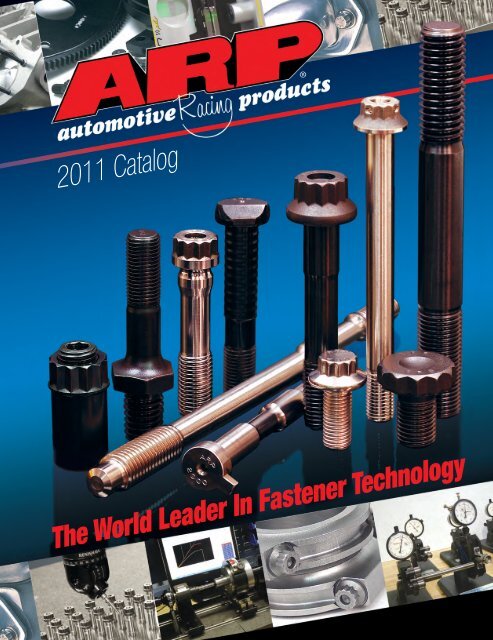

ARP Automotive Racing Catalog

They say that to be successful you must identify a need and satisfy it. Back in 1968 racing enthusiast Gary Holzapfel saw that many of his friends’ broken engines were caused by fastener failure. At the time, there were no commercially available studs and

They say that to be successful you must identify a need and satisfy it. Back in 1968 racing enthusiast Gary Holzapfel saw that many of his friends’ broken engines were caused by fastener failure. At the time, there were no commercially available studs and

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2011 <strong>Catalog</strong><br />

The World Leader In Fastener Technology

Stock Replacement<br />

Rod Bolts<br />

pages 32-36, 72-74<br />

Harmonic Balancer<br />

Bolts - page 58<br />

Camshaft Bolts<br />

page 59<br />

Flywheel/Flexplate<br />

Bolts - pages 64-65<br />

Valve Cover Bolts<br />

& Studs - pages 50, 62<br />

Header Studs<br />

& Bolts - page 51<br />

Thermostat<br />

Housing Bolts<br />

pages 56, 61<br />

Rocker Arm<br />

Adjusters - page 49<br />

Rocker Arm Studs - page 48<br />

Aftermarket Replacement<br />

Rod Bolts- page 30-31<br />

ASSEMBLE YOUR ENGINE<br />

THE RIGHT WAY WITH<br />

<strong>ARP</strong> FASTENERS!<br />

Front Cover<br />

Studs - page 53<br />

Water Pump<br />

Bolts - pages 53, 61<br />

HI-PERFORMANCE<br />

FOR COMPETITION<br />

Distributor Hold-Down<br />

Studs - pages 57, 60<br />

Wheel Studs<br />

pages 68-69<br />

4 800-826-3045<br />

Torque Converter<br />

Bolts - page 65<br />

Intake Manifold<br />

Bolts - pages 55, 62, 70<br />

Drive Plate<br />

Bolts - page 68

FASTENERS<br />

AND STREET<br />

Header Studs<br />

& Bolts -<br />

page 51<br />

Air Cleaner<br />

Studs - page 56<br />

Main Studs &<br />

Bolts - pages 45-47, 77<br />

1863 Eastman Avenue<br />

Ventura, CA 93003<br />

web: arp-bolts.com<br />

arpdiesel.com<br />

e-mail: info@arpfasteners.com<br />

phone: 805-339-2200<br />

fax: 805-650-0742<br />

800-826-3045<br />

800-<br />

© 2011 <strong>Automotive</strong> <strong>Racing</strong> Products, Inc.<br />

Carburetor<br />

Studs - pages 55, 71<br />

Head Studs & Bolts -<br />

pages 37-44, 75-76<br />

All Rights Reserved. “<strong>ARP</strong>”, the <strong>ARP</strong> logo,<br />

Wave-Loc, Perma-Loc, <strong>ARP</strong>2000, <strong>ARP</strong>3.5 and <strong>ARP</strong><br />

Ultra-Torque are registered trademarks of <strong>Automotive</strong> <strong>Racing</strong><br />

Products, Inc. All other trademarks are property of their respective owners.<br />

INDEX<br />

Accessory rear cam drive .........................................54<br />

Air cleaner studs .......................................................56<br />

Alternator bolts .........................................................61<br />

Alternator studs .................................................. 60, 71<br />

Apparel .....................................................................99<br />

Assembly lube ..........................................................93<br />

Bellhousing stud kits .......................................... 54, 66<br />

Blower studs .............................................................57<br />

Brake hat bolts ................................................... 67, 70<br />

Bulk fastener bins.....................................................86<br />

Camshaft bolts ..........................................................59<br />

Cam sprocket bolt kits ..............................................78<br />

Carburetor float bowl bolts .......................................57<br />

Carburetor studs ................................................. 55, 71<br />

Carrier fasteners ...................................................... 67<br />

Chrome moly bolt 5-packs ..................................79-85<br />

Clutch cover bolt kits ................................................65<br />

Coil bracket bolts ................................................ 56, 60<br />

Cylinder head bolts ..............................................43-44<br />

Distributor studs ................................................. 57, 60<br />

Drive pins ..................................................................68<br />

Drive plate bolts ........................................................68<br />

Engine accessory kits ...............................................63<br />

Flexplate bolts ..........................................................65<br />

Flywheel bolts ..........................................................64<br />

Front cover bolts and studs ......................................53<br />

Front mandrel bolts ..................................................71<br />

Fuel pump bolts .................................................. 53, 61<br />

Fuel pump pushrods .................................................58<br />

General purpose nuts ..........................................87-88<br />

General purpose washers .........................................91<br />

Harmonic balancer bolts ..........................................58<br />

Head bolts ......................................................43-44, 76<br />

Head studs ............................................... 37-44, 75-76<br />

Header bolts & studs ................................................51<br />

Hex nuts ....................................................................88<br />

Insert washers ..........................................................92<br />

Intake manifold bolts .................................... 55, 62, 70<br />

Main studs & bolts .........................................45-47, 77<br />

Metric exhaust/accessory studs ...............................78<br />

Motor mount bolts .............................................. 53, 66<br />

Nyloc nut 5-packs .....................................................88<br />

Oil pan bolts & studs........................................... 52, 62<br />

Oil pump drives .........................................................59<br />

Perma-Loc adjusters ................................................49<br />

Plate nuts ..................................................................89<br />

Porsche specialty fasteners .....................................78<br />

Pressure plate bolts ..................................................65<br />

Rear end cover bolts .................................................66<br />

Ring compressors .....................................................96<br />

Ring gear bolts .........................................................67<br />

Rocker arm studs .....................................................48<br />

Rod bolt extensions ..................................................95<br />

Rod bolt stretch gauge .............................................96<br />

Rod bolts .................................................. 30-36, 72-74<br />

Spark plug indexer ...................................................95<br />

Special purpose washers ....................................90-91<br />

Stainless steel bolt 5-packs ................................80-85<br />

Stand-off brackets ....................................................92<br />

Starter bolts ..............................................................54<br />

Thermostat housing bolts ................................... 56, 61<br />

Thread chasers .........................................................95<br />

Thread sealer ............................................................94<br />

Torque converter bolts ..............................................65<br />

Torque specs .......................................................24-26<br />

Transmission pan bolts .............................................65<br />

Valve cover bolts & studs ................................... 50, 62<br />

Water pump bolts ............................................... 53, 61<br />

Weld bungs ...............................................................92<br />

