Marine Lubricants technicaL reference Guide - ShipServ

Marine Lubricants technicaL reference Guide - ShipServ

Marine Lubricants technicaL reference Guide - ShipServ

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

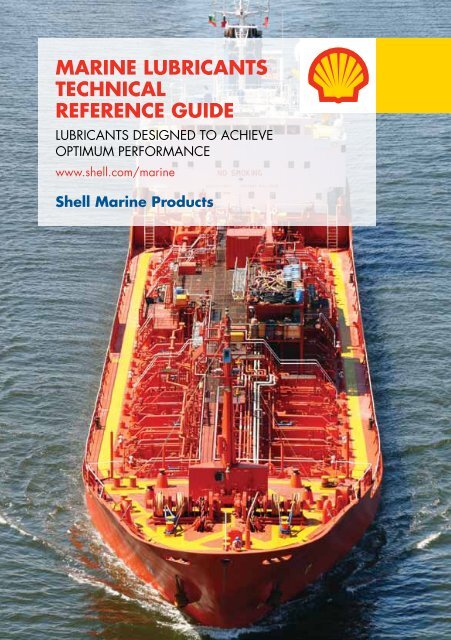

<strong>Marine</strong> <strong>Lubricants</strong><br />

<strong>technicaL</strong><br />

<strong>reference</strong> <strong>Guide</strong><br />

<strong>Lubricants</strong> designed to achieve<br />

optimum performance<br />

www.shell.com/marine<br />

shell <strong>Marine</strong> Products

Preface<br />

Welcome to the <strong>Marine</strong> <strong>Lubricants</strong> Technical Reference <strong>Guide</strong> from<br />

Shell <strong>Marine</strong> Products.<br />

Shell has, over many years, developed a comprehensive portfolio<br />

of exceptional lubricants, many of which have multiple functions or<br />

specialised applications for the marine industry.<br />

This Technical Reference <strong>Guide</strong> is designed as a useful and quick<br />

<strong>reference</strong> for personnel responsible for engineering operations<br />

and maintenance in the marine sector. The <strong>Guide</strong> only provides<br />

a summary of Shell's main lubricant grades at the time of printing,<br />

and contains typical physical characteristics together with brief<br />

product and application descriptions. Further details on Shell marine<br />

lubricants and their applications can be obtained from your Shell<br />

<strong>Marine</strong> Products Representative.

table of contents<br />

cateGory<br />

Low-sPeed enGine<br />

SheLL ALexiA 50............................................................................................................................. 2<br />

SheLL ALexiA LS.............................................................................................................................. 4<br />

SheLL MeLinA S 30........................................................................................................................ 5<br />

MediuM-sPeed enGine<br />

SheLL ARGinA T.............................................................................................................................6<br />

SheLL ARGinA x.............................................................................................................................8<br />

SheLL ARGinA xL.......................................................................................................................... 10<br />

SheLL GAdiniA............................................................................................................................ 12<br />

SheLL GAdiniA AL........................................................................................................................ 14<br />

hiGh-sPeed enGine<br />

SheLL SiRiuS 15W-40....................................................................................................................16<br />

SheLL SiRiuS x.............................................................................................................................. 17<br />

SheLL RiMuLA R3 TuRbo................................................................................................................18<br />

hydrauLic systeMs<br />

SheLL TeLLuS S2 V.........................................................................................................................19<br />

Gear systeMs<br />

SheLL oMALA S2 G ..................................................................................................................... 21<br />

SheLL oMALA S4 Gx ................................................................................................................... 23<br />

SheLL oMALA S4 We................................................................................................................... 25<br />

SheLL MoRLinA S4 b.................................................................................................................... 27<br />

air coMPressors<br />

SheLL CoRenA S2 P..................................................................................................................... 29<br />

SheLL CoRenA S4 P..................................................................................................................... 31<br />

SheLL CoRenA S4 R.................................................................................................................... 33<br />

refriGeration coMPressors<br />

SheLL ReFRiGeRATion oiL S4 FR-F................................................................................................... 35<br />

SheLL ReFRiGeRATion oiL S4 FR-V................................................................................................... 36<br />

steaM turbines<br />

SheLL TuRbo T............................................................................................................................. 38<br />

stern tubes<br />

SheLL STRoMbuS MP....................................................................................................................40<br />

bearinG and circuLation systeMs<br />

SheLL MoRLinA S2 b....................................................................................................................41<br />

heat transfer fLuid<br />

SheLL heAT TRAnSFeR FLuid S2..................................................................................................... 42<br />

Greases<br />

SheLL GAduS S2 A320................................................................................................................ 44<br />

SheLL GAduS S2 V100................................................................................................................. 45<br />

SheLL GAduS S2 V220................................................................................................................. 46<br />

SheLL GAduS S2 V220Ad.............................................................................................................48<br />

SheLL GAduS S3 T220................................................................................................................. 49<br />

SheLL GAduS S3 V220C...............................................................................................................50

shell alexia 50<br />

cylinder lubricant for low-speed crosshead diesel engines<br />

shell alexia 50 is a premium quality cylinder lubricant designed for use in all low-speed<br />

crosshead diesel engines which burn residual fuel with sulphur content higher than 1.5%wt.<br />

it is particularly suitable for the new generation of highly rated, fuel-efficient, low-speed marine<br />

diesel engines operating with higher pressures and higher liner wall temperatures.<br />

shell alexia 50 is blended from high viscosity index base oils and additive technology developed<br />

by shell.<br />

Main aPPLications<br />

n Cylinder lubrication of low-speed marine diesel<br />

engines which burn residual fuel with sulphur<br />

content higher than 1.5%wt.<br />

n Shell Alexia 50 is suitable for use in applications<br />

where high levels of acid stress occur. high levels<br />

of acid stress can occur if liner wall temperatures<br />

are too low, charge air temperatures are too low<br />

or lubrication feed rate is not sufficient to ensure a<br />

suitable bn throughput for acid neutralisation.<br />

PerforMance sPecifications<br />

Approved by all manufacturers of low-speed<br />

crosshead diesel engines.<br />

PerforMance benefits<br />

improved engine reliability<br />

n outstanding acid neutralising properties which<br />

help to prolong the life of components.<br />

n Minimal deposits on pistons, piston rings, ring<br />

grooves, under piston spaces and in cylinder<br />

ports.<br />

n Low cylinder and piston ring wear with typical<br />

cylinder wear rates below 0.05 mm per 1000<br />

hours due to enhanced boundary lubrication<br />

properties.<br />

Lower maintenance costs<br />

n Keeps engines exceptionally clean, minimises<br />

maintenance requirements and allows the periods<br />

between overhauls to be extended.<br />

re-assurance<br />

n Completely stable in storage under all the widely<br />

varying conditions encountered aboard ship.<br />

n Proven ability to keep engines clean, and control<br />

wear and scuffing in the latest engine designs.<br />

n Compatible with all normal oil seal materials.<br />

2 MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong><br />

oiL feed rates<br />

insufficient cylinder oil feed rates can contribute to<br />

acid stress and hence higher rates of corrosive wear.<br />

insufficient cylinder oil feed rates can also reduce the<br />

cleaning of ring/groove deposits, which in turn can<br />

lead to seized and broken rings, blow-by of hot gases,<br />

and scavenger fire risks.<br />

To obtain optimum performance with Shell Alexia 50 it<br />

is important to:<br />

n observe the engine manufacturers' recommended<br />

cylinder oil feed rates.<br />

n observe the engine manufacturers' recommendations<br />

in terms of engine operating parameters.<br />

n Regularly scavenge port inspections to verify<br />

acceptable running conditions.<br />

n Consider using higher rates, especially when running<br />

in new liners and/or rings and under conditions of<br />

high acid stress.<br />

n ensure equally distributed oil feeds to each injection<br />

quill.<br />

n ensure the lubricator drive system is well maintained<br />

and properly adjusted.<br />

n Clean and overhaul lubricator boxes according to<br />

engine manufacturers’ recommendations.<br />

advice<br />

n Applications where the fuel sulphur content is<br />

consistently below 1.5%wt should be discussed with<br />

your Shell representative.<br />

n Please note that due to its high additive content, it is<br />

not advisable to mix Shell Alexia 50 with any other<br />

cylinder lubricant.<br />

n Advice on applications not covered in this leaflet may<br />

be obtained from your Shell Representative.

