Continous Treatment - Gütling Wassertechnologie GmbH

Continous Treatment - Gütling Wassertechnologie GmbH

Continous Treatment - Gütling Wassertechnologie GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

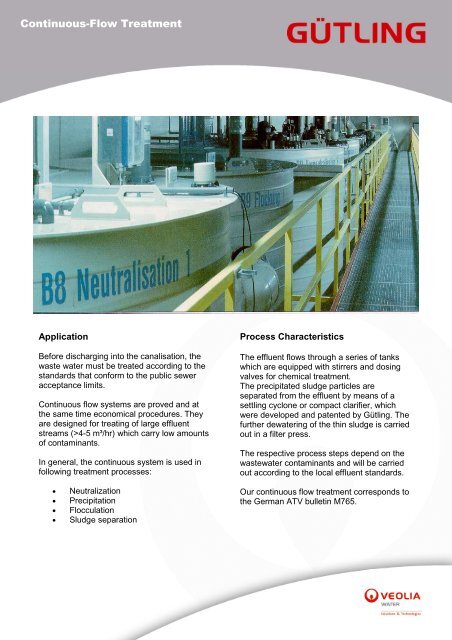

Continuous-Flow <strong>Treatment</strong><br />

Application<br />

Before discharging into the canalisation, the<br />

waste water must be treated according to the<br />

standards that conform to the public sewer<br />

acceptance limits.<br />

Continuous flow systems are proved and at<br />

the same time economical procedures. They<br />

are designed for treating of large effluent<br />

streams (>4-5 m³/hr) which carry low amounts<br />

of contaminants.<br />

In general, the continuous system is used in<br />

following treatment processes:<br />

• Neutralization<br />

• Precipitation<br />

• Flocculation<br />

• Sludge separation<br />

Process Characteristics<br />

The effluent flows through a series of tanks<br />

which are equipped with stirrers and dosing<br />

valves for chemical treatment.<br />

The precipitated sludge particles are<br />

separated from the effluent by means of a<br />

settling cyclone or compact clarifier, which<br />

were developed and patented by <strong>Gütling</strong>. The<br />

further dewatering of the thin sludge is carried<br />

out in a filter press.<br />

The respective process steps depend on the<br />

wastewater contaminants and will be carried<br />

out according to the local effluent standards.<br />

Our continuous flow treatment corresponds to<br />

the German ATV bulletin M765.

Continuous-Flow <strong>Treatment</strong><br />

Inlet<br />

Storage tank<br />

Description of the plant<br />

The waste water is buffered in a storage tank in order to equalise the fluctuation of concentration and<br />

volume flow. The waste water is transferred with a pumping station to the intake height of the<br />

continuous treatment unit. The effluent flows at free slope without any shear stress. Depending on the<br />

available installation height and the kind of the arising sludge, the sludge can be separated by means of<br />

a settling cyclone or a compact clarifier. The separated wet sludge can be further compacted in a<br />

sludge thickener.<br />

A chamber filter press is usually used to dewater the sludge to a depositable dry sludge. In special<br />

cases, a membrane filter press can also be used.<br />

In certain critical applications, the use of a sandfilter in combination with a selective ion exchanger is<br />

indicated.<br />

<strong>Gütling</strong> <strong>Wassertechnologie</strong><br />

Merowingerstraße 7<br />

D - 70736 Fellbach<br />

Tel.: + 49 (0) 711/518550 – 0<br />

Fax: + 49 (0) 711/518550 – 220<br />

www.guetling.com<br />

guetling@veoliawater.com<br />

Chemicals<br />

p H<br />

M p H<br />

Chemicals Flocculant<br />

Advantages<br />

pH<br />

M pH M<br />

Flotat<br />

Clarified<br />

effluent<br />

Flow treatment Settling cyclone,<br />

alternatively compact<br />

clarifier<br />

Thin sludge<br />

• Processing of high waste water volumes with low<br />

pollutant concentration<br />

• Continuous process<br />

• Little floor space requirements<br />

• Standard dimensions<br />

• Corrosion-resistant construction<br />

• High standard of automation<br />

• Low operating costs<br />

• Sludge separation and pre-thickening in one system<br />

12/2008