APPWD Schedule of Rates for Road and Bridges - Arunachalpwd.org

APPWD Schedule of Rates for Road and Bridges - Arunachalpwd.org APPWD Schedule of Rates for Road and Bridges - Arunachalpwd.org

Preamble: 39 Chapter – 6 CEMENT CONCRETE PAVEMENT 1 High capacity batch mix plants of 75 cum/hour (effective output) has been considered in the rate analysis of cement concrete pavement works. 2 While tippers have been provided for tranportation of dry lean cement concrete and rolled cement concrete, transit truck mixers have been considered for the cement concrete pavement. 3 Super plasticizer admixture has been provided to improve workability with reduced water cement ratio. 4 Cement 43 grade has been catered for the cement concrete pavement i.e., for pavement quality concrete to get higher strength. However, for dry lean concrete, cement of 33 grade may be preferred. 5 While a slip form paver has been catered for the top layer of concrete pavement, a mechanical paver has been provided for dry lead and roller cement concrete. 6 Materials provided in the rate analysis are for estimating prupose. Exact quantity of materiasl be determined for the job mix formula.

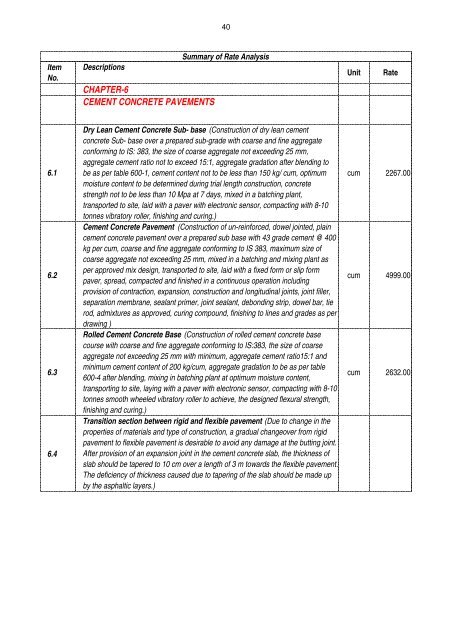

Item No. 6.1 6.2 6.3 6.4 Descriptions CHAPTER-6 CEMENT CONCRETE PAVEMENTS Summary of Rate Analysis Dry Lean Cement Concrete Sub- base (Construction of dry lean cement concrete Sub- base over a prepared sub-grade with coarse and fine aggregate conforming to IS: 383, the size of coarse aggregate not exceeding 25 mm, aggregate cement ratio not to exceed 15:1, aggregate gradation after blending to be as per table 600-1, cement content not to be less than 150 kg/ cum, optimum moisture content to be determined during trial length construction, concrete strength not to be less than 10 Mpa at 7 days, mixed in a batching plant, transported to site, laid with a paver with electronic sensor, compacting with 8-10 tonnes vibratory roller, finishing and curing.) Cement Concrete Pavement (Construction of un-reinforced, dowel jointed, plain cement concrete pavement over a prepared sub base with 43 grade cement @ 400 kg per cum, coarse and fine aggregate conforming to IS 383, maximum size of coarse aggregate not exceeding 25 mm, mixed in a batching and mixing plant as per approved mix design, transported to site, laid with a fixed form or slip form paver, spread, compacted and finished in a continuous operation including provision of contraction, expansion, construction and longitudinal joints, joint filler, separation membrane, sealant primer, joint sealant, debonding strip, dowel bar, tie rod, admixtures as approved, curing compound, finishing to lines and grades as per drawing ) Rolled Cement Concrete Base (Construction of rolled cement concrete base course with coarse and fine aggregate conforming to IS:383, the size of coarse aggregate not exceeding 25 mm with minimum, aggregate cement ratio15:1 and minimum cement content of 200 kg/cum, aggregate gradation to be as per table 600-4 after blending, mixing in batching plant at optimum moisture content, transporting to site, laying with a paver with electronic sensor, compacting with 8-10 tonnes smooth wheeled vibratory roller to achieve, the designed flexural strength, finishing and curing.) Transition section between rigid and flexible pavement (Due to change in the properties of materials and type of construction, a gradual changeover from rigid pavement to flexible pavement is desirable to avoid any damage at the butting joint. After provision of an expansion joint in the cement concrete slab, the thickness of slab should be tapered to 10 cm over a length of 3 m towards the flexible pavement. The deficiency of thickness caused due to tapering of the slab should be made up by the asphaltic layers.) 40 Unit Rate cum 2267.00 cum 4999.00 cum 2632.00

