1 ⁄8, ⁄2<br />

1 1 ⁄8 6,000<br />

C125117 7 .014 1 5 1 ⁄8, ⁄2 2 6,000<br />

-21601-2 8 .014 3<br />

⁄4<br />

5 1 ⁄8, ⁄2<br />

1 2 ⁄16 6,000<br />

CAUTION: Improper speeds and/or feeds may cause cutting tools<br />

to shatter. Always wear safety glasses when using cutting tools.<br />

Standard Twist<br />

Part No.<br />

Dia.<br />

(In.)<br />

Wire<br />

Size<br />

(In.)<br />

KP75684 3 .014 3<br />

⁄8<br />

KP75789 4 .014 1<br />

⁄2<br />

KP36304 4 .014 1<br />

⁄2<br />

KP75685 6 .014 1<br />

⁄2<br />

-19095-3 8 .023 5<br />

⁄8<br />

Face<br />

Width<br />

(In.)<br />

Arbor<br />

Hole<br />

(In.)<br />

Trim<br />

Lgth.<br />

(In.)<br />

Max.<br />

(rpm)<br />

879<br />

1 3 ⁄2, ⁄8<br />

5<br />

⁄8 25,000<br />

5 ⁄8-11 7<br />

⁄8 20,000<br />

5 ⁄8-11 7<br />

⁄8 20,000<br />

5 1 ⁄8, ⁄2<br />

3 1 ⁄8 9,000<br />

5<br />

⁄8<br />

5 1 ⁄8 6,000<br />

Continued on next page<br />

Page F-1<br />

SAFETY SUPPLIES

Continued from previous page<br />

Stringer Bead Twist<br />

Part No.<br />

Encapsulated Wire Wheels<br />

Power & Hand Tube<br />

Brushes<br />

Premium Wood Handle<br />

Deburring Brushes<br />

MATERIAL HANDLING/<br />

HARDWARE/RUBBER<br />

14847<br />

• Metal wires encapsulated in elastomer<br />

• Strong brushing action — no inefficient wire flare out; increased<br />

brush life<br />

• Fast cutting with minimum pressure<br />

• Applications: Heavy deburring, deflashing, weld cleaning, oxide<br />

and rust removal and surface prep<br />

• Wire size: .014<br />

Part No.<br />

Dia.<br />

(In.)<br />

C125143 3 1 ⁄4<br />

Face<br />

Width<br />

(In.)<br />

Arbor<br />

Hole<br />

(In.)<br />

Trim<br />

Lgth.<br />

(In.)<br />

Max.<br />

(rpm)<br />

1 ⁄2 1 20,000<br />

20239<br />

• Premium 4" long solid birch wood handle<br />

• Single spiral 2-ply tempered carbon steel bristles<br />

• Bristles include 20% more material than a standard fitting brush<br />

• Tough galvanized 2-ply wire stem<br />

• Made in U.S.A.<br />

• Unit is 2 for all part numbers<br />

Part No.<br />

Dia.<br />

(In.)<br />

Dia.<br />

(In.)<br />

Wire<br />

Size<br />

(In.)<br />

Actual<br />

Dia. (In.)<br />

Face<br />

Width<br />

(In.)<br />

Arbor<br />

Hole<br />

(In.)<br />

Trim<br />

Lgth.<br />

(In.)<br />

Wire<br />

Size<br />

(In.) Length (In.)<br />

KP72783 1 ⁄4<br />

3<br />

⁄8 .014 1 6<br />

KP72784 3 ⁄8<br />

1<br />

⁄2 .014 1 6<br />

KP72785 1 ⁄2<br />

5<br />

⁄8 .014 1 6<br />

KP72786 3 ⁄4<br />

7<br />

⁄8 .014 1 6<br />

KP72787 1 11 ⁄8 .014 1 6<br />

Max.<br />

(rpm)<br />

KP36307 4 .020 3<br />

⁄16<br />

5 ⁄8-11 7<br />

⁄8 20,000<br />

998242 4" .020 SS 3<br />

⁄16"<br />

5 ⁄8-11" 7<br />

⁄8 20,000<br />

C125136 6 .020 3<br />

⁄16<br />

5 ⁄8-11 1 1 ⁄8 12,500<br />

19095 6 .023 1<br />

⁄2<br />

5 ⁄8-11 3 1 ⁄8 9,000<br />

-19095-2 6 .023 1<br />

⁄2<br />

1 5 ⁄2, ⁄8<br />

3 1 ⁄8 9,000<br />

998243 6 1 ⁄2" .020 3 ⁄16" 5 ⁄8-11" 1 1 ⁄8 9,000<br />

Cable Twist<br />

Part No.<br />

Dia.<br />

(In.)<br />

Wire<br />

Size<br />

(In.)<br />

-19095-1 4 .020 1 ⁄4<br />

Face<br />

Width<br />

(In.)<br />

Arbor<br />

Hole<br />

(In.)<br />

Trim<br />

Lgth.<br />

(In.)<br />

Max.<br />

(rpm)<br />

5 ⁄8-11 7 ⁄8 20,000<br />

CAUTION: Improper speeds and/or feeds may cause cutting tools<br />

to shatter. Always wear safety glasses when using cutting tools.<br />

Overall<br />

Length (In.)<br />

Heavy-Duty Power & Hand<br />

Tube Brushes<br />

• All steel brushes (STL.) are manufactured using heat treated,<br />

high tensile wire providing superior fatigue resistance and<br />

cutting action<br />

• Single stem, single spiral nylon brushes with loop end are ideal<br />

for a variety of hand held, industrial cleaning applications<br />

• Tube brushes are used for cleaning and deburring tubes, pipes,<br />

holes, grooves and keyways<br />

• Made in the U.S.A.<br />

• Unit is 2 for all part numbers<br />

• Max rpm: 2,000<br />

Straight Black Nylon Filled Brush with<br />

Looped Handle<br />

Part No.<br />

Dia.<br />

(In.)<br />

Stem<br />

Dia.<br />

Wire<br />

Size<br />

(In.)<br />

FVendor Stocked<br />

Page G-1 Page H-1 Page I-1 Page J-1 Page K-1 Page L-1 Page M-1 Page N-1 Page O-1<br />