Wheel studs .........................................................68-69<br />

Rod Bolts<br />

pages 30-36<br />

replacement and aftermarket<br />

cylindeR head<br />

pages 37-44, 48-51, 75-76<br />

Head studs & bolts, rocker arm studs<br />

& adjusters, valve cover & header<br />

engine Block<br />

pages 45-47, 52-54<br />

Main studs & bolts, oil pan & pump,<br />

front cover, water pump<br />

intake system<br />

pages 55-57<br />

Manifold bolts, carb, air cleaner &<br />

blower studs, coil, distributor<br />

engine components<br />

pages 58-59<br />

Cam, harmonic damper bolts,<br />

fuel pump pushrod, oil pump<br />

accessoRies<br />

pages 60-63<br />

Complete bolt kits, individual bolts<br />

from intake to oil pan<br />

dRiveline<br />

pages 64-68<br />

Flywheel, flex & pressure plate,<br />

converter, rear end, wheel studs<br />

nascaR specialties<br />

pages 69-71<br />

Special fasteners for NASCAR<br />

competition<br />

spoRt compact<br />

pages 72-78<br />

Rod bolts, head bolts & studs, main<br />

bolts & studs, cam & accessory studs<br />

Bulk fasteneRs<br />

pages 79-92<br />

Bolt 5-packs, washers, nuts, bulk bins<br />

weld bungs, stand-off brackets<br />

tools<br />

pages 93-97<br />

Rod bolt extenders, stretch gauge,<br />

ring compressors, thread chasers<br />

appaRel<br />

page 99

the company<br />

4<br />

A Brief History<br />

They say that to be successful you must identify a need<br />

and satisfy it. Back in 1968 racing enthusiast Gary Holzapfel<br />

saw that many of his friends’ broken engines were caused<br />

by fastener failure. At the time, there were no commercially<br />

available studs and bolts up to the challenge. So Holzapfel<br />

called upon his many years of fastener<br />

making experience for a leading aerospace<br />

subcontractor and founded <strong>ARP</strong> ®<br />

(<strong>Automotive</strong> <strong>Racing</strong> Products). In<br />

the ensuing years, the firm has grown<br />

from what was literally a backyard<br />

garage workshop into a highly diversi-<br />

Gary Holzapfel<br />

Founder and CEO<br />

fied manufacturer with five operational<br />

entities in Southern California with<br />

a combined area in excess of 148,000<br />

square feet. These include forging, machining, finishing and<br />

packaging/warehousing facilities in Santa Paula and Ventura,<br />

California. There is even a unique racing-themed restaurant at<br />

the main Santa Paula facility (called “Hozy’s Grill” - which is<br />

open to the public).<br />

<strong>ARP</strong>’s state-of-the-art manufacturing facility in Santa Paula.<br />

Packaging, warehousing and sales operations are handled out of Ventura.<br />

<strong>ARP</strong>’s new forging facility in Santa Paula, California.<br />

On hand at the Grand Opening of <strong>ARP</strong>’s new manufacturing facility<br />

in Santa Paula, CA were (l to r) 12-time NHRA World Champ<br />

John Force, <strong>ARP</strong>’s VP Sales & Marketing Bob Florine, Founder and<br />

CEO Gary Holzapfel, Assistant Sales Manager Chris Raschke and<br />

<strong>ARP</strong> President Mike Holzapfel.<br />

Today, <strong>ARP</strong>’s product line contains thousands of part<br />

numbers, and has expanded to include virtually every fastener<br />

found in an engine and driveline. These range from quality<br />

high performance OEM replacement parts to exotic specialty<br />

hardware for Formula 1, IndyCar, NASCAR and NHRA drag<br />

racing and marine applications.<br />

As a matter of fact, <strong>ARP</strong>’s customer list reads like a “who’s<br />

who” of motorsports around the world. In the past several<br />

years, virtually every major championship on the planet has<br />

been won with engines prepared by <strong>ARP</strong> customers. These<br />

include NASCAR Sprint Cup, IRL, Formula 1, NHRA Top<br />

Fuel, Funny Car & Pro Stock, NASCAR Nationwide Series<br />

and Camping World Truck Series. And so it goes. <strong>ARP</strong> works<br />

closely with many, many teams as a supplier of engine and<br />

driveline fasteners, and has clearly become recognized as “the”<br />

preeminent source for serious racers.<br />

In addition to its core automotive business, <strong>ARP</strong> has an<br />

Aerospace Division, and is one of the very few companies in<br />

the world fully licensed by the United States Government to<br />

manufacture MS-21250 fatigue rated fasteners.<br />

<strong>ARP</strong> also manufactures a variety of industrial fasteners on a<br />

contract basis, and is known for its ability to promptly provide<br />

efficient solutions to problems at hand.<br />

All metal finishing operations are done in this Santa Paula plant.<br />

This facility is home to <strong>ARP</strong>’s heat-treating operations.<br />

800-826-3045

The Manufacturing Process…<br />

In order to ensure optimum quality control, <strong>ARP</strong> has<br />

grown to be exceptionally self-reliant and now controls<br />

all aspects of the manufacturing process. All operations<br />

are performed in-house and closely monitored. This is<br />

how <strong>ARP</strong> has been able to establish a reputation for “zero<br />

defects” quality throughout the industry.<br />

The process begins right at the mill, where <strong>ARP</strong> orders<br />

only premium grade materials including several proprietary<br />

alloys. The ever-popular 8740 chrome moly steel, for<br />

example, comes from the mill in four distinct grades. The<br />

lowest is “commercial,” which is followed by “aircraft quality.”<br />

<strong>ARP</strong> uses only the top two grades (SDF and CHQ), which<br />

cost twice as much, but provide the foundation for defect-free<br />

fasteners. These materials come in bar stock (for studs) and<br />

huge coils (for bolts).<br />

Transforming raw material into a fastener begins with<br />

“hot” and “cold” heading processes. Material is fed into powerful<br />

devices and cold forged, or induction-heated and formed<br />

under tons of pressure.<br />

<strong>ARP</strong>’s bank of cold-headers can handle material up to 5/8˝ diameter<br />

and form bolts in a multi-phase operation.<br />

An overview of part of <strong>ARP</strong>’s expansive machining operations. The shop<br />

is laid out for optimum efficiency.<br />

800-826-3045<br />

Material comes from the<br />

mill in large coils...which<br />

subsequently will be fed into<br />

cold-headers and formed into<br />

bolts.<br />

Some bolts begin as induction-heated lengths of<br />

bar stock that are forged on huge presses with the<br />

desired head shape.<br />

Lengths of bar stock are automatically fed into special machines and<br />

cut to the appropriate length.<br />

the company<br />

5

the company<br />

6<br />

Following the basic shaping, material is heat-treated to<br />

desired levels. This crucial process is done entirely in-house<br />

to assure total quality control. <strong>ARP</strong> uses special vertical racks<br />

to hold each piece individually and assure complete 360° penetration.<br />

This is far superior to commonly-used methods of<br />

dumping items into a large bin and batch-treating.<br />

Studs are centerless ground to guarantee concentricity.<br />

The thread rolling operation (to MIL-S-8879A specs) is done<br />

after heat-treat, which accounts for a fatigue strength up to<br />

ten times higher than fasteners which are threaded prior to<br />

heat-treat.<br />

<strong>ARP</strong> manufactures nuts in a multi-step process that begins<br />

with raw material being fed into a giant forming device that<br />

“blanks” the hex and 12-point nuts and continues with highly<br />

sophisticated automated threading equipment tapping each<br />

nut with an accuracy of .001˝ (which is five times higher than<br />

the aerospace standard). This ensures an exceptionally closetolerance<br />

fit between the bolt/stud and nut.<br />

Metal finishing is also performed in-house at <strong>ARP</strong>.<br />

Operations include black oxide coating of chrome moly or<br />

polishing stainless steel to a brilliant luster.<br />

A series of CNC-threading machines are employed by <strong>ARP</strong> to accurately tap the threads in<br />

nuts. Tolerances held are 5 times better than aerospace standards.<br />

Heat-treating is critically important in obtaining the correct tensile strength.<br />

Fasteners are placed in special vertical racks to ensure complete 360˚ penetration.<br />

