HAWE press release Silage Field Transfer Trailer ... - HAWE Wester

HAWE press release Silage Field Transfer Trailer ... - HAWE Wester

HAWE press release Silage Field Transfer Trailer ... - HAWE Wester

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>HAWE</strong> <strong>press</strong> <strong>release</strong> <strong>Silage</strong> <strong>Field</strong> <strong>Transfer</strong> <strong>Trailer</strong> February 2009<br />

New <strong>Field</strong> <strong>Transfer</strong> <strong>Trailer</strong> for <strong>Silage</strong><br />

The distances to be covered in the silage harvesting chain become ever greater. This has<br />

encouraged <strong>HAWE</strong>-<strong>Wester</strong>, the trailer specialist from Emsland in Germany and already<br />

renowned manufacturer of <strong>Field</strong> <strong>Transfer</strong> <strong>Trailer</strong>s for grain and sugar beet, to now introduce<br />

an interesting similar concept for the forage harvest.<br />

Protecting soil structure on arable and pasture land<br />

Large silage harvesters with 1000 HP and high chopping performance require the<br />

appropriate scale of transport back-up. Big biogas plants or dairy farms need huge amounts<br />

of forage and high harvesting performance so that the green feed is ensiled as quickly as<br />

possible. Continually increasing numbers of silage trailers with low ground <strong>press</strong>ure tyres to<br />

meet this demand increase transport cost input and therefore cannot be the right way to<br />

achieve cost-optimised forage harvesting.<br />

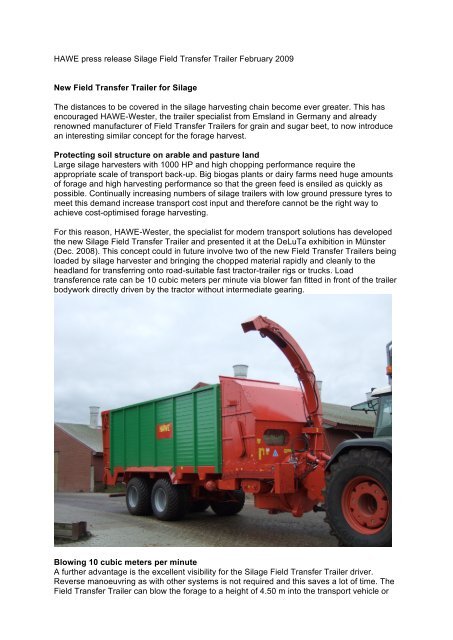

For this reason, <strong>HAWE</strong>-<strong>Wester</strong>, the specialist for modern transport solutions has developed<br />

the new <strong>Silage</strong> <strong>Field</strong> <strong>Transfer</strong> <strong>Trailer</strong> and presented it at the DeLuTa exhibition in Münster<br />

(Dec. 2008). This concept could in future involve two of the new <strong>Field</strong> <strong>Transfer</strong> <strong>Trailer</strong>s being<br />

loaded by silage harvester and bringing the chopped material rapidly and cleanly to the<br />

headland for transferring onto road-suitable fast tractor-trailer rigs or trucks. Load<br />

transference rate can be 10 cubic meters per minute via blower fan fitted in front of the trailer<br />

bodywork directly driven by the tractor without intermediate gearing.<br />

Blowing 10 cubic meters per minute<br />

A further advantage is the excellent visibility for the <strong>Silage</strong> <strong>Field</strong> <strong>Transfer</strong> <strong>Trailer</strong> driver.<br />

Reverse manoeuvring as with other systems is not required and this saves a lot of time. The<br />