TOOLS &<br />

SECURITY<br />

ABRASIVES ELECTRICAL VEHICLE PRODUCTS WELDING<br />

Power & Hand Tube Brushes<br />

Brush<br />

Length (In.)<br />

KP36316 1<br />

⁄4<br />

3<br />

⁄32 .005 2 1 6 ⁄4<br />

KP36317 3<br />

⁄8<br />

3<br />

⁄32 .005 2 1 6 ⁄4<br />

KP36318 1<br />

⁄2<br />

1<br />

⁄8 .010 3 1 8 ⁄2<br />

KP36319 3<br />

⁄4<br />

1<br />

⁄8 .012 3 1 8 ⁄2<br />

KP36320 1 5<br />

⁄32 .014 4 1 12 ⁄4<br />

20241<br />

Overall<br />

Length (In.)<br />

Round Style Single Spiral Brush with<br />

Stainless Steel Stem<br />

Part No.<br />

Dia.<br />

(In.)<br />

Stem<br />

Dia.<br />

Wire<br />

Size<br />

(In.)<br />

Brush<br />

Length (In.)<br />

KP36321 3 ⁄8<br />

1<br />

⁄8 .004STL 1 1 3 ⁄2<br />

KP36327 3 ⁄8<br />

1<br />

⁄8 .004SS 1 1 3 ⁄2<br />

KP36322 7 ⁄16<br />

1<br />

⁄8 .005STL 1 1 3 ⁄2<br />

KP36328 7 ⁄16<br />

1<br />

⁄8 .005SS 1 1 3 ⁄2<br />

KP36323 1 ⁄2<br />

3<br />

⁄16 .005STL 1 1 3 ⁄2<br />

KP36329 1 ⁄2<br />

3<br />

⁄16 .005SS 1 1 3 ⁄2<br />

KP36324 5 ⁄8<br />

3<br />

⁄16 .005STL 1 1 3 ⁄2<br />

KP36325 3 ⁄4<br />

7<br />

⁄32 .006STL 1 1 3 ⁄2<br />

KP36326 1 1<br />

⁄4 .008STL 1 1 3 ⁄2<br />

Overall<br />

Length (In.)<br />

Round Style Double Spiral Brush with<br />

Double Stem<br />

Part No.<br />

Dia.<br />

(In.)<br />

Stem<br />

Dia.<br />

Wire<br />

Size<br />

(In.)<br />

Brush<br />

Length (In.)<br />

KP36330 3<br />

⁄8<br />

1<br />

⁄8 .006 1 1 ⁄2 4<br />

KP36331 1<br />

⁄2<br />

5<br />

⁄32 .006 2 5<br />

KP36332 5<br />

⁄8<br />

7<br />

⁄32 .008 2 5<br />

KP36333 3<br />

⁄4<br />

1<br />

⁄4 .0104 1 2 ⁄2<br />

1 5 ⁄2<br />

KP36334 1 1<br />

⁄4 .0104 1 2 ⁄2<br />

1 5 ⁄2<br />

Overall<br />

Length (In.)<br />

Polyflex Encapsulated Brushes 30616<br />

• An encapsulated brush has had its wire filaments encased in a<br />

synthetic elastomer<br />

• The elastomer holds the wire tips firmly in place producing a<br />

very controlled brushing face for maximum cutting action<br />

• These brushes are used for the most demanding applications and<br />

will outlast standard brushes by more than 4 to 1<br />

• Recommended for use on surfaces up to 180°F<br />

• Made in the USA<br />

• KP78803 is a standard brush type; used with a bench, drill, and<br />

arc grinder<br />

• KP78804 and KP78805 are conflex brush types used with a drill<br />

or die grinder<br />

• KP78806 is a hollow brush type and used with a drill or die<br />

grinder<br />

• Unit is 1 for all part numbers<br />

Part No.<br />

Brush Dia.<br />

(In.)<br />

Adapters<br />

• For adapting 5/8"-11 Arbor holes to metric M10<br />

• Use with depressed center wheels and wire brushes with 5/8"-11<br />

Arbor<br />

Part No. Description Unit<br />

21523 5 ⁄8"-11 fixed to M.10 x 1.25 adapteded 1<br />

21523-1 5 ⁄8"-11 fixed to M.10 x 1.50 adapteded 1<br />

Cross Reference<br />

Part No. Make Model No. Male Thd. Size Description<br />

21523 Jet 490004 M.10 x 1.25 Jet 400<br />

21523 Makita 9501BKIT M.10 x 1.25 4" Grinder<br />

21523 Makita M-952 M.10 x 1.25 4" Grinder<br />

21523-1 B & D 4246-09 M.10 x 1.50 4<br />

Continued on next page<br />

1 ⁄2" Angle<br />

Grinder<br />

TECHNICAL<br />

DATA<br />

Wire<br />

Size<br />

Trim Lgth.<br />

(In.)<br />

ALPHA<br />

INDEX<br />

Arbor/<br />

Stem Dia.<br />

(In.)<br />

Max<br />

RPMs<br />

KP78803 3 .014 1 1<br />

⁄2 20,000<br />

KP78804 2 .0118 1 ⁄2<br />

1<br />

⁄4 20,000<br />

KP78805 3 .0118 1 1<br />

⁄4 20,000<br />

KP78806 1 .014 7<br />

⁄8<br />

1<br />

⁄4 14,000<br />

712<br />

PART NO.<br />

INDEX<br />

Tools & <strong>Abrasives</strong><br />

H<br />

75

Tools & <strong>Abrasives</strong><br />

H<br />

76<br />

Power & Hand Tube Brushes<br />

Continued from previous page Threaded Adapter<br />

Part No. Make Model No. Male Thd. Size Description<br />

21523-1 B & D 6247 M.10 x 1.50 4" Angle<br />

Grinder<br />

21523-1 Hitachi G10 M.10 x 1.50 4" Grinder<br />

21523-1 Hitachi G10SA M.10 x 1.50 4" Grinder<br />

21523-1 Hitachi PDS-11SA M.10 x 1.50 4 1 ⁄2" Grinder<br />

21523-1 Hitachi PDS-11SA M.10 x 1.50 4 1 ⁄2" Grinder<br />

21523-1 Sioux 1240 M.10 x 1.50 4 1 ⁄2" Grinder<br />

21523-1 Skill 9405 M.10 x 1.50 4 1 ⁄2" Grinder<br />

CAUTION: Improper speeds and/or feeds may cause cutting tools<br />

to shatter. Always wear safety glasses when using cutting tools.<br />

FVendor Stocked<br />

Page A-1 Page B-1 Page C-1 Page D-1<br />

ASSORTMENTS<br />

& CABINETRY<br />

• At type<br />

• For use with wire wheel brushes<br />

Part No. Description Unit<br />

C125500 5<br />

Cross Reference<br />

Part No. Make Model No. Male Thd. Size Description<br />

21523 Jet 490004 M.10 x 1.25 Jet 400<br />