The Grinding Department is where all studs are centerless ground to<br />

ensure that they are perfectly concentric. As many as ten machining<br />

steps are required to achieve this level of accuracy.<br />

Powerful cold-forging equipment is used to make<br />

<strong>ARP</strong>’s hex and 12-point nuts. Multi-stage dies are<br />

employed to precision-form the finished “blanks.”<br />

<strong>ARP</strong> performs the thread<br />

rolling operation after<br />

heat-treating, which results<br />

in a fatigue strength up to<br />

10-times higher than fasteners<br />

with threads rolled prior<br />

to elevating the material’s<br />

tensile strength.<br />

800-826-3045

Also on the premises is a fully-equipped lab for R&D and<br />

quality control. It has everything required to ensure that <strong>ARP</strong><br />

products measure up to the company’s ultra high standards.<br />

Some of the tests that <strong>ARP</strong> personnel perform on a daily basis<br />

include proof loading (using a 120,000 lb. capability tensile<br />

machine), fatigue cycle (Amsler) and hardness (Rockwell).<br />

Visual inspections include use of an optical comparator (to<br />

check thread root contour, etc.), fixtured micrometers and<br />

microscopic grain flow analysis. The computer-controlled<br />

fatigue cycle testers allow <strong>ARP</strong> to take fasteners to a failure<br />

point in millions of cycles – as opposed to the aerospace norm<br />

of 65,000 average to 130,000 cycles maximum. This allows<br />

<strong>ARP</strong> engineers to verify the design specifications of each<br />

fastener, and prove its ability to provide superior long-term<br />

service.<br />

Finished products are packaged and warehoused in <strong>ARP</strong>’s<br />

Ventura facility, which is also home to the firm’s customer<br />

service, technical and sales office.<br />

Fasteners are shot-peened after heat-treatment to improve overall<br />

external integrity.<br />

800-826-3045<br />

Contemporary EDM<br />

technology is used to<br />

perform special operations,<br />

such as hex-broaching<br />

the nose of a unique<br />

short-run fastener<br />

A bank of CNC machining centers are<br />

employed at <strong>ARP</strong> to perform specialty<br />

operations.<br />

<strong>ARP</strong>’s popular stainless steel engine & accessory fasteners are polished to<br />

a brilliant luster using this specialized equipment.<br />

The finishing touch for most chrome moly fasteners is the black oxiding<br />

operation. Fasteners go through a series of “baths.”<br />

the company<br />

7

the company<br />

8<br />

Behind The Scenes<br />

There are a number of important elements in the production<br />

of specialty fasteners, not the least of which are materials,<br />

design and manufacturing. As you read further into this<br />

catalog, you will get a better idea of the extraordinary steps<br />

taken by <strong>ARP</strong> to produce the very finest products of their<br />

kind on the market today. The key to success in all areas is<br />

personnel. And here’s where <strong>ARP</strong>’s cadre of highly qualified<br />

and dedicated specialists shines brightly.<br />

Two valuable resources in the design of <strong>ARP</strong> products are<br />

Dr. Kenneth Foster and Russell Sherman, P.E. Both men have<br />

extensive backgrounds in mechanical engineering, metallurgy<br />

and stress analysis. Their academic credentials are substantial,<br />

and real world experience equally impressive. Dr. Foster has<br />

a Ph.D. in Engineering Mechanics from Cornell University<br />

and has taught at several colleges. He was formerly the head<br />

of Stress & Dynamics at Hughes Aircraft, Space Systems<br />

division. Mr. Sherman has been awarded a fellowship from<br />

A.S.M. International, a technical achievement award from<br />

Fastener Technology International, and holds a number of<br />

fastener patents.<br />

High powered magnifiers are used to carefully inspect critical components.<br />

<strong>ARP</strong>’s quality control team is relentless!<br />

A computer-controlled Instron tensile machine is used to determine<br />

the ultimate tensile strength of studs and bolts.<br />

Kenneth Foster, PhD<br />

Consulting Engineer<br />

Russell Sherman, P.E.<br />

Consulting Engineer<br />

Robert Logsdon<br />

Q.C. Consultant<br />

Some of the most valuable work done by Foster and<br />

Sherman includes analyzing various aspects of engine, chassis<br />

and driveline structural loads, and coming up with solutions to<br />

the problems at hand. In this manner, the <strong>ARP</strong> Research Team<br />

is able to continually expand the company’s product line.<br />

<strong>ARP</strong> has added Robert Logsdon to its cadre of consultants.<br />

He comes to <strong>ARP</strong> with vast experience in the area of Metrology,<br />

Quality Control, Manufacturing, Acquisition and Configuration<br />

Management. Logsdon is a graduate of the U.S. Naval Academy<br />

of Metrology Engineering, the Defense Management College<br />

A series of special checking devices are employed to monitor<br />

the quality of threads. For every thread size, there is a checking device.<br />

<strong>ARP</strong> has two of these highly sophisticated Amsler fatigue machines,<br />

which check fasteners through millions of cycles.<br />

800-826-3045

and U.S. Air Force Institute of Technology. Additionally, <strong>ARP</strong><br />

has one of the industry’s most complete in-house R&D/QC<br />

facilities and a wide variety of testing equipment. Through the<br />

combined efforts of Logsdon and <strong>ARP</strong>’s management team, the<br />

ISO 9001 Level 1 (Quality Manual), Level 2 (Quality System<br />

Procedures) and Level 3 (Work Instructions) documentation<br />

has been finalized and is being implemented. <strong>ARP</strong> is now ISO<br />

9001 and AS9100 registered.<br />

<strong>ARP</strong> also enjoys a solid working relationship with many of<br />

the most respected professional engine builders and race teams<br />

from the world over – including those involved in Formula 1,<br />

NASCAR, NHRA, IHRA, World of Outlaws and a host of<br />

others. Constant interaction with these racing experts to provide<br />

fasteners for a wide variety of competition applications<br />

enables <strong>ARP</strong> to stay on the cutting edge of fastener technology<br />

development.<br />

You will find <strong>ARP</strong> fasteners sold by leading performance<br />

retailers and professional engine builders from coast to coast.<br />

These firms know that <strong>ARP</strong> fasteners are the standard of the<br />

industry, and smart consumers will accept no substitutions. As<br />

you can see, all <strong>ARP</strong> fasteners are proudly made in the USA<br />

The finished goods are given a protective coating and stored in sealed<br />

containers, awaiting packaging. Millions are in stock!<br />

After final packaging the kits are placed in storage racks and are ready<br />

for order fulfillment. Thousands of SKU’s are warehoused.<br />

800-826-3045<br />

to the industry’s highest standards. <strong>ARP</strong> also supports racers<br />

through generous contingency awards programs with many<br />

racing programs. <strong>ARP</strong> is a long-time NHRA Major Sponsor.<br />

What <strong>ARP</strong> Can Do For You<br />

In addition to manufacturing a comprehensive array of<br />

cataloged fasteners for automotive and aerospace applications,<br />

<strong>ARP</strong> thrives on the challenges of developing fasteners to solve<br />

unique problems. Racers, Pro Street enthusiasts and street<br />

rodders have, over the years, approached <strong>ARP</strong> about manufacturing<br />

special fasteners for unique applications, and the<br />

company has responded with innovative solutions.<br />

<strong>ARP</strong> can provide complete R&D services, including metallurgical<br />

research, product design, prototype machining and<br />

extensive laboratory testing. Moreover, <strong>ARP</strong> has experience<br />

manufacturing fasteners from a wide variety of materials. All<br />

work can be performed under the strictest confidence. <strong>ARP</strong><br />

is well versed in facilitating proprietary research and custom<br />

manufacturing for corporations the world over.<br />

It is for good reason that <strong>ARP</strong> is recognized as “The World<br />

