Paper Technology Journal 19 - Voith

Paper Technology Journal 19 - Voith

Paper Technology Journal 19 - Voith

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2<br />

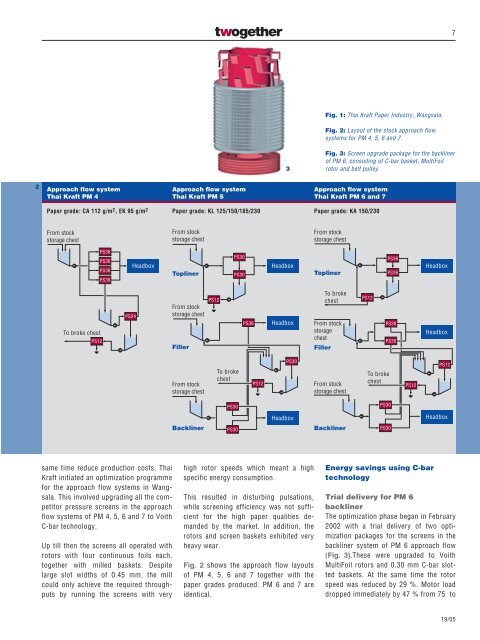

Approach flow system<br />

Thai Kraft PM 4<br />

From stock<br />

storage chest<br />

To broke chest<br />

PS12<br />

PS36<br />

PS36<br />

PS36<br />

PS36<br />

PS24<br />

Headbox<br />

same time reduce production costs, Thai<br />

Kraft initiated an optimization programme<br />

for the approach flow systems in Wangsala.<br />

This involved upgrading all the competitor<br />

pressure screens in the approach<br />

flow systems of PM 4, 5, 6 and 7 to <strong>Voith</strong><br />

C-bar technology.<br />

Up till then the screens all operated with<br />

rotors with four continuous foils each,<br />

together with milled baskets. Despite<br />

large slot widths of 0.45 mm, the mill<br />

could only achieve the required throughputs<br />

by running the screens with very<br />

Approach flow system<br />

Thai Kraft PM 5<br />

From stock<br />

storage chest<br />

Topliner<br />

Filler<br />

Backliner<br />

PS12<br />

To broke<br />

chest<br />

PS30<br />

PS30<br />

PS30<br />

PS30<br />

PS36<br />

PS12<br />

3<br />

Headbox<br />

PS30<br />

Headbox<br />

Fig. 1: Thai Kraft <strong>Paper</strong> Industry, Wangsala.<br />

Fig. 2: Layout of the stock approach flow<br />

systems for PM 4, 5, 6 and 7.<br />

Fig. 3: Screen upgrade package for the backliner<br />

of PM 6, consisting of C-bar basket, MultiFoil<br />

rotor and belt pulley.<br />

Approach flow system<br />

Thai Kraft PM 6 and 7<br />

<strong>Paper</strong> grade: CA 112 g/m 2 , EK 95 g/m 2 <strong>Paper</strong> grade: KL 125/150/185/230 <strong>Paper</strong> grade: KA 150/230<br />

From stock<br />

storage chest<br />

From stock<br />

storage chest<br />

Headbox<br />

high rotor speeds which meant a high<br />

specific energy consumption.<br />

This resulted in disturbing pulsations,<br />

while screening efficiency was not sufficient<br />

for the high paper qualities demanded<br />

by the market. In addition, the<br />

rotors and screen baskets exhibited very<br />

heavy wear.<br />

Fig. 2 shows the approach flow layouts<br />

of PM 4, 5, 6 and 7 together with the<br />

paper grades produced. PM 6 and 7 are<br />

identical.<br />

From stock<br />

storage chest<br />

Topliner<br />

Filler<br />

To broke<br />

chest<br />

From stock<br />

storage<br />

chest<br />

From stock<br />

storage chest<br />

Backliner<br />

PS12<br />

To broke<br />

chest<br />

PS30<br />

PS30<br />

PS36<br />

PS36<br />

PS30<br />

PS30<br />

PS12<br />

Energy savings using C-bar<br />

technology<br />

Headbox<br />

Headbox<br />

PS12<br />

Headbox<br />

7<br />

Trial delivery for PM 6<br />

backliner<br />

The optimization phase began in February<br />

2002 with a trial delivery of two optimization<br />

packages for the screens in the<br />

backliner system of PM 6 approach flow<br />

(Fig. 3).These were upgraded to <strong>Voith</strong><br />

MultiFoil rotors and 0.30 mm C-bar slotted<br />

baskets. At the same time the rotor<br />

speed was reduced by 29 %. Motor load<br />

dropped immediately by 47 % from 75 to<br />

<strong>19</strong>/05