21523 Makita 9501BKIT M.10 x 1.25 4" Grinder<br />

21523 Makita M-952 M.10 x 1.25 4" Grinder<br />

21523-1 B & D 4246-09 M.10 x 1.50 4 1 ⁄2" Angle<br />

Grinder<br />

FASTENERS FITTINGS & HOSE<br />

CHEMICALS<br />

16271<br />

Part No. Make Model No. Male Thd. Size Description<br />

21523-1 B & D 6247 M.10 x 1.50 4" Angle<br />

Grinder<br />

21523-1 Hitachi G10 M.10 x 1.50 4" Grinder<br />

21523-1 Hitachi G10SA M.10 x 1.50 4" Grinder<br />

21523-1 Hitachi PDS-11SA M.10 x 1.50 4 1 ⁄2" Grinder<br />

21523-1 Hitachi PDS-11SA M.10 x 1.50 4 1 ⁄2" Grinder<br />

21523-1 Sioux 1240 M.10 x 1.50 4 1 ⁄2" Grinder<br />

21523-1 Skill 9405 M.10 x 1.50 4 1 ⁄2" Grinder<br />

CAUTION: Improper speeds and/or feeds may cause cutting tools<br />

to shatter. Always wear safety glasses when using cutting tools.<br />

Page E-1<br />

MAINTENANCE &<br />

SHOP SUPPLIES<br />

Page F-1<br />

SAFETY SUPPLIES

MATERIAL HANDLING/<br />

HARDWARE/RUBBER<br />

Steel Wool<br />

Industrial Steel Wool<br />

Steel Wool<br />

21179<br />

• A proven performer, steel wool represents an outstanding value<br />

that offers a wide range of uses<br />

• Its unique characteristics make steel wool an alternative to<br />

sandpaper<br />

• For use with all solvent and water based chemicals, such as<br />

strippers and refinishers<br />

• Steel wool's flexible nature, abrasive qualities and cost per use<br />

outperforms many synthetic alternatives<br />

• All steel wool pad bags are color coded for ease of identification<br />

GRADE APPLICATION<br />

Super Fine For rubbing surfaces to a smooth and<br />

0000<br />

lustrous finish<br />

Extra Fine For producing a slightly rough<br />

000<br />

and dull finish<br />

Very Fine For cleaning copper and brass.<br />

00<br />

To prepare lacquered or varnished<br />

coats for final finishing<br />

Fine<br />

To clean chrome and aluminium.<br />

0<br />

For removing rust spots<br />

Medium For buffing finishes and rubbing<br />

1<br />

between coats of enamel<br />

Medium Coarse<br />

2<br />

For removing paint, varnish, wax and dirt<br />

Coarse<br />

To take off paint and varnish with a<br />

3<br />

chemical remover<br />

Extra Coarse For smoothing rough surfaces<br />

4<br />

requiring a heavy abrasive<br />

• Special steel fibers specifically designed for smoothing and<br />

polishing surfaces<br />

• Unique inter-weave construction helps<br />

• maintain pad shape; prevents shredding; minimizes waste<br />

• Assortment includes 2 pads each of steel wool pad nos. 0, 1, 3<br />

Part No. Grade<br />

Pads<br />

per Bag Unit<br />

120-2207437 No.3 Coarse 16 1 bag<br />

12331<br />

Power & Hand Tube Brushes/Files - Hand<br />

Terminology<br />

File Terminology<br />

Standard Tooth Cuts<br />

— The following illustration compares the cuts of 10-inch single<br />

and double-cut file. The shorter the file, the less coarse the teeth.<br />

The longer the file, the coarser the teeth. However, the same<br />

relative difference in coarseness exists among files of the same<br />

length.<br />

B- Bastard Cut<br />

— A standard cut with coarse teeth for rapid stock removal.<br />

2- Second Cut<br />

— Medium teeth for moderate stock removal.<br />

S- Smooth Cut<br />

— Fine teeth for smooth finishes.<br />

Back<br />

— The rounded side of Half-Round and Great American Crosscut<br />

files. Also the side opposite the narrow edge of knife and similarly<br />

shaped files.<br />

Blunt<br />

— A file having an equal cross section from heel to point.<br />

Edge<br />

— The narrowest cutting surface and corners on triangular-shaped<br />

files.<br />

File Cut<br />

— The chisel cuts which form the teeth or cutting edges of the file<br />

are either single cut or double cut. The single cut consists of one<br />

series of parallel, equally spaced cuts or teeth machined at an<br />

angle across the face or width of the file. The double cut consists<br />

of two series of parallel teeth crossing each other to form many<br />

small cutting points.<br />

File Cut<br />

The first series of cuts is called the over cut, and the second series<br />

the up cut.<br />

Heel or Shoulder<br />

— The end of the file next to the tang.<br />

Length<br />

— The distance between the point and the heel (tang not<br />

included). On files without tangs, length is measured overall.<br />

Point<br />

— The end of the file opposite the tang.<br />

Safe<br />

— The uncut edge, side, or back of the file.<br />

Shape<br />

— The file cross section (round, square, knife, etc.)<br />

FVendor Stocked<br />

Page G-1 Page H-1 Page I-1 Page J-1 Page K-1 Page L-1 Page M-1 Page N-1 Page O-1<br />