Leader In Fastener Technology!”<br />

<strong>ARP</strong> fasteners are prominently featured at leading performance retailers<br />

worldwide.<br />

Components for each kit are placed on the appropriate display cards,<br />

sealed and labeled. Through-put has been significantly increased.<br />

the company<br />

9

fastener tech<br />

10<br />

John carroll smith: a tribute<br />

There are many of us who can say we knew John Carroll<br />

Smith in life.<br />

Carroll Smith was known around the engineering shops<br />

as a design and development engineer. He was known on<br />

race circuits as a team manager, driver coach and racing<br />

guru. And before that, he was known for his 30+ years of<br />

racing experience, driving in SCCA events, as well as on circuits<br />

in Europe including the Targa Florio and Le Mans.<br />

Even more of us know Carroll Smith through his books.<br />

His “To Win” series of books brought technical acclaim<br />

as they became staples for amateur and professional racers,<br />

while his “Engineer in Your Pocket” are today highly<br />

regarded as engineering handbooks. We’re never surprised<br />

to find his name on or featured in – books on race car<br />

design, preparation, engineering and tuning.<br />

Among his peers at the Society of <strong>Automotive</strong> Engineers,<br />

he served as a judge for the Formula SAE competition.<br />

One of his proudest honors was the Society’s Excellence in<br />

Engineering Education award.<br />

Carroll Smith was a race engineer and special motorsports<br />

consultant with <strong>Automotive</strong> <strong>Racing</strong> Products for more than<br />

decade. The pages of our catalog alone bear the mark of his<br />

enormous contributions to our efforts.<br />

Here at <strong>ARP</strong>, as elsewhere, Carroll Smith’s mission was<br />

THE “AEROSPACE QUALITY” MYTH<br />

In areas from hose ends to engine fasteners the terms<br />

“Aerospace material and Aerospace Quality” have become buzz<br />

words implying the very best in design, materials and quality<br />

control.<br />

“It isn’t necessarily so”, says Gary Holzapfel, founder and CEO<br />

of Santa Paula, California based <strong>ARP</strong>, Inc. <strong>ARP</strong> (<strong>Automotive</strong><br />

<strong>Racing</strong> Products) supplies extremely high strength and fatigue<br />

resistant threaded engine fasteners to NASCAR, IRL, NHRA<br />

and Formula One engine builders and manufacturers. Holzapfel<br />

explained his reasons in an interview with Carroll Smith.<br />

Smith: “Gary, do you believe that the term “aerospace quality”<br />

is over rated in the specialty fastener industry?”<br />

“Yes I do. First of all, the term is meaningless. Any AMS<br />

(Aerospace Material Specification) material must be matched<br />

to the specific application. As an example, some airframe bolts<br />

(AN3-20) are legitimate “aerospace parts” and are very well suited<br />

for the low stress applications for which they were designed. But<br />

with a minimum ultimate tensile strength of 125,000 psi, and<br />

a relatively low temperature limit, they would be completely<br />

unsuitable for use in a racing engine.<br />

We started out in the aerospace fastener business and we<br />

understand it. That’s why we’re not in it any longer. What is not<br />

generally understood about aerospace fasteners is that the fastener<br />

manufacturers do not design the product. The nuts, bolts and<br />

studs are spec’d by the airframe or engine designers and put out<br />

for bid. As long as the supplier certifies that the product meets<br />

the minimum requirement of the specification and it passes the<br />

customer’s inspection procedures, low bid wins.”<br />

simple. He was determined to impart the encyclopedic<br />

knowledge of racing and the machinery of racing that he<br />

learned during those decades on the world’s racetracks,<br />

around those shops and among his engineering peers.<br />

He left us at <strong>ARP</strong> with a significant engineering inheritance.<br />

Much of what we now know from Carroll will<br />

ensure we remain the world leader in the field of racing<br />

fasteners. It is our way of reciprocating for what he gave us<br />

that we impart his expertise and experience in the form we<br />

know best, superior engineered products.<br />

As an engineer, Carroll Smith had successes in Formula<br />

5000, numerous GT and sports car races, and with the<br />

Ferrari Formula 1 team. He is best known, however, for<br />

his work with Carroll Shelby and the Ford GT40 program<br />

which he helped develop into a winner at Le Mans.<br />

Ford has recently announced it is bringing back the<br />

GT40, its signature race car and a vehicle which, even forty<br />

years later, bears Carroll’s fingerprints. To those of us who<br />

knew him in person and through his work, the return of the<br />

GT40 is just another indicator of the enormous contribution<br />

to race engineering that John Carroll Smith continues<br />

to make, even after his passing.<br />

Carroll Smith passed away at his California home on<br />

May 16, 2003, from pancreatic cancer.<br />

Smith: “Are you implying that the aerospace fastener manufacturers<br />

cut corners in order to win contracts?”<br />

“No, it’s a matter of manufacturing goals and simple economics.<br />

The aerospace market is price dominated. In order to get the<br />

contract, the fastener manufacturer’s goal is to meet the specification<br />

at the least cost, not to produce the best possible part.<br />

This means that they are going to use the least expensive steel<br />

and manufacturing processes that will meet the specification.<br />

There is nothing wrong with this approach.<br />

It certainly does not mean that certified aerospace fasteners are<br />

unsafe in any aspect. They will do the job for which they were<br />

designed.<br />

There is another factor. Airframe<br />

and aircraft engine manufacturers<br />

design their components to a<br />

very high margin of safety. Further,<br />

aerospace structures are designed to<br />

be “fail safe.” There is a back up or<br />

second line of defense for virtually<br />

every structural component so that<br />

an isolated failure will not lead to<br />

disaster. They are also subjected to<br />

frequent and rigorous inspections.”<br />

Smith: “What’s different about<br />

motor racing?”<br />

“Quite a lot, really. While the<br />

demands for strength, fatigue<br />

resistance and quality control can<br />

be similar, and the assembly and<br />

inspection procedures in racing can<br />

This spring was wound<br />

from un-shaved<br />

material.<br />

It failed on the<br />

seam line.<br />

800-826-3045

<strong>ARP</strong>’s Mike Holzapfel and Russ Sherman discuss a fastener’s alloy.<br />

be as rigorous as aerospace, in professional racing very few parts<br />

are over designed and there are no fail safe features.<br />

There are no back up provisions for component failure. A<br />

failed (or even loosened) nut or bolt in a racing engine means<br />

disaster - instant catastrophic failure. An expensive engine is<br />

destroyed and a race is lost.<br />

That is why random failures are unacceptable in motor racing,<br />

and why aerospace standards should be only a starting point. This<br />

means that a specialist in the production of high performance<br />

engine fasteners must design and manufacture the very best fasteners<br />

that can be produced.”<br />

Smith: “So where does the production for a new racing<br />

fastener begin?”<br />

“The design process begins with the customer’s requirements<br />

the operating conditions and loads to be expected, the packaging<br />

constraints and the weight and cost targets. This allows us<br />

to select the optimum material for the part, and to do the initial<br />

mechanical design.<br />

There is more to material selection than simply choosing the<br />

best alloy. It means using only the cleanest and purest steel available,<br />

which, in turn, means researching to identify the best and<br />

most modern steel mills. It means working closely with the mills<br />

both to insure consistent quality and to develop new and better<br />

alloys.<br />

5 stage<br />

“Cold Header”<br />

used in the production<br />

of <strong>ARP</strong> bolts<br />

800-826-3045<br />

There are not only a<br />

myriad of alloys to choose<br />

from; but for each alloy there<br />

are several grades of “aircraft<br />

specification” steel wire from<br />

which fasteners can be made.<br />

We believe that only the top<br />

(and most expensive) grade<br />

– shaved-seamless, guaranteed<br />

defect-free – is suitable for<br />

racing engine applications.<br />

We also believe that samples<br />

from each batch should<br />

be subjected to complete<br />

metallurgical inspection.”<br />

Smith: “How many alloys<br />

do you work with?”<br />

“We are currently produc-<br />

ing fasteners from at least 10 different steel alloys<br />

from 8740 chrome moly to the very high strength<br />

chromium-cobalt-nickel alloys such as Custom Age<br />

625+. We also use stainless steel and titanium. With<br />

UTSs (Ultimate Tensile Strength) from 180,000 to<br />

270,000 psi, we can suit the material to the job and<br />

the customer’s cost restraints. We are continually<br />

researching and experimenting with new alloys<br />

and manufacturing processes – some with all<br />

around better strength and fatigue properties.”<br />

Smith: “Once the design work is done and<br />

material has been selected, what’s<br />

next?”<br />

“Next comes the actual process of<br />

manufacturing. It goes without saying<br />

that all high strength bolts must have<br />

rolled rather than cut threads, and that<br />

the threads must be rolled after heattreatment.<br />

But there is more to it. The old saying<br />

to the effect of, “If you are doing something<br />

in a particular way because that’s the way it has always been<br />

done, the chances are that you are doing it wrong,” holds true in<br />

fastener technology.<br />

Technology advances, and we have to advance with it. All of<br />

the manufacturing processes should be subject to continuous<br />

experimentation and development. As an example, with some<br />

alloys, cold heading produces a better product than hot heading,<br />

and vice versa. The number and force of the blows of the cold<br />

heading machine can make a significant difference in the quality<br />

of the end product. Excessive numbers of blows can lead to voids<br />

in the bolt head. <strong>ARP</strong>, in fact, holds significant patents on cold<br />