- Page 1 and 2: PUBLIC WORKS DEPARTMENT ARUNACHAL P

- Page 3 and 4: INDEX Lead Chart for carriage of ma

- Page 5 and 6: CARRIAGE OF MATERIALS BY MECHANICAL

- Page 7 and 8: CARRIAGE OF MATERIALS BY MECHANICAL

- Page 9 and 10: 6 (A) Usage Rates of Plant and Mach

- Page 11 and 12: 8 (B) Labour Sl. No. Description of

- Page 13 and 14: 10 Sl. No. Description Unit Rate M-

- Page 15 and 16: M-162 Seeds kg 250 M-163 Selected e

- Page 17 and 18: A. Roads Works Basic Notes for Prep

- Page 19 and 20: 8. Labour 8.1 The avarage market ra

- Page 21 and 22: Preamble: CHAPTER - 1 CARRIAGE OF M

- Page 23 and 24: Preamble: Chapter - 2 SITE CLEARANC

- Page 25 and 26: Summary of Rate Analysis Item No. D

- Page 27 and 28: Preamble: Chapter - 3 EARTHWORK, ER

- Page 29 and 30: Summary of Rate Analysis Item No. D

- Page 31 and 32: Item No. 3.26 3.27 3.28 3.29 3.30 3

- Page 33 and 34: Preamble: Chapter - 4 SUB-BASES, BA

- Page 35 and 36: 32 Summary of Rate Analysis Item No

- Page 37 and 38: Preamble: 34 Chapter - 5 BASES AND

- Page 39 and 40: 36 Summary of Rate Analysis Item No

- Page 41: Item No. 5.19 5.20 5.21 5.22 (i) (i

- Page 45 and 46: 16 The rate analysis for traffic im

- Page 47 and 48: Item No. 8.9 8.10 8.11 8.12 8.13 8.

- Page 49 and 50: Item No. 8.24 8.25 8.27 8.28 8.29 B

- Page 51 and 52: Item No. 8.45 8.46 Descriptions Sum

- Page 53 and 54: Item No. 9.1 9.2 9.3 Descriptions C

- Page 55 and 56: Item No. 10.1 10.2 10.3 10.4 10.5 D

- Page 57 and 58: Item No. 10.21 Descriptions Summary

- Page 59 and 60: Item No. 11.1 11.2 Descriptions CHA

- Page 61 and 62: Preamble: Chapter - 12 FOUNDATION 1

- Page 63 and 64: Item No. Descriptions CHAPTER-12 FO

- Page 65 and 66: 62 Summary of Rate Analysis Item No

- Page 67 and 68: 64 Summary of Rate Analysis Item No

- Page 69 and 70: 66 Summary of Rate Analysis Item No

- Page 71 and 72: 68 Summary of Rate Analysis Item No

- Page 73 and 74: 70 Summary of Rate Analysis Item No

- Page 75 and 76: 72 Summary of Rate Analysis Item No

- Page 77 and 78: Item No. Descriptions CHAPTER-13 SU

- Page 79 and 80: Item No. 13.9 13.10 13.11 13.12 13.