<strong>Field</strong> <strong>Transfer</strong> <strong>Trailer</strong> can blow the forage to a height of 4.50 m into the transport vehicle or

the digester container of a biogas plant. Additionally, the new trailer has proved itself as not<br />

susceptible to rolling over during testing under commercial farming conditions, the design<br />

being based on the renowned <strong>HAWE</strong> <strong>Silage</strong> <strong>Trailer</strong> with load volumes of up to 60 cubic<br />

meters. For biogas plant managers the new <strong>HAWE</strong> <strong>Silage</strong> <strong>Field</strong> <strong>Transfer</strong> <strong>Trailer</strong> offers the<br />

possibility of filling the digester container every day, with transport of fermenting material<br />

from greater distances than before. To make it more efficient under these conditions the new<br />

<strong>Silage</strong> <strong>Field</strong> <strong>Transfer</strong> <strong>Trailer</strong> features a robust timber bodywork that has performed well even<br />

with corrosive silage and displayed a much better resistance to damage than the more usual<br />

coated steel profile panels, which continue to give good service on standard silage trailers.<br />

With large-scale biogas plants, or in groups of several 500 kW units, the <strong>Silage</strong> <strong>Field</strong><br />

<strong>Transfer</strong> <strong>Trailer</strong> offers a higher performance compared with telescopic loaders, even where<br />

the silage clamps are in the vicinity of the digester containers.<br />

Experience and reliability<br />

Customers can select from a large range of extra equipment for the new <strong>HAWE</strong> <strong>Silage</strong> <strong>Field</strong><br />

<strong>Transfer</strong> <strong>Trailer</strong>s with tandem or tridem running gear. These accessories have already been<br />

tried and tested on other trailers and their robustness under working conditions well proven.<br />

Mechanical, hydraulic and pneumatic suspension, a variety of tyre types and the solid BPW<br />

axles are all available. Hydraulic drawbar suspension is incorporated as standard equipment<br />

and customers can choose the hitch system most suitable for their own situation. The drives<br />

are simple, robust and, above all, low-maintenance and overall wear and tear resistance is<br />

also a feature of the trailer.<br />

Logistics for professionals<br />

The new <strong>Silage</strong> <strong>Field</strong> <strong>Transfer</strong> <strong>Trailer</strong> from <strong>HAWE</strong> offers completely new opportunities in the<br />

modern and future-oriented silage harvesting chain and in the daily “feeding” of biogas<br />

plants. During the harvest season the system offers savings in silage trailers and enables<br />

rapid and clean transference onto trucks that can cover the ever-greater distances from field<br />

to ensiling point faster and above all more cost-efficiently. And under wet silage harvesting<br />

conditions the low ground <strong>press</strong>ure tyres leave a minimum of tracks and soil compaction.<br />

Over and above this, the concept offers the bioenergy farmer completely new opportunities<br />

for bringing silage into the biogas plants from much further afield than was possible before -<br />

and of feeding it into the digester container directly with the high performance blower.<br />

With the new <strong>Silage</strong> <strong>Field</strong> <strong>Transfer</strong> <strong>Trailer</strong> from <strong>HAWE</strong> farmers, bioenergy producers,<br />

machine rings and contractors all have the chance of a future oriented, cost-effective concept<br />

which is new but despite this has already proved its practicality and working dependability<br />

through tried and tested components from other trailers that are now built into the concept –<br />

a concept that opens up new possibilities for saving labour and costs and at the same time<br />

increasing performance.<br />

<strong>HAWE</strong>-<strong>Wester</strong> GmbH & Co. KG Maschinenbau<br />

Zum Turm 16, 26892 Wippingen<br />

Tel.: 04966 / 91880, Fax 04966 / 1211<br />

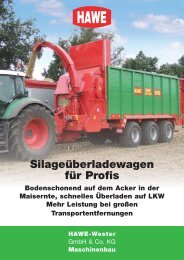

Caption:

The new <strong>HAWE</strong> <strong>Silage</strong> <strong>Field</strong> <strong>Transfer</strong> <strong>Trailer</strong> is exceptionally suitable for daily filling of biogas<br />

plants. In silage harvesting it also offers an important new link in the transport chain with the<br />

ability to transfer 10 cubic meters of maize silage per minute.<br />

.