heading procedures for the higher nickel and cobalt based alloys.<br />

In a typical aerospace manufacturing process, these alloys are hot<br />

headed from bars, reduced in diameter from 48 to 50% by cold<br />

drawing, resulting in a hardness of about Rockwell C46 which<br />

is too hard for cold heading. So, the blanks are locally induction<br />

heated in a very narrow temperature envelope and hot headed.<br />

If care is not taken the process can reduce the hardness of<br />

the bolt head and the area immediately under it as much as 3<br />

to 5 points on the Rockwell C scale. Subsequent heat-treatment<br />

does not restore this partially annealed area to full hardness and<br />

strength. Therefore, the final result can be a relatively soft headed<br />

bolt. This process is not preferred by <strong>ARP</strong>.<br />

Our patented process begins with a softer wire that can be cold<br />

forged. The process work hardens the head and the under head<br />

area to the desired hardness. We then power extrude the front end<br />

to achieve the reduction and hardness in the shank resulting in a<br />

bolt with even strength and hardness from end to end.<br />

The same is true of thread rolling. Temperature and die speed<br />

must be controlled and changed for different alloys. Many bolt<br />

manufacturers who meet the Aerospace Specifications don’t come<br />

close to meeting our standards. We consistently go beyond<br />

standard aerospace specs.<br />

Our concern with the manufacturing processes extends to the<br />

details of heat-treating, shot-peening, fillet rolling and grinding<br />

– down to the frequency of dressing the grinding wheels. In the<br />

arena where aerospace standards are a starting point and random<br />

failures are unacceptable, I feel <strong>ARP</strong> stands alone as a primary<br />

11<br />

the company

fastener tech<br />

12<br />

engineering and manufacturing source for specialty and custom<br />

fasteners for use in motorsports.<br />

It is important to realize that simply quoting an AMS<br />

(Aerospace Material Specification) number without strength and<br />

percentage of elongation numbers is meaningless. Statements that<br />

the use of a particular material will, in itself, result in extreme<br />

strength and resistance to fatigue can be misleading. In the world<br />

of high strength alloys, whether they are used for bolts or for<br />

landing gears, the manufacturing processes are at least as important<br />

as the material specification.<br />

Some in our industry claim to inspect materials at the “molecular”<br />

level. In metallurgical terms, molecules are not necessarily<br />

part of the vocabulary. Our engineers tell us that talking about<br />

molecules is misleading. When reference is made to metal, it is<br />

typically in terms of atom structures. We routinely check metallurgical<br />

features microscopically. By the way, the same is true for<br />

claims of manufacturing to “zero tolerance.”<br />

“Our engineers tell us that this is technically unrealistic.”<br />

Smith: “How does the actual process work at <strong>ARP</strong>?”<br />

“For each new design, we produce a number of prototype<br />

parts using different design aspects and sometimes different<br />

methods.<br />

We inspect and test after each process, choose the best design<br />

and method of manufacture, and then freeze the design and write<br />

the manufacturing specification.”<br />

Smith: “You have mentioned the importance of fatigue<br />

resistance. Is there a difference in the procedures for<br />

strength and fatigue testing between aerospace and the<br />

specialty racing industry?”<br />

“Yes. While the ultimate tensile strength testing is the same,<br />

fatigue testing is different. Aerospace fasteners are fatigue tested<br />

to the relevant specification of fluctuating tension load and<br />

number of cycles typically 130,000 cycles with the high tension<br />

load at 50% of the UTS and the low load at 10% of the high<br />

load. If all of the test samples last 85,000 cycles (per AMS 5842-<br />

D), the lot is accepted.<br />

Even though racing fasteners are not continuously subjected<br />

to their maximum design load, at 18,000 rpm, 100,000 cycles<br />

takes just 5 minutes, thirty-four seconds. Except for drag racing,<br />

measured in seconds, no race lasts just 5 minutes. Therefore we<br />

consider this Aerospace Standard to be inadequate. At <strong>ARP</strong>, we<br />

fatigue test to elevated loads (10% above aerospace requirements)<br />

and to a minimum cycle life that exceeds 350,000 cycles. The<br />

majority of samples are routinely tested to one million cycles.<br />

During material development...and in the case of extremely critical<br />

new designs, we test to destruction.<br />

Thread rolling is the last mechanical operation in our manufacturing<br />

process. For each production run the thread rolling<br />

machine is shut down after a few parts. These parts are inspected<br />

for dimensional accuracy and thread quality, and are physically<br />

tested for both strength and fatigue before the run is continued.<br />

Random samples are inspected and tested throughout the run.<br />

Extremely critical components are individually inspected for<br />

dimensional integrity.”<br />

Smith: “What about out sourcing?”<br />

“Economics often dictate that many processes in the manufacture<br />

of aerospace fasteners are out sourced or farmed out. In<br />

fact, 30 plus years ago, <strong>ARP</strong> began as an out source thread rolling<br />

shop.<br />

Over the years, however, we have found, through experience,<br />

that the only way to maintain the quality we require is to keep<br />

everything in-house. From heading through machining, grinding,<br />

heat-treat, thread rolling, and shot-peening to black oxide<br />

treatment we perform every operation in house on our own<br />

equipment with our own employees.”<br />

Smith: “Gary, One of the things that I am hearing is that<br />

every aspect of the manufacture of racing engine fasteners<br />

is more expensive than that of similar aerospace items.”<br />

“True, but the bottom line is that we have to look at the cost<br />

aspect of the very best fastener versus the cost aspect of a blown<br />

engine and a lost race. In the end, the manufacturing of fasteners<br />

for racing comes down to a matter of attitude; a refusal to accept<br />

published standards and procedures as the best that can be done<br />

and most of all a determination to learn and to make still better<br />

products.”<br />

800-826-3045

There are literally hundreds of standards and specifications. For all types of applications, from bridges to spaceships. None are, however,<br />

as critical as those required for real-world motorsports applications. In an environment where lighter is faster there is clearly no room for<br />

redundancy systems, like those found in military and aerospace applications. The mere nature of Motorsports requires designers to produce<br />

fasteners that are light; yet produce toughness, fatigue and reliability factors that extend far beyond other acknowledged application standards.<br />

The design and production of fasteners, exclusively for racing, clearly involves many complex factors. Some so special no standards or design<br />

criteria exist; and so everyone at <strong>ARP</strong> is totally dedicated to the development and analysis of appropriate bolt designs exclusively for special<br />

applications. Designs that take into account the special loads and endurance that must be carried, the material selection, processing, and the<br />

methods of installation that will continue to deliver <strong>ARP</strong> quality and reliability.<br />

The focus of the following material, prepared by the <strong>ARP</strong> engineering staff, could be called:<br />

“MOTORSPORTS FASTENER ENGINEERING for the NON-ENGINEER.”<br />

It is hoped that by providing an overview of the engineering, design and production forces <strong>ARP</strong> applies daily, you –<br />

as the end user – will be better equipped to evaluate your initial fastener requirements, effectiveness and performance.<br />