heaLth & safety<br />

Shell Alexia 50 is unlikely to present any significant<br />

health or safety hazard when properly used in the<br />

recommended application and good standards of<br />

personal hygiene are maintained. Avoid contact with<br />

skin. use impervious gloves with used oil. After skin<br />

contact, wash immediately with soap and water. For<br />

further guidance on Product health and Safety refer to<br />

the appropriate Shell Product Safety data Sheet.<br />

tyPicaL PhysicaL characteristics<br />

shell alexia 50 test units result<br />

sae viscosity Grade<br />

Kinematic viscosity<br />

50<br />

@ 40°C ASTM d445 iP 71 mm 2 /s 225<br />

@100°C ASTM d445 iP 71 mm 2 /s 19.5<br />

viscosity index<br />

density<br />

ASTM d2270 iP 226 > 95<br />

@ 15°C ASTM d4052 iP 365 kg/m 3<br />

932<br />

flash Point PMcc ASTM d 93 iP 34 °C > 205<br />

Pour Point ASTM d 97 iP 15 °C < –6<br />

bn ASTM d2896 iP 276 mg Koh/g 70<br />

sulphated ash ASTM d874 iP 163 % wt 8.7<br />

These characteristics are typical of current production. Whilst future production<br />

will conform to Shell's specification, variations in these characteristics may<br />

occur.<br />

For more information please contact your Shell <strong>Marine</strong> Products Representative or refer to the Port Services <strong>Guide</strong> on our website<br />

www.shell.com/marine. Shell is not liable for application/advice errors when Product data Sheets are obtained from non-official<br />

sources/sites other than the official website as shown above.<br />

MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong> 3

shell alexia Ls<br />

special cylinder oil for low-speed diesel engines<br />

shell alexia Ls is a special 40bn, sae 50 cylinder lubricant, for improved piston running<br />

conditions in low speed crosshead diesel engines burning low sulphur fuels.<br />

Main aPPLications<br />

n Cylinders of low-speed crosshead diesel engines<br />

burning fuels with sulphur content below 2%wt,<br />

where the designer recommends a lower base<br />

number (bn) oil to reduce the risk of "sudden<br />

severe wear" or scuffing.<br />

PerforMance features<br />

n reduced piston deposits<br />

The reduced ash level of Shell Alexia LS helps to<br />

avoid excessive piston top land deposits, which<br />

can sometimes build up when 70bn oils are<br />

used with low sulphur fuel.<br />

n Good piston ring and port cleanliness<br />

Shell Alexia LS contains “hidden” detergency, not<br />

reflected in the bn of the product. This enables it<br />

to keep the ring belt and scavenge airports clean<br />

in spite of the reduced bn.<br />

n Greater feed rate flexibility<br />

The control of deposits and lower ash allows<br />

Shell Alexia LS to be used over a wider range of<br />

feed rates with less danger of excessive deposits<br />

than a 70bn cylinder oil.<br />

PerforMance sPecifications<br />

Shell Alexia LS is approved by Wartsila (Sulzer) and<br />

MAn.<br />

oiL feed rates<br />

insufficient cylinder oil feed rates can lead to<br />

corrosive wear, seized and broken rings and<br />

consequent blow-by and scavenge fire risks, and to<br />

the formation of excessive and tenacious deposits.<br />

Toobtain optimum performance with Shell Alexia LS<br />

it is important to:<br />

n observe the engine manufacturers' recommended<br />

cylinder oil feed rates as the minimum.<br />

n Consider using higher rates, especially when<br />

running in new liners and/or rings.<br />

n equally distribute the oil between injection quills.<br />

n ensure the lubricator drive system is well<br />

maintained and properly adjusted.<br />

4 MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong><br />

n Clean and overhaul lubricator boxes according<br />

to engine manufacturers' recommendations.<br />

advice<br />

Advice on applications not covered in this leaflet may<br />

be obtained from your Shell Representative.<br />

heaLth & safety<br />

Shell Alexia LS is unlikely to present any significant<br />

health or safety hazard when properly used in the<br />

recommended application, and good standards of<br />

industrial and personal hygiene are maintained.<br />

Avoid contact with skin. use impervious gloves with<br />

used oil. After skin contact, wash immediately with<br />

soap and water. For further guidance on Product<br />

health refer to the appropriate Shell Product Satety<br />

data Sheet.<br />

tyPicaL PhysicaL characteristics<br />

shell alexia Ls test units result<br />

sae viscosity Grade 50<br />

Kinematic viscosity<br />

@ 40°C iP 71 cSt 211.0<br />

@100°C iP 71 cSt 19.5<br />

viscosity index iP 226 100<br />

density<br />

@ 15°C iP 365 kg/m 3 925<br />

flash Point iP 34 °C 210<br />

(Pensky-Martens Closed Cup)<br />

Pour Point iP 15 °C -6<br />

bn iP 276 mg 40<br />

Koh/g<br />

sulphated ash iP 163 % wt 5.3<br />

These characteristics are typical of current production.<br />

Whilst future production will conform to Shell's specification,<br />

variations in these characteristics may occur.<br />

For more information please contact your Shell <strong>Marine</strong> Products Representative or refer to the Port Services <strong>Guide</strong> on our website<br />

www.shell.com/marine. Shell is not liable for application/advice errors when Product data Sheets are obtained from non-official<br />

sources/sites other than the official website as shown above.

shell Melina s 30<br />

Multifunctional lubricant for low speed marine diesel engines<br />

shell melina s is a high performance multifunctional low speed diesel engine lubricant based on<br />

a blend of highly refined high viscosity index mineral oils and a balanced selection of additives.<br />

it is designed to provide the highest levels of machinery protection in highly rated low-speed<br />

marine engines, but being multifunctional, can also be used in many different items of marine<br />

equipment and used to rationalise the number of grades of lubricant carried on board ship.<br />

Please note that Shell Melina S 30 is NOT recommended for trunk-piston engines.<br />

Main aPPLications<br />

n Low speed marine diesel engine crankcase and<br />

piston cooling systems.<br />

n Turbochargers, geared transmissions, oil<br />

lubricated stern tubes and deck machinery.<br />

n All ancillary equipment requiring an SAe 30 oil.<br />

PerforMance benefits<br />

improved engine operation and reliability<br />

n Shell Melina S 30 effectively neutralises the<br />

highly corrosive combustion acids which can<br />

contaminate the main system when cylinder oil<br />

drains leak past piston rod glands.<br />

n Good resistance to corrosion results in protection<br />

of metal surfaces from corrosion.<br />

n Good detergency keeps crankcases and under<br />

piston spaces clean and optimise efficiency.<br />

n Good air release and antifoam properties mean<br />

that air is released from the oil without foaming.<br />

Lower maintenance costs<br />

n Good oxidation stability combats thermal.<br />

degradation of the oil and extends its useful life.<br />

n Good water shedding properties mean that water<br />

can be easily removed by centrifuge.<br />

n extreme pressure properties make the oil suitable<br />

for many gear oil applications.<br />

re-assurance<br />

n Shell Melina S 30 oil is approved by all major<br />

low-speed diesel engine manufacturers.<br />

advice<br />

condition monitoring<br />

n Shell RLA and Shell RLA oPiCA engine condition<br />

monitoring services are ideal for users of Shell<br />

Melina S 30. use of these services enable the<br />

ship operator to monitor the condition of the oil<br />

and equipment, and enable remedial action<br />

to be taken when necessary. This helps to avoid<br />

breakdowns,costly downtime and all the associated<br />

inconvenience.To fully benefit from this service,<br />

samples should be taken at regular intervals of<br />

approximately 750 hours.<br />

n Advice on applications not covered in this leaflet<br />

may be obtained from your Shell Representative.<br />

heaLth & safety<br />

Shell Melina S is unlikely to present any significant<br />

health or safety hazard when properly used in the<br />

recommended application. Avoid contact with<br />

skin. use impervious gloves with used oil. After skin<br />

contact, wash immediately with soap and water. For<br />

further guidance on Product health and Safety refer to<br />

the appropriate Shell Product Safety data Sheet.<br />

tyPicaL PhysicaL characteristics<br />

shell Melina s 30 test units result<br />

sae viscosity Grade 30<br />

Kinematic viscosity<br />

@ 40°C iP 71 mm 2 /s 104<br />

@ 100°C iP 71 mm 2 /s 11.6<br />

viscosity index<br />

density<br />

iP 226 102<br />

@15°C iP 365 kg/m 3<br />

888<br />

flash Point closed cup iP 34 °C 227<br />

Load carrying capacity FZG 11 Failure Load Stage<br />

Pour Point iP15 °C –18<br />

bn iP 276 mg Koh/g 5<br />

These characteristics are typical of current production.<br />

Whilst future production will conform to Shell's specification,<br />

variations in these characteristics may occur.<br />

For more information please contact your Shell <strong>Marine</strong> Products Representative or refer to the Port Services <strong>Guide</strong> on our website<br />

www.shell.com/marine. Shell is not liable for application/advice errors when Product data Sheets are obtained from non-official<br />

sources/sites other than the official website as shown above.<br />

MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong> 5

shell argina t<br />

Medium-speed trunk-piston diesel engine oil<br />

shell argina t is a multifunctional crankcase lubricant for highly rated medium-speed diesel engines<br />

operating on residual fuel. shell argina t is designed for conditions of moderate oil stress.<br />

