handtmann PA 30-7

handtmann PA 30-7

handtmann PA 30-7

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

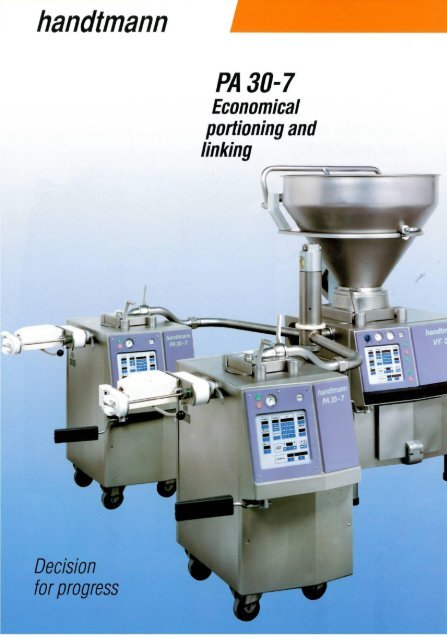

<strong>handtmann</strong><br />

<strong>PA</strong> <strong>30</strong>-7<br />

Economical<br />

portioning and<br />

linking

<strong>handtmann</strong><br />

The superior technology<br />

ofthe <strong>PA</strong> <strong>30</strong>-7 guarantees<br />

enhanced productivity<br />

and profitability.<br />

The <strong>handtmann</strong> <strong>PA</strong> <strong>30</strong>-7 portioning and linking<br />

machine rationalizes sausage production<br />

in natural-, collagen- and artificial<br />

casings. The foUowing are some of the profit<br />

generating advantages of the equipment:<br />

• Hydraulic drive<br />

I Standard electronic MC-controls<br />

• High portioning and linking speeds,<br />

up to 450 portions/min.<br />

• High portioning accuracy<br />

• Portioning ränge up to 100 kg<br />

• Unbeatable product quality<br />

• Continuously adjustable clipping rate<br />

• Automatic holding device HV 60-6/7 for<br />

all types of casings<br />

• Hygienicsmooth surfaces<br />

• Convincingly ergonomic<br />

• Quiet Operation<br />

• Robust and reliable<br />

• Clean and rapid Operation thanks to<br />

product return-suction feature<br />

• Weight compensation for exact<br />

first portion

The <strong>handtmann</strong>vane<br />

cell feed<br />

System guarantees<br />

quality conscious<br />

producers versatile<br />

operational abilities<br />

and excellent product<br />

quality.<br />

I <strong>handtmann</strong> f<br />

<strong>PA</strong> <strong>30</strong>-7 l<br />

<strong>handtmann</strong><br />

For efficient sausage production, up to three <strong>PA</strong> <strong>30</strong>-7 devices<br />

can be attached to a VF-<strong>30</strong>0 industrial vacuum filier. The<br />

vacuum filier supplies the attachments with a steady stream of<br />

evacuated filling. Gentie handling and transport of the filling<br />

guarantee an even product consistency. Compactly filled sausages<br />

are not only a question of quality but also of saving in<br />

casings.<br />

The universal <strong>handtmann</strong><br />

vane-cell feed System<br />

Gentie product handling is a recognizable feature of all <strong>handtmann</strong><br />

filling and portioning machines. This tried and tested filling System<br />

is also used in the <strong>PA</strong> <strong>30</strong>-7 with added functionality: adjustable<br />

eccentric tensioning ensures effective sealing and thereby guarantees<br />

excellent portioning accuracy and product quality.<br />

The optimized shape of the outlet from the vacuum filier to the <strong>PA</strong><br />

<strong>30</strong>-7 feeder system guarantees excellent filling of the vane-cell<br />

Chambers with evacuated sausage filling. The feeder System is constructed<br />

in industry Standard fatigue resistant special steel, ensuring<br />

solidity and reliability — the hallmarks of reliable and economical<br />

daily Performance by the <strong>PA</strong> <strong>30</strong>-7.

<strong>handtmann</strong><br />

The convincing advantages<br />

ofthe innovative <strong>PA</strong> <strong>30</strong>-7<br />

Integrated Accessory Box<br />

An accessory box is accommodated in the<br />

front panel of the <strong>PA</strong> <strong>30</strong>-7. The accessories<br />