TOOLS &<br />

SECURITY<br />

ABRASIVES ELECTRICAL VEHICLE PRODUCTS WELDING<br />

900<br />

Side<br />

— The broad, flat cutting surface.<br />

Tang<br />

— The pointed portion of the file that is inserted into the handle.<br />

Taper<br />

— The unequal or tapering with and/or file thickness. Also the<br />

name of a type of saw file.<br />

American Pattern Files<br />

American Pattern Files<br />

• Machinists files are generally double cut for rapid stock<br />

removal; used on all types of metals<br />

• Saw Files are generally single cut resulting in a smoother<br />

finish pressed edge tools<br />

• Packaged individually in plastic sleeve or in standard industrial<br />

box quantities<br />

All-Purpose Files<br />

• The built-in handle provides maximum versatility for a wide<br />

range of applications<br />

• Features a double cut on one side, a single cut on the other side<br />

• One edge cut and one edge safe (uncut) for shoulder filing<br />

• Parallel in width and thickness<br />

Part No. Size (In.) Unit<br />

e73-18750- 8 x 31 ⁄32 x 3 ⁄16 12<br />

-20577-8 8 x 31 ⁄32 x 3 ⁄16 1<br />

e73-18800- 10 x 31 ⁄32 x 3 ⁄16 12<br />

-20577-10 10 x 31 ⁄32 x 3 ⁄16 1<br />

Aluminum Flat Files<br />

• Coarse, fast cutting tooth design that is very effective in<br />

eliminating clogging<br />

• Developed for use on soft materials such as aluminum<br />

• Double cut and taper toward the point in width and thickness<br />

Part No. Size (In.) Unit<br />

e73-27500 8 x 25 ⁄32 x 7 ⁄32 12<br />

e73-27550 10 x 31 ⁄32 x 1 ⁄4 12<br />

e73-27600 12 x 1 5 ⁄32 x 9 ⁄32 6<br />

Aluminum Half Round Files<br />

• Half round shape with fast cutting tooth design<br />

• Great for rounding out holes, corners and crevices on soft<br />

materials<br />

• Double cut and taper toward the point in width and thickness<br />

Part No. Size (In.) Unit<br />

e73-37300 6 x 19 ⁄32 x 5 ⁄32 12<br />

e73-37400 10 x 15 ⁄16 x 9 ⁄32 12<br />

e73-37450 12 x 1 1 ⁄8 x 11 ⁄32 6<br />

TECHNICAL<br />

DATA<br />

ALPHA<br />

INDEX<br />

892<br />

6694<br />

6695<br />

6696<br />

PART NO.<br />

INDEX<br />

Tools & <strong>Abrasives</strong><br />

H<br />

77

Tools & <strong>Abrasives</strong><br />

H<br />

78<br />

Files - Hand<br />

Auger Bit Files<br />

• Used to touch-up the cutting edges on auger bits<br />

• One end single cut with safe edges, one end safe (uncut) with<br />

single edges<br />

• Measured on the overall length<br />

Part No. Size (In.) Unit<br />

e73-58050- 7 x 11 ⁄32 x 1 ⁄16 12<br />

Chain Saw Round Files<br />

• Used for sharpening and maintaining proper tooth shape on<br />

chain saws<br />

• Fast, smooth cutting action that leaves an excellent “keen” edge<br />

cutting finish<br />

Part No. Size (In.) Unit<br />

73-74061 7 ⁄32 x 8 12<br />

C123050 3 ⁄16 X 8 4<br />

C85890 5 ⁄32 x 6 12<br />

Flat Files<br />

• Excellent for “hogging” or rapid stock removal<br />

• Double cut on both sides, single cut on the edges and taper<br />

toward the point in width<br />

• Features the exclusive “wavy tooth” design<br />

Part No.<br />

Bastard Second Cut Smooth Size (In.) Unit<br />

73-22700- — 73-22800- 4 x 15 ⁄32 x 3 ⁄32 12<br />

73-22950- — 73-23050- 6 x 5 ⁄8 x 5 ⁄32 12<br />

-20561-6 — — 6 x 5 ⁄8 x 5 ⁄32 1<br />

73-23200- e73-23250 73-23300- 8 x 25 ⁄32 x 7 ⁄32 12<br />

-20561-8 — -20562-8 8 x 25 ⁄32 x 7 ⁄32 1<br />

73-23400- e73-23450 73-23500- 10 x 31 ⁄32 x 1 ⁄4 12<br />

-20561-10 — -20562-10 10 x 31 ⁄32 x 1 ⁄4 1<br />

73-23600- e73-23650 73-23700- 12 x 1 5 ⁄32 x 9 ⁄32 6<br />

-20561-12 — -20562-12 12 x 1 5 ⁄32 x 9 ⁄32 1<br />

e73-23800 — e73-23900 14 x 1 11 ⁄32 x 9 ⁄32 6<br />

e73-23950 — — 16 x 1 17 ⁄32 x 11 ⁄32 6<br />

Half Round Files<br />

• Superb for rounding out holes, corners and crevices<br />

• Double cut on both sides and taper toward the point in width and<br />

thickness<br />

• Features a built-in “twist & roll” action on the half round side<br />

produced by the Simonds “spiral cut” design<br />

• Exclusive “wavy tooth” design on the flat side<br />

Part No.<br />

Bastard Second Cut Smooth Size (In.) Unit<br />

73-31500- e73-31550- 73-31600- 4 x 7 ⁄16 x 1 ⁄8 12<br />