Main aPPLications<br />

n Medium-speed industrial or marine propulsion and<br />

auxiliary engines, burning residual fuel oils, which<br />

create conditions of moderate oil stress. These<br />

conditions usually occur:<br />

- in engine designs more than 5 years old, or<br />

- where oil consumption is 1g/kWh or more, or<br />

- in newer designs where load factors are<br />

predominantly 85% or less, or<br />

- where fuels with sulphur

heaLth & safety<br />

Shell Argina T oils are unlikely to present any significant<br />

health or safety hazard when properly used in the<br />

recommended application, and good standards of<br />

industrial and personal hygiene are maintained. Avoid<br />

contact with skin. use impervious gloves with used oil.<br />

After skin contact, wash immediately with soap and<br />

water. For further guidance on Product health and<br />

Safety refer to the appropriate Shell Product Safety<br />

data Sheet.<br />

tyPicaL PhysicaL characteristics<br />

shell argina t test units result<br />

sae viscosity Grade 30 40<br />

Kinematic viscosity<br />

@ 40°C ASTM d 445, iP 71 cSt 110 125<br />

@ 100°C ASTM d 445, iP 71 cSt 12 14<br />

viscosity index ASTM d 2270, iP 226 100 100<br />

density<br />

@ 15°C ASTM d 4052, iP 365 kg/m 3 918 921<br />

flash Point ASTM d 93, iP 34 °C 212 225<br />

(Pensky-Martens Closed Cup)<br />

Pour Point ASTM d 97, iP 15 °C –18 –18<br />

bn ASTM d 874, iP 163 mg Koh/g 30 30<br />

sulphated ash iP 163 %wt 3.7 3.7<br />

Load carrying capacity iP 334 A/8.3/90 11 11<br />

(FZG Gear Machine)<br />

Failure Load Stage<br />

These characteristics are typical of current production. Whilst future production will<br />

conform to Shell's specification, variations in these characteristics may occur.<br />

For more information please contact your Shell <strong>Marine</strong> Products Representative or refer to the Port Services <strong>Guide</strong> on our website:<br />

www.shell.com/marine. Shell is not liable for application/advice errors when Product data Sheets are obtained from non-official<br />

sources/sites other than the official website as shown above.<br />

MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong> 7

shell argina X<br />

Medium-speed trunk-piston diesel engine oil<br />

shell argina X is a multifunctional crankcase lubricant for highly rated medium-speed diesel<br />

engines operating on residual fuel. shell argina X is designed for conditions of high oil stress<br />

and has been further optimised to improve deposit control.<br />

Main aPPLications<br />

PerforMance sPecifications<br />

n Medium-speed industrial or marine propulsion Shell Argina x enjoys a comprehensive range of<br />

and auxiliary engines, burning residual fuel oils, original equipment Manufacturers’ approvals through<br />

which create conditions of high oil stress. These field experience over many years and meets the engine<br />

conditions usually occur:<br />

- in newer engine designs, less than 10 years old<br />

test criteria for APi CF.<br />

and/or fitted with flame rings,<br />

PerforMance benefits<br />

- where oil consumption is 0.5 – 1 g/kWh,<br />

- where load factors are >85%,<br />

n improved engine reliability<br />

- effective detergent and dispersancy additives<br />

- where fuels with sulphur >3% are in use.<br />

prevent the build up of soot, black sludge and<br />

n <strong>Marine</strong> engine reduction gears (SAe 40 only)<br />

heavy fuel contaminants in critical parts of the<br />

and certain other ship-board applications, where engine and keep the engine exceptionally clean.<br />

specialist lubricants are not required.<br />

- Combustion acids are effectively neutralised and<br />

n Medium-speed engines burning residual fuel<br />

the engine is protected from acidic corrosion.<br />

need very specialised lubricants. heavy fuels n Lower Maintenance costs:<br />

contaminate the oil with asphaltenes, requiring - Good thermal and oxidation stability allows oil<br />

special types of detergency to avoid sludges. The drain intervals to be extended.<br />

combustion of high sulphur fuels produces sulphur - excellent piston/liner wear control and good gear<br />

acids, which cause high wear rates of piston rings performance help reduce component costs.<br />

and cylinder liners unless neutralised by a high<br />

basicity reserve in the oil. The oil is in service<br />

for very long periods, so centrifugal separators<br />

are used to remove water and combustion<br />

n re-assurance:<br />

The oils have a comprehensive range of engine<br />

manufacturers’ approvals.<br />

contaminants from the oil. Medium-speed engine<br />

oils must be specially designed to release these advice<br />

contaminants in the separator.<br />

n Shell RLA and RLA oPiCA engine condition<br />

monitoring services are recommended for users<br />

PerforMance features<br />

n engine cleanliness<br />

has built a reputation over many years for very<br />

good engine cleanliness. The formulation has<br />

been further optimised to reduce deposits in<br />

critical areas, e.g. piston undercrown.<br />

n rapid neutralisation of acidic<br />

of Shell Argina x. use of these services enable<br />

the ship operator to monitor the condition of the<br />

oil and equipment, and enable remedial action<br />

to be taken when necessary. This helps to avoid<br />

breakdowns, costly downtime, and all the associated<br />

inconvenience. To fully benefit from this service,<br />

samples should be taken at regular intervals of<br />

approximately 750 hours.<br />

combustion products<br />

Gives long-term protection against corrosion of<br />

ferrous and non-ferrous metals.<br />

n Advice on applications not covered in this leaflet may<br />

be obtained from your Shell Representative.<br />

n thermal stability and resistance to<br />

oxidation<br />

Provides excellent high temperature deposit control<br />

and contributes to long oil life.<br />

n suitability for centrifugal separators<br />

heaLth & safety<br />

Shell Argina x oils are unlikely to present any significant<br />

health or safety hazard when properly used in the<br />

recommended application, and good standards of<br />

industrial and personal hygiene are maintained. Avoid<br />

effective detergent and dispersancy formulation contact with skin. use impervious gloves with used oil.<br />

releases contaminants and water readily in After skin contact, wash immediately with soap and<br />

centrifugal separators.<br />

water. For further guidance on Product health and<br />

Safety refer to the appropriate Shell Product Safety<br />

data Sheet.<br />

8 MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong>

tyPicaL PhysicaL characteristics<br />

shell argina X test units result<br />

sae viscosity Grade<br />

Kinematic viscosity<br />

40<br />

@ 40°C ASTM d 445, iP 71 cSt 135<br />

@ 100°C ASTM d 445, iP 71 cSt 14<br />

viscosity index<br />

density<br />

ASTM d 2270, iP 226 100<br />

@ 15°C ASTM d 4052, iP 365 kg/m 3 916<br />

flash Point<br />

(Pensky-Martens Closed Cup)<br />

ASTM d 93, iP 34 °C 205<br />

Pour Point ASTM d 97, iP 15 °C –18<br />

bn ASTM d 2896, iP 276 mg Koh/g 40<br />

sulphated ash ASTM d 874, iP 163 %wt 4.9<br />

Load carrying capacity iP 334 A/8.3/90<br />

(FZG Gear Machine)<br />

Failure Load Stage<br />

10<br />

These characteristics are typical of current production. Whilst future production will<br />

conform to Shell's specification, variations in these characteristics may occur.<br />