DESIGN PROCEDURES for AUTOMOTIVE BOLTS<br />

Presented by Dr. Kenneth Foster, PhD<br />

The design of automotive bolts is a complex process, involving<br />

a multitude of factors. These include the determination of operating<br />

loads and the establishment of geometric configuration. The<br />

process for connecting rod bolts is described in the following<br />

paragraphs as an example.<br />

The first step in the process of designing a connecting rod bolt<br />

is to determine the load that it must carry. This is accomplished<br />

by calculating the dynamic force caused by the oscillating piston<br />

and connecting rod. This force is determined from the classical<br />

concept that force equals mass times acceleration. The mass<br />

includes the mass of the piston plus a portion of the mass of the<br />

rod. This mass undergoes oscillating motion as the crankshaft<br />

rotates. The resulting acceleration, which is at its maximum value<br />

when the piston is at top dead center and bottom dead center,<br />

is proportional to the stroke and the square of the engine speed.<br />

The oscillating force is sometimes called the reciprocating weight.<br />

Its numerical value is proportional to:<br />

It is seen that the design load, the reciprocating weight,<br />

depends on the square of the RPM speed. This means that if the<br />

speed is doubled, for example, the design load is increased by a<br />

factor of 4. This relationship is shown graphically below for one<br />

particular rod and piston.<br />

800-826-3045<br />

A typical value for this reciprocating weight is in the vicinity<br />

of 20,000 lbs. For purposes of bolt design, a “rule of thumb” is to<br />

size the bolts and select the material for this application such that<br />

each of the 2 rod bolts has a strength of approximately 20,000 lbs.<br />

(corresponding to the total reciprocating weight). This essentially<br />

builds in a nominal safety factor of 2. The stress is calculated<br />

according to the following formula:<br />

so that the root diameter of the thread can be calculated from<br />

the formula:<br />

This formula shows that the thread size can be smaller if a<br />

stronger material is used. Or, for a given thread size, a stronger<br />

material will permit a greater reciprocating weight. The graph<br />

(see page 14) shows the<br />

relationship between<br />

thread size and material<br />

strength.<br />

It must be realized<br />

that the direct reciprocating<br />

load is not the<br />

only source of stresses in<br />

bolts. A secondary effect<br />

arises because of the<br />

flexibility of the journal<br />

end of the connecting<br />

rod. The reciprocating<br />

load causes bending<br />

deformation of the bolted<br />

joint (yes, even steel<br />

deforms under load).<br />

This deformation causes<br />

bending stresses in the<br />

bolt as well as in the<br />

rod itself. These bending<br />

stresses fluctuate<br />

“H” beam-deformed.<br />

Total translation<br />

contours.<br />

For loading in<br />

tension due to<br />

acceleration forces<br />

at 8000 RPM<br />

13<br />

fastener tech

fastener tech<br />

14<br />

from zero to their maximum level during each revolution of the<br />

crankshaft.<br />

The next step is to establish the details of the geometric configuration.<br />

Here the major consideration is fatigue, the fracture<br />

that could occur due to frequent repetition of high stresses, such<br />

as the bending stresses described above. Several factors must be<br />

considered in preventing fatigue; attention to design details is<br />

essential.<br />

Fatigue failure is frequently caused by localized stress risers,<br />

such as sharp corners. In bolts, this would correspond to the<br />

notch effect associated with the thread form. It is well known that<br />

the maximum stress in an engaged bolt occurs in the last engaged<br />

thread. By removing the remaining, non-engaged threads, the<br />

local notch effect can be reduced. This leads to the standard<br />

configuration used in most <strong>ARP</strong> rod bolts: a reduced diameter<br />

shank and full engagement for the remaining threads. Providing<br />

a local fillet radius at the location of the maximum stress further<br />

reduces the local notch effect. Thus this configuration represents<br />

the optimum with respect to fatigue strength.<br />

The reduced diameter shank is helpful in another sense. It<br />

reduces the bending stiffness of the bolt. Therefore, when the bolt<br />

bends due to deformation of the connecting rod, the bending<br />

stresses are reduced below what they would otherwise be. This<br />

further increases the fatigue resistance of the bolt. A typical bolt<br />

configuration is shown below.<br />

Once the bolt configuration has been established, the manufacturing<br />

process comes into play. This involves many facets,<br />

which are discussed in detail elsewhere. Here, however, one process<br />

is of primary interest. With respect to bolt fatigue strength,<br />

thread rolling is a major consideration. Threads are rolled after<br />

heat treating. This process, which deforms the metal, produces a<br />

beneficial compressive stress in the root of the thread. It is beneficial<br />

because it counteracts the fluctuating tensile stresses that<br />

can cause fatigue cracking. If heat-treatment were to occur after<br />

rolling, the compressive stresses would be eliminated. This would<br />

therefore reduce the fatigue resistance of the bolt.<br />

An additional factor must be taken into account in defining<br />

the bolt configuration: the length of engaged thread. If too few<br />

threads are engaged, the threads will shear at loads that are lower<br />

than the strength of the bolt. As a practical matter, the thread<br />

length is always selected so that the thread shear strength is<br />

significantly greater than the bolt tension strength.<br />

This problem is especially important in bolts used in aluminum<br />

rods because of the fact that the shear strength of aluminum<br />

is much lower than the shear strength of steel.<br />

Finally, although not a design parameter, the subject of bolt<br />

installation preload must be addressed. It is a fundamental engineering<br />

concept that the force in a bolt in an ideal preloaded<br />

joint will remain equal to the preload until the externally applied<br />

force exceeds the preload. Then the force in the bolt will be equal<br />

to the external force. This means that fluctuating external forces<br />

will not cause fluctuating forces in a preloaded bolt as long as the<br />

preload exceeds the external force. The result is that fatigue failure<br />

will not occur. In a non-ideal joint, such as in a connecting rod,<br />

the bolt will feel fluctuating stresses due to fluctuating rod distortions.<br />

These are additive to the preload, so that fatigue could<br />

result. In connecting rods, precise preloads are required because<br />

if they are too low, the external forces (the reciprocating weights)<br />

will exceed the preloads, thus causing fatigue. If they are too high,<br />

they provide a high mean stress that combines with the fluctuating<br />

stresses due to rod distortion. Again, fatigue is promoted.<br />

The objective, then, is to preload a bolt so that it just exceeds<br />

the external load, and no higher. To sum up: both insufficient<br />

preloads and excessive preloads can lead to fatigue failures.<br />

Appropriate preloads are specified for each <strong>ARP</strong> bolt. These<br />

preloads can be attained in a connecting rod by applying proper<br />

torque using a torque wrench or by measuring the amount of<br />

stretch in the bolt using a stretch gauge (it is known that a bolt<br />

stretches in proportion to the tension in it). The torque method<br />

is sometimes inaccurate because of the uncertainty in the coefficient<br />

of friction at the interface between the bolt and the rod.<br />

This inaccuracy can be minimized by using the lubricant supplied<br />

by <strong>ARP</strong>.<br />

Other factors, equally as important as design, include material<br />

selection, verification testing, processing, and quality control.<br />

These aspects of bolt manufacturing are discussed elsewhere in<br />

this document.<br />

The foregoing discussion concentrated on the design of bolts.<br />

The same considerations apply in the design of studs.<br />

800-826-3045

800-826-3045<br />

recognizing common failures<br />

There are six types of metallurgical failures that affect fasteners. Each type has unique identifying physical characteristics.<br />

The following chart is designed to be used like a spark plug reading chart to help analyze fastener failures. While few of us have<br />

access to sophisticated analysis equipment, a standard Bausch and Lomb three lens magnifying glass will generally show 98%<br />

of what we want to see. Several of the photos below have been taken utilizing a Scanning Electron Microscope (SEM) and are<br />

presented to simply illustrate typical grain configurations after failure.<br />

1. Typical Tensile Overload<br />

In a tensile overload failure the bolt will stretch and “neck down” prior to rupture. One of the fracture faces will form a cup and<br />

the other a cone. This type of failure indicates that either the bolt was inadequate for the installation or it was preloaded beyond the<br />

material’s yield point.<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

2. Torsional Shear (twisting)<br />

Fasteners are not normally subjected to torsional stress. This sort of failure<br />

is usually seen in drive shafts, input shafts and output shafts. However we have<br />

seen torsional shear failure when galling takes place between the male and female<br />

threads (always due to using the wrong lubricant or no lubricant) or when the<br />

male fastener is misaligned with the female thread. The direction of failure is obvious<br />

and, in most cases, failure occurs on disassembly.<br />

3. Impact Shear<br />

Fracture from impact shear is similar in appearance to torsional shear failure<br />

with flat failure faces and obvious directional traces. Failures due to impact shear<br />

occur in bolts loaded in single shear, like flywheel and ring gear bolts. Usually<br />

the failed bolts were called upon to locate the device as well as to clamp it and,<br />

almost always, the bolts were insufficiently preloaded on installation. Fasteners<br />

are designed to clamp parts together, not to locate them. Location is the function<br />

of dowels. Another area where impact failures are common is in connecting rod<br />

bolts, when a catastrophic failure, elsewhere in the engine (debris from failing<br />

camshaft or crankshaft) impacts the connecting rod.<br />

4. Cyclic fatigue failure originated by hydrogen embrittlement.<br />

Some of the high strength “quench and temper” steel alloys used in fastener<br />

manufacture are subject to “hydrogen embrittlement.” L-19, H-11, 300M,<br />

Aeromet 100 and other similar alloys popular in drag racing, are particularly susceptible<br />

and extreme care must be exercised in manufacture. The spot on the first<br />

photo is typical of the origin of this type of failure. The second is a SEM photo<br />

at 30X magnification.<br />

5. Cyclic fatigue cracks propagated from a rust pit (stress corrosion)<br />

Again, many of the high strength steel alloys are susceptible to stress corrosion.<br />