- Page 81 and 82: Item No. Descriptions CHAPTER-14 SU

- Page 83 and 84: 80 Summary of Rate Analysis Item No

- Page 85 and 86: Item No. 14.11 14.15 14.16 Descript

- Page 87 and 88: Preamble: Chapter - 15 PROTECTION W

- Page 89 and 90: Item No. 15.13 Descriptions Summary

- Page 91 and 92: Item No. 16.1 16.2 16.3 16.4 16.5 1

Item<br />

No.<br />

6.1<br />

6.2<br />

6.3<br />

6.4<br />

Descriptions<br />

CHAPTER-6<br />

CEMENT CONCRETE PAVEMENTS<br />

Summary <strong>of</strong> Rate Analysis<br />

Dry Lean Cement Concrete Sub- base (Construction <strong>of</strong> dry lean cement<br />

concrete Sub- base over a prepared sub-grade with coarse <strong>and</strong> fine aggregate<br />

con<strong>for</strong>ming to IS: 383, the size <strong>of</strong> coarse aggregate not exceeding 25 mm,<br />

aggregate cement ratio not to exceed 15:1, aggregate gradation after blending to<br />

be as per table 600-1, cement content not to be less than 150 kg/ cum, optimum<br />

moisture content to be determined during trial length construction, concrete<br />

strength not to be less than 10 Mpa at 7 days, mixed in a batching plant,<br />

transported to site, laid with a paver with electronic sensor, compacting with 8-10<br />

tonnes vibratory roller, finishing <strong>and</strong> curing.)<br />

Cement Concrete Pavement (Construction <strong>of</strong> un-rein<strong>for</strong>ced, dowel jointed, plain<br />

cement concrete pavement over a prepared sub base with 43 grade cement @ 400<br />

kg per cum, coarse <strong>and</strong> fine aggregate con<strong>for</strong>ming to IS 383, maximum size <strong>of</strong><br />

coarse aggregate not exceeding 25 mm, mixed in a batching <strong>and</strong> mixing plant as<br />

per approved mix design, transported to site, laid with a fixed <strong>for</strong>m or slip <strong>for</strong>m<br />

paver, spread, compacted <strong>and</strong> finished in a continuous operation including<br />

provision <strong>of</strong> contraction, expansion, construction <strong>and</strong> longitudinal joints, joint filler,<br />

separation membrane, sealant primer, joint sealant, debonding strip, dowel bar, tie<br />

rod, admixtures as approved, curing compound, finishing to lines <strong>and</strong> grades as per<br />

drawing )<br />

Rolled Cement Concrete Base (Construction <strong>of</strong> rolled cement concrete base<br />

course with coarse <strong>and</strong> fine aggregate con<strong>for</strong>ming to IS:383, the size <strong>of</strong> coarse<br />

aggregate not exceeding 25 mm with minimum, aggregate cement ratio15:1 <strong>and</strong><br />

minimum cement content <strong>of</strong> 200 kg/cum, aggregate gradation to be as per table<br />

600-4 after blending, mixing in batching plant at optimum moisture content,<br />

transporting to site, laying with a paver with electronic sensor, compacting with 8-10<br />

tonnes smooth wheeled vibratory roller to achieve, the designed flexural strength,<br />

finishing <strong>and</strong> curing.)<br />

Transition section between rigid <strong>and</strong> flexible pavement (Due to change in the<br />

properties <strong>of</strong> materials <strong>and</strong> type <strong>of</strong> construction, a gradual changeover from rigid<br />

pavement to flexible pavement is desirable to avoid any damage at the butting joint.<br />

After provision <strong>of</strong> an expansion joint in the cement concrete slab, the thickness <strong>of</strong><br />

slab should be tapered to 10 cm over a length <strong>of</strong> 3 m towards the flexible pavement.<br />

The deficiency <strong>of</strong> thickness caused due to tapering <strong>of</strong> the slab should be made up<br />

by the asphaltic layers.)<br />

40<br />

Unit Rate<br />

cum 2267.00<br />

cum 4999.00<br />

cum 2632.00