For more information please contact your Shell <strong>Marine</strong> Products Representative or refer to the Port Services <strong>Guide</strong> on our website<br />

www.shell.com/marine. Shell is not liable for application/advice errors when Product data Sheets are obtained from non-official<br />

sources/sites other than the official website as shown above.<br />

MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong> 9

shell argina XL<br />

Medium-speed trunk-piston diesel engine oil<br />

shell argina XL is a multifunctional crankcase lubricant for highly rated medium-speed diesel<br />

engines operating on residual fuel. shell argina XL is designed for conditions of very high oil<br />

stress and has been further optimised to improve deposit control.<br />

Main aPPLications<br />

n Medium-speed industrial or marine propulsion<br />

and auxiliary engines, burning residual fuel<br />

oils, which create conditions of very high oil<br />

stress. These conditions usually occur:<br />

- in newer engine designs, with flame rings,<br />

especially from Wartsila,<br />

- where oil consumption is 90%,<br />

- where fuels with sulphur >3% are in use.<br />

n Medium-speed engines burning residual fuel<br />

need very specialised lubricants. heavy fuels<br />

contaminate the oil with asphaltenes, requiring<br />

special types of detergency to avoid sludges.<br />

The combustion of high sulphur fuels produces<br />

sulphur acids, which cause high wear rates of<br />

piston rings and cylinder liners unless<br />

neutralised by a high basicity reserve in the oil.<br />

The oil is in service for very long periods, so<br />

centrifugal separators are used to remove water<br />

and combustion contaminants from the oil.<br />

Medium-speed engine oils must be specially<br />

designed to release these contaminants in the<br />

separator. Shell Argina xL has been specially<br />

designed for very high stress conditions, found<br />

most often in modern Wartsila engines in<br />

power plant or ship propulsion applications.<br />

PerforMance features<br />

n excellent engine cleanliness<br />

higher detergency than even Shell Argina x,<br />

leading to exceptionally clean crankcase, valve<br />

deck and pistons. The formulation has been<br />

further optimised to reduce deposits in critical<br />

areas, e.g. piston undercrown.<br />

n very high oxidation resistance<br />

Longer oil life and greater resistance to<br />

oxidative thickening.<br />

10 MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong><br />

n extra high base number (50)<br />

Longer oil life in engines where life is limited by<br />

depletion of base number (bn). in many cases a<br />

satisfactory equilibrium bn level can be maintained<br />

in conditions where this would be impossible with a<br />

40bn oil.<br />

n very good base number retention<br />

Resists secondary loss of base number due to<br />

oxidation.<br />

n suitability for centrifugal separators<br />

effective detergent and dispersancy formulation<br />

releases contaminants and water readily in<br />

centrifugal separators.<br />

n full compatibility with shell argina family<br />

Shell Argina xL can be used to top up engines<br />

already running on any other member of the Shell<br />

Argina family, giving immediate control of bn<br />

without the need for an oil change.<br />

PerforMance sPecifications<br />

Shell Argina xL is approved by Wartsila and meets the<br />

engine test criteria for APi CF.<br />

improved engine reliability<br />

n extremely high detergency and dispersency<br />

which prevent sludge from forming and keeps<br />

crankcases, valves, pistons lands and the critical<br />

piston under-crown area exceptionally clean.<br />

n An extra high base number (50) which means a<br />

satisfactory equilibrium base number level can be<br />

maintained in conditions which would be<br />

impossible with a 40 Tbn oil.<br />

Lower maintenance costs<br />

n Good thermal and oxidative stability which resists<br />

thickening and results in much longer oil life.<br />

n Minimises the wear of piston rings and cylinder<br />

liners.<br />

re-assurance<br />

n A comprehensive range of engine manufacturers<br />

approvals.

advice<br />

n Shell RLA and RLA oPiCA engine condition<br />

monitoring services are recommended for users<br />

of Shell Argina xL. use of these services enable<br />

the ship operator to monitor the condition of<br />

the oil and equipment, and enable remedial<br />

action to be taken when necessary. This helps to<br />

avoid breakdowns, costly downtime, and all the<br />

associated inconvenience. To fully benefit from<br />

this service, samples should be taken at regular<br />

intervals of approximately 750 hours.<br />

n Please note that due to its high base number,<br />

this oil has a high ash content. To avoid<br />

excessive ash deposits, do not use with<br />

low sulphur fuels, or engines with high oil<br />

consumption. Advice on applications are not<br />

covered in this leaflet.<br />

tyPicaL PhysicaL characteristics<br />

shell argina XL test units result<br />

sae viscosity Grade<br />

Kinematic viscosity<br />

40<br />

@ 40°C ASTM d 445, iP 71 cSt 135<br />

@ 100°C ASTM d 445, iP 71 cSt 14<br />

viscosity index<br />

density<br />

ASTM d 2270, iP 226 100<br />

@ 15°C ASTM d 4052, iP 365 kg/m 3 921<br />

flash Point<br />

(Pensky-Martens Closed Cup)<br />

ASTM d 93, iP 34 °C 229<br />

Pour Point ASTM d 97, iP 15 °C –18<br />

bn ASTM d 2896, iP 276 mg Koh/g 50<br />

sulphated ash ASTM d 874, iP 163 %wt 6.1<br />

These characteristics are typical of current production. Whilst future production will<br />

conform to Shell's specification, variations in these characteristics may occur.<br />

heaLth & safety<br />

Shell Argina xL is unlikely to present any significant<br />

health or safety hazard when properly used in the<br />

recommended application, and good standards<br />

of industrial and personal hygiene are maintained.<br />

Avoid contact with skin. use impervious gloves with<br />

used oil. After skin contact, wash immediately with<br />

soap and water. For further guidance on Product<br />

health and Safety refer to the appropriate Shell<br />

Product Safety data Sheet.<br />

For more information please contact your Shell <strong>Marine</strong> Products Representative or refer to the Port Services <strong>Guide</strong> on our website<br />

www.shell.com/marine. Shell is not liable for application/advice errors when Product data Sheets are obtained from non-official<br />

sources/sites other than the official website as shown above.<br />

MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong> 11

shell Gadinia<br />

<strong>Lubricants</strong> for medium-speed marine diesel engines running on<br />

distillate fuels<br />

shell gadinia are premium quality multifunctional diesel engine lubricants that are specially<br />

designed for the most severe service main propulsion and auxiliary marine trunk piston engines<br />

burning distillate fuels with a sulphur content up to 1%. they also perform satisfactorily in<br />

smaller high-speed engines of fishing fleets that operate under arduous conditions and have<br />

small sumps.<br />

Main aPPLications<br />

n highly rated, medium-speed, main propulsion and<br />

auxiliary trunk-piston marine diesel engines.<br />

n Turbochargers, oil-filled stern tubes, variable pitch<br />

propellers and geared transmissions.<br />

n deck machinery and other marine applications<br />

requiring SAe 30 or 40 viscosity oils.<br />

PerforMance benefits<br />

improved engine reliability<br />

n Greater tolerance to engine overload or poor<br />

combustion due to improved piston cleanliness.<br />

n Reduced deposits in piston ring belt and cylinder<br />

liners.<br />

Lower maintenance costs<br />

n extended diesel engine life through reduced risk of<br />

ring sticking and breakage.<br />

n Longer oil life, especially in high stress engines,<br />

because of Shell Gadinia’s excellent resistance to<br />

oxidation and thermal degradation under severe<br />

operating conditions.<br />

n Superior protection against corrosion for all<br />

engine components, due to Shell Gadinia’s unique<br />

formulation giving excellent alkalinity retention.<br />

n improved control of liner lacquer leads to better<br />

control of oil consumption and contributes to lower<br />

cost of operation.<br />

re-assurance<br />

n Greater safety margin to protect highly loaded<br />

bearings, in the event of water contamination,<br />

because of Shell Gadinia’s improved water<br />

tolerance and separation in separators.<br />

n oeM endorsement by leading diesel engine<br />

manufacturers following extensive field approval<br />

trials, means that Shell Gadinia is suitable for the<br />

widest range of modern diesel engines.<br />

12 MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong><br />

PerforMance sPecifications<br />

n APi CF.<br />

n Shell Gadinia is approved by leading trunk piston<br />

engine manufacturers.<br />

advice<br />

condition monitoring<br />

n Shell RLA engine condition monitoring service<br />

enables the ship operator to monitor the condition of<br />

the oil and equipment, and to take remedial action<br />

when necessary. This helps to avoid breakdowns and<br />

costly downtime. Shell RLA oPiCA is an integrated<br />

software system enabling RLA data to be received<br />

electronically in the office and/or on the vessel. it<br />

contains powerful data management and graphics,<br />

enabling efficiency gains in report handling and<br />

machine condition monitoring.<br />

n Advice on applications not covered in this leaflet may<br />

be obtained from your Shell Representative.<br />

heaLth & safety<br />

Shell Gadinia are unlikely to present any significant<br />

health or safety hazard when properly used in the<br />

recommended application, and good standards of<br />

personal hygiene are maintained. Avoid contact with<br />

skin. use impervious gloves with used oil. After skin<br />

contact, wash immediately with soap and water. For<br />

further guidance please request a Shell Product Safety<br />

data Sheet.