The photos illustrate such a failure. The first picture is a digital photo with an<br />

arrow pointing to the double origin of the fatigue cracks. The second photograph<br />

at 30X magnification shows a third arrow pointing to the juncture of the cracks<br />

propagating from the rust pits. L-19, H-11, 300M and Aeromet 100, are particularly<br />

susceptible to stress corrosion and must be kept well oiled and never exposed<br />

to moisture including sweat. Inconel 718, <strong>ARP</strong> 3.5 and Custom age 625+ are<br />

immune to both hydrogen embrittlement and stress corrosion.<br />

6. Cyclic fatigue cracks initiated by improper installation preload<br />

Many connecting rod bolt failures are caused by insufficient preload. When<br />

a fastener is insufficiently preloaded during installation the dynamic load may<br />

exceed the clamping load resulting in cyclic tensile stress and eventual failure.<br />

The first picture is a digital photo of such a failure with the bolt still in the rod.<br />

The arrows indicate the location of a cut made to free the bolt. The third arrow<br />

shows the origin of the fatigue crack. In the second picture – an SEM photo at<br />

30X magnification that clearly shows the origin of the failure (1), and the telltale<br />

“thumbprint” or “beach mark” (2). Finally (3) tracks of the outwardly propagating<br />

fatigue cracks, and the point where the bolt (unable to carry any further load)<br />

breaks-away.<br />

15<br />

fastener tech

fastener tech<br />

16<br />

The following material is intended to provide a brief overview of<br />

the metallurgical considerations that, daily, influence the design and<br />

production of the most reliable fasteners in motorsports. It is hoped<br />

that a simple understanding of the knowledge and commitment<br />

required to produce this reliability will make your future fastener<br />

decisions much, much easier.<br />

metallurgy for the<br />

non-engineer<br />

By Russell Sherman, PE<br />

1. What is grain size and how important is it?<br />

Metals freeze from the liquid state during melting from<br />

many origins and each one of these origins grows until it<br />

bumps into another during freezing. Each of these is a grain<br />

and in castings, they are fairly large. Grains can be refined<br />

(made smaller); by first cold working and then by recrystallizing<br />

at high temperature. Alloy steels, like chrome moly, do not<br />

need any cold work; to do this – reheat treatment will refine<br />

the grain size. But austenitic steels and aluminum require cold<br />

work first. Grain size is very important for mechanical properties.<br />

High temperature creep properties are enhanced by large<br />

grains but good toughness and fatigue require fine grain size<br />

– the finer the better. All <strong>ARP</strong> bolts and studs are fine grain –<br />

usually ASTM 8 or finer. With 10 being the finest.<br />

2. How do you get toughness vs. brittleness?<br />

With steels, as the strength goes up, the toughness decreases.<br />

At too high a strength, the metal tends to be brittle. And<br />

threads accentuate the brittleness. A tool steel which can be<br />

<strong>ARP</strong> engineers use “Scanning Electron Microscopic” inspection capable of<br />

detecting all elements in the periodic table with atomic numbers greater<br />

than 5 – permitting the acquisition of high resolution imaging.<br />

heat-treated to 350,000 psi, would be a disaster as a bolt<br />

because of the threads.<br />

3. Define Rockwell as we use it. Why do we use the<br />

C scale?<br />

A man named Rockwell developed a means of measuring<br />

hardness of metals which was superior to other methods. A<br />

Rockwell hardness tester measures the depth of penetration<br />

into the metal when a load is applied. For hard materials, a<br />

diamond penetrator is used. For soft material, small balls are<br />

used – 1/16˝ or 1/8˝ diameter-and the machine measures the<br />

depth. We use the C scale for the 120,000 psi strength level<br />

Metallurgist, Russell Sherman, PE, and stress/dynamics engineer<br />

Dr. Kenneth Foster, PhD, are the heart of <strong>ARP</strong>’s technical power team.<br />

and above. The C scale uses the greatest load – 150 Kg. The A<br />

scale uses only a 60 Kg. load but can be correlated with C. It<br />

is necessary to use the A scale for thin sheets because using the<br />

150 Kg load would cause the<br />

diamond to penetrate almost<br />

all the way through.<br />

4. What is<br />

“micro hardness?”<br />

Some parts are too small to<br />

be Rockwell hardness tested.<br />

They are placed in hard plastic<br />

and a microscope is used to<br />

place a small indenter into the<br />

metal. Using the microscope<br />

the length of the impression<br />

is measured.<br />

5. How does modulus of<br />

elasticity refer to our<br />

products?<br />

The modulus of elasticity<br />

of all alloy steels is exactly the<br />

same – 30,000,000 psi. This<br />

is true whether it is heattreated<br />

or not – whether it is<br />

100,000 psi strength level or<br />

300,000 psi. Metals are like<br />

a spring – put a load on them<br />

and they will stretch – double the load and they will stretch<br />

double. This is important in connecting rod bolts because by<br />

measuring the stretch we really are measuring the load. Load<br />

is what is important and measuring stretch of a given size and<br />

configuration bolt will indicate how much load is stretching<br />

the bolt.<br />

6. What are metal carbides and what is their significance?<br />

The strength of all alloy and carbon steels is derived from<br />

the metal carbides formed during heat treat. The carbon in<br />

steels combines with iron, vanadium and with chromium, as<br />

well as many other metal alloy additions to form compounds,<br />

which are a very hard phase within the iron matrix. Tool steels<br />

generally have high carbon content (above .8%) and can be<br />

made very hard – but brittle.<br />

800-826-3045

7. What exactly is chrome?<br />

Chrome is the metal chromium and is typically used for<br />

plating because it is shiny. It is also used as an alloy addition<br />

to iron to form a stainless steel. A stainless steel must contain<br />

at least 12% chromium, but these lean chromium steels can<br />

still show some rust on the surface. Using 18% chromium<br />

will make a more rust resisting stainless. Exposing any stainless<br />

to oxygen at temperatures above 1200˚F will cause the<br />

chromium to join the oxygen and therefore leave the surface<br />

depleted in chromium. If it falls below 12% the surface will<br />

show rust.<br />

8. What does it mean when a broken part looks<br />

crystallized?<br />

When the fracture face has a rocky appearance it is because<br />

the material had a very large grain structure. Basically the<br />

grain grew during manufacturing due to poor technique and<br />

handling. A properly processed part will have a silky smooth<br />

appearance which is an indication of fine grain size. So crystallization<br />

does not occur as a result of load or fatigue – it was<br />

present in the material at the time of manufacture.<br />

9. Define “precipitation hardening” and “phase change.”<br />

The precipitation hardening comes from microscopic precipitation<br />

of hard phases which serve to keep rows of atoms<br />

from moving under stress. Some metals undergo a change in<br />

atomic structure at high temperature. Alloy steels, which are<br />

bcc at room temperature, become fcc at temperatures above<br />

1400°F. This switch over is called a phase change. When cooled<br />

down they revert back to the bcc structure. Management of<br />

this phase is extremely critical and <strong>ARP</strong> maintains a complete<br />