are located within easy reach but are kept<br />

clean and are clearly identified to the user.<br />

Yet another practical <strong>handtmann</strong> Solution.<br />

Precision Control<br />

ofthe <strong>PA</strong> <strong>30</strong>-7<br />

The instrument panel is inclined towards the<br />

operator to ensure ease of reach and Vision.<br />

Without changing position a Single operator<br />

can make all the necessary adjustments and<br />

checks.<br />

MC-controls are Standard fitting on the <strong>PA</strong><br />

<strong>30</strong>-7. Apart from ease of use, microcomputer<br />

controls offer a ränge of production information,<br />

such as the number of portions per<br />

casing, the number of portions in a day's<br />

production, total production in liters and<br />

automatic shut-off after a specified number<br />

of portions. 80 product programs can be stored,<br />

recalled and modified as required.<br />

The practically unlimited portioning control<br />

ranging between 5 and 100.000 grammes is<br />

complemented by precision adjustment<br />

down to 01 grammes for exact group<br />

weights. Of particular advantage for clean<br />

and rapid working is the product return-suction<br />

feature, which is a Standard fitting. Eli-<br />

mination of filling loss on the filier tube<br />

improves workplace hygiene. Weight compensation<br />

to ensure exact weight for the first<br />

portion isalso Standard.<br />

The MC control is provided with fault diagnosis<br />

and service displays to indicate<br />

machine operating states. The LED display<br />

indicates when a service is due or when Operation<br />

is incorrect.<br />

The knee control is adjustable and can be<br />

adapted to any leg position.<br />

Decision<br />

for progress<br />

Advantages of the<br />

electronic and<br />

hydraulic control<br />

Electronic portioning has proven<br />

itself in many years of use in the<br />

industry. In the <strong>PA</strong> <strong>30</strong>-7 this technology<br />

guarantees gentle product transport,<br />

exposing filling and casing to<br />

minimum stress. Direct drive and precision<br />

control provide unequalled portioning<br />

accuracy for high filling frequencies.<br />

The hydraulic drive is virtually free of<br />

wear and offers high Performance with<br />

minimum energy consumption. The Option<br />

to use high filling pressures allows you to<br />

create your own sausage specialties.

The drive of the new <strong>handtmann</strong> <strong>PA</strong><br />

<strong>30</strong>-7 connects automatically with<br />

that of the linking gearbox and the<br />

automatic holding device.<br />

<strong>handtmann</strong><br />

Practical accessories increase<br />

the versatility of the <strong>PA</strong> <strong>30</strong>-7<br />

Versatile Working<br />

Economical and efficient portioning and linking<br />

- the new <strong>PA</strong> <strong>30</strong>-7 sets new Standards<br />

for industrial sausage production.<br />

The linking gearbox type 34-4 is easily attached<br />

to the <strong>PA</strong> <strong>30</strong>-7 above the worktable.<br />

The drive of the linking gearbox is automatically<br />

connected to that of the filier. Replacement<br />

of filling tubes and attachment units is<br />

simple and rapid. Exchanging equipment is<br />

an easy task requiring no tools.<br />

The automatic holding device HV 60-6<br />

(long) or HV 60-7 (short) is coupled directly<br />

to the linking gearbox. Effortless one-handed<br />

Operation will improve daily Output for all<br />

casing types. Holding device and linking<br />

gearbox make up a compact assembly above<br />

the worktable. The holding device and the<br />

linking gearbox are supported on the swivel<br />

arm for quick changeover from portioning to<br />

linking in a matter of seconds.<br />

Casing spooling device<br />

type 78-5<br />

The casing spooling device type 78-5 is<br />

offered as optional equipment to further<br />

increase production of sausages in natural<br />

casings. Casings can be spooled gently and<br />

quicklyonto the linking nozzle.<br />

The <strong>PA</strong> <strong>30</strong>-7 is designed for easy fitting of<br />

the casing spooling device without the need<br />

for tools.<br />

Hygiene and safety<br />

The particularly solid design of the <strong>PA</strong> <strong>30</strong>-7<br />

itself meets the most important requirements<br />

of hygiene and safety. Smooth surfaces facilitate<br />

simple and rapid cleaning. All parts<br />

that come into contact with the product are<br />

easily accessible and can be removed and<br />

replaced with great ease to facilitate thorough<br />

cleaning.<br />

The machine meets the requirements of the<br />

German Employers Liabilty Insurance Association.

<strong>handtmann</strong><br />

<strong>PA</strong> <strong>30</strong>-7<br />

Filling capacity (infinitely variable).<br />

<strong>PA</strong> <strong>30</strong>-7<br />

Filling pressure<br />

<strong>PA</strong> <strong>30</strong>-7<br />

Portioning speed<br />

up to 450 portions/min. (tolerance -<br />

4800 kg/h<br />

upto 55 bar<br />

Portioning ränge 5-100 000 gramms<br />

Linking gearbox type 34-4<br />

Product return suction<br />

Compensation for<br />

Ist portion weight Standard<br />

Number of twists u p to 15<br />

Electric rating 4,5 kW i<br />

Standard accessories for <strong>PA</strong> <strong>30</strong>-7<br />

4 Linking nozzles, size 12,15,19, 22 mm 0<br />

1 Accessory panel<br />

1 Setof small parts<br />

1 Set of tools<br />

1 Operating instructions<br />

1 Spare parts Iist<br />

Weights and dimensions<br />

weight net<br />

weight gross<br />

Case dimensions 1140x880x1870 mm<br />

Connection pipe 72-1 or 72-52<br />

Shipping dimensions 89x84x151 cm<br />

Gross weight 507 kg<br />

Net weight 392 kg<br />

Optional accessories<br />

Automatic holding device<br />

HV 60-6/7<br />

Special linking nozzles with<br />

holdung star and brake ring 9,<br />

10,11,12,14,15,17,19, 22,25<br />

and 28 mm 0<br />

Clipper attachment set V 24<br />

Electrical socket<br />

375 kg<br />

470 kg<br />

Patented in West Germany and abroad.<br />

Technical data subject to alteration.<br />

EP 0013 552 -US: 4,347, 646 —<br />

D 36 01313<br />

Canada: EP 0232 812<br />

US: 4, 744,129 -<br />

Canada 1257135 (1989) - EP 0247 462<br />

Technical<br />

data<br />

3663<br />

Albert Handtmann<br />

Maschinenfabrik GmbH & Co. KG<br />

Birkenallee 25-29, P. O. Box<br />

D-88396 Biberach/Riss, Germany<br />

Phone (07351)342-0<br />

Fax (07351) 424<strong>30</strong><br />

http://www.<strong>handtmann</strong>.de<br />

http://www.vacuumfiller.de<br />

sales.machines@<strong>handtmann</strong>.de