tyPicaL PhysicaL characteristics<br />

shell Gadinia test units result<br />

sae viscosity Grade<br />

Kinematic viscosity<br />

30 40<br />

@ 40°C ASTM d 445, iP 71 mm 2 /s 104 139<br />

@ 100°C ASTM d 445, iP 71 mm 2 density<br />

/s 11.8 14.4<br />

@ 15°C ASTM d 4052, iP 365 kg/m 3 897 900<br />

flash Point<br />

(Pensky-Martens Closed Cup)<br />

ASTM d 93, iP 34 °C 200+ 225+<br />

Pour Point ASTM d 97, iP 15 °C –18 –18<br />

bn ASTM d 2896, iP 276 mg Koh/g 12 12<br />

sulphated ash ASTM d874, iP 163 %wt 1.35 1.35<br />

These characteristics are typical of current production. Whilst future production<br />

will conform to Shell's specification, variations in these characteristics may occur.<br />

For more information please contact your Shell <strong>Marine</strong> Products Representative or refer to the Port Services <strong>Guide</strong> on our website<br />

www.shell.com/marine. Shell is not liable for application/advice errors when Product data Sheets are obtained from non-official<br />

sources/sites other than the official website as shown above.<br />

MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong> 13

shell Gadinia aL<br />

advanced lubricant for medium-speed trunk-piston engines<br />

running on distillate fuel<br />

shell gadinia aL is a premium quality marine diesel engine oil designed for use in mediumspeed<br />

trunk piston engines, which operate on distillate fuels. shell gadinia aL is specially<br />

designed to control oil consumption in modern engines, where liner lacquering is a potential<br />

problem. being multifunctional shell gadinia aL can also be used for other shipboard<br />

applications such as reduction gears.<br />

Main aPPLications<br />

n highly rated medium-speed diesel engines<br />

operating under high load or overload conditions.<br />

n General ship application, including gears, where<br />

specialist lubricants are not required.<br />

benefits<br />

improved reliability<br />

n excellent piston and crankcase cleanliness, which<br />

helps to maintain engine efficiency.<br />

n Load carrying properties required for use in<br />

reduction gears.<br />

Lower maintenance costs<br />

n excellent liner lacquer control that maintains<br />

lubricating oil consumption at its normal level.<br />

n A high level of protection against bore polishing –<br />

another cause of high oil consumption.<br />

re-assurance<br />

n Protection for engines where cylinder liner<br />

lacquering is likely to occur.<br />

PerforMance sPecifications<br />

n APi CF<br />

aPProvaLs<br />

n Rolls-Royce, bergen.<br />

n deutz AG.<br />

n MAn bandW diesel AG.<br />

n Simplex (Compact Sterntube Seals).<br />

n MAK.<br />

14 MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong><br />

Liner LacquerinG<br />

The medium-speed diesel engine is becoming more<br />

demanding to lubricate. higher engine efficiencies<br />

are being achieved through engine designs, which<br />

incorporate higher cylinder-pressures, higher combustion<br />

temperatures, and the use of very high-pressure fuel<br />

injection. in some modern distillate fuelled engines,<br />

these conditions may lead to the formation of a layer of<br />

brown or black lacquer on the cylinder liner surfaces.<br />

This can fill in the honing pattern, resulting in a loss<br />

of oil control and runaway oil consumption. The<br />

condition is particularly common in severe operations<br />

(e.g. overload or high torque conditions). There is also<br />

evidence that it is more common where low sulphur<br />

(

tyPicaL PhysicaL characteristics<br />

shell Gadinia aL test units result<br />

sae viscosity Grade<br />

Kinematic viscosity<br />

30 40<br />

@ 40°C ASTM d 445, iP 71 mm 2 /s 94.5 140<br />

@ 100°C ASTM d 445, iP 71 mm 2 density<br />

/s 11.4 14.3<br />

@ 15°C ASTM d 4052, iP 365 kg/m 3 893 900<br />

flash Point<br />

(Pensky-Martens Closed Cup)<br />

ASTM d 93, iP 34 °C 200+ 225+<br />

Pour Point ASTM d 97, iP 15 °C –18 –18<br />

bn ASTM d 2896, iP 276 mg Koh/g 15 15<br />

sulphated ash ASTM d874, iP 163 %wt 1.35 1.35<br />

Load carrying capacity iP 334<br />

(FZG Gear Machine)<br />

Fail Stage 12 12<br />

These characteristics are typical of current production. Whilst future production will<br />

conform to Shell's specification, variations in these characteristics may occur.<br />

For more information please contact your Shell <strong>Marine</strong> Products Representative or refer to the Port Services <strong>Guide</strong> on our website<br />

www.shell.com/marine. Shell is not liable for application/advice errors when Product data Sheets are obtained from non-official<br />

sources/sites other than the official website as shown above.<br />

MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong> 15

shell sirius 15w-40<br />

oil for high-speed marine diesel engines<br />

shell sirius 15W-40 is a high-performance, multifunctional diesel engine lubricant designed for<br />

use in all modern high speed (>1200rpm) diesel engines, burning distillate fuels with a sulphur<br />

content of up to 1%wt.<br />

Main aPPLications<br />

n high-speed propulsion engines<br />

e.g. coastal vessels, fishing trawlers, rescue boats<br />

and lifeboats.<br />

n high-speed generators engines<br />

PerforMance features & benefits<br />

n unique new formulation<br />

Shell technologists have developed exclusive<br />

formulations for the new generation of Shell Sirius<br />

designed to deliver a step change in performance<br />

levels to improve the efficiency and life of your<br />

machinery.<br />

n Greater protection and higher<br />

temperatures<br />

With increasing power, modern engines have to<br />

work harder for longer, resulting in increased heat<br />

and stress on the engine oil. Shell Sirius 15W-40<br />

has been demonstrated to provide increased<br />

resistance to thermal breakdown ensuring<br />

continued protection throughout the drain interval,<br />

even under the most severe conditions.<br />

n Longer oil life<br />

With their exclusive additive formulations, the new<br />

Shell Sirius 15W-40 oils can fight the combined<br />

effects of combustion acids and increased heat for<br />

longer than their predecessors. This performance<br />

reserve ensures that the oil continues to protect<br />

against wear and corrosion right up til the oil<br />

drain.<br />

n approved by leading engine makers<br />

The new formulation Shell Sirius 15W-40<br />

engine oils meet a wide range of engine maker<br />

requirements.<br />

sPecification & aPProvaLs<br />

shell sirius 15w-40 meets the<br />

requirements of:<br />

– APi: Ch-4<br />

– ACeA: e3, e5<br />

– Caterpillar: eCF-1<br />

– Cummins: CeS 200-71,-72, 76<br />

– Cummins (bandC Series): CeS 200-75<br />

– GM Allison: G4<br />

16 MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong><br />

shell sirius 15w-40 is approved against<br />

detroit diesel/MTu Type i<br />

(Series 2000and 4000)<br />

MAn 3275<br />

heaLth & safety<br />

Guidance on health and Safety are available on the<br />

appropriate Material Safety data Sheet which can be<br />

obtained from your Shell Representative.<br />

Protect the environMent<br />

Take used oil to an authorised collection point. do not<br />

discharge into drains, soil or water.<br />

tyPicaL PhysicaL characteristics<br />

shell sirius 15w-40 test units result<br />

sae viscosity Grade 15W-40<br />

Kinematic viscosity<br />

@ 40°C iP 71, mm 2 /s 105.1<br />

ASTM d445<br />

@ 100°C iP 71, mm 2 /s 14.3<br />

ASTM d445<br />

dynamic viscosity<br />

@ -15°C ASTM d5293 mPa*s -<br />

@ -20°C ASTM d5293 mPa*s 6600<br />

@ -25°C ASTM d5293 mPa*s -<br />

viscosity index iSo 2909, 139<br />

ASTM d2270<br />

density iP 365, kg/m 3 886<br />

@ 15°C iSo12185<br />

flash Point iP 94, °C 205<br />

PMcc ASTM d93<br />

Pour Point iSo 3016, °C -39<br />

ASTM d97<br />

tbn iSo 3771, mg 10.8<br />

ASTM d2896 Koh/g<br />

sulphated ash ASTM d874 %wt 1.44<br />

These characteristics are typical of current production.<br />

Whilst future production will conform to Shell's<br />

specification, variations in these characteristics may occur.