in-house heat-treatment facility. It’s the only way we can<br />

assure material integrity.<br />

10. What does a “face centered cubic” (fcc)<br />

atom arrangement look like? How many atoms?<br />

A face centered cubic arrangement of atoms<br />

(austenitic) looks like a Las Vegas die with a five<br />

showing on all six faces. This can’t be seen visually<br />

by any type of microscope.<br />

The number of atoms in any one cubic cell<br />

would be 14 – these do not stand alone but<br />

are attached to other cells which share some<br />

of the atoms.<br />

11. How does a “body center cubic”<br />

(bcc) atom look? How many atoms?<br />

The body center cubic structure would<br />

look like a die<br />

with a four on<br />

all faces and one<br />

atom in the center<br />

of the cube. The<br />

atomic arrangment<br />

of pure iron is bcc<br />

at room temperature<br />

and does not change<br />

until the temperature<br />

reaches 1674˚F. At this<br />

temperature it changes<br />

to austenite which is<br />

face center cubic (fcc).<br />

The addition of carbon<br />

to the iron lowers this transition<br />

temperature. This is the basis for heat treat-<br />

800-826-3045<br />

ment of steel. If the iron carbon alloy (steel) is<br />

quenched from the fcc field, the<br />

structure becomes martensite,<br />

a very hard strong<br />

condition.<br />

12. What does<br />

a “stainless<br />

steel” atom<br />

arrangement<br />

look like?<br />

The 300 Series<br />

stainless steels are<br />

face-centered cubic<br />

and are not heat-treatable.<br />

Heavy reduction<br />

(power dumping), in the cross<br />

section, during forging causes a dramatic<br />

increase in strength. This is the process <strong>ARP</strong> uses to<br />

make 304 Stainless Steel reach 170,000 psi UTS.<br />

13. How do the space lattice or crystal structures appear?<br />

Body-Centered Cubic Face-Centered Cubic<br />

All grains or crystals are composed of atoms bound<br />

together in a definite pattern. These structures are called<br />

space lattice or crystal structures. At a fixed temperature,<br />

the atoms in an array are spaced a definite distance from one<br />

another, although they vibrate about their mean position.<br />

Even though atoms are actually not held together in this<br />

manner, it is helpful to picture the crystals as a 3-dimensional<br />

latticework connected by imaginary lines. Metallurgists<br />

who primarily study ferrous metal are interested in only two<br />

basic crystal structures: bcc (body-centered cubic) and fcc<br />

(face-centered cubic).<br />

14. What are the metallurgical ramifications of “cold<br />

heading” vs. “hot heading?”<br />

Cold heading is a more efficient process and allows the<br />

part to be cold worked. The temperatures used for hot forging<br />

will reduce the effect of work hardening. This is important<br />

for metals which derive much of their strength from the cold<br />

work. Cold heading produces a better product than hot heading.<br />

The number and force of the blows of the cold heading<br />

machine can make a significant difference in the quality of the<br />

end product. Excessive numbers of blows can lead to voids in<br />

17<br />

fastener tech

fastener tech<br />

18<br />

the bolt head. <strong>ARP</strong>, in fact, holds significant patents on cold<br />

heading procedures for the higher nickel and cobalt based<br />

alloys.<br />

Our patented process begins with a cold drawn wire that<br />

can be cold forged. The process work hardens the head and<br />

the under head area to the desired hardness. We then power<br />

extrude the front end to achieve the reduction and hardness in<br />

the shank resulting in a bolt with even strength and hardness<br />

from end to end.<br />

In a typical aerospace manufacturing process, these alloys are<br />

hot headed from bars, reduced in diameter from 48 to 50% by<br />

cold drawing, resulting in a hardness of about Rockwell C46<br />

which is too hard for cold heading. So, the blanks are locally<br />

induction heated in a very narrow temperature envelope<br />

and hot headed. The process reduces the hardness<br />

immediately in the area under the head approximately<br />

3 to 5 points on the Rockwell C scale. Subsequent<br />

heat treatment does not restore this partially annealed<br />

area to full hardness and strength. The final result is a<br />

relatively soft-headed bolt. Therefore, this process is not<br />

used by <strong>ARP</strong>.<br />

15. What is the difference between the usage of<br />

“bar” material vs. “wire?”<br />

Bars produced by the mill in straight sections are<br />

normally shipped in 12 foot lengths. Wire is supplied in<br />

continuous coil form and is hundreds of feet in length.<br />

Bars are cut to length and the bolts are hot forged from<br />

these lengths. Wire on the other hand is fed into a cold<br />

header in a continuous manner.<br />

16. What exactly is A286? And to what is it compared?<br />

A286 is a 25% nickel and 18% chromium alloy with<br />

smaller amounts of titanium and aluminum, which precipitate<br />

during aging – after solution treatment. It is a true stainless<br />

steel due to the high chromium and it is austenitic due to the<br />

high nickel. A286 was developed as a high temperature alloy<br />

for use in pre-jet aircraft engines. The strength level was only<br />

140,000 psi, but it had good high temperature strength and<br />

exceptional toughness, making it an excellent fastener alloy.<br />

Rocketdyne became interested in it for rocket engines being<br />

developed in the early 60’s. But they required higher strength.<br />

We were part of the team that developed a thermo-mechanical<br />

method to produce a strength level of 200,000 psi. This involved<br />

severe cold reduction after solution treatment and before<br />

aging. An aerospace material spec (AMS) was then written<br />

requiring this treatment for 200,000 psi strength level. There<br />

is no other steel<br />

alloy, at this level,<br />

which can match A286 for corrosion resistance, toughness or<br />

bolt fatigue strength.<br />

17. Define “Power Dump.”<br />

This is a term used to define the heavy extrusion of the fastener<br />

body during forging. The part is forced into a die much<br />

smaller than the blank thereby causing a severe reduction in<br />

cross section area. This reduction of the cross sectional area is<br />

accompanied by an increase in length because metals can’t be<br />

5-stage “Cold Header” used by <strong>ARP</strong><br />

compressed. However, power dumping or reduction, delivers<br />

a significant increase in strength properties and is part of the<br />

patented process we use to produce fasteners from 304 stainless<br />

steel with 170,000 psi UTS and AMS 5844 (<strong>ARP</strong> 3.5)<br />

with ultimate tensile strengths in the 270,000 psi UTS range<br />

with outstanding fatigue.<br />

18. What is the difference between 4130 and 8740 chrome<br />

moly?<br />

Both are alloy steels with similar chemistry. The 4130 has<br />

only .3% carbon and can’t be hardened as high as 8740, which<br />

has .4% carbon. Also, 8740 has about .45% nickel and 4130<br />

has none. Both have moly (most alloy steels have moly). The<br />

chromium content of 4130 is slightly higher, .95% instead of<br />

.55%. However, 8740 is generally considered to have slightly<br />

better toughness due to the nickel.<br />

800-826-3045

19. What exactly is <strong>ARP</strong>2000 and how does it compare to<br />

8740 and 4340?<br />

<strong>ARP</strong>2000 is a heavily alloyed martensitic quench and<br />

temper steel. It has excellent stability at high temperatures.<br />

But most important, <strong>ARP</strong> research discovered that in addition<br />

to temperature stability it has excellent notch toughness<br />

in the higher strength ranges and is alloyed to be tempered to<br />

Rockwell C44/47. 8740 and 4340 can be tempered to the<br />

same hardness. But, the tempering temperature would yield<br />

material in the “temper brittle zone” (between 500° and<br />

700°F), producing significant notch sensitivity. <strong>ARP</strong>2000 is<br />

tempered above that temperature range and has a strength<br />

between 200,000 and 220,000 psi.<br />

20. How does L19 compare to <strong>ARP</strong>2000?<br />

L19 differs from <strong>ARP</strong>2000 in that it is a vacuum melted<br />

alloyed steel with sufficient chromium and carbon to achieve<br />

high hardness (but below the level of a stainless steel). L19 is<br />

air-cooled from the hardening temperature in a way that does<br />

not require an oil quench to achieve full hardness and is tempered<br />

to assure full conversion to martensite between 1025°F<br />