VITAMIN A FORTIFIed PEANUT BUTTER - The Official Website of ...

VITAMIN A FORTIFIed PEANUT BUTTER - The Official Website of ...

VITAMIN A FORTIFIed PEANUT BUTTER - The Official Website of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Use <strong>of</strong> a different brand <strong>of</strong> fortificant. In the study <strong>of</strong> Galvez et al. (2003), the microencapsulated<br />

vitamin A palmitate used was from Wright Enrichment, Inc. and was described as a free flowing form <strong>of</strong><br />

vitamin A compounded with sugar, fish gelatin and modified food starch with dL-alpha tocopherol as<br />

antioxidant. In this study, the microencapsulated vitamin A palmitate used by FDC was from BASF<br />

(Carmelray Compound, Canlubang, Laguna) which was described as a free flowing, light yellow powder<br />

consisting <strong>of</strong> spherical particles that contain vitamin A palmitate in droplets <strong>of</strong> 1-2 μm embedded in a<br />

matrix <strong>of</strong> gum arabic (E 414) and sucrose, coated with starch, t-butyl-hydroxytoluene (BHT, E321) and<br />

sodium ascorbate (E301) as antioxidants and tricalcium phosphate (E-341) as an anti-caking product. <strong>The</strong><br />

difference in the composition <strong>of</strong> the vitamin A fortificants and the amount <strong>of</strong> fortificant added, may have<br />

affected vitamin A stability in the finished product. Galvez et al (2003) reported that the combined<br />

effects <strong>of</strong> the type <strong>of</strong> fortificant and level <strong>of</strong> fortification significantly affected the amount <strong>of</strong> vitamin A<br />

retained in the sample.<br />

Use <strong>of</strong> a different stabilizer. In the study <strong>of</strong> Galvez et al. (2003), it was reported that the amount<br />

<strong>of</strong> vitamin A retained in stabilized peanut butter samples was significantly affected by the brands <strong>of</strong><br />

stabilizer used. <strong>The</strong> study <strong>of</strong> Galvez et al. (2003) used Myvatex, a hydrogenated rapeseed and cottonseed<br />

oil blend while FDC used Myverol, a hydrogenated palm oil. <strong>The</strong> latter was used upon the<br />

recommendation <strong>of</strong> the local distributor who mentioned that Myvatex was no longer available in the<br />

domestic market.<br />

Study 2. Preliminary Verification <strong>of</strong> the Suitability <strong>of</strong> Incorporating the Fortificant and Stabilizer<br />

After the 2 nd Grinding Step During the Vitamin A Fortification <strong>of</strong> Peanut Butter at the FDC Product<br />

Development Laboratory<br />

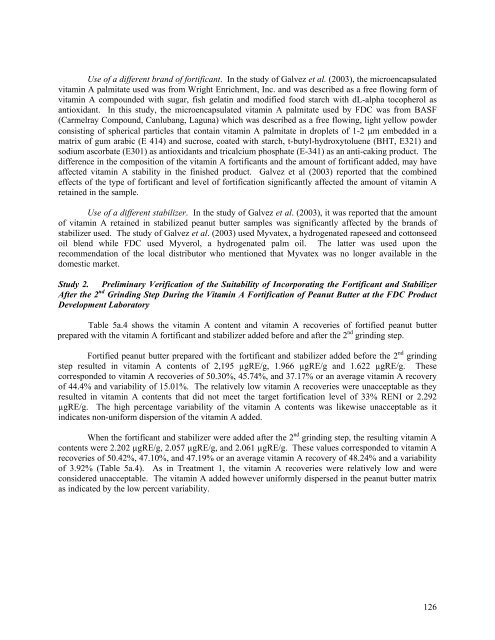

Table 5a.4 shows the vitamin A content and vitamin A recoveries <strong>of</strong> fortified peanut butter<br />

prepared with the vitamin A fortificant and stabilizer added before and after the 2 nd grinding step.<br />

Fortified peanut butter prepared with the fortificant and stabilizer added before the 2 nd grinding<br />

step resulted in vitamin A contents <strong>of</strong> 2,195 µgRE/g, 1.966 µgRE/g and 1.622 µgRE/g. <strong>The</strong>se<br />

corresponded to vitamin A recoveries <strong>of</strong> 50.30%, 45.74%, and 37.17% or an average vitamin A recovery<br />

<strong>of</strong> 44.4% and variability <strong>of</strong> 15.01%. <strong>The</strong> relatively low vitamin A recoveries were unacceptable as they<br />

resulted in vitamin A contents that did not meet the target fortification level <strong>of</strong> 33% RENI or 2.292<br />

µgRE/g. <strong>The</strong> high percentage variability <strong>of</strong> the vitamin A contents was likewise unacceptable as it<br />

indicates non-uniform dispersion <strong>of</strong> the vitamin A added.<br />

When the fortificant and stabilizer were added after the 2 nd grinding step, the resulting vitamin A<br />

contents were 2.202 µgRE/g, 2.057 µgRE/g, and 2.061 µgRE/g. <strong>The</strong>se values corresponded to vitamin A<br />

recoveries <strong>of</strong> 50.42%, 47.10%, and 47.19% or an average vitamin A recovery <strong>of</strong> 48.24% and a variability<br />

<strong>of</strong> 3.92% (Table 5a.4). As in Treatment 1, the vitamin A recoveries were relatively low and were<br />

considered unacceptable. <strong>The</strong> vitamin A added however uniformly dispersed in the peanut butter matrix<br />

as indicated by the low percent variability.<br />

126