shell sirius X<br />

super high performance diesel engine oil<br />

shell sirius X is a top quality lubricant, of the super high performance diesel engine oil<br />

(shpdo) class. it is designed for the highest output, high-speed diesel engines, burning distillate<br />

fuel, and is formulated to give better engine protection and longer drain intervals than normal<br />

diesel engine oils. shell sirius X is especially suitable for the high power/weight units used in<br />

fast vessels and compact generator sets.<br />

Main aPPLications<br />

n high-speed diesel engines operating on distillate<br />

fuels.<br />

n not suitable for n. American automotive type<br />

engines, for which APi CF-4 type oils are required.<br />

PerforMance features<br />

n outstanding piston cleanliness<br />

Free-running piston rings, even under difficult<br />

operational conditions, ensuring maximum reliability.<br />

n exceptional protection against bore<br />

polishing<br />

Control of blow-by and oil consumption,<br />

preserving engine efficiency. ShPdo type oils are<br />

preferred by many engine manufacturers to guard<br />

against bore polishing.<br />

n exceptional engine cleanliness<br />

Ability to retain high levels of soot safely in<br />

suspension, even with extended drain intervals.<br />

n oxidation resistance twice that of<br />

conventional oils<br />

Ability to withstand high temperatures for longer,<br />

in severe service or with extended drain intervals.<br />

n high reserve alkalinity<br />

A Tbn-e (Total base number) of 17 to neutralise<br />

acids and provide corrosion protection until the<br />

next drain interval, even with the higher sulphur<br />

levels sometimes found in marine distillate fuels.<br />

PerforMance sPecifications<br />

n APi<br />

n CF<br />

PerforMance benefits<br />

improved engine reliability<br />

n outstanding piston cleanliness, even under high<br />

thermal loading, which enables maximum engine<br />

efficiency to be achieved.<br />

n exceptional protection against bore polishing,<br />

control of oil blow-by and oil consumption.<br />

n Minimisation of lacquer and deposit formation.<br />

Lower maintenance costs<br />

n exceptional engine cleanliness and less maintenance<br />

even with extended drain intervals.<br />

aPProvaLs<br />

Shell Sirius x is approved by:<br />

n MTu (type ii high performance category).<br />

n CWeC (Cummins Wärtsilä engine Company).<br />

n MWM deutz (high output, high speed) and meets<br />

the requirements of Caterpillar 3600 Series.<br />

Advice on applications not covered in this leaflet may<br />

be obtained from your Shell Representative.<br />

heaLth & safety<br />

Shell Sirius x is unlikely to present any significant<br />

health or safety hazard when properly used in the<br />

recommended application, and good standards of<br />

industrial and personal hygiene are maintained. Avoid<br />

contact with skin. use impervious gloves with used oil.<br />

After skin contact, wash immediately with soap and<br />

water. For further guidance on Product health and<br />

Safety refer to the appropriate Shell Product Safety<br />

data Sheet.<br />

tyPicaL PhysicaL characteristics<br />

shell sirius X units result<br />

sae viscosity Grade<br />

Kinematic viscosity<br />

40<br />

@ 40°C cSt 139<br />

@ 100°C cSt 14<br />

density @ 15°C kg/m 3 890<br />

flash Point, closed cup, °C 230<br />

Pour Point °C –18<br />

tbn-e mg Koh/g 17<br />

sulphated ash %wt 1.85<br />

These characteristics are typical of current production.<br />

Whilst future production will conform to Shell's specification,<br />

variations in these characteristics may occur.<br />

For more information please contact your Shell <strong>Marine</strong> Products Representative or refer to the Port Services <strong>Guide</strong> on our website<br />

www.shell.com/marine. Shell is not liable for application/advice errors when Product data Sheets are obtained from non-official<br />

sources/sites other than the official website as shown above.<br />

MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong> 17

shell rimula r3 turbo<br />

Multigrade heavy duty diesel engine oils<br />

shell rimula r3 turbo oils feature proven lubricant chemistry specifically designed for use in<br />

modern high-speed auxiliary engines. this adaptive technology features enhanced additive<br />

systems to provide control thickening and wear caused by soot and other debris that can<br />

build up in the oil to provide low wear for long engine life and cleanliness to maintain engine<br />

performance.<br />

With a wide array of engine maker approvals, it is suitable for most heavy duty engines nonturbocharged<br />

and turbocharged alike.<br />

PerforMance benefits<br />

n equipment manufacturer<br />

acceptance<br />

Shell Rimula R3 Turbo oils are approved for use<br />

in a variety of engine applications by leading<br />

oeMs.<br />

n engine cleanliness<br />

The high thermal stability and oil oxidation<br />

resistance provide a high standard of protection<br />

against piston deposits. engine cleanliness<br />

is further enhanced through the use of highperformance<br />

dispersants to control sludge and<br />

deposits in other parts of the engine.<br />

n Low engine wear<br />

The combination of active anti-wear additives<br />

and good engine cleanliness control engine wear<br />

gives long engine life, maintains engine power<br />

and efficiency, and lowers servicing costs.<br />

sPecification & aPProvaLs<br />

shell rimula r3 turbo meets the<br />

requirements of:<br />

– APi: Ch-4, CG-4, CF-4, CF<br />

– ACeA: e2<br />

– Caterpillar: eCF-1-A<br />

– Cummins: CeS 20076<br />

– Cummins: CeS 20071<br />

– MACK: eo-M<br />

– MACK: eo-M+<br />

– MAn: 271<br />

– Mb – Approval: 228.1<br />

– Volvo: VdS<br />

18 MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong><br />

heaLth & safety<br />

Shell Rimula R3 Turbo oils are unlikely to present any<br />

significant health or safety hazard when properly used<br />

in the recommended application, and good standards<br />

of industrial and personal hygiene are maintained.<br />

Avoid contact with skin. use impervious gloves with<br />

used oil. After skin contact, wash immediately with soap<br />

and water. For further guidance on Product health and<br />

Safety refer to the appropriate Shell Product Safety<br />

data Sheet.<br />

Protect the environMent<br />

Take used oil to an authorised collection point. do not<br />

discharge into drains, soil or water.<br />

advice<br />

Advice on applications not covered in this leaflet may<br />

be obtained from your Shell Representative.<br />

tyPicaL PhysicaL characteristics<br />

shell rimula r3 turbo units result<br />

sae viscosity Grade<br />

Kinematic viscosity<br />

R3 Turbo<br />

15W-40<br />

@ 40°C ASTM d 445 mm 2 /s 105.1<br />

@ 100°C ASTM d 445 mm 2 dynamic viscosity<br />

/s 14.3<br />

@ -20°C ASTM d 5293 mPa s 6600<br />

@ -15°C ASTM d 5293 mPa s -<br />

viscosity index<br />

density<br />

ASTM d 2270 139<br />

@ 15°C ASTM d 4052 kg/m 3 886<br />

flash Point coc ASTM d 92 °C 205<br />

Pour Point ASTM d 97 °C -36<br />

tbn ASTM d 2896 mg<br />

Koh/g<br />

9.2<br />

sulphated ash ASTM d 874 % 1.25<br />

These characteristics are typical of current production.<br />

Whilst future production will conform to Shell's<br />

specification, variations in these characteristics may occur.

