Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Lightweight contaminants<br />

containing fibers<br />

Filtrate<br />

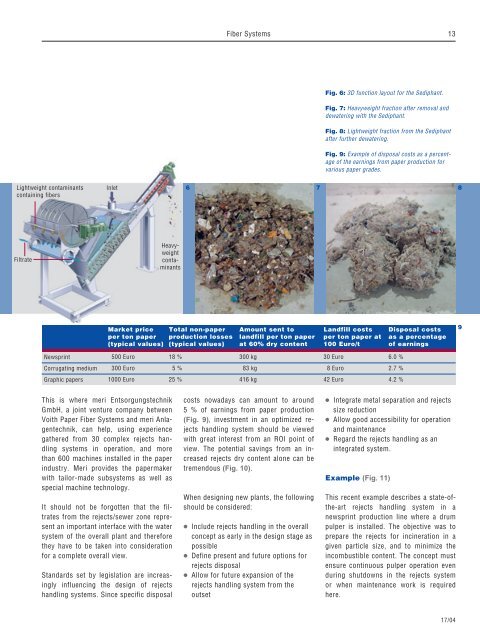

Newsprint<br />

Corrugating medium<br />

Graphic papers<br />

Inlet<br />

Market price<br />

per ton paper<br />

(typical values)<br />

500 Euro<br />

300 Euro<br />

1000 Euro<br />

Heavyweightcontaminants<br />

This is where meri Entsorgungstechnik<br />

GmbH, a joint venture company between<br />

<strong>Voith</strong> <strong>Paper</strong> Fiber Systems and meri Anlagentechnik,<br />

can help, using experience<br />

gathered from 30 complex rejects handling<br />

systems in operation, and more<br />

than 600 machines installed in the paper<br />

industry. Meri provides the papermaker<br />

with tailor-made subsystems as well as<br />

special machine technology.<br />

It should not be forgotten that the filtrates<br />

from the rejects/sewer zone represent<br />

an important interface with the water<br />

system of the overall plant and therefore<br />

they have to be taken into consideration<br />

for a complete overall view.<br />

Standards set by legislation are increasingly<br />

influencing the design of rejects<br />

handling systems. Since specific disposal<br />

6<br />

Total non-paper<br />

production losses<br />

(typical values)<br />

18 %<br />

5 %<br />

25 %<br />

Fiber Systems<br />

Amount sent to<br />

landfill per ton paper<br />

at 60% dry content<br />

300 kg<br />

83 kg<br />

416 kg<br />

costs nowadays can amount to around<br />

5 % of earnings from paper production<br />

(Fig. 9), investment in an optimized rejects<br />

handling system should be viewed<br />

with great interest from an ROI point of<br />

view. The potential savings from an increased<br />

rejects dry content alone can be<br />

tremendous (Fig. 10).<br />

When designing new plants, the following<br />

should be considered:<br />

● Include rejects handling in the overall<br />

concept as early in the design stage as<br />

possible<br />

● Define present and future options for<br />

rejects disposal<br />

● Allow for future expansion of the<br />

rejects handling system from the<br />

outset<br />

Fig. 6: 3D function layout for the Sediphant.<br />

Fig. 7: Heavyweight fraction after removal and<br />

dewatering with the Sediphant.<br />

Fig. 8: Lightweight fraction from the Sediphant<br />

after further dewatering.<br />

Fig. 9: Example of disposal costs as a percentage<br />

of the earnings from paper production for<br />

various paper grades.<br />

● Integrate metal separation and rejects<br />

size reduction<br />

● Allow good accessibility for operation<br />

and maintenance<br />

● Regard the rejects handling as an<br />

integrated system.<br />

Example (Fig. 11)<br />

13<br />

7 8<br />

Landfill costs<br />

per ton paper at<br />

100 Euro/t<br />

30 Euro<br />

8 Euro<br />

42 Euro<br />

Disposal costs<br />

as a percentage<br />

of earnings<br />

6.0 %<br />

2.7 %<br />

4.2 %<br />

This recent example describes a state-ofthe-art<br />

rejects handling system in a<br />

newsprint production line where a drum<br />

pulper is installed. The objective was to<br />

prepare the rejects for incineration in a<br />

given particle size, and to minimize the<br />

incombustible content. The concept must<br />

ensure continuous pulper operation even<br />

during shutdowns in the rejects system<br />

or when maintenance work is required<br />

here.<br />

<strong>17</strong>/04<br />

9