73-31700- e73-31750 73-31800- 6 x 19 ⁄32 x 5 ⁄32 12<br />

-20564-6 — — 6 x 19 ⁄32 x 5 ⁄32 1<br />

73-31900- e73-31950 73-32000- 8 x 3 ⁄4 x 7 ⁄32 12<br />

-20564-8 — — 8 x 3 ⁄4 x 7 ⁄32 1<br />

FVendor Stocked<br />

Page A-1 Page B-1 Page C-1 Page D-1<br />

ASSORTMENTS<br />

& CABINETRY<br />

6697<br />

6699<br />

6701<br />

6702<br />

Part No.<br />

Bastard Second Cut Smooth Size (In.) Unit<br />

73-32100- e73-32150 73-32200- 10 x 15 ⁄16 x<br />

9<br />

⁄32<br />

-20564-10 — — 10 x 15 ⁄16 x<br />

9<br />

⁄32<br />

73-32300- e73-32350 73-32400- 12 x 11 ⁄8 x<br />

11<br />

⁄32<br />

-20564-12 — — 12 x 11 ⁄8 x<br />

11<br />

⁄32<br />

e73-32500- — — 14 x 19 ⁄32 x<br />

13<br />

⁄32<br />

Knife Files<br />

• For use on slots, keyways and acute angles<br />

• Double cut on both sides, single cut on the “knife edge” with a<br />

safe (uncut) back and taper toward the point in width and<br />

thickness<br />

• Features the exclusive “wavy tooth” design<br />

Bastard<br />

Part No.<br />

Second Cut Smooth Size (In.) Unit<br />

e73-<br />

49850-<br />

— e73-49950- 4 x 15 ⁄32 x 7 ⁄64 12<br />

73-<br />

50000e73-50050<br />

73-50100- 6 x 21 ⁄32 x 5 73-<br />

⁄32 12<br />

50150-<br />

73-<br />

50300-<br />

Long Angle Lathe Files<br />

• Primarily for lathe work and bench filing<br />

• Single cut with both edges safe (uncut) and taper toward the<br />

point in width<br />

• Teeth are designed on a “long angle” to provide free cutting and<br />

rapid filing while leaving a smooth finish.<br />

Part No. Size (In.) Unit<br />

e73-25550- 10 x 3 ⁄32 x 1 ⁄4 12<br />

e73-25600- 12 x 1 5 ⁄32 x 9 ⁄32 6<br />

Mill Files<br />

• Excellent for a wide range of applications such as sharpening,<br />

draw filing, lathe work and general shop use<br />

• Single cut on the sides and edges, and taper towards the point in<br />

width<br />

Part No.<br />

Bastard Second Cut Smooth Size (In.) Unit<br />

73-14050- — 73-14150- 4 x 7 ⁄16 x<br />

5<br />

⁄64<br />

73-14300- — 73-14400- 6 x 19 ⁄32 x<br />

7<br />

⁄64<br />

-20571-6 73-14350- -20572-6 6 x 19 ⁄32 x<br />

7<br />

⁄64<br />

73-14550- e73-14600 73-14650- 8 x 25 ⁄32 x<br />

9<br />

⁄64<br />

-20571-8 — -20572-8 8 x 25 ⁄32 x<br />

9<br />

⁄64<br />

73-14750- e73-14800 73-14850- 10 x 31 ⁄32 x<br />

11<br />

⁄64<br />

FASTENERS FITTINGS & HOSE<br />

CHEMICALS<br />

12<br />

e73-50200 73-50250- 8 x 27 ⁄32 x 3 ⁄16 12<br />

e73-50350 73-50400- 10 x 1 1 ⁄32 x<br />

1 ⁄4<br />

1<br />

6<br />

1<br />

6<br />

6703<br />

12<br />

6704<br />

6705<br />

12<br />

12<br />

1<br />

12<br />

1<br />

12<br />

Part No.<br />

Bastard Second Cut Smooth Size (In.) Unit<br />

-20571-10 — -20572-10 10 x 31 ⁄32 x<br />

11 ⁄64<br />

73-14950- e73-15000- 73-15050- 12 x 1 5 ⁄32<br />

Multi-Kut ® Flat Files<br />

• Obtain almost any required finish simply by changing the feed<br />

pressure<br />

• Single cut coarse tooth files that taper toward the point in width<br />

• Simonds' exclusive Multi-Kut ® design features a diamond pattern<br />

“double chip breaker” allowing for fast stock removal while<br />

leaving a smooth finish<br />

• Combines the performance of flat and mill files<br />

Part No. Size (In.) Unit<br />

e73-24300- 8 x 25 ⁄32 x 7 ⁄32 12<br />

-20563-8 8 x 25 ⁄32 x 7 ⁄32 1<br />

e73-24350- 10 x 31 ⁄32 x 1 ⁄4 12<br />

-20563-10 10 x 31 ⁄32 x 1 ⁄4 1<br />

e73-24400- 12 x 1 5 ⁄32 x 9 ⁄32 6<br />

-20563-12 12 x 1 5 ⁄32 x 9 ⁄32 1<br />

e73-24450 14" x 1 11 ⁄32 x 5 ⁄16 6<br />

Round Files<br />

• Intended for enlarging and rounding out circular openings or<br />

concave surfaces<br />

• Double cut and taper toward the point in width and thickness<br />

• Round files are often referred to as “rat tail” files<br />

Part No.<br />

Bastard Second Cut Smooth Size (In.) Unit<br />

73-39300- — 73-39400- 4 x 5 ⁄32 12<br />

73-39600- e73-39650 73-39700- 6 x 7 ⁄32 12<br />

-20565-6 — — 6 x 7 ⁄32 1<br />

73-39850- e73-39900 73-39950- 8 x 5 ⁄16 12<br />

-20565-8 — — 8 x 5 ⁄16 1<br />

73-40050- — 73-40150- 10 x 3 ⁄8 12<br />

-20565-10 — — 10 x 3 ⁄8 1<br />

73-40250- — 73-40350- 12 x 1 ⁄2 6<br />