shell tellus s2 v<br />

Previous names: Shell Tellus T<br />

industrial hydraulic fluid for wide temperature range<br />

shell tellus s2 v fluids are high-performance hydraulic fluids that use shell’s unique patented<br />

technology with excellent viscosity control under both severe mechanical stress and across a<br />

wide range of temperatures. they provide outstanding protection and performance in most<br />

mobile equipment and other applications subjected to wider ranges of ambient or operating<br />

temperatures.<br />

PerforMance benefits<br />

n Long fluid life – Maintenance-saving<br />

Shell Tellus S2 V fluids help extend equipment<br />

maintenance intervals by resisting thermal and<br />

chemical breakdown. This minimises sludge<br />

formation and provides excellent performance in<br />

the industry standard ASTM d 943 ToST (Turbine<br />

oil Stability Test), providing better reliability and<br />

system cleanliness.<br />

Shell Tellus S2 V fluids also have good stability in<br />

the presence of moisture, which ensures long fluid<br />

life and reduces the risk of corrosion and rusting,<br />

particularly in moist or humid environments.<br />

highly shear stable viscosity modifiers help<br />

minimise variations in the fluid properties<br />

throughout the fluid drain interval.<br />

n outstanding wear protection<br />

Proven zinc-based anti-wear additives are<br />

incorporated to be effective throughout the range<br />

of operating conditions, including low load and<br />

severe duty high load conditions. outstanding<br />

performance in a range of piston and vane<br />

pump tests, including the tough denison T6C (dry<br />

and wet versions) and the demanding Vickers<br />

35VQ25, demonstrates how Shell Tellus S2 V<br />

fluids can help system components last longer.<br />

n Maintaining system efficiency<br />

The extended temperature range capability<br />

of Shell Tellus S2 V allows efficient operation<br />

of mobile equipment from cold start to normal<br />

operating conditions.<br />

Superior cleanliness, excellent filterability and<br />

high-performance water separation, air release<br />

and anti-foam characteristics all help contribute<br />

to maintaining or enhancing the efficiency of<br />

hydraulic systems.<br />

The unique additive system in Shell Tellus S2 V,<br />

in combination with superior cleanliness (meeting<br />

the requirements of max iSo 4406 21/19/16<br />

class, ex Shell filling lines. As recognised by din<br />

51524 specification, the oil is exposed to various<br />

influences with transport and storage that could<br />

effect the cleanliness level) helps reduce the impact<br />

of contaminants on filter blocking, allowing both<br />

extended filter life and use of finer filtration for extra<br />

equipment protection.<br />

Shell Tellus S2 V fluids are formulated for fast air<br />

release without excessive foaming to help efficient<br />

hydraulic power transfer and minimise fluid and<br />

equipment impacts of cavitation-induced oxidation<br />

that can shorten fluid life.<br />

aPPLications<br />

n Mobile/exterior hydraulic applications<br />

hydraulic and fluid power transmission systems<br />

in exposed environments can be subject to wide<br />

variations in temperature. The high viscosity<br />

index of Shell Tellus S2 V helps deliver responsive<br />

performance from cold start conditions to full load,<br />

severe duty operation.<br />

n Precision hydraulic systems<br />

Precision hydraulic systems require excellent control<br />

of fluid viscosity over the operating cycle. Shell Tellus<br />

S2 V provides greater temperature-viscosity stability<br />

compared to iSo hM fluids that can help improve<br />

the performance of such systems.<br />

For more severe operating conditions, longer fluid life<br />

and enhanced efficiency, the Shell Tellus S3 and S4<br />

ranges offer additional performance benefits.<br />

MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong> 19

sPecifications & aPProvaLs<br />

Shell Tellus S2 V fluids have the following approvals:<br />

– denison hydraulics (hF-0, hF-1, hF-2).<br />

– Cincinnati Machine P-68 (iSo 32), P-70 (iSo 46),<br />

P-69 (iSo 68).<br />

– eaton Vickers M-2950 S.<br />

– eaton Vickers i-286 S.<br />

Shell Tellus S2 V fluids meet or exceed the<br />

requirements of:<br />

– Swedish Standard SS 15 54 34 AM.<br />

– iSo 11158 (hV fluids).<br />

– AFnoR nF-e 48-603.<br />

– ASTM 6158-05 (hV fluids).<br />

– din 51524 Part 3 hVLP type.<br />

– Gb 111181-1-94 (hV fluids).<br />

For a full listing of equipment approvals and<br />

recommendations please consult your local Shell<br />

Technical help desk.<br />

heaLth & safety<br />

Guidance on health & Safety is available on the<br />

appropriate Material Safety data Sheet, which can<br />

be obtained from your Shell Representative.<br />

tyPicaL PhysicaL characteristics<br />

shell tellus s2 v test units result<br />

iso viscosity Grade 15 22 32 46 68 100<br />

iso fluid type<br />

Kinematic viscosity<br />

hV hV hV hV hV hV<br />

@ -20°C ASTM d 445 cSt 350 695 1300 2350<br />

@ 40°C ASTM d 445 cSt 15 22 32 46 68 100<br />

@ 100°C ASTM d 445 cSt 3.8 4.8 6.1 7.9 10.5 14.0<br />

viscosity index iSo 2909 142 142 143 143 142 142<br />

density iSo 12185 kg/m 3 @ 15°C<br />

872 872 872 872 877 880<br />

flash Point<br />

(Cleveland open Cup)<br />

iSo 2592 °C 170 190 210 225 225 225<br />

Pour Point iSo 3016 °C –42 –42 –39 –39 –36 –30<br />

These characteristics are typical of current production. Whilst future production will conform to Shell's specification,<br />

variations in these characteristics may occur.<br />

20 MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong><br />

coMPatibiLity<br />

Shell Tellus S2 V fluids are suitable for use with most<br />

hydraulic pumps. however, please consult your Shell<br />

Representative before using in pumps containing silverplated<br />

components.<br />

fLuid coMPatibiLity<br />

Shell Tellus S2 V fluids are compatible with most other<br />

mineral oil based hydraulic fluids. however, mineral<br />

oil hydraulic fluids should not be mixed with other fluid<br />

types (e.g. environmentally acceptable or fire resistant<br />

fluids).<br />

seaL & Paint coMPatibiLity<br />

Shell Tellus S2 V fluids are compatible with seal<br />

materials and paints normally specified for use with<br />

mineral oils.<br />

Protect the environMent<br />

Take used hydraulic fluid to an authorised collection<br />

point. do not discharge into drains, soil or water.<br />

advice<br />

Advice on applications not covered in this leaflet may<br />

be obtained from your Shell Representative.

shell omala s2 G<br />

Previous name: Shell omala oils<br />

advanced bearing and circulating oils<br />

shell omala s2 g oils are high quality extreme-pressure oils designed primarily for the lubrication<br />

of heavy duty industrial gears. their high load carrying capacity and anti-friction characteristics<br />