-20565-12 — — 12 x 1 ⁄2 1<br />

Page E-1<br />

MAINTENANCE &<br />

SHOP SUPPLIES<br />

x 7 ⁄32<br />

-20571-12 — — 12 x 15 ⁄32<br />

x 7 ⁄32<br />

e73-15150- — e73-15250- 14 x 1 5 ⁄16<br />

x 1 ⁄4<br />

-20571-14 — — 14 x 15 ⁄16<br />

x 1 ⁄4<br />

e73-15350 — — 16 x 11 ⁄2 x<br />

9<br />

⁄32<br />

1<br />

6<br />

1<br />

6<br />

1<br />

6<br />

6707<br />

6708<br />

Page F-1<br />

SAFETY SUPPLIES

Square Files<br />

• Created for slots, keyways, square holes or general surface filing<br />

• Double cut and taper toward the point in width and thickness<br />

• Features the exclusive “wavy tooth” design<br />

Part No.<br />

Bastard Smooth Size (In.) Unit<br />

e73-42800- e73-42900 6 x 7 ⁄32 12<br />

-20566-6 — 6 x 7 ⁄32 1<br />

e73-43000- e73-43100 8 x 5 ⁄16 12<br />

-20566-8 — 8 x 5 ⁄16 1<br />

— e73-43300 10 x 3 ⁄8 12<br />

-20566-10 — 10 x 3 ⁄8 1<br />

e73-43400 — 12 x 1 ⁄2 6<br />

-20566-12 — 12 x 1 ⁄2 1<br />

Taper Saw Files<br />

• Designed for filing all types of saws with 60° angle teeth<br />

• Triangular in shape with cut edges and taper toward the point in<br />

width and thickness<br />

Part No. Size (In.) Type Unit<br />

e73-53700- 6 x 11 ⁄32 Slim 12<br />

-20573-6 6 x 11 ⁄32 Slim 1<br />

e73-53800- 8 x 15 ⁄32 Slim 12<br />

-20573-8 8 x 15 ⁄32 Slim 1<br />

eC83995 8 x 15 ⁄32 Extra Slim 1<br />

e73-53850- 10 x 5 ⁄8 Slim 12<br />

-20573-10 10 x 5 ⁄8 Slim 1<br />

Three-Square Files<br />

• Excellent for cleaning out corners or for use on cutters, taps and<br />

flat surfaces<br />

• Double cut and taper toward the point in width and thickness<br />

• Features the exclusive “wavy tooth” design<br />

Part No.<br />

Bastard Smooth Size (In.) Unit<br />

73-51650- e73-51750 6 x 15 ⁄32 12<br />

-20567-6 — 6 x 15 ⁄32 1<br />

73-51800- e73-51900 8 x 5 ⁄8 12<br />

-20567-8 — 8 x 5 ⁄8 1<br />

73-51950- e73-52050 10 x 3 ⁄4 12<br />

-20567-10 — 10 x 3 ⁄4 1<br />

Tungsten Point Files<br />

• Single cut<br />

• For cleaning contact points in magnetics, switches, electric bells<br />

and distributor points and spark plugs in engines<br />

Part No. Description Unit<br />

C22087 5" Regular 10<br />

MATERIAL HANDLING/<br />

HARDWARE/RUBBER<br />

6709<br />

6710<br />

6711<br />

16276<br />

Warding Files<br />

• Preferred by locksmiths for filing “wards” in locks and keys<br />

• Great for narrow spaces where other files will not fit<br />

• Double cut with single edges and taper toward the point in width<br />

• Features the exclusive “wavy tooth” design<br />

• Bastard cut only<br />

Part No. Size (In.) Unit<br />

e73-47900 4 x 15 ⁄32 x 3 ⁄64 12<br />

e73-48100 6 x 5 ⁄8 x 5 ⁄64 12<br />

e73-48250 8 x 25 ⁄32 x 3 ⁄32 12<br />

Vixen Milled Tooth Files<br />

Babbitt Files<br />

• For filing babbitt, lead, brass and copper<br />

• Larger, coarser tooth design than a standard cut to help remove<br />

material faster<br />

• Available in flat shape only with safe (uncut) edges<br />

Part No. Size (In.) Unit<br />

e81-13350 12 x 1 5 ⁄32 x 17 ⁄64 6<br />

e81-13400 14 x 1 11 ⁄32 x 5 ⁄16 6<br />

Flat Files<br />

With Tang<br />

• Ideal for fast filing on aluminum, brass, copper and hard rubber<br />

• Standard cut on both sides with safe (uncut) edges<br />

Part No. Size (In.) Unit<br />

e81-12550 8 x 13 ⁄16 x 11 ⁄64 12<br />

e81-12700 10 x 1 x 7 ⁄32 12<br />

e81-12850 12 x 1 5 ⁄32 x 17 ⁄64 6<br />

Flat Files<br />

Flexible<br />

• Great for all types of auto body and sheet metal work<br />

• Teeth on both sides with safe (uncut) edges<br />

• When used with the proper holder, files can be adjusted to file<br />

concave, convex and flat surfaces<br />

Part No. Size (In.) Cut Unit<br />

e81-11250 12 x 1 5 ⁄32 x 3 ⁄16 Standard 6<br />

e81-11450 14 x 1 11 ⁄32 x 3 ⁄16 8 Tooth 6<br />

Half Round Shell Files<br />

• Designed for use on concave surfaces<br />

• Eight tooth cut with teeth on the convex side only<br />

• With safe (uncut) edges<br />

Part No. Size (In.) Unit<br />

e81-12200 14 x 1 15 ⁄32 x 1 ⁄8 6<br />

FVendor Stocked<br />

Page G-1 Page H-1 Page I-1 Page J-1 Page K-1 Page L-1 Page M-1 Page N-1 Page O-1<br />