combine to offer superior performance in gears.<br />

PerforMance benefits<br />

n Long oil life – Maintenance saving<br />

Shell omala S2 G oils are formulated to resist<br />

thermal and chemical breakdown throughout<br />

the maintenance interval. They withstand high<br />

thermal loading and resist the formation of sludge<br />

to provide extended oil life capability, even with<br />

bulk oil temperatures of up to 100°C in certain<br />

applications.<br />

n excellent wear and corrosion protection<br />

excellent load carrying capacity reduces gear<br />

tooth and bearing wear on both steel and bronze<br />

components.<br />

Shell omala S2 G has excellent corrosion<br />

protection, protecting both steel and bronze<br />

components, even in the presence of<br />

contamination by water and solids.<br />

n Maintaining system efficiency<br />

Shell omala S2 G oils have excellent water<br />

separation properties, such that excess water can<br />

be drained easily from lubrication systems to help<br />

extend the life of the gears and ensure efficient<br />

lubrication of the contact areas.<br />

Water can greatly accelerate surface fatigue of<br />

gears and bearings as well as promote ferrous<br />

corrosion on internal surfaces. Water<br />

contamination should therefore be avoided<br />

or removed as quickly as possible after the<br />

occurrence.<br />

aPPLications<br />

n enclosed industrial gear systems<br />

Shell omala S2 G oils are formulated using an<br />

effective sulphur-phosphorus additive system to<br />

provide an extreme pressure performance which<br />

allow trouble-free application in most enclosed<br />

industrial gearboxes using steel spur and helical<br />

gears.<br />

n highly loaded gears<br />

Shell omala S2 G oils have an effective full extreme<br />

pressure (eP) additive system allowing them to be<br />

used in highly loaded gear systems.<br />

n other applications<br />

Shell omala S2 G oils are suitable for lubrication of<br />

bearings and other components in circulating and<br />

splash-lubricated systems.<br />

For highly-loaded worm drives the Shell omala “W”<br />

series oils are recommended.<br />

For automotive hypoid gears, the appropriate Shell<br />

Spirax oil should be used.<br />

sPecifications & aPProvaLs<br />

shell omala s2 G meets the<br />

requirements of:<br />

– iSo 12925-1 Type CKd, except iSo 680-1000.<br />

– din 51517- Part 3 (CLP), except iSo 680-1000.<br />

– AGMA 9005- eo2 (eP).<br />

– uS Steel 224.<br />

– david brown S1.53.101,102,103,104.<br />

– Cincinatti Machine P34,35,59,63, 74, 76-78.<br />

– Flender C, iSo 100-220 and e, iSo 460-680.<br />

heaLth & safety<br />

Guidance on health & Safety is available on the<br />

appropriate Material Safety data Sheet, which can be<br />

obtained from your Shell Representative.<br />

Protect the environMent<br />

Take used oil to an authorised collection point. do not<br />

discharge into drains, soil or water.<br />

advice<br />

Advice on applications not covered in this leaflet may<br />

be obtained from your Shell Representative.<br />

MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong> 21

tyPicaL PhysicaL characteristics<br />

shell omala s2 G units test result<br />

iso viscosity Grade iSo 3448 68 100 150<br />

Kinematic viscosity<br />

@ 40°C mm²/s iSo 3104 68 100 150<br />

@ 100°C mm²/s iSo 3104 8.7 11.4 15.0<br />

viscosity index iSo 2909 99 100 100<br />

flash Point coc °C iSo 2592 236 240 240<br />

Pour Point °C iSo 3016 -24 -24 -24<br />

density kg/m 3 iSo 12185 887 891 897<br />

@ 15°C<br />

shell omala s2 G units test result<br />

iso viscosity Grade iSo 3448 220 320 460<br />

Kinematic viscosity<br />

@ 40°C mm²/s iSo 3104 220 320 460<br />

@ 100°C mm²/s iSo 3104 19.4 25.0 30.8<br />

viscosity index iSo 2909 100 100 97<br />

flash Point coc °C iSo 2592 240 255 260<br />

Pour Point °C iSo 3016 -18 -15 -12<br />

density kg/m 3 iSo 12185 899 903 904<br />

@ 15°C<br />

These characteristics are typical of current production. Whilst future production will conform to Shell's specification,<br />

variations in these characteristics may occur.<br />

22 MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong>

shell omala s4 GX<br />

Previous name: Shell omala hd<br />

advanced synthetic industrial gear oil<br />

shell omala s4 gX is an advanced synthetic heavy duty industrial gear oil offering outstanding<br />

lubrication performance under severe operating conditions, including reduced friction, long<br />

service life, and high resistance to micro-pitting for optimal gear protection.<br />

PerforMance benefits<br />

n Long oil life – Maintenance saving<br />

Shell omala S4 Gx is formulated using an<br />

advanced additive system in combination with<br />

specially selected synthetic base fluids to provide<br />

outstanding resistance to breakdown over long<br />

durations and/or high-temperature operations.<br />

This performance is recognised by Flender AG,<br />

where a formal approval for 20,000 hours<br />

(four years) at 80°C usage has been granted.<br />

Shell omala S4 Gx can operate successfully at<br />

bulk temperatures up to 120°C.<br />

Shell omala S4 Gx offers the potential to<br />

significantly extend service intervals compared to<br />

conventional industrial gear oils.<br />

n excellent wear and corrosion protection<br />

Shell omala S4 Gx is formulated to have<br />

excellent load carrying capacity and micro-pitting<br />

performance providing long component life even<br />

under shock loading conditions. These features<br />

provide benefits over mineral oil-based products in<br />

terms of gear and bearing component life.<br />

Shell omala S4 Gx also has excellent corrosion<br />

protection, even in the presence of contamination<br />

by water and solids.<br />

n Maintaining system efficiency<br />

Shell omala S4 Gx can help maintain or<br />

enhance the efficiency of industrial gear systems<br />

through improved low temperature performance<br />

and lower friction in comparison to mineral oilbased<br />

products. This provides better lubrication at<br />

low startup temperatures.<br />

Shell omala S4 Gx oils have excellent water<br />

separation properties, such that excess water can<br />

be drained easily from lubrication systems to help<br />

extend the life of the gears and ensure efficient<br />

lubrication of the contact areas.<br />

aPPLications<br />

n wind turbines and other inaccessible<br />

installations<br />

Shell omala S4 Gx is particularly recommended<br />

for certain systems where extra long life is<br />

required, maintenance is infrequent or systems are<br />

inaccessible.<br />

n enclosed industrial gear systems<br />

Recommended for industrial reduction gear systems<br />

operating under severe operating conditions, such as<br />

high load, very low or elevated temperatures, and<br />

wide temperature variations<br />

n other applications<br />

Shell omala S4 Gx oils are suitable for lubrication<br />

of bearings and other components in circulating and<br />

splash-lubricated systems.<br />

For highly loaded worm drives the Shell omala “W”<br />

series oils are recommended.<br />

For automotive hypoid gears, the appropriate Shell<br />

Spirax oil should be used.<br />

sPecifications & aPProvaLs<br />

shell omala s4 GX meets the<br />

requirements of:<br />

– iSo 12925-1 Type CKd, except iSo 1000.<br />

– AnSi/AGMA 9005-e02 (eP), except iSo 1000.<br />

– uS Steel 224, except iSo 1000.<br />

– Flender AG .<br />

– david brown S1.53.106, except iSo 1000.<br />

– din 51517-3 (CLP), except iSo 1000.<br />

approved for wind turbine gearboxes by:<br />

– Gamesa.<br />

– dongfang Wind Turbines.<br />

– dalian heavy industries.<br />

– Sinovel.<br />

heaLth & safety<br />

Guidance on health and Safety is available on the<br />

appropriate Material Safety data Sheet, which can be<br />

obtained from your Shell Representative.<br />

MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong> 23

Protect the environMent<br />

Take used oil to an authorised collection point. do not<br />

discharge into drains, soil or water.<br />

advice<br />

Check compatibility with other products before use.<br />

Advice on applications not covered in this leaflet may<br />

be obtained from your Shell representative.<br />

tyPicaL PhysicaL characteristics<br />

shell omala s4 GX units test result<br />

iso viscosity Grade<br />

Kinematic viscosity<br />

iSo 3448 220<br />

@ 40°C mm 2 /s iSo 3104 229.4<br />

@ 100°C mm 2 /s iSo 3104 28.3<br />

viscosity index iSo 2909 160<br />

flash Point coc °C iSo 2592 250<br />

Pour Point °C iSo 3016 –45<br />

density kg/m 3 @ 15°C<br />

iSo 12185 881<br />

fZG Load<br />

carrying test<br />

din 51354-2<br />

failure Load stage A/8,3/90 >14<br />

A/16,6/90 >14<br />

timken oK Load lbs ASTM d 2782 >85<br />

These characteristics are typical of current production. Whilst future<br />

production will conform to Shell's specification, variations in these<br />

characteristics may occur.<br />

24 MARine LubRiCAnTS TeChniCAL ReFeRenCe <strong>Guide</strong>

shell omala s4 we<br />

Previous name: Shell Tivela S<br />

advanced synthetic industrial gear oil<br />

PerforMance benefits<br />

n Long oil life – Maintenance saving<br />

Shell omala S4 We is formulated to provide<br />

excellent oxidation and thermal stability, extending<br />

lubricant life and resisting the formation of harmful<br />

oxidation products at high operating temperatures.<br />

This helps maintain system cleanliness over<br />

extended maintenance intervals.<br />

This performance is recognised by Flender AG,<br />

where a formal approval for 20,000 hours (four<br />

years) at 80°C (bulk oil temperature) usage has<br />

been granted.<br />

Shell omala S4 We offers the potential to<br />

extend service intervals significantly compared to<br />

conventional industrial gear oils.<br />

n excellent wear protection<br />

Shell omala S4 We is formulated to have<br />

excellent load carrying capacity providing<br />

long component life even under shock loading<br />

conditions. it also has a high resistance to<br />

micro-pitting. These features provide benefits over<br />

mineral oil-based products in terms of gear and<br />

bearing component life.<br />

n Maintaining system efficiency<br />

Shell omala S4 We offers improved energy<br />

efficiency and lower operating temperatures<br />

in worm gear applications. Rig testing has<br />

shown efficiency improvements of up to 15% in<br />

comparison with mineral oil-based products and<br />

11% over other synthetic hydrocarbon-based<br />

lubricants. These results have been confirmed by<br />

oeM testing and field experience.<br />

aPPLications<br />

n enclosed industrial worm gear systems<br />