TOOLS &<br />

SECURITY<br />

ABRASIVES ELECTRICAL VEHICLE PRODUCTS WELDING<br />

6712 Whizcut Files<br />

6714<br />

6715<br />

6716<br />

6718<br />

Needle Files<br />

Individual Shapes<br />

TECHNICAL<br />

DATA<br />

Files - Hand<br />

• Standard cut<br />

• Produces an especially smooth finish on assorted surfaces<br />

• Designed with long chip-beakers that eliminate clogging<br />

• Off-center teeth generate a faster, easier shearing action<br />

• Available in flat shape only with safe (uncut) edges<br />

Part No. Size (In.) Unit<br />

e81-13950 12 x 1 5 ⁄32 x 17 ⁄64 6<br />

Swiss Pattern Files<br />

• Used for applications similar to the larger tanged files<br />

• For production work on small electronic parts<br />

• Provide excellent detail work capabilities<br />

• Available with knurled steel handles<br />

Equalling<br />

Part No. Length (In./mm) Cut Unit<br />

e83-53450- 6 1 ⁄4/160 0 12<br />

e83-53500- 6 1 ⁄4/160 2 12<br />

Flat<br />

Part No. Length (In./mm) Cut Unit<br />

e83-52400- 6 1 ⁄4/160 0 12<br />

Half-Round<br />

Part No. Length (In./mm) Cut Unit<br />

e83-52600- 6 1 ⁄4/160 0 12<br />

e83-52650- 6 1 ⁄4/160 2 12<br />

Round<br />

Part No. Length (In./mm) Cut Unit<br />

e83-53000- 6 1 ⁄4/160 0 12<br />

e83-53050- 6 1 ⁄4/160 2 12<br />

Three Square<br />

Part No. Length (In./mm) Cut Unit<br />

e83-53900- 6 1 ⁄4/160 2 12<br />

ALPHA<br />

INDEX<br />

6717<br />

6719<br />

PART NO.<br />

INDEX<br />

Tools & <strong>Abrasives</strong><br />

H<br />

79

Tools & <strong>Abrasives</strong><br />

H<br />

80<br />

Files - Hand<br />

FVendor Stocked<br />

Sets, Handles &<br />

Accessories<br />

Professional File Kit<br />

• Five pieces<br />

• Packaged complete in a vinyl pouch<br />

• Made in U.S.A.<br />

Part No. Contents Unit<br />

20578 (1) each: 8" multi-kut (No. 20563-8),<br />

8" flat (No. 20561-8),<br />

8" mill (No. 20571-8),<br />

8" round (No. 20565-8)<br />

8" half round (No. 20564-8). 20564-8)<br />

1 Kit<br />

CAUTION: Always wear safety glasses when using cutting tools.<br />

Precision Needle File Set<br />

• Tool steel construction professional quality; outstanding service<br />

life<br />

• Precise tooth formation for fine, exact filing of small areas<br />

• Built-in rounded handle ends; comfortable grip; no separate<br />

handles required<br />

• Custom vinyl carrying/storage case protects files and keeps<br />

them together<br />

• Each file is approximately 6-1/4" long; ideal for tight-fitting<br />

applications<br />

Part No. No. Pces. Contents Unit<br />

21749 6 1 each; flat square, three square,<br />

round, equalling, and half round.<br />

1<br />

KP8616 12 1 ea- 1 square, 3 square round,<br />

half round, knife crossing,<br />

equalling, barrette marking, flat,<br />

slitting, joint<br />

1<br />

CAUTION: Always wear safety glasses when using cutting tools.<br />

Page A-1 Page B-1 Page C-1 Page D-1<br />

ASSORTMENTS<br />

& CABINETRY<br />

687<br />

690<br />

File-All ® Set<br />

• Unique three-in-one portable tool kit<br />

• Contains six-inch round, mill and square file<br />

• Exclusive Black Maxi Sharp ® finish<br />

• Packaged in a high impact plastic case that becomes the handle<br />

when in use<br />

Part No. Description Unit<br />

20579 File-All ® Set (Sleeved) 1<br />

Wood File Handles<br />

Push-On Type<br />

• Manufactured from soft wood; absorbs hand moisture more<br />

readily<br />

• Sizes vary with file lengths; ensures a proper file to handle fit<br />

• NOTE: A tanged file should never be used without a file handle<br />

Part No. Description Unit<br />

20585 4" for files 4" to 6" 1<br />

20586 4 2 ⁄3" for files 6" to 8" 1<br />

20587 4 3 ⁄4" for files 8" to 10" 2<br />

20589 5" for files 10" to 14" 2<br />

CAUTION: Always wear safety glasses when using cutting tools.<br />

Wood File Handles - Thread-On 20260<br />

• Wooden file handles have a threaded insert for "easy on and<br />

easy off"<br />

• Reusable and long lasting<br />

• Wood handle absorbs moisture for added safety<br />

Part No. File Size Unit<br />

KP8631 6" File 1<br />

KP8632 8" File 1<br />

KP8633 10" File 1<br />

KP8634 12" File 1<br />

KP8635 14" File 1<br />

FASTENERS FITTINGS & HOSE<br />

CHEMICALS<br />

6720<br />

693<br />

Plastic File Handles<br />

• High-impact plastic construction offers professional quality;<br />

outstanding service life<br />

• High-quality, tempered-steel threader securely grips file; resists<br />

wear-out<br />

• Grooved, contoured handle for a secure, comfortable fit<br />

• Pre-drilled mounting hole allows convenient storage on pegboard<br />

Part No. Size Description Unit<br />

21741 Small Fits 6"—8" files 2<br />

21745 Medium Fits 8"—10" files 2<br />

21742 Large Fits10"—14" files 2<br />

CAUTION: Always wear safety glasses when using cutting tools.<br />

Bearing Scraper<br />

• Handle included<br />

• Precision ground scraper for hand finishing bearing surfaces,<br />

casting joints and other metal seats<br />

• Carbon steel, three-square blade<br />

• Made in U.S.A.<br />

Part No. Description Unit<br />

20575 3 1 ⁄4" Hollow Ground 1<br />

CAUTION: Always wear safety glasses when using cutting tools.<br />

Disposable Deburring Tool<br />

Thread Restoring Files<br />

• Renews threads on any diameter bolt, stud, axle or shaft<br />

• Used just like a file can also be used as a thread gauge<br />

• Each thread size is clearly marked<br />

Continued on next page<br />

Page E-1<br />

MAINTENANCE &<br />

SHOP SUPPLIES<br />

694<br />

679<br />

30773<br />

• Swivel blade design removes burrs, flash and ragged edges from<br />

steel, aluminum or plastic pieces after drilling or cutting<br />

• Solid aluminum construction handle with high speed steel blade<br />

• Removes burrs from small holes and openings that files cannot<br />

reach<br />

Part No. Description Unit<br />

KP84651 Deburring Tool 1<br />

280<br />

Page F-1<br />

SAFETY